Market Overview

The Powdered Metal Bushings Parts Market plays a pivotal role in various industries, offering durable and cost-effective solutions for bearing applications. Powdered metal bushings, also known as sintered bearings or self-lubricating bearings, are manufactured through the powder metallurgy process, wherein metal powders are compacted and sintered to form intricate shapes with precise dimensions and properties. These bushings find extensive use in automotive, industrial machinery, appliances, aerospace, and other sectors, where they provide reliable performance, reduced friction, and extended service life compared to traditional metal or plastic bearings.

Meaning

Powdered metal bushings parts refer to self-lubricating bearings produced using powdered metal materials and advanced manufacturing techniques. These bushings are engineered to withstand high loads, temperatures, and harsh operating conditions, making them ideal for various applications that demand durability, reliability, and performance. By utilizing powdered metal technology, manufacturers can produce complex bushing geometries with tight tolerances and exceptional mechanical properties, offering cost-effective solutions for demanding bearing applications.

Executive Summary

The Powdered Metal Bushings Parts Market has witnessed significant growth in recent years, driven by the increasing demand for lightweight, high-strength components in automotive, industrial, and aerospace applications. The market offers numerous opportunities for manufacturers to innovate and expand their product offerings to cater to diverse customer needs and industry requirements. However, challenges such as material selection, process optimization, and quality control need to be addressed to maintain competitiveness and ensure customer satisfaction in a dynamic market environment.

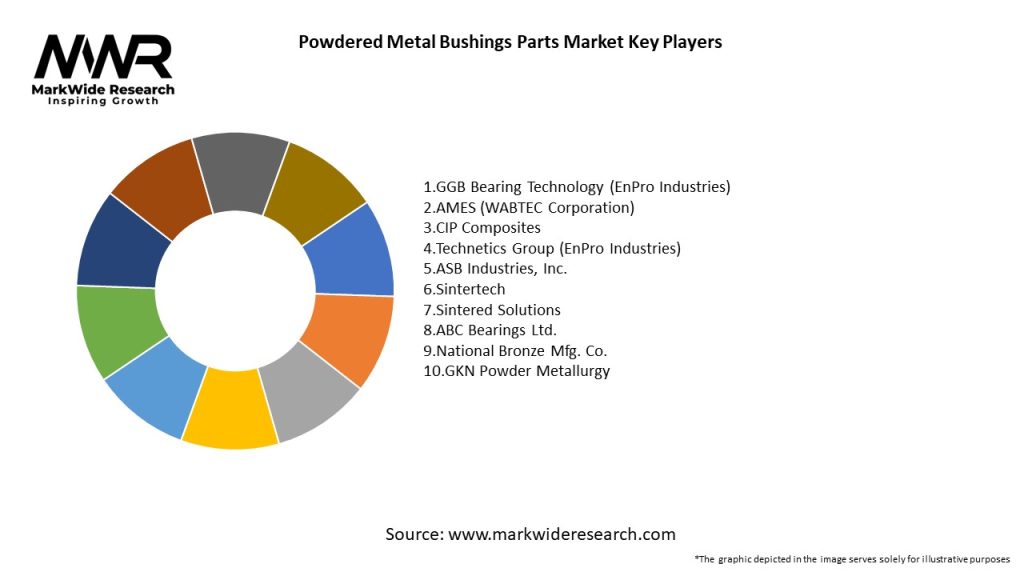

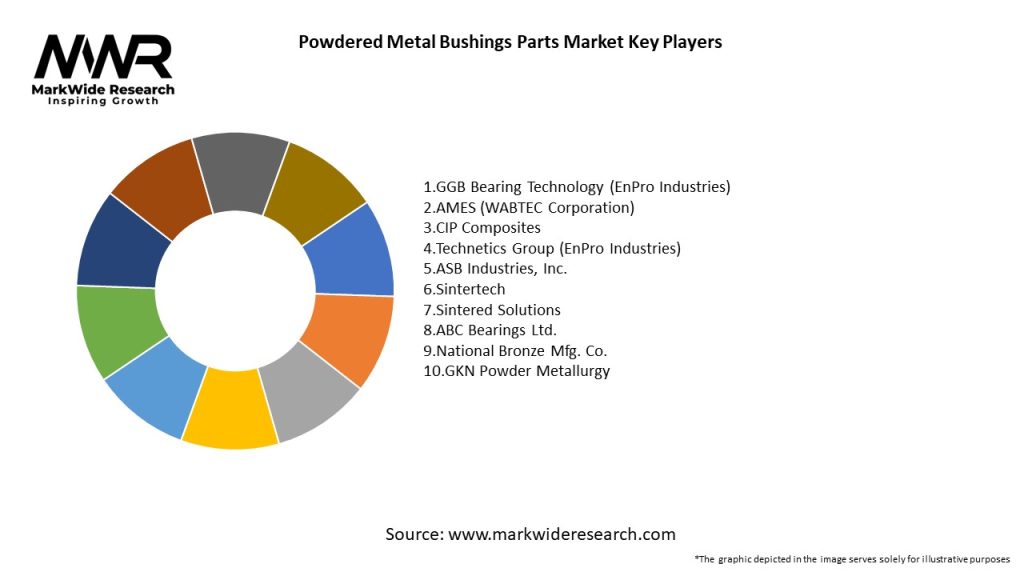

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing Demand for Lightweight Components: The demand for powdered metal bushings parts is fueled by the automotive industry’s shift towards lightweighting to improve fuel efficiency and reduce emissions. Powdered metal bearings offer a lightweight alternative to traditional metal bearings, making them ideal for applications where weight savings are critical, such as engine, transmission, and chassis components.

- Rising Adoption of Electric Vehicles: The increasing adoption of electric vehicles (EVs) presents opportunities for powdered metal bushings parts manufacturers. EVs require high-performance bearings that can withstand the unique operating conditions of electric drivetrains, including high torque, low noise, and minimal maintenance. Powdered metal bushings offer self-lubricating properties, low friction, and high wear resistance, making them well-suited for EV applications.

- Focus on Sustainability: Sustainability concerns are driving the adoption of powdered metal bushings parts in various industries. Powder metallurgy processes utilize recycled metal powders and produce minimal waste compared to conventional machining methods, making them environmentally friendly. Additionally, self-lubricating properties reduce the need for external lubricants, further enhancing the sustainability credentials of powdered metal bearings.

- Technological Advancements: Advances in powder metallurgy technology, materials science, and manufacturing processes are driving innovation in the powdered metal bushings parts market. Manufacturers are developing new materials, such as iron-based alloys, copper infiltrated bearings, and hybrid composites, to enhance performance and expand application possibilities. Furthermore, advancements in additive manufacturing techniques enable the production of complex bushing geometries with improved accuracy and efficiency.

Market Drivers

- Automotive Industry Growth: The automotive industry’s expansion, particularly in emerging markets, is driving demand for powdered metal bushings parts. These bearings are used in various automotive applications, including engine components, transmission systems, steering assemblies, and suspension systems, to improve performance, reliability, and durability.

- Industrial Automation: The growing trend towards industrial automation and smart manufacturing is driving demand for high-performance bearings in machinery and equipment. Powdered metal bushings parts offer advantages such as self-lubrication, reduced maintenance, and extended service life, making them ideal for critical applications in robotics, machine tools, conveyor systems, and industrial automation equipment.

- Infrastructure Development: Infrastructure development projects, such as construction, mining, and transportation, require reliable and durable components to withstand harsh operating conditions. Powdered metal bushings parts find applications in heavy-duty equipment, earthmoving machinery, hydraulic systems, and material handling equipment, providing superior performance and longevity in demanding environments.

- Focus on Total Cost of Ownership: Manufacturers and end-users are increasingly focused on the total cost of ownership (TCO) when selecting bearing solutions. Powdered metal bushings parts offer cost-effective solutions with lower maintenance requirements, reduced downtime, and extended service intervals compared to traditional bearings, resulting in overall cost savings over the lifecycle of the equipment.

Market Restraints

- Material Limitations: Despite advancements in powdered metal technology, certain material limitations exist, particularly in high-temperature and high-load applications. While powdered metal bushings offer excellent performance in most operating conditions, extreme temperatures, corrosive environments, and heavy shock loads may require alternative bearing materials or designs.

- Quality Control Challenges: Maintaining consistent quality and performance across large-scale production volumes presents challenges for powdered metal bushings manufacturers. Variations in powder composition, sintering conditions, and post-processing treatments can affect the properties and performance of finished bushings, requiring stringent quality control measures and process optimization.

- Competitive Pressure: The powdered metal bushings market faces competitive pressure from alternative bearing technologies, such as polymer bearings, ceramic bearings, and coated bearings. These alternatives offer unique advantages in specific applications, posing challenges for powdered metal bushings manufacturers to differentiate their products and capture market share effectively.

- Regulatory Compliance: Compliance with regulatory standards and industry specifications, such as ASTM, SAE, and ISO, is essential for powdered metal bushings manufacturers to ensure product quality, reliability, and safety. Meeting stringent regulatory requirements may entail additional testing, certification, and documentation efforts, increasing compliance costs and time-to-market for new products.

Market Opportunities

- Customization and Specialization: The growing trend towards customization and specialization presents opportunities for powdered metal bushings manufacturers to develop tailored solutions for specific applications and industries. By understanding customer requirements and offering customized products with unique features and performance characteristics, manufacturers can differentiate their offerings and capture niche markets effectively.

- Aftermarket Services: The aftermarket for powdered metal bushings parts offers opportunities for manufacturers to provide value-added services, such as maintenance, repair, and overhaul (MRO), to end-users. By offering comprehensive aftermarket support, including replacement parts, refurbishment services, and technical assistance, manufacturers can enhance customer loyalty and generate recurring revenue streams.

- Expansion into Emerging Markets: Emerging markets, such as Asia Pacific, Latin America, and the Middle East, present untapped opportunities for powdered metal bushings manufacturers. Rapid industrialization, infrastructure development, and increasing investments in automotive and manufacturing sectors in these regions create demand for high-quality bearing solutions, offering avenues for market expansion and growth.

- Collaboration and Partnerships: Collaboration with industry partners, such as OEMs, distributors, and research institutions, enables powdered metal bushings manufacturers to leverage complementary strengths, resources, and expertise. Strategic partnerships facilitate access to new markets, technologies, and customer segments, accelerating innovation, and market penetration efforts.

Market Dynamics

The Powdered Metal Bushings Parts Market operates in a dynamic environment shaped by various factors, including technological advancements, industry trends, regulatory changes, and competitive dynamics. Manufacturers and stakeholders must navigate these dynamics strategically to capitalize on opportunities, mitigate risks, and maintain competitiveness in the market. Understanding the market dynamics is crucial for informed decision-making and long-term success in the powdered metal bushings industry.

Regional Analysis

The Powdered Metal Bushings Parts Market exhibits regional variations in terms of market size, growth potential, industry concentration, and demand dynamics. Key regions for the powdered metal bushings market include:

- North America: The North American market is characterized by a strong presence of automotive, industrial, and aerospace sectors, driving demand for powdered metal bushings parts. The United States and Canada are major contributors to market growth, with established manufacturing capabilities and stringent quality standards.

- Europe: Europe is a prominent market for powdered metal bushings parts, supported by a robust automotive industry, advanced manufacturing technologies, and stringent regulatory standards. Germany, Italy, France, and the United Kingdom are key markets for powdered metal bearings, with a focus on automotive, machinery, and aerospace applications.

- Asia Pacific: Asia Pacific is a rapidly growing market for powdered metal bushings parts, driven by industrialization, urbanization, and infrastructure development. China, Japan, India, and South Korea are key contributors to market growth, with expanding automotive, manufacturing, and construction sectors driving demand for bearing solutions.

- Latin America: Latin America offers growth opportunities for powdered metal bushings manufacturers, fueled by increasing investments in infrastructure, mining, and transportation sectors. Countries like Brazil, Mexico, Argentina, and Chile present opportunities for market expansion, supported by favorable economic conditions and rising demand for durable bearing solutions.

- Middle East and Africa: The Middle East and Africa region offer potential for powdered metal bushings market growth, driven by infrastructure projects, oil and gas exploration, and industrial development initiatives. Countries like Saudi Arabia, UAE, South Africa, and Nigeria are key markets for powdered metal bearings, with demand from construction, mining, and energy sectors.

Competitive Landscape

Leading Companies in the Powdered Metal Bushings Parts Market:

- GGB Bearing Technology (EnPro Industries)

- AMES (WABTEC Corporation)

- CIP Composites

- Technetics Group (EnPro Industries)

- ASB Industries, Inc.

- Sintertech

- Sintered Solutions

- ABC Bearings Ltd.

- National Bronze Mfg. Co.

- GKN Powder Metallurgy

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Powdered Metal Bushings Parts Market can be segmented based on various factors, including:

- Material Type: Segmentation by material type includes iron-based alloys, copper-based alloys, bronze alloys, and stainless steel alloys, each offering unique properties and performance characteristics for specific applications.

- End-Use Industry: Segmentation by end-use industry includes automotive, industrial machinery, aerospace, construction, agriculture, and others, reflecting the diverse applications and demand drivers for powdered metal bushings parts.

- Application: Segmentation by application includes engine components, transmission systems, chassis components, steering assemblies, suspension systems, hydraulic systems, and others, highlighting the wide-ranging applications and functional requirements for powdered metal bearings.

- Geography: The market can be segmented into regions, countries, and cities based on demand patterns, industry dynamics, and market opportunities in specific geographic locations.

Segmentation provides a deeper understanding of market dynamics, customer preferences, and competitive landscapes, enabling manufacturers to tailor their strategies, product offerings, and marketing efforts to target specific segments effectively.

Category-wise Insights

- Automotive Applications: Powdered metal bushings parts find extensive use in automotive applications, including engine bearings, transmission bushings, suspension components, and steering assemblies, offering advantages such as reduced weight, improved fuel efficiency, and enhanced durability for vehicle performance and reliability.

- Industrial Machinery: Powdered metal bushings parts are utilized in various industrial machinery and equipment, including pumps, compressors, motors, actuators, valves, and gearboxes, providing self-lubricating, wear-resistant solutions for high-load, high-speed, and continuous operation in manufacturing and processing industries.

- Aerospace Components: The aerospace industry relies on powdered metal bushings parts for critical applications such as aircraft landing gear, flight control systems, engine mounts, and structural components, where lightweight, high-strength, and reliable bearing solutions are essential for aircraft safety and performance.

- Construction Equipment: Powdered metal bushings parts are used in construction equipment such as excavators, bulldozers, cranes, and compactors, where they provide robust, maintenance-free solutions for heavy-duty, high-impact, and abrasive environments encountered in construction and infrastructure projects.

- Agricultural Machinery: The agriculture sector utilizes powdered metal bushings parts in farm machinery and equipment such as tractors, combines, harvesters, and tillers, where they offer reliable, long-lasting solutions for agricultural operations in diverse climates, terrains, and soil conditions.

Key Benefits for Industry Participants and Stakeholders

The Powdered Metal Bushings Parts Market offers several benefits for industry participants and stakeholders:

- Enhanced Performance: Powdered metal bushings parts offer superior performance characteristics such as self-lubrication, low friction, high wear resistance, and extended service life compared to traditional bearings, providing reliable solutions for demanding applications.

- Cost Savings: Powdered metal bushings parts offer cost-effective solutions with lower maintenance requirements, reduced downtime, and extended service intervals, resulting in overall cost savings over the lifecycle of machinery and equipment.

- Customization Options: Powdered metal bushings manufacturers offer customization options to tailor bearing solutions to specific customer requirements, including material selection, geometry, dimensions, and performance specifications, enabling personalized solutions for diverse applications.

- Environmental Benefits: Powdered metal bushings parts offer environmental benefits such as reduced material waste, energy efficiency, and minimal lubrication requirements, aligning with sustainability goals and regulatory requirements for environmentally friendly manufacturing practices.

- Supply Chain Integration: Powdered metal bushings manufacturers integrate seamlessly into the supply chain, offering reliable, just-in-time delivery of bearings, technical support, and aftermarket services to OEMs, distributors, and end-users worldwide.

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats in the Powdered Metal Bushings Parts Market:

- Strengths:

- Superior performance characteristics

- Cost-effective solutions

- Customization options

- Environmental benefits

- Weaknesses:

- Material limitations in extreme conditions

- Quality control challenges in large-scale production

- Opportunities:

- Customization and specialization

- Aftermarket services

- Expansion into emerging markets

- Collaboration and partnerships

- Threats:

- Competitive pressure from alternative bearing technologies

- Regulatory compliance requirements

- Economic volatility and uncertainty

Understanding these factors through a SWOT analysis helps businesses capitalize on strengths, address weaknesses, leverage opportunities, and mitigate threats in the powdered metal bushings market.

Market Key Trends

- Material Innovation: Advances in material science and metallurgy are driving innovation in powdered metal bushings parts, enabling the development of new alloys, composites, and coatings with enhanced performance properties such as wear resistance, fatigue strength, and corrosion resistance.

- Digitalization and Industry 4.0: The integration of digital technologies such as IoT sensors, AI algorithms, and predictive analytics is transforming the powdered metal bushings industry, enabling real-time monitoring, predictive maintenance, and remote diagnostics for improved reliability and efficiency.

- Additive Manufacturing: Additive manufacturing technologies, such as 3D printing, are revolutionizing the production of powdered metal bushings parts, enabling rapid prototyping, complex geometries, and on-demand manufacturing with reduced lead times and production costs.

- Circular Economy Initiatives: Powdered metal bushings manufacturers are embracing circular economy principles by recycling metal powders, reusing production waste, and minimizing environmental impact throughout the product lifecycle, contributing to sustainable development and resource conservation.

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Powdered Metal Bushings Parts Market. While the initial disruption caused by lockdowns, supply chain disruptions, and reduced demand affected market growth, the subsequent recovery and adaptation to new norms have led to opportunities for innovation, resilience, and market expansion. Key impacts of Covid-19 on the powdered metal bushings market include:

- Supply Chain Disruptions: The pandemic disrupted global supply chains, causing delays in raw material procurement, production shutdowns, and logistics challenges for powdered metal bushings manufacturers. However, the adoption of digital supply chain solutions and agile manufacturing strategies helped mitigate disruptions and ensure continuity of operations.

- Shift in Demand Patterns: Changes in consumer behavior, economic uncertainty, and industry dynamics resulted in shifting demand patterns for powdered metal bushings parts. While some sectors experienced reduced demand due to slowdowns in automotive, aerospace, and industrial sectors, others saw increased demand for essential applications such as medical equipment, HVAC systems, and food processing machinery.

- Focus on Resilience and Adaptation: The pandemic underscored the importance of resilience, adaptability, and innovation in the powdered metal bushings industry. Manufacturers implemented measures to enhance operational flexibility, optimize inventory management, and diversify supply chain sources to mitigate risks and ensure business continuity in volatile market conditions.

- Accelerated Digital Transformation: The Covid-19 pandemic accelerated the adoption of digital technologies and remote collaboration tools in the powdered metal bushings industry. Manufacturers embraced digitalization initiatives such as virtual design, remote monitoring, and digital twin simulations to streamline operations, improve efficiency, and enhance resilience in a distributed work environment.

Key Industry Developments

- Advanced Materials Development: Powdered metal bushings manufacturers are investing in R&D to develop advanced materials with enhanced performance characteristics such as higher strength, improved wear resistance, and better tribological properties for demanding applications in automotive, aerospace, and industrial sectors.

- Industry 4.0 Integration: Industry 4.0 technologies such as IoT, AI, and cloud computing are being integrated into powdered metal bushings manufacturing processes to enable real-time monitoring, predictive maintenance, and data-driven decision-making for improved quality, efficiency, and reliability.

- Sustainable Manufacturing Practices: Powdered metal bushings manufacturers are adopting sustainable manufacturing practices such as energy-efficient processes, waste reduction, and recycling initiatives to minimize environmental impact and align with corporate sustainability goals and regulatory requirements.

- Strategic Partnerships and Collaborations: Collaboration among powdered metal bushings manufacturers, material suppliers, research institutions, and end-users is increasing to foster innovation, share best practices, and address common challenges in product development, manufacturing, and market penetration.

Analyst Suggestions

In the Powdered Metal Bushings Parts Market, analysts suggest several strategies for manufacturers and stakeholders to navigate the evolving landscape:

- Investment in R&D: Manufacturers should prioritize investment in research and development to develop advanced materials, manufacturing processes, and product innovations that meet evolving customer needs and industry requirements.

- Quality Assurance: Ensuring consistent quality and performance is crucial for powdered metal bushings manufacturers to maintain customer satisfaction and competitive advantage. Implementing robust quality control measures, process optimization, and continuous improvement initiatives can enhance product reliability and market acceptance.

- Customer-Centric Approach: Manufacturers should adopt a customer-centric approach to product development, focusing on understanding and addressing the specific needs, preferences, and pain points of end-users across different industries and applications. Providing customized solutions, technical support, and aftermarket services can enhance customer loyalty and retention.

- Digital Transformation: Embracing digital transformation initiatives such as digital design, simulation, and manufacturing technologies can improve efficiency, agility, and competitiveness in the powdered metal bushings industry. Manufacturers should leverage digital tools and analytics to optimize production processes, reduce lead times, and enhance product quality.

- Sustainability Initiatives: Incorporating sustainable manufacturing practices such as recycling, energy efficiency, and waste reduction can enhance the environmental credentials of powdered metal bushings manufacturers and meet increasing demand for eco-friendly solutions from customers, regulators, and stakeholders.

Future Outlook

The Powdered Metal Bushings Parts Market is poised for steady growth in the coming years, driven by increasing demand from automotive, industrial, aerospace, and other sectors for lightweight, durable bearing solutions. Technological advancements, material innovations, and industry trends such as digitalization, sustainability, and customization will shape the future of the powdered metal bushings industry. Manufacturers that embrace innovation, adaptability, and collaboration will be well-positioned to capitalize on emerging opportunities and maintain competitiveness in a rapidly evolving market landscape.

Conclusion

The Powdered Metal Bushings Parts Market offers durable, cost-effective bearing solutions for various industries, providing superior performance, reliability, and efficiency compared to traditional metal or plastic bearings. With increasing demand from automotive, industrial, aerospace, and other sectors, the market presents significant opportunities for manufacturers to innovate, expand product offerings, and capture market share. However, challenges such as material limitations, quality control, and competitive pressure need to be addressed to maintain competitiveness and meet evolving customer needs. By investing in R&D, embracing digital transformation, and adopting sustainable manufacturing practices, powdered metal bushings manufacturers can position themselves for long-term success and contribute to the advancement of the global bearing industry.