444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview The precision measuring instruments market serves as the bedrock of industries reliant on accuracy, precision, and quality assurance. These instruments, ranging from calipers and micrometers to coordinate measuring machines (CMMs) and laser trackers, play a pivotal role in ensuring compliance with stringent quality standards and specifications. As industries diversify and technology advances, the demand for precise measurement solutions proliferates, propelling the precision measuring instruments market into a realm of sustained growth and innovation.

Meaning Precision measuring instruments encompass a spectrum of tools and devices designed to quantify dimensions, distances, and geometric attributes with exceptional accuracy and repeatability. From mechanical gauges to advanced optical and laser-based systems, these instruments serve as indispensable assets across industries such as manufacturing, aerospace, automotive, and healthcare. Precision measurement, underpinned by the principles of metrology and standards compliance, forms the cornerstone of quality assurance and process optimization in modern industrial settings.

Executive Summary The precision measuring instruments market stands at the nexus of technological innovation, industrial automation, and quality assurance imperatives. With industries increasingly prioritizing precision, accuracy, and reliability, the demand for advanced measurement solutions continues to soar. However, amidst the deluge of opportunities, challenges loom on the horizon, necessitating a nuanced understanding of market dynamics, technological trends, and industry-specific requirements.

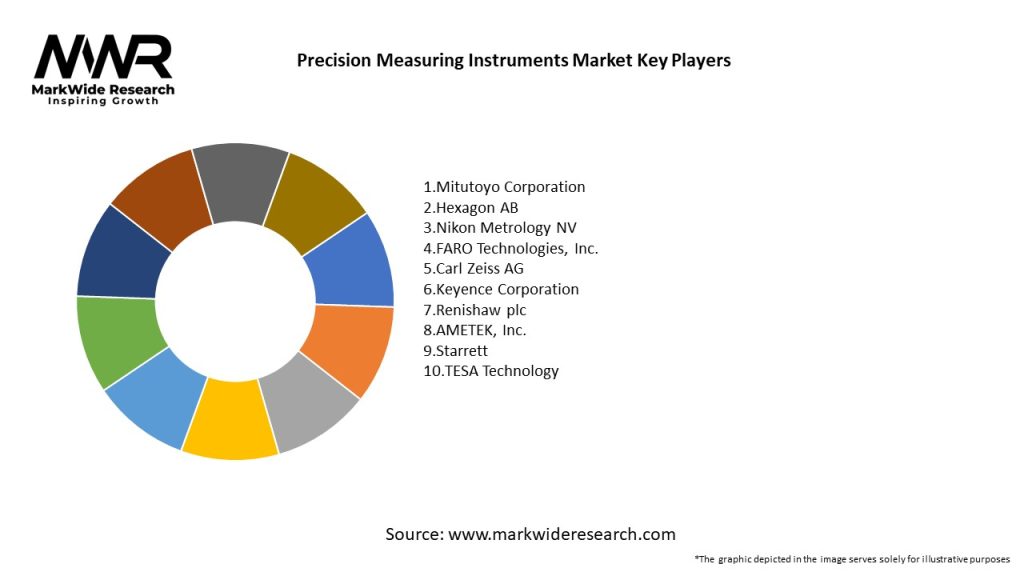

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics The precision measuring instruments market operates within a dynamic ecosystem shaped by technological innovation, regulatory frameworks, industry trends, and macroeconomic factors. From the relentless pursuit of accuracy and repeatability to the quest for automation and digitalization, market dynamics underscore the imperative for adaptability, agility, and foresight.

Regional Analysis The precision measuring instruments market exhibits regional variations driven by factors such as industrial specialization, technological infrastructure, regulatory environments, and economic conditions. From the manufacturing powerhouses of Asia-Pacific to the innovation hubs of North America and Europe, each region presents a unique tapestry of opportunities and challenges for market participants.

Competitive Landscape

Leading Companies in the Precision Measuring Instruments Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

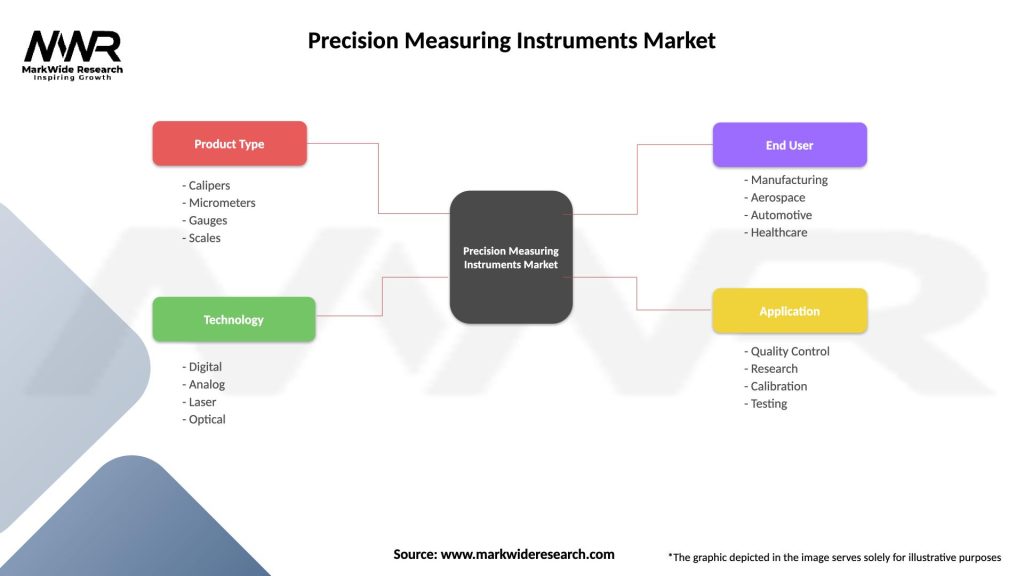

Segmentation The precision measuring instruments market can be segmented based on various parameters, including product type, technology, end-user industry, and geographic region. From traditional mechanical gauges to advanced optical, laser, and digital systems, segmentation delineates the contours of market demand, adoption trends, and technological preferences.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact The Covid-19 pandemic exerted profound ramifications on the precision measuring instruments market, disrupting supply chains, delaying projects, and reshaping demand dynamics. From the surge in remote work to the imperative for contactless measurement solutions, Covid-19 accelerated digital adoption, innovation, and resilience in the precision measurement ecosystem.

Key Industry Developments

Analyst Suggestions

Future Outlook The future of the precision measuring instruments market brims with promise and potential, anchored in the relentless pursuit of accuracy, efficiency, and innovation. From the integration of Industry 4.0 technologies to the embrace of sustainable manufacturing practices, the market charts a course towards a future defined by precision, reliability, and digital transformation.

Conclusion In conclusion, the precision measuring instruments market stands as a linchpin of modern industrial ecosystems, enabling industries to uphold exacting quality standards, drive process optimization, and foster innovation. From traditional mechanical gauges to advanced optical and laser-based systems, precision measurement solutions underpin the quest for accuracy, repeatability, and reliability across industry verticals. By embracing digital transformation, innovation, and resilience, market participants can navigate the dynamic currents of change, harnessing the full potential of precision measurement in their quest for operational excellence and market leadership.

What is Precision Measuring Instruments?

Precision measuring instruments are tools used to measure physical quantities with high accuracy and precision. They are essential in various fields such as manufacturing, engineering, and scientific research to ensure quality control and compliance with specifications.

What are the key players in the Precision Measuring Instruments Market?

Key players in the Precision Measuring Instruments Market include Mitutoyo Corporation, Hexagon AB, and Keysight Technologies, among others. These companies are known for their innovative products and solutions that cater to various industries such as aerospace, automotive, and electronics.

What are the main drivers of the Precision Measuring Instruments Market?

The Precision Measuring Instruments Market is driven by the increasing demand for high-quality manufacturing processes, advancements in technology, and the growing emphasis on automation in industries. Additionally, the rise in quality control standards across sectors further fuels market growth.

What challenges does the Precision Measuring Instruments Market face?

Challenges in the Precision Measuring Instruments Market include the high cost of advanced measuring equipment and the need for skilled personnel to operate these instruments. Furthermore, rapid technological changes can lead to obsolescence of existing tools.

What opportunities exist in the Precision Measuring Instruments Market?

Opportunities in the Precision Measuring Instruments Market include the development of smart measuring devices and the integration of IoT technology. These innovations can enhance measurement accuracy and efficiency, opening new avenues for growth in various sectors.

What trends are shaping the Precision Measuring Instruments Market?

Trends in the Precision Measuring Instruments Market include the increasing adoption of digital measuring tools and the shift towards portable and user-friendly devices. Additionally, there is a growing focus on sustainability and eco-friendly practices in the manufacturing of these instruments.

Precision Measuring Instruments Market

| Segmentation Details | Description |

|---|---|

| Product Type | Calipers, Micrometers, Gauges, Scales |

| Technology | Digital, Analog, Laser, Optical |

| End User | Manufacturing, Aerospace, Automotive, Healthcare |

| Application | Quality Control, Research, Calibration, Testing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Precision Measuring Instruments Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at