444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The polyurethane braid air hose market has been experiencing significant growth due to the increasing demand for lightweight, durable, and flexible hoses in various industrial applications. Polyurethane braid air hoses are specialized tubes designed to transport compressed air, fluids, and gases in pneumatic systems, fluid handling equipment, and air tool assemblies. This comprehensive market overview aims to provide insights into various aspects of the polyurethane braid air hose market, including its current state, key trends, competitive landscape, and future prospects.

Meaning

Polyurethane braid air hoses are flexible tubing assemblies made from polyurethane resin reinforced with braided synthetic fibers or wire spirals to enhance strength, durability, and pressure resistance. These hoses are commonly used in pneumatic systems, air compressors, and air tool applications where lightweight, abrasion-resistant, and kink-free hoses are required for efficient fluid transfer and operation. Polyurethane braid air hoses offer advantages such as flexibility, chemical resistance, and long service life compared to traditional rubber hoses, making them ideal for demanding industrial environments.

Executive Summary

The polyurethane braid air hose market is witnessing steady growth, driven by factors such as increasing adoption of pneumatic tools, growing industrialization, and rising demand for lightweight, high-performance hoses. Key players in the market are focusing on product innovation, material advancements, and market expansion to meet the diverse needs of industrial end-users and gain a competitive edge in the dynamic hose manufacturing industry.

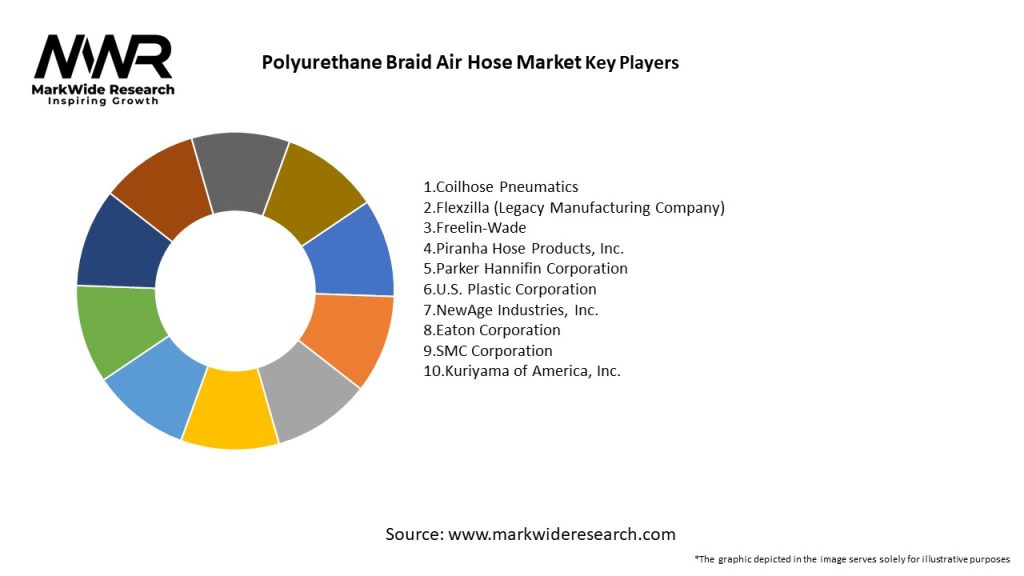

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The polyurethane braid air hose market is characterized by innovation, customization, and collaboration. Manufacturers, distributors, and end-users are partnering to develop advanced hose solutions that meet the evolving needs and challenges of modern industrial applications. Advances in material science, hose construction, and manufacturing technologies are driving the development of polyurethane braid air hoses with superior performance, durability, and versatility. Additionally, industry associations and standards organizations are promoting knowledge sharing, technology adoption, and best practices in the polyurethane braid air hose market, fostering innovation and market growth.

Regional Analysis

Geographically, North America dominates the polyurethane braid air hose market, owing to the presence of a large industrial base, extensive distribution networks, and stringent safety regulations driving demand for high-quality hoses. Europe follows closely, with a focus on energy efficiency, environmental sustainability, and workplace ergonomics promoting the adoption of polyurethane braid air hoses in the region. The Asia Pacific region presents significant opportunities for market expansion, fueled by rapid industrialization, infrastructure development, and manufacturing growth in countries such as China, India, and Southeast Asia.

Competitive Landscape

Leading Companies in the Polyurethane Braid Air Hose Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The polyurethane braid air hose market can be segmented based on:

Understanding these segmentation factors enables manufacturers and suppliers to tailor their product offerings and marketing strategies to meet the specific needs of customers across diverse industrial applications and end-user sectors.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders benefit from polyurethane braid air hoses in several ways, including improved productivity, safety, and cost savings in industrial fluid handling and air tool applications. By investing in polyurethane braid air hoses, manufacturers, distributors, and end-users can achieve higher efficiency, reliability, and performance in pneumatic systems, contributing to overall operational excellence and competitiveness in the marketplace.

SWOT Analysis

A SWOT analysis offers insights into the strengths, weaknesses, opportunities, and threats facing the polyurethane braid air hose market. Strengths include the lightweight, durable, and flexible nature of polyurethane hoses that offer superior performance and reliability in industrial applications. Weaknesses encompass challenges related to cost competitiveness, technical compatibility, and market saturation. Opportunities arise from the expanding market potential in new applications and geographic regions, development of innovative hose technologies, and collaboration between stakeholders. Threats include competitive pressures, regulatory constraints, and economic uncertainties impacting industrial demand and investment.

Market Key Trends

Several key trends are shaping the polyurethane braid air hose market, including the adoption of advanced materials, such as polyurethane blends, thermoplastic elastomers, and hybrid polymers, for enhanced durability, chemical resistance, and flexibility in hose construction. Additionally, there is growing interest in hose accessories, such as quick-connect couplings, safety whip hoses, and hose reels, for improved efficiency, ergonomics, and safety in industrial fluid handling and air tool operations. Moreover, there is increasing emphasis on sustainability, energy efficiency, and waste reduction driving innovation and differentiation in the polyurethane braid air hose market.

Covid-19 Impact

The Covid-19 pandemic has influenced the polyurethane braid air hose market by highlighting the importance of industrial hygiene, safety, and automation in manufacturing and construction sectors. While the pandemic has disrupted supply chains and production schedules, it has also accelerated trends such as remote monitoring, digitalization, and robotics driving investments in polyurethane braid air hoses that support these objectives and enhance operational resilience. Additionally, the pandemic has increased awareness of workplace safety, health protocols, and risk management leading to greater demand for hoses that promote employee well-being and productivity in industrial settings.

Key Industry Developments

Key industry developments in the polyurethane braid air hose market include the development of advanced hose materials such as bio-based polyurethanes, recycled thermoplastics, and anti-microbial additives for enhanced sustainability, environmental stewardship, and performance in industrial applications. Additionally, there is growing interest in smart hose technologies, such as embedded sensors, RFID tags, and IoT connectivity enabling real-time monitoring, asset tracking, and predictive maintenance of hoses in pneumatic systems and fluid handling equipment. Moreover, there is increasing emphasis on training programs, certification standards, and safety guidelines promoting best practices, quality assurance, and professional development in hose manufacturing and usage.

Analyst Suggestions

Analysts suggest several strategies for industry participants to navigate the evolving landscape of the polyurethane braid air hose market, including investing in research and development to advance hose materials, manufacturing processes, and smart technologies, expanding market outreach and education to raise awareness of hose benefits and applications, and collaborating with customers, suppliers, and regulators to develop tailored hose solutions that meet industry needs and address market challenges. By adopting these strategies, stakeholders can capitalize on emerging opportunities, mitigate risks, and contribute to the growth and sustainability of the polyurethane braid air hose market.

Future Outlook

The future outlook for the polyurethane braid air hose market is positive, with continued growth expected in the coming years. The increasing demand for lightweight, durable hoses in industrial fluid handling, pneumatic systems, and air tool applications is driving investment in polyurethane braid air hose solutions that offer superior performance, reliability, and efficiency. Additionally, technological advancements in hose design, material science, and smart technologies are enabling greater customization, integration, and intelligence in polyurethane braid air hose solutions, driving innovation and market expansion. Moving forward, industry players are expected to focus on innovation, collaboration, and sustainability to address emerging challenges and opportunities in the dynamic and rapidly evolving polyurethane braid air hose market.

Conclusion

In conclusion, the polyurethane braid air hose market offers versatile and high-performance solutions for industrial fluid handling and air tool applications. Polyurethane braid air hoses play a critical role in ensuring productivity, safety, and efficiency in pneumatic systems, manufacturing processes, and construction operations. Despite challenges such as cost constraints, technical compatibility, and market competition, the market continues to witness steady growth, driven by increasing demand for lightweight, durable hoses and rising adoption of advanced hose technologies. By embracing innovation, collaboration, and sustainability, industry participants can unlock new opportunities, address market challenges, and contribute to the growth and resilience of the polyurethane braid air hose market.

Polyurethane Braid Air Hose Market

| Segmentation Details | Description |

|---|---|

| Product Type | Reinforced Hoses, Lightweight Hoses, High-Pressure Hoses, Standard Hoses |

| Application | Industrial Use, Automotive Repair, Construction, Pneumatic Tools |

| End User | Manufacturers, Contractors, DIY Enthusiasts, Service Providers |

| Distribution Channel | Online Retail, Wholesale Distributors, Specialty Stores, Direct Sales |

Leading Companies in the Polyurethane Braid Air Hose Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at