444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The pre-fabricated glass block market has witnessed significant growth in recent years, driven by the increasing demand for aesthetically appealing and energy-efficient building materials. Pre-fabricated glass blocks, also known as glass bricks, are hollow, translucent building blocks made of glass. They provide a unique combination of transparency, durability, and thermal insulation properties, making them an attractive choice for architects, designers, and homeowners.

Meaning

Pre-fabricated glass blocks are prefabricated building materials that are manufactured in controlled factory environments and then transported to construction sites for installation. These blocks are typically made of high-quality, durable glass and come in various sizes, shapes, and patterns. They are designed to interlock with each other, creating a solid and visually appealing wall or partition.

Executive Summary

The pre-fabricated glass block market has experienced steady growth due to the rising demand for eco-friendly and energy-efficient construction materials. These blocks offer several advantages over traditional building materials, such as enhanced thermal insulation, soundproofing capabilities, and aesthetic appeal. The market is driven by the increasing construction activities across residential, commercial, and industrial sectors, as well as the growing focus on sustainable building practices.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The pre-fabricated glass block market is driven by several factors that contribute to its growth and widespread adoption:

Market Restraints

Despite the positive growth prospects, the pre-fabricated glass block market faces some challenges that could hinder its progress:

Market Opportunities

Market Dynamics

The pre-fabricated glass block market is characterized by dynamic factors that influence its growth and evolution. These dynamics include changing consumer preferences, technological advancements, market trends, and regulatory policies. Understanding these dynamics is crucial for industry participants to capitalize on emerging opportunities and overcome challenges.

Regional Analysis

The pre-fabricated glass block market is analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own unique market dynamics influenced by factors such as construction activities, economic growth, government policies, and cultural preferences. The demand for pre-fabricated glass blocks may vary across regions based on these factors.

In North America and Europe, the market for pre-fabricated glass blocks is well-established and mature. The presence of advanced infrastructure, strong architectural design capabilities, and a focus on energy-efficient construction contribute to the demand in these regions.

Asia Pacific, with its rapid urbanization and infrastructure development, is expected to be a significant growth driver for the pre-fabricated glass block market. The increasing population, rising disposable income, and growing awareness of sustainable construction practices create favorable market conditions in this region.

Latin America, the Middle East, and Africa are also witnessing steady growth in the construction sector, presenting opportunities for the adoption of pre-fabricated glass blocks. However, market awareness and affordability may play a crucial role in the growth of these regions.

Competitive Landscape

Leading Companies in the Pre-Fabricated Glass Block Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

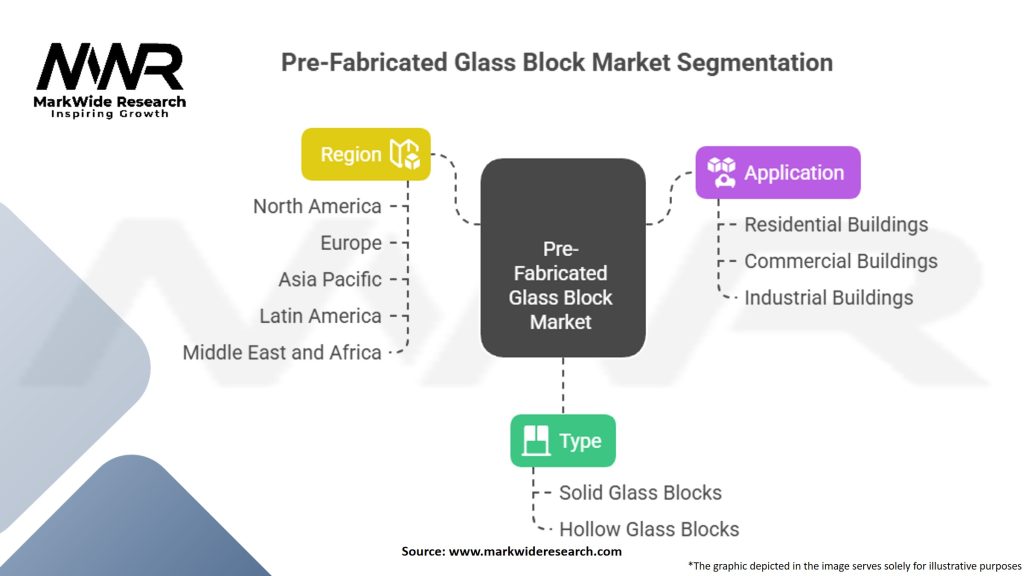

Segmentation

The pre-fabricated glass block market can be segmented based on various factors, including product type, application, end-use industry, and region.

Based on product type, the market can be segmented into clear glass blocks, colored glass blocks, patterned glass blocks, and others. Each type offers distinct visual effects and design possibilities.

In terms of application, pre-fabricated glass blocks find use in interior walls, exterior walls, partitions, windows, flooring, and decorative elements. The versatility of these blocks allows for their application in various architectural and design contexts.

End-use industries for pre-fabricated glass blocks include residential, commercial, and industrial sectors. Residential applications include homes, apartments, and condominiums, while commercial applications encompass offices, retail spaces, hotels, and restaurants. Industrial applications can range from warehouses to manufacturing facilities.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive understanding of the pre-fabricated glass block market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these factors can help industry participants formulate effective strategies to capitalize on strengths, address weaknesses, exploit opportunities, and mitigate threats.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the construction industry, including the pre-fabricated glass block market. The pandemic led to disruptions in the global supply chain, temporary halts in construction activities, and economic uncertainties. However, the market showed resilience due to the growing demand for energy-efficient and sustainable construction materials.

The pandemic also highlighted the importance of health and safety in building design. Pre-fabricated glass blocks, with their inherent properties such as easy maintenance and natural light penetration, gained attention as they contribute to creating healthier and more comfortable indoor environments.

The shift towards remote work and the increased focus on indoor spaces resulted in the adaptation of residential and commercial buildings to accommodate changing needs. Pre-fabricated glass blocks, with their design flexibility and aesthetic appeal, were well-suited to meet the demand for adaptable and visually appealing spaces.

Overall, while the Covid-19 pandemic presented challenges, it also created opportunities for the pre-fabricated glass block market to innovate and contribute to the changing landscape of construction and design.

Key Industry Developments

Analyst Suggestions

Based on market trends and dynamics, analysts suggest the following strategies for industry participants:

Future Outlook

The future of the pre-fabricated glass block market looks promising, driven by factors such as sustainable construction practices, energy efficiency requirements, and the growing emphasis on aesthetics in architectural design. Technological advancements, including smart glass blocks and improved manufacturing processes, will further enhance the market’s potential.

The market is expected to witness growth in both developed and emerging economies as urbanization and infrastructure development continue to drive construction activities. Additionally, increasing environmental regulations and incentives for sustainable building practices will create opportunities for the adoption of pre-fabricated glass blocks.

However, challenges such as high initial costs and limited market awareness need to be addressed. Industry participants should focus on cost optimization, product diversification, and educational initiatives to overcome these challenges and capitalize on the market’s growth potential.

Conclusion

The pre-fabricated glass block market is experiencing steady growth driven by the demand for sustainable, energy-efficient, and aesthetically appealing construction materials. Pre-fabricated glass blocks offer advantages such as thermal insulation, design flexibility, and durability. While the market faces challenges such as high costs and limited awareness, opportunities in green building initiatives, renovation projects, and emerging economies are paving the way for future growth.

Industry participants should focus on innovation, customization, and collaboration to stay competitive. Technological advancements, sustainable manufacturing practices, and digitalization will play key roles in shaping the market’s future. By addressing challenges, embracing opportunities, and meeting evolving customer demands, the pre-fabricated glass block market is poised for a positive outlook in the coming years.

What is Pre-Fabricated Glass Block?

Pre-Fabricated Glass Block refers to modular glass units that are manufactured in a factory setting and used in construction for walls, windows, and decorative features. These blocks are known for their aesthetic appeal, durability, and ability to provide natural light while maintaining privacy.

What are the key players in the Pre-Fabricated Glass Block Market?

Key players in the Pre-Fabricated Glass Block Market include companies like Pittsburgh Corning, Trosifol, and TGL Glass. These companies are known for their innovative designs and high-quality products, catering to both residential and commercial construction needs, among others.

What are the growth factors driving the Pre-Fabricated Glass Block Market?

The growth of the Pre-Fabricated Glass Block Market is driven by increasing demand for energy-efficient building materials, the rising trend of modern architecture, and the growing popularity of sustainable construction practices. Additionally, the versatility of glass blocks in various applications contributes to market expansion.

What challenges does the Pre-Fabricated Glass Block Market face?

The Pre-Fabricated Glass Block Market faces challenges such as high manufacturing costs and competition from alternative materials like traditional bricks and concrete. Additionally, the fragility of glass blocks can pose installation difficulties, impacting their adoption in certain projects.

What opportunities exist in the Pre-Fabricated Glass Block Market?

Opportunities in the Pre-Fabricated Glass Block Market include the potential for product innovation, such as the development of smart glass blocks with integrated technology. Furthermore, expanding into emerging markets and increasing awareness of the benefits of glass blocks in sustainable design present significant growth avenues.

What trends are shaping the Pre-Fabricated Glass Block Market?

Current trends in the Pre-Fabricated Glass Block Market include the increasing use of textured and colored glass blocks for aesthetic purposes, as well as the integration of energy-efficient technologies. Additionally, there is a growing interest in using glass blocks for interior design, enhancing both functionality and style.

Pre-Fabricated Glass Block Market

| Segmentation Details | Details |

|---|---|

| Type | Solid Glass Blocks, Hollow Glass Blocks |

| Application | Residential Buildings, Commercial Buildings, Industrial Buildings |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Pre-Fabricated Glass Block Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at