444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Plastic Pyrolysis Plant market is witnessing significant growth, driven by the increasing demand for sustainable waste management solutions and the rising awareness of plastic pollution and environmental degradation. Pyrolysis plants offer an effective and eco-friendly way to convert plastic waste into valuable products such as fuel oil, gas, and char, thereby reducing landfill waste, conserving natural resources, and mitigating the impact of plastic pollution on the environment. With growing regulatory support, technological advancements, and investment in waste-to-energy projects, the market for plastic pyrolysis plants is expected to continue expanding globally.

Meaning

Plastic Pyrolysis Plants are industrial facilities designed to thermally decompose plastic waste into useful products such as fuel oil, gas, and char through pyrolysis, a chemical process that breaks down organic materials at high temperatures in the absence of oxygen. These plants utilize advanced technologies and equipment to convert various types of plastic waste, including packaging materials, single-use plastics, and industrial plastics, into valuable resources that can be used as alternative fuels or raw materials in various industries. Plastic pyrolysis plants play a vital role in waste management, recycling, and sustainable development by reducing plastic pollution, conserving energy, and promoting circular economy principles.

Executive Summary

The Plastic Pyrolysis Plant market is experiencing robust growth, driven by increasing concerns about plastic pollution, waste management, and environmental sustainability. Key market players are investing in research and development to improve plant efficiency, product quality, and environmental performance. Additionally, government regulations, policies, and initiatives promoting waste-to-energy projects and circular economy models are driving market expansion and adoption of plastic pyrolysis technologies worldwide.

Key Market Insights

The Plastic Pyrolysis Plant market is characterized by technological advancements, regulatory support, and industry trends shaping the demand for sustainable waste management solutions. Key market players are focusing on developing innovative pyrolysis technologies, process optimizations, and product diversification to meet the evolving needs and preferences of waste management companies, recyclers, and industrial users. Additionally, the integration of digital technologies, automation, and predictive analytics is gaining traction to enhance plant efficiency, safety, and reliability.

Market Drivers

Several factors are driving the growth of the Plastic Pyrolysis Plant market, including:

Market Restraints

Despite the growth opportunities, the Plastic Pyrolysis Plant market faces certain challenges, including:

Market Opportunities

The Plastic Pyrolysis Plant market presents significant opportunities for market players to capitalize on, including:

Market Dynamics

The Plastic Pyrolysis Plant market is characterized by dynamic market dynamics, driven by technological advancements, regulatory support, and industry trends shaping the demand for sustainable waste management solutions. Market players need to adapt to these changes by continuously innovating, investing in research and development, and collaborating with stakeholders across the value chain to address evolving customer needs and market opportunities. Strategic partnerships, joint ventures, and alliances with waste management companies, recyclers, and industrial users are essential for driving innovation, market penetration, and sustainable growth in the Plastic Pyrolysis Plant market.

Regional Analysis

The Plastic Pyrolysis Plant market is experiencing growth across regions, with Asia Pacific, Europe, and North America leading the market expansion. In Asia Pacific, countries such as China, India, and Southeast Asian nations are driving market growth through investments in waste management infrastructure, environmental regulations, and circular economy initiatives. In Europe, the European Union’s Circular Economy Action Plan and Waste Framework Directive are driving investment in plastic recycling and waste-to-energy projects, creating opportunities for pyrolysis plant operators and technology suppliers. In North America, the United States and Canada are witnessing increasing interest and investment in plastic pyrolysis technologies, driven by regulatory pressures, corporate sustainability goals, and public awareness of plastic pollution.

Competitive Landscape

The Plastic Pyrolysis Plant market is highly competitive, with key market players competing on factors such as technology leadership, product quality, project execution, and customer service. Major players operating in the market include Plastic Energy, Recycling Technologies Ltd., Agilyx Corporation, Nexus Fuels, and Pyrolyx AG. These companies offer a range of pyrolysis technologies, equipment, and services for converting plastic waste into valuable products such as fuel oil, gas, and chemicals. Additionally, emerging players and start-ups are entering the market with innovative pyrolysis solutions, process optimizations, and business models to address niche segments and market opportunities.

Segmentation

The Plastic Pyrolysis Plant market can be segmented based on technology type, feedstock type, end product, and geography. By technology type, the market can be segmented into batch pyrolysis, continuous pyrolysis, and hybrid pyrolysis systems. By feedstock type, the market can be segmented into mixed plastics, post-consumer plastics, post-industrial plastics, and plastic residues. By end product, the market can be segmented into fuel oil, pyrolysis gas, and solid char. Geographically, the market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Category-wise Insights

In terms of technology type, continuous pyrolysis systems are gaining traction in the Plastic Pyrolysis Plant market due to their higher throughput, energy efficiency, and automation capabilities compared to batch pyrolysis systems. Continuous pyrolysis plants offer continuous operation, real-time monitoring, and process control, enabling operators to achieve higher productivity, quality consistency, and operational flexibility. In terms of feedstock type, mixed plastics are the most commonly processed in pyrolysis plants, including a wide range of plastic materials such as polyethylene, polypropylene, polystyrene, and polyvinyl chloride. Mixed plastics offer a diverse and abundant feedstock source for pyrolysis, allowing operators to optimize plant performance, product yields, and economics based on local market conditions and waste streams.

Key Benefits for Industry Participants and Stakeholders

Plastic Pyrolysis Plants offer several key benefits for industry participants and stakeholders, including:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Plastic Pyrolysis Plant market include:

Covid-19 Impact

The Covid-19 pandemic has had mixed impacts on the Plastic Pyrolysis Plant market, with both challenges and opportunities arising from the global crisis. On one hand, the pandemic has disrupted supply chains, manufacturing operations, and project development timelines, leading to delays and cancellations of pyrolysis projects in some regions. On the other hand, the pandemic has highlighted the importance of sustainable waste management, circular economy principles, and environmental resilience in building resilient and sustainable communities and economies. Governments, businesses, and investors are increasingly recognizing the value of plastic pyrolysis technology in addressing plastic pollution, promoting resource efficiency, and reducing dependence on fossil fuels, creating new opportunities for market expansion and innovation in the post-pandemic recovery.

Key Industry Developments

Recent developments in the Plastic Pyrolysis Plant market include:

Analyst Suggestions

Industry analysts suggest that market players focus on the following strategies to capitalize on emerging opportunities and mitigate potential challenges in the Plastic Pyrolysis Plant market:

Future Outlook

The future outlook for the Plastic Pyrolysis Plant market remains highly promising, with sustained growth expected in the coming years. Factors such as increasing concerns about plastic pollution, waste management challenges, and environmental sustainability, along with technological advancements and regulatory support, are driving market expansion and adoption of pyrolysis technologies worldwide. Additionally, the integration of digital technologies, automation, and predictive analytics is expected to further enhance plant efficiency, safety, and reliability. As governments, businesses, and communities prioritize sustainable waste management solutions and circular economy principles, the Plastic Pyrolysis Plant market is poised for significant growth and development.

Conclusion

In conclusion, the Plastic Pyrolysis Plant market is experiencing robust growth, driven by increasing concerns about plastic pollution, waste management challenges, and environmental sustainability. Pyrolysis plants offer an effective and eco-friendly solution for converting plastic waste into valuable products such as fuel oil, gas, and char, thereby reducing landfill waste, conserving natural resources, and mitigating the impact of plastic pollution on the environment. Market players are investing in research and development to improve plant efficiency, product quality, and environmental performance, while governments, regulators, and investors are supporting waste-to-energy projects and circular economy models. By embracing technological innovations, fostering partnerships, and adopting customer-centric approaches, market players can position themselves for success and contribute to building a cleaner, greener, and more sustainable future.

What is Plastic Pyrolysis Plant?

A Plastic Pyrolysis Plant is a facility that converts plastic waste into usable fuels and other valuable products through a thermal decomposition process in the absence of oxygen. This technology helps in managing plastic waste while producing energy and raw materials.

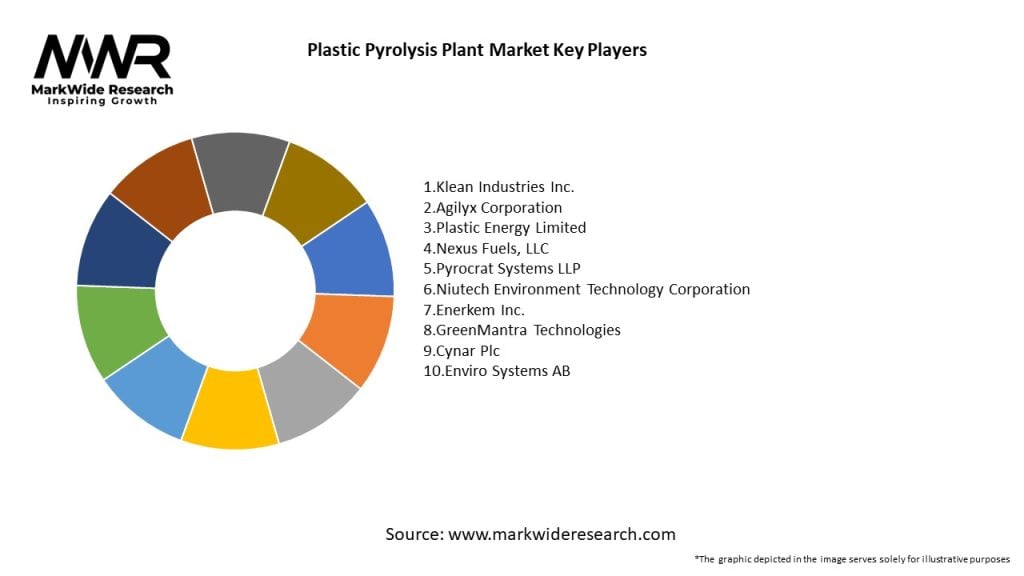

What are the key players in the Plastic Pyrolysis Plant Market?

Key players in the Plastic Pyrolysis Plant Market include companies like Pyrocrat Systems, Klean Industries, and Agilyx, which are known for their innovative technologies and solutions in plastic waste management, among others.

What are the growth factors driving the Plastic Pyrolysis Plant Market?

The growth of the Plastic Pyrolysis Plant Market is driven by increasing plastic waste generation, rising demand for sustainable waste management solutions, and the need for alternative energy sources. Additionally, government regulations promoting recycling and waste-to-energy technologies contribute to market expansion.

What challenges does the Plastic Pyrolysis Plant Market face?

The Plastic Pyrolysis Plant Market faces challenges such as high initial investment costs, technological complexities, and regulatory hurdles. Additionally, public perception and acceptance of pyrolysis technology can impact its adoption.

What opportunities exist in the Plastic Pyrolysis Plant Market?

Opportunities in the Plastic Pyrolysis Plant Market include advancements in pyrolysis technology, increasing investments in waste-to-energy projects, and growing partnerships between private and public sectors to enhance recycling initiatives. These factors can lead to innovative solutions for plastic waste management.

What trends are shaping the Plastic Pyrolysis Plant Market?

Trends shaping the Plastic Pyrolysis Plant Market include the integration of automation and AI in plant operations, the development of more efficient pyrolysis processes, and a focus on circular economy principles. These trends aim to improve efficiency and sustainability in plastic waste processing.

Plastic Pyrolysis Plant Market

| Segmentation Details | Description |

|---|---|

| Product Type | Batch, Continuous, Semi-Continuous, Modular |

| Technology | Thermal, Catalytic, Hydrothermal, Microwave |

| End User | Manufacturers, Waste Management, Energy Producers, Research Institutions |

| Application | Fuel Production, Chemical Feedstock, Carbon Black, Others |

Leading Companies in the Plastic Pyrolysis Plant Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at