444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Refined naphthalene, also known as white naphthalene, is a crystalline hydrocarbon derived from coal tar. It is an important chemical compound extensively used across various industries, including textiles, construction, plastics, and agriculture. Refined naphthalene is primarily utilized in the production of phthalic anhydride, which serves as a key ingredient in the manufacturing of dyes, resins, and plastics. Its versatile properties, such as excellent solubility, high melting point, and low volatility, contribute to its wide-ranging applications.

Meaning

Refined naphthalene refers to the processed form of naphthalene obtained through purification techniques, ensuring high purity levels. The refining process involves the removal of impurities, such as sulfur, and the concentration of naphthalene to meet industry-specific requirements. Refined naphthalene is available in various grades, including technical grade, pharmaceutical grade, and industrial grade, catering to different industry demands.

Executive Summary

The refined naphthalene market has witnessed significant growth in recent years, driven by the increasing demand from end-use industries and the expansion of key market players. This executive summary provides a succinct overview of the market, highlighting its key characteristics, growth factors, and challenges. Additionally, it outlines the major market trends and offers a glimpse into the future outlook of the refined naphthalene industry.

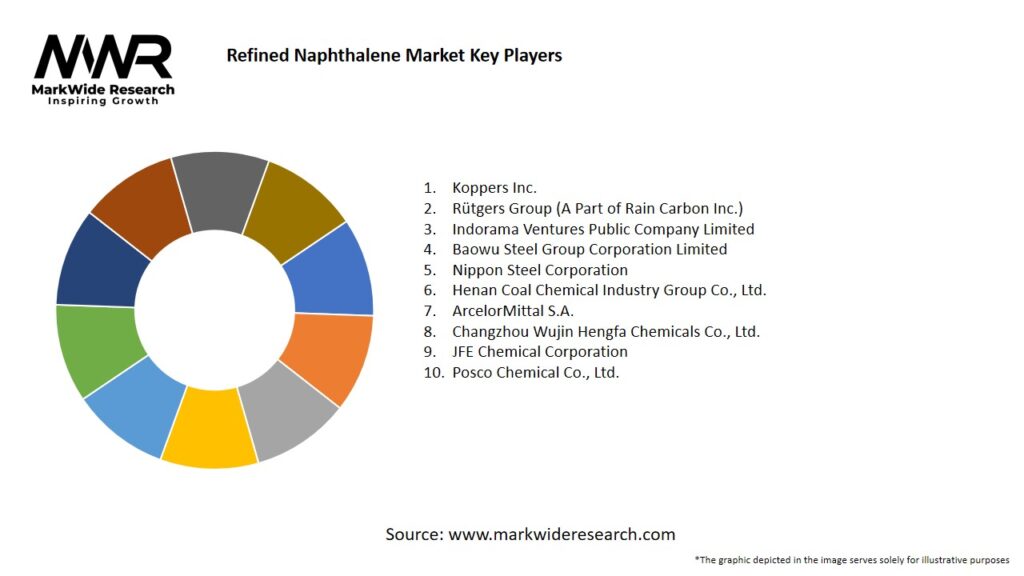

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

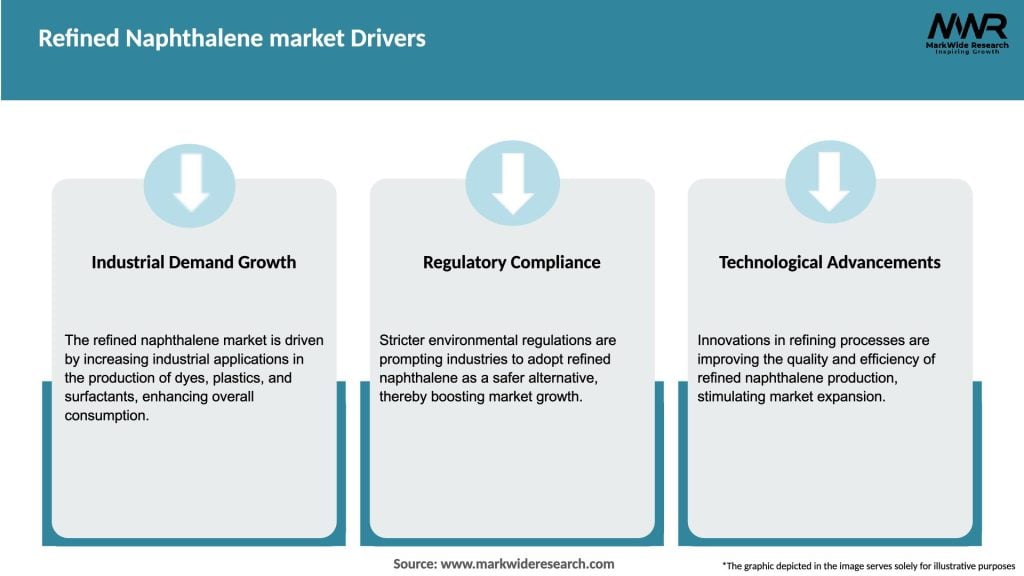

The Refined Naphthalene Market is driven by its critical role as a chemical intermediate in multiple downstream industries, particularly in construction chemicals, dyes, resins, and agrochemicals. Market dynamics are shaped by fluctuations in raw material availability, evolving environmental regulations, and steady demand from infrastructure and industrial development. As a coal-tar-derived aromatic compound, refined naphthalene remains essential for applications requiring purity, consistency, and predictable chemical performance. Key market dynamics include:

Demand from Construction Chemicals:

Strong use of refined naphthalene in the production of naphthalene sulfonate-based superplasticizers supports demand, particularly in concrete admixtures used for infrastructure and commercial construction projects.

Dependence on Coal Tar Feedstock:

Availability and pricing of coal tar, a primary raw material, directly influence refined naphthalene production economics, creating sensitivity to steel production trends and coke oven operations.

Environmental and Safety Regulations:

Increasing regulatory scrutiny related to handling, emissions, and worker safety affects production processes, storage practices, and transportation requirements, influencing operational costs and compliance investments.

Industrial Application Stability:

Unlike highly volatile specialty chemicals, refined naphthalene benefits from stable, long-term demand across established industrial applications, providing resilience against short-term market fluctuations.

Competitive Pricing Pressure:

Competition from alternative aromatic compounds and substitutes in certain applications encourages manufacturers to optimize production efficiency and maintain competitive pricing strategies.

Regional Analysis

The Refined Naphthalene market exhibits distinct characteristics across different regions:

Competitive Landscape

Leading Companies in the Refined Naphthalene Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

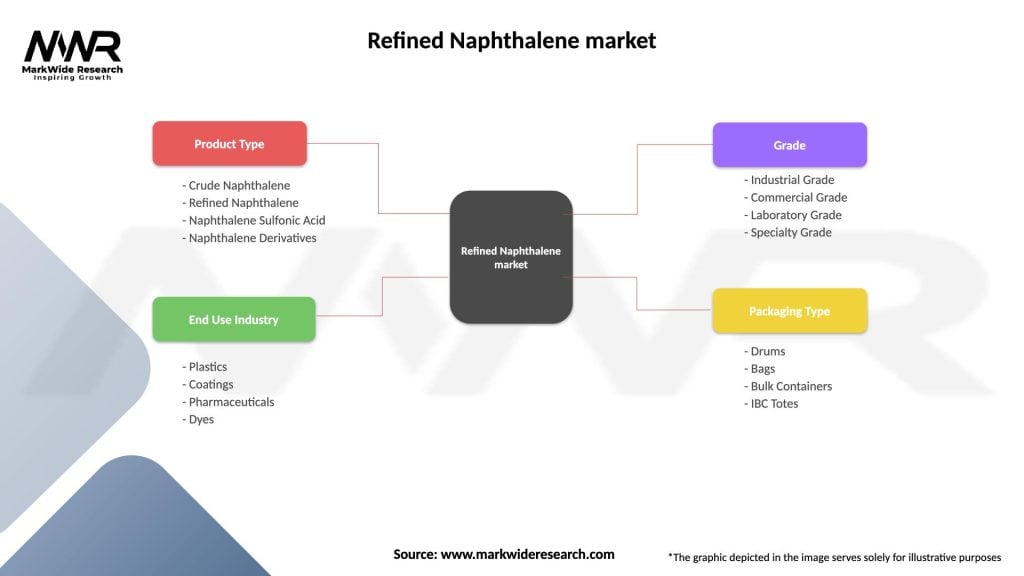

Segmentation

The Refined Naphthalene market can be segmented based on various factors, including:

Category-wise Insights

Chemical Production: Refined Naphthalene is a critical intermediate for the production of chemicals like phthalic anhydride, which is used in plastics, resins, and coatings.

Plastics Industry: In the plastics industry, Refined Naphthalene is used in the production of various plasticizers and resins.

coatings and Resins:* Refined Naphthalene is a key component in the formulation of coatings and resins for various applications.

Insect Repellents:* It is also used in the production of insect repellents.

Key Benefits for Industry Participants and Stakeholders

Stakeholders in the Refined Naphthalene market, including manufacturers, suppliers, and end-users, can benefit from:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the Refined Naphthalene market. While some industries faced disruptions in production and demand, others experienced increased demand for essential products, driving the consumption of Refined Naphthalene. The pandemic highlighted the importance of resilient supply chains and adaptability within the industry.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Refined Naphthalene market is expected to continue growing as industries across the globe seek reliable chemical intermediates. Innovations in production processes, sustainability efforts, and expansion into emerging markets are likely to shape the industry’s future.

Conclusion

The Refined Naphthalene market serves as a critical component of various industries, offering versatile applications in the production of chemicals, plastics, coatings, and more. As industries continue to evolve and demand reliable and sustainable solutions, the Refined Naphthalene market is expected to thrive. Stakeholders should focus on innovation, sustainability, and market diversification to ensure long-term success in this dynamic industry.

What is Refined Naphthalene?

Refined Naphthalene is a polycyclic aromatic hydrocarbon derived from the distillation of coal tar or petroleum. It is primarily used in the production of various chemicals, dyes, and as a solvent in industrial applications.

What are the key companies in the Refined Naphthalene market?

Key companies in the Refined Naphthalene market include Koppers Inc., AECI Limited, and INEOS, among others. These companies are involved in the production and distribution of refined naphthalene for various applications.

What are the growth factors driving the Refined Naphthalene market?

The growth of the Refined Naphthalene market is driven by increasing demand from the chemical industry, particularly for the production of phthalic anhydride and surfactants. Additionally, the rise in construction activities boosts the demand for naphthalene-based products in concrete additives.

What challenges does the Refined Naphthalene market face?

The Refined Naphthalene market faces challenges such as stringent environmental regulations regarding emissions and waste disposal. Additionally, fluctuations in raw material prices can impact production costs and market stability.

What opportunities exist in the Refined Naphthalene market?

Opportunities in the Refined Naphthalene market include the development of new applications in the pharmaceutical and agrochemical sectors. Furthermore, advancements in production technologies can enhance efficiency and reduce environmental impact.

What trends are shaping the Refined Naphthalene market?

Current trends in the Refined Naphthalene market include a shift towards sustainable production methods and the increasing use of refined naphthalene in specialty chemicals. Additionally, there is a growing interest in recycling and reusing naphthalene derivatives.

Refined Naphthalene market

| Segmentation Details | Description |

|---|---|

| Product Type | Crude Naphthalene, Refined Naphthalene, Naphthalene Sulfonic Acid, Naphthalene Derivatives |

| End Use Industry | Plastics, Coatings, Pharmaceuticals, Dyes |

| Grade | Industrial Grade, Commercial Grade, Laboratory Grade, Specialty Grade |

| Packaging Type | Drums, Bags, Bulk Containers, IBC Totes |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Refined Naphthalene Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at