444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: The Respirator Cartridges and Filters Market is an integral component of the personal protective equipment (PPE) industry, providing essential respiratory protection to workers in various hazardous environments. Respirator cartridges and filters are designed to remove contaminants, such as dust, fumes, gases, and airborne particles, from the air to prevent inhalation and safeguard respiratory health. The market for respirator cartridges and filters is driven by occupational safety regulations, industrial hygiene standards, and the growing awareness of respiratory hazards in the workplace.

Meaning: Respirator cartridges and filters are replaceable components of respiratory protective devices, such as half-face respirators, full-face respirators, and powered air-purifying respirators (PAPRs). These cartridges and filters contain sorbents, particulate filters, or combination filters that trap harmful contaminants present in the air, ensuring clean and breathable air for the wearer. Respirator cartridges and filters play a critical role in protecting workers from respiratory hazards, including chemical vapors, biological agents, and airborne pollutants, in industrial, healthcare, and emergency response settings.

Executive Summary: The Respirator Cartridges and Filters Market is witnessing steady growth driven by the increasing emphasis on workplace safety, stringent regulatory requirements, and the rising demand for respiratory protection across diverse industries. Key market players are investing in research and development initiatives to develop advanced filtration technologies, improve filter efficiency, and enhance wearer comfort. With the growing focus on respiratory health and the adoption of stringent safety standards, the market for respirator cartridges and filters is poised for continuous expansion in the foreseeable future.

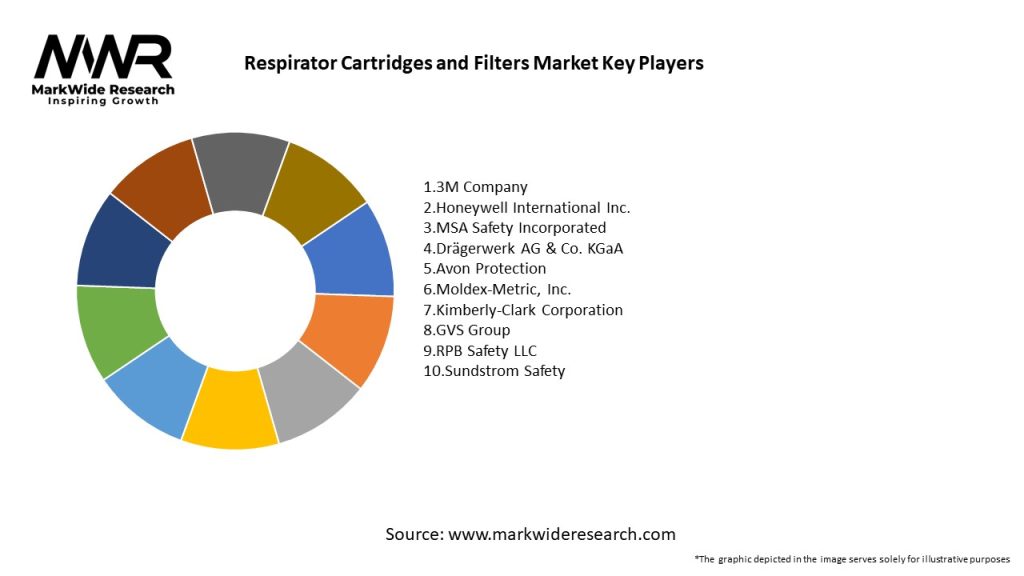

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The Respirator Cartridges and Filters Market is characterized by dynamic interactions between regulatory requirements, technological innovation, and market demand. Market players need to navigate these dynamics by investing in product development, regulatory compliance, and market expansion strategies to capitalize on emerging opportunities and address evolving customer needs.

Regional Analysis: The Respirator Cartridges and Filters Market exhibits regional variations influenced by factors such as industrialization rates, regulatory frameworks, and healthcare infrastructure. North America and Europe dominate the market due to stringent safety regulations, high occupational health standards, and the presence of key market players. Emerging economies in Asia Pacific and Latin America offer significant growth potential driven by industrial growth, urbanization, and increasing awareness of respiratory hazards in the workplace.

Competitive Landscape: The Respirator Cartridges and Filters Market is characterized by intense competition among leading manufacturers, suppliers, and distributors of respiratory protective equipment. Key market players include companies such as 3M Company, Honeywell International Inc., MSA Safety Incorporated, and Kimberly-Clark Corporation. Competitive strategies focus on product innovation, strategic partnerships, market expansion, and regulatory compliance to gain a competitive edge in the global market.

Segmentation: The Respirator Cartridges and Filters Market can be segmented based on product type, filtration efficiency, application, end-user, and geography. Product types include particulate filters, gas/vapor cartridges, combination filters, and specialty filters. Filtration efficiency ranges from N95 (non-oil resistant) to P100 (oil-proof) for particulate filters and from organic vapor (OV) to multi-gas (MG) for gas/vapor cartridges. Applications encompass industrial, healthcare, construction, mining, oil & gas, and emergency response. End-users include manufacturing facilities, healthcare institutions, laboratories, construction sites, and first responder units.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact: The Covid-19 pandemic has underscored the importance of respiratory protection in preventing the transmission of infectious diseases, such as Covid-19, in healthcare settings, workplaces, and public spaces. The surge in demand for respirator cartridges and filters, particularly N95 respirators and surgical masks, has strained global supply chains, leading to shortages, price volatility, and counterfeit products. The pandemic has also accelerated the adoption of respiratory protective equipment, teleworking arrangements, and remote monitoring solutions in response to evolving health and safety challenges.

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The Respirator Cartridges and Filters Market is poised for significant growth driven by increasing awareness of respiratory hazards, stringent safety regulations, and technological advancements in filtration materials and smart respirator technologies. Market players need to focus on innovation, sustainability, and regulatory compliance to capitalize on emerging opportunities and address evolving customer needs in respiratory protection.

Conclusion: The Respirator Cartridges and Filters Market plays a crucial role in protecting workers from respiratory hazards, ensuring workplace safety, and promoting respiratory health in various industries and applications. By leveraging advanced filtration technologies, smart respirator solutions, and collaborative partnerships, stakeholders can contribute to the advancement of respiratory protection and the well-being of workers worldwide.

Respirator Cartridges and Filters Market

| Segmentation Details | Description |

|---|---|

| Product Type | Particulate Filters, Chemical Cartridges, Combination Filters, P100 Filters |

| Application | Construction, Healthcare, Manufacturing, Agriculture |

| End User | Industrial Workers, Healthcare Professionals, First Responders, General Public |

| Technology | Activated Carbon, HEPA, Electrostatic, Mechanical |

Leading Companies in Respirator Cartridges and Filters Market (Font Size 12pt)

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at