444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Process spectroscopy involves the use of spectroscopic techniques to analyze materials in real-time as they are processed or manufactured. This allows for a greater understanding of the composition and quality of the materials being produced, as well as enabling the monitoring and control of various manufacturing processes. The process spectroscopy market is a rapidly growing field, driven by the increasing demand for high-quality and efficient manufacturing processes across a range of industries. In this article, we will provide an overview of the process spectroscopy market, including key market insights, drivers, restraints, opportunities, and regional analysis.

Process spectroscopy involves the use of various spectroscopic techniques, such as infrared (IR) spectroscopy, Raman spectroscopy, and near-infrared (NIR) spectroscopy, to analyze materials in real-time during the manufacturing process. These techniques allow for the measurement of various chemical and physical properties of materials, such as composition, molecular structure, and concentration. Process spectroscopy is widely used in a range of industries, including pharmaceuticals, food and beverages, chemicals, and biotechnology. It is used for quality control, process monitoring and control, and in-process testing, among other applications.

Executive Summary

The global process spectroscopy market is expected to grow at a CAGR of over 7% during the forecast period (2021-2026). The market is driven by the increasing demand for high-quality and efficient manufacturing processes across a range of industries, as well as the growing adoption of automation and Industry 4.0 technologies.

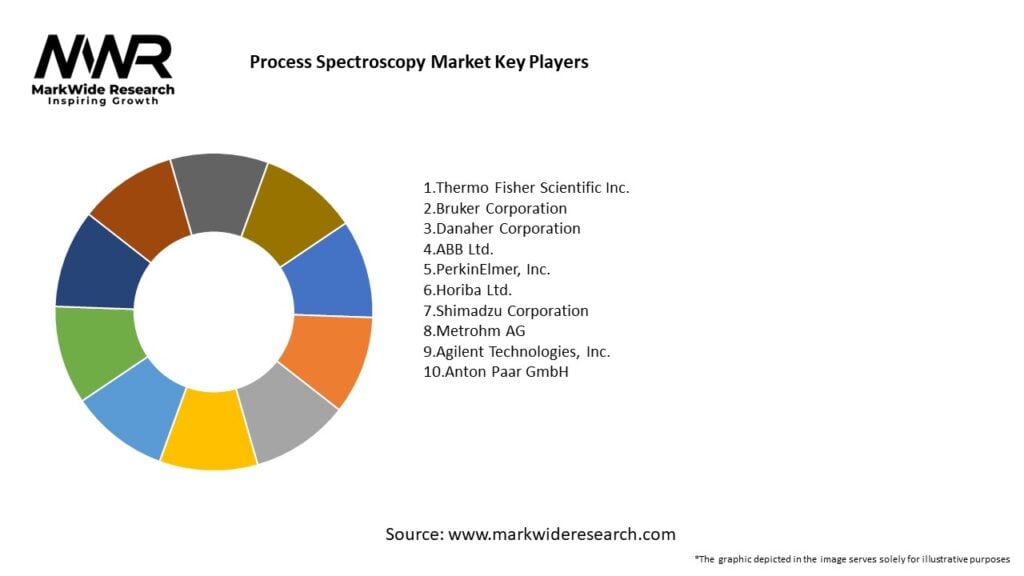

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The increasing demand for high-quality and efficient manufacturing processes is a key driver of the process spectroscopy market. As companies seek to improve the quality and consistency of their products, they are turning to process spectroscopy as a tool for real-time monitoring and control of manufacturing processes.

The growing adoption of automation and Industry 4.0 technologies is another key driver of the process spectroscopy market. As companies seek to improve their manufacturing processes and reduce costs, they are turning to automation and digital technologies, which require real-time monitoring and control of processes.

The increasing focus on quality control and regulatory compliance is also driving the process spectroscopy market. As companies seek to ensure the safety and efficacy of their products, they are turning to process spectroscopy as a tool for real-time monitoring and control of manufacturing processes.

Market Restraints

The High Costs of Spectroscopy Equipment are a major restraint for the process spectroscopy market. The cost of spectroscopy equipment can be prohibitive for some companies, especially small and medium-sized enterprises (SMEs), which may limit the adoption of these technologies.

The lack of skilled professionals is another major restraint for the process spectroscopy market. The operation and maintenance of spectroscopy equipment requires specialized knowledge and expertise, which may not be readily available in some regions or industries.

The complexity of spectroscopy techniques is also a challenge for the process spectroscopy market. Spectroscopy techniques can be complex and require specialized training to operate and interpret data, which may limit their adoption in some industries or applications.

Market Opportunities

The emerging applications of process spectroscopy in healthcare and life sciences represent a significant opportunity for the market. Process spectroscopy can be used for real-time monitoring and control of pharmaceutical manufacturing processes, as well as for disease diagnosis and monitoring.

The increasing demand for process analytical technologies (PAT) is another opportunity for the process spectroscopy market. As companies seek to improve their manufacturing processes and reduce costs, they are turning to PAT, which require real-time monitoring and control of processes.

The adoption of cloud-based spectroscopy solutions is also an opportunity for the process spectroscopy market. Cloud-based solutions can provide real-time monitoring and control of manufacturing processes, as well as remote access to data and analytics.

Market Dynamics

The process spectroscopy market is a dynamic and rapidly evolving field, driven by a range of factors, including technological advancements, changing industry trends, and regulatory requirements. Some of the key dynamics shaping the market include:

Technological advancements are driving the process spectroscopy market, as new spectroscopy techniques and equipment are developed and commercialized. For example, the development of portable and handheld spectroscopy devices is enabling real-time monitoring and control of manufacturing processes in remote locations.

Changing industry trends, such as the increasing adoption of automation and digital technologies, are also driving the process spectroscopy market. As companies seek to improve their manufacturing processes and reduce costs, they are turning to process spectroscopy as a tool for real-time monitoring and control.

Regulatory requirements are also shaping the process spectroscopy market, as companies seek to ensure compliance with quality and safety standards. Process spectroscopy can be used for real-time monitoring and control of manufacturing processes, as well as for quality control and in-process testing, which can help companies meet regulatory requirements.

Regional Analysis

The process spectroscopy market is a global market, with significant growth potential in emerging economies. Some of the key regional markets for process spectroscopy include:

North America is expected to be the largest regional market for process spectroscopy, driven by the presence of a large number of pharmaceutical and chemical companies in the region. The United States is expected to be the largest market in the region, followed by Canada.

Europe is also a significant market for process spectroscopy, driven by the presence of a large number of pharmaceutical and chemical companies in the region. The United Kingdom, Germany, and France are expected to be the largest markets in the region.

The Asia-Pacific region is expected to be the fastest-growing regional market for process spectroscopy, driven by the increasing adoption of automation and digital technologies in the region. China, India, and Japan are expected to be the largest markets in the region.

Competitive Landscape

Leading companies in the Process Spectroscopy Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

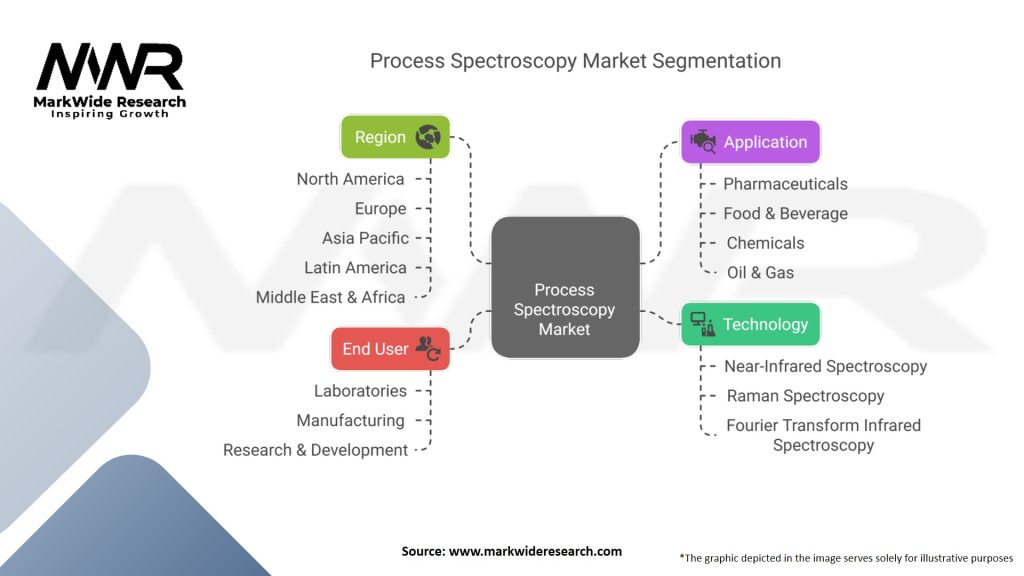

The process spectroscopy market can be segmented based on technology, application, and region.

The process spectroscopy market can be segmented based on technology into:

The process spectroscopy market can be segmented based on application into:

The process spectroscopy market can be segmented based on region into:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The process spectroscopy market offers a range of benefits for industry participants and stakeholders, including:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Some of the key trends shaping the process spectroscopy market include:

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the process spectroscopy market, with both positive and negative effects.

On the positive side, the pandemic has highlighted the importance of real-time monitoring and control of manufacturing processes, as companies seek to ensure the safety and quality of their products. This has increased the demand for process spectroscopy in a range of industries, including pharmaceuticals, food and beverages, and chemicals.

On the negative side, the pandemic has also led to supply chain disruptions and reduced demand in some industries, which may limit the adoption of process spectroscopy technologies. In addition, the pandemic has also led to economic and political instability, which may impact the growth of the market in some regions.

Key Industry Developments

Some of the key industry developments in the process spectroscopy market include:

Analyst Suggestions

To succeed in the process spectroscopy market, companies should focus on:

Future Outlook

The process spectroscopy market is expected to continue to grow in the coming years, driven by the increasing demand for high-quality and efficient manufacturing processes across a range of industries. Advancements in spectroscopy technology, automation and Industry 4.0 technologies, and the adoption of cloud-based solutions are expected to further drive the growth of the market.

However, the market is also likely to face challenges, including the high costs of spectroscopy equipment, the lack of skilled professionals, and the complexity of spectroscopy techniques. Companies that can overcome these challenges and stay ahead of emerging industry trends are likely to succeed in the process spectroscopy market.

Conclusion

The process spectroscopy market is a dynamic and rapidly evolving field, driven by the increasing demand for high-quality and efficient manufacturing processes across a range of industries. The market offers a range of benefits for industry participants and stakeholders, including real-time monitoring and control of manufacturing processes, improved quality control and product consistency, and increased efficiency and productivity.

To succeed in the market, companies should focus on developing innovative and cost-effective spectroscopy solutions, investing in research and development, and building strong partnerships and collaborations. Despite the challenges facing the market, the future outlook for process spectroscopy is positive, with significant growth potential in emerging applications and regions. As the world continues to become more digital and connected, the adoption of automation and Industry 4.0 technologies is expected to further drive the growth of the process spectroscopy market. These technologies enable real-time monitoring and control of manufacturing processes, allowing companies to improve their efficiency and productivity while reducing costs.

What is Process Spectroscopy?

Process Spectroscopy refers to the use of spectroscopic techniques to analyze and monitor chemical processes in real-time. This technology is widely used in industries such as pharmaceuticals, food and beverage, and petrochemicals to ensure product quality and process efficiency.

Who are the key players in the Process Spectroscopy Market?

Key players in the Process Spectroscopy Market include companies like Agilent Technologies, PerkinElmer, Bruker Corporation, and Thermo Fisher Scientific, among others.

What are the main drivers of growth in the Process Spectroscopy Market?

The main drivers of growth in the Process Spectroscopy Market include the increasing demand for real-time monitoring in manufacturing processes, the need for quality control in various industries, and advancements in spectroscopic technologies that enhance accuracy and efficiency.

What challenges does the Process Spectroscopy Market face?

Challenges in the Process Spectroscopy Market include the high initial investment costs for advanced spectroscopic equipment, the need for skilled personnel to operate these systems, and potential regulatory hurdles that can affect implementation in certain industries.

What opportunities exist in the Process Spectroscopy Market?

Opportunities in the Process Spectroscopy Market include the growing adoption of automation in industrial processes, the expansion of applications in emerging sectors like renewable energy, and the increasing focus on sustainability and environmental monitoring.

What trends are shaping the Process Spectroscopy Market?

Trends shaping the Process Spectroscopy Market include the integration of artificial intelligence for data analysis, the development of portable spectroscopic devices, and the increasing use of spectroscopy in quality assurance and regulatory compliance across various industries.

Process Spectroscopy Market

| Segmentation | Details |

|---|---|

| Technology | Near-Infrared (NIR) Spectroscopy, Raman Spectroscopy, Fourier Transform Infrared (FTIR) Spectroscopy, Others |

| Application | Pharmaceuticals, Food & Beverage, Chemicals, Oil & Gas, Others |

| End User | Laboratories, Manufacturing, Research & Development |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Process Spectroscopy Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at