444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Ramp Pressure Tester Market plays a critical role in ensuring the safety and reliability of aircraft ground handling operations. These testers are essential tools used to measure and monitor hydraulic pressure in aircraft ramp systems, including hydraulic ground support equipment (GSE) such as ground power units (GPUs), hydraulic jacks, and aircraft servicing platforms. Ramp pressure testers help aviation maintenance technicians and ground personnel perform pre-flight and post-flight checks, diagnose hydraulic system issues, and maintain compliance with regulatory requirements. As the aviation industry continues to prioritize safety, efficiency, and regulatory compliance, the demand for ramp pressure testers is expected to grow.

Meaning

Ramp pressure testers are specialized instruments used to measure hydraulic pressure in aircraft ramp systems during ground handling operations. These testers play a crucial role in ensuring the safe and efficient operation of hydraulic equipment and systems, including aircraft brakes, landing gear, and cargo loading systems. Ramp pressure testers are designed to withstand the harsh operating conditions of airport ramp environments and provide accurate and reliable pressure readings for maintenance and troubleshooting purposes.

Executive Summary

The Ramp Pressure Tester Market caters to the aviation industry’s need for reliable and accurate tools to monitor hydraulic pressure in aircraft ramp systems. As aviation safety regulations become increasingly stringent and aircraft maintenance practices evolve, the demand for high-quality ramp pressure testers is expected to rise. Manufacturers of ramp pressure testers focus on innovation, durability, and user-friendly features to meet the evolving needs of aviation maintenance technicians, ground handlers, and regulatory authorities.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Ramp Pressure Tester Market operates in a dynamic environment shaped by factors such as regulatory requirements, technological advancements, market competition, and economic conditions. Understanding market dynamics is essential for manufacturers and service providers to identify opportunities, address challenges, and develop effective strategies to meet customer needs and achieve business growth.

Regional Analysis

The demand for ramp pressure testers varies by geographic region, influenced by factors such as aircraft fleet size, regulatory environment, infrastructure development, and economic conditions. Key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East present unique market dynamics and opportunities for ramp pressure tester manufacturers and service providers.

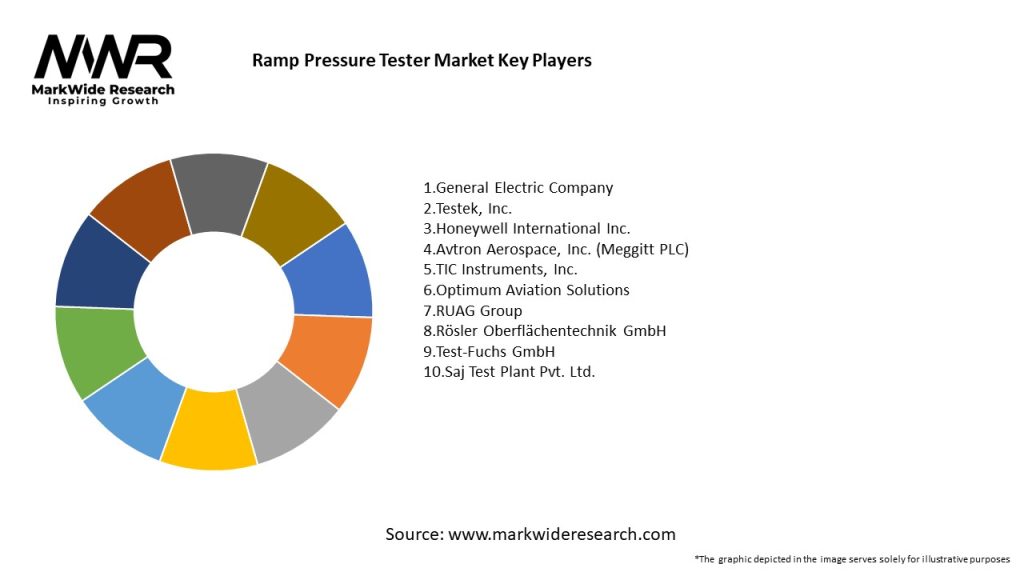

Competitive Landscape

The Ramp Pressure Tester Market is characterized by competition among manufacturers, distributors, and service providers offering a wide range of testing equipment and services for aircraft hydraulic systems. Key players in the market include established aerospace equipment manufacturers, specialized testing equipment suppliers, and emerging startups. Competition is driven by factors such as product quality, performance, reliability, pricing, customer support, and brand reputation.

Segmentation

The Ramp Pressure Tester Market can be segmented based on factors such as aircraft type, hydraulic system configuration, testing capabilities, geographic region, and end-user industry. Segmentation enables manufacturers to target specific market segments, customize product offerings, and address customer needs and preferences effectively.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the Ramp Pressure Tester Market, guiding strategic decision-making and risk management efforts for industry participants and stakeholders.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Ramp Pressure Tester Market include advances in sensor technology, data analytics, and connectivity; integration of wireless and IoT capabilities for remote monitoring and diagnostics; development of portable and handheld testers for increased mobility and convenience; and emphasis on user-friendly interfaces and intuitive controls for enhanced usability.

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the aviation industry, including the Ramp Pressure Tester Market. Disruptions in air travel demand, supply chain operations, and aircraft production have affected market dynamics and customer behaviors. As the aviation industry recovers and adapts to the new normal, opportunities for market recovery, innovation, and growth emerge, driven by increasing air travel demand, fleet modernization programs, and infrastructure investments.

Key Industry Developments

Recent developments in the Ramp Pressure Tester Market include advances in sensor technology for improved accuracy and reliability; development of cloud-based and mobile-enabled testing solutions for enhanced connectivity and remote monitoring; and integration of predictive maintenance capabilities for proactive equipment maintenance and troubleshooting.

Analyst Suggestions

Analysts suggest that industry participants focus on product innovation, market diversification, operational efficiency, and customer engagement strategies to navigate market dynamics and achieve sustainable growth in the Ramp Pressure Tester Market. Investing in research and development, technology adoption, and talent development enables companies to differentiate themselves, meet customer expectations, and capitalize on emerging opportunities in the aviation sector.

Future Outlook

The future outlook for the Ramp Pressure Tester Market is positive, with opportunities for growth and innovation driven by factors such as aircraft fleet expansion, technological advancements, regulatory requirements, and market demand for high-quality testing equipment and services. Despite challenges such as cost pressures, training requirements, and market competition, opportunities for market recovery, expansion, and diversification exist, enabling industry participants to thrive in the dynamic aviation market.

Conclusion

The Ramp Pressure Tester Market plays a vital role in ensuring the safety, reliability, and compliance of aircraft ground handling operations. As the aviation industry continues to evolve, driven by technological advancements, changing regulatory requirements, and market dynamics, the demand for high-quality testing equipment such as ramp pressure testers is expected to grow. Industry players must innovate, collaborate, and adapt to meet the evolving needs of aviation maintenance technicians, ground handlers, and regulatory authorities, positioning themselves for success in the dynamic Ramp Pressure Tester Market.

What is Ramp Pressure Tester?

A Ramp Pressure Tester is a device used to measure and evaluate the pressure levels in various systems, ensuring they operate within specified limits. These testers are commonly utilized in industries such as automotive, aerospace, and manufacturing to ensure safety and performance standards are met.

What are the key players in the Ramp Pressure Tester Market?

Key players in the Ramp Pressure Tester Market include companies like Fluke Corporation, Ametek, and Omega Engineering, which provide a range of pressure testing solutions. These companies are known for their innovative technologies and reliable products, among others.

What are the growth factors driving the Ramp Pressure Tester Market?

The Ramp Pressure Tester Market is driven by the increasing demand for quality assurance in manufacturing processes and the growing automotive sector. Additionally, advancements in testing technology and the need for compliance with safety regulations are contributing to market growth.

What challenges does the Ramp Pressure Tester Market face?

Challenges in the Ramp Pressure Tester Market include the high costs associated with advanced testing equipment and the need for skilled personnel to operate these devices. Furthermore, the rapid pace of technological change can make it difficult for companies to keep up with the latest innovations.

What opportunities exist in the Ramp Pressure Tester Market?

Opportunities in the Ramp Pressure Tester Market include the expansion of the aerospace and automotive industries, which require precise pressure testing solutions. Additionally, the growing trend towards automation in testing processes presents new avenues for market growth.

What trends are shaping the Ramp Pressure Tester Market?

Trends in the Ramp Pressure Tester Market include the integration of digital technologies for enhanced data analysis and remote monitoring capabilities. There is also a shift towards more compact and portable testing devices, catering to the needs of various industries.

Ramp Pressure Tester Market

| Segmentation Details | Description |

|---|---|

| Product Type | Digital Testers, Analog Testers, Portable Testers, Bench Testers |

| End User | Automotive Manufacturers, Aerospace Companies, Industrial Equipment, Maintenance Providers |

| Technology | Hydraulic, Pneumatic, Electronic, Mechanical |

| Application | Leak Testing, Calibration, Quality Control, Research & Development |

Leading Companies in the Ramp Pressure Tester Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at