444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The PET preform machine market is experiencing significant growth due to the rising demand for PET (polyethylene terephthalate) preform products across various industries. PET preforms are widely used in the packaging industry for beverages, food, personal care products, and more. These preforms act as a precursor to PET bottles and containers, making them an essential component in the manufacturing process. This market overview delves into the meaning, key insights, drivers, restraints, opportunities, dynamics, regional analysis, competitive landscape, segmentation, and more, providing a comprehensive understanding of the PET preform machine market.

Meaning

PET preform machines are advanced manufacturing equipment designed to produce PET preforms. These machines play a crucial role in the production of PET bottles and containers by injecting molten PET material into preform molds. The preforms produced by these machines serve as the initial shape of the final product, which undergoes subsequent blowing and molding processes. The PET preform machine market comprises various types of machines, including injection molding machines, stretch blow molding machines, and hybrid machines, catering to the diverse needs of manufacturers in different industries.

Executive Summary

The PET preform machine market is witnessing robust growth, driven by the increasing demand for PET bottles and containers across industries such as beverages, food and beverage, personal care, pharmaceuticals, and more. This executive summary provides a concise overview of the market, highlighting key trends, market drivers, restraints, opportunities, and regional analysis. It also includes insights into the competitive landscape, market segmentation, and key industry developments. With a focus on delivering high-quality preforms efficiently, the PET preform machine market presents lucrative prospects for industry participants and stakeholders.

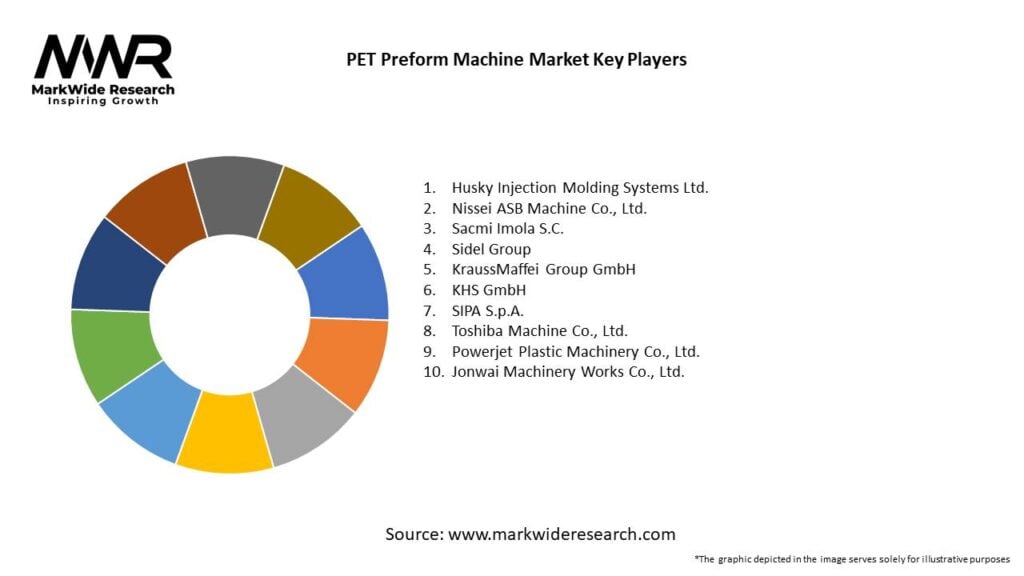

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Several critical insights are driving the PET Preform Machine Market:

Technological Advancements:

Continuous improvements in injection molding, extrusion processes, and automation are enhancing the speed, accuracy, and efficiency of PET preform production.

Increasing Demand for PET Packaging:

The global rise in consumption of bottled beverages, packaged foods, and consumer goods is spurring investments in high-capacity preform machines.

Sustainability Focus:

Growing environmental concerns and regulatory pressures drive manufacturers to adopt energy-efficient and waste-reducing technologies.

Digital Integration:

The incorporation of IoT, machine learning, and real-time data analytics is transforming production processes and maintenance practices in the industry.

Global Trade and Expansion:

Expanding export markets and increased industrialization, especially in emerging economies, are key contributors to market growth.

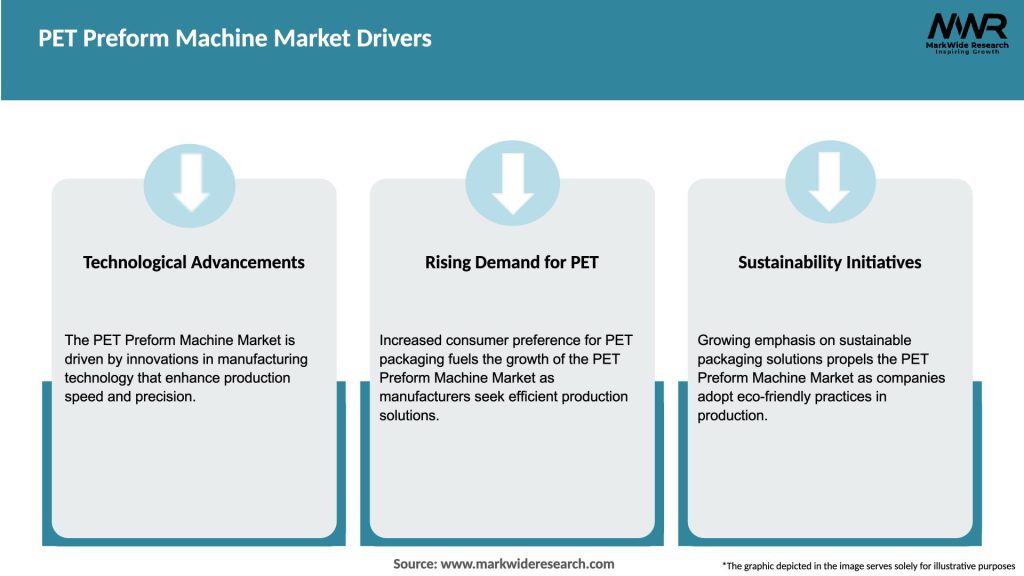

Market Drivers

Key factors propelling the PET Preform Machine Market include:

Rising Demand for PET Bottles:

As consumer preference for PET packaging grows across the beverage, food, and personal care industries, demand for preform machines increases.

Advancements in Automation:

The integration of robotic and automated systems in production lines reduces labor costs and enhances precision, leading to higher throughput and product consistency.

Energy Efficiency and Cost Reduction:

New technological innovations in machinery design have resulted in lower energy consumption and reduced operating costs, making investments more attractive.

Globalization of Packaging Needs:

Increasing international trade and the expansion of multinational brands drive the need for high-quality and scalable PET preform production capabilities.

Sustainability Regulations and Initiatives:

Stringent environmental regulations and a shift toward eco-friendly packaging solutions are encouraging manufacturers to upgrade to more efficient and sustainable preform machine technologies.

Market Restraints

Despite the market’s promising growth, several challenges may hinder progress:

High Capital Investment:

The acquisition and installation of advanced PET preform machines require significant upfront investment, potentially deterring small- and medium-sized enterprises.

Maintenance and Operational Costs:

The complexity of advanced machinery can lead to high maintenance expenses and the need for skilled technicians.

Technology Adoption Barriers:

Transitioning from conventional machinery to state-of-the-art preform machines may encounter resistance due to workforce retraining and process reengineering requirements.

Competition from Alternative Packaging Materials:

The availability of alternative packaging materials and recycling challenges associated with PET can affect market growth.

Supply Chain Disruptions:

Fluctuations in the supply of raw materials, such as PET resin, can impact production costs and market stability.

Market Opportunities

The PET Preform Machine Market presents numerous growth avenues:

Emerging Economies Expansion:

Rapid industrialization and urbanization in regions such as Asia-Pacific, Latin America, and Africa offer significant opportunities for expanding high-capacity PET preform production.

Green Manufacturing Initiatives:

Investments in sustainable and energy-efficient technologies align with global trends toward eco-friendly manufacturing, enhancing market appeal.

Customization and Advanced Configurations:

Development of machines capable of producing a broader range of preform sizes and shapes can capture niche market segments and specialty packaging applications.

Digital and IoT Integration:

Embracing advanced digital tools for real-time monitoring, predictive maintenance, and process optimization can create significant competitive advantages.

Strategic Collaborations and Partnerships:

Collaborations among machinery manufacturers, raw material suppliers, and end-user industries can drive innovation and improve market penetration.

Market Dynamics

The market dynamics for PET Preform Machines are influenced by a mix of supply, demand, and economic factors:

Supply Side Factors:

Technological Innovation:

Breakthroughs in process automation, sensor technology, and energy-efficient design are boosting production capabilities.

Capacity Expansion:

Investments in modern production facilities and large-scale manufacturing systems are driving economies of scale.

Raw Material Sourcing:

The stability of PET resin supply and pricing directly influences machine operation costs and profitability.

Demand Side Factors:

Consumer Packaging Trends:

Growing consumer demand for packaged beverages and foods is a primary driver of increased production capacity.

Industry Shift to Automation:

The need for high-speed, high-precision production is prompting operators to upgrade their machinery.

Environmental Regulations:

Compliance with environmental standards is encouraging the use of energy-efficient and sustainable manufacturing technologies.

Economic Factors:

Global Industrial Growth:

Economic expansion, particularly in emerging markets, supports increased investments in modern packaging machinery.

Cost-Benefit Considerations:

Long-term savings from reduced energy consumption and maintenance costs reinforce the business case for advanced preform machines.

Investment in Research and Development:

Ongoing R&D investments are critical for driving technological progress and ensuring competitive product offerings.

Regional Analysis

The PET Preform Machine Market exhibits unique trends across regions:

North America:

Advanced Technological Adoption:

The region’s mature industrial base and high consumer spending support the early adoption of innovative preform machines.

Strong Market Demand:

Established beverage and packaging industries drive consistent demand for high-capacity machinery.

Europe:

Stringent Environmental Regulations:

European markets emphasize sustainable manufacturing practices, promoting the use of energy-efficient and eco-friendly machines.

Robust Packaging Sector:

A well-developed packaging industry and high-quality standards drive the demand for precision-engineered preform machines.

Asia-Pacific:

Rapid Industrialization:

The region is experiencing significant growth in manufacturing and packaging sectors, particularly in countries like China, India, and Japan.

Cost-Effective Production:

Lower production and labor costs, combined with increasing investments in technology, are fueling market growth in this region.

Latin America:

Emerging Market Potential:

Increasing urbanization and a growing middle class are boosting demand for packaged beverages, driving investments in modern manufacturing systems.

Infrastructure Challenges:

Variability in industrial infrastructure can impact production efficiency and market adoption.

Middle East and Africa:

Market Growth Opportunities:

Expanding retail and consumer goods sectors, along with infrastructure modernization initiatives, are creating opportunities for growth.

Regional Economic Variability:

Economic challenges and regulatory differences may affect market penetration and investment levels.

Competitive Landscape

Leading companies in the PET Preform Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

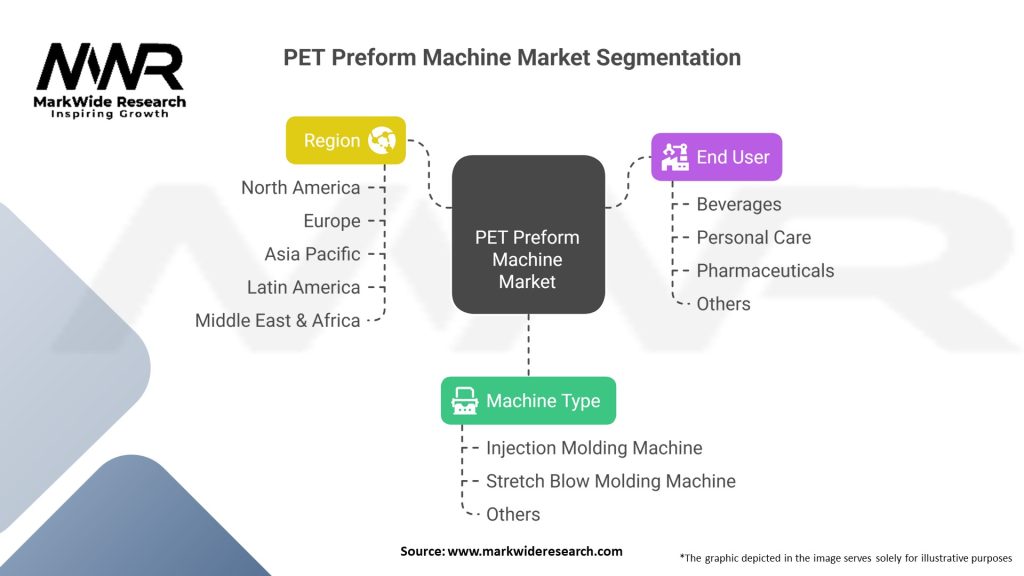

Segmentation

The market can be segmented based on several criteria:

By Machine Type:

Extrusion Machines:

Produce PET preforms by melting and shaping PET resin through extrusion processes.

Injection Molding Machines:

Use injection molding techniques to form PET preforms with high precision and consistency.

Hybrid Systems:

Combine extrusion and injection molding technologies to offer versatility in preform production.

By Production Capacity:

Low Capacity Machines:

Suitable for small-scale operations or specialty production.

Medium Capacity Machines:

Designed for mid-sized manufacturing facilities.

High Capacity Machines:

Targeted for large-scale production and high-volume output in integrated packaging plants.

By End-User Industry:

Food and Beverage:

Major users of PET bottles for water, soft drinks, juices, and alcoholic beverages.

Pharmaceuticals:

Use PET preforms for packaging medicines and healthcare products.

Personal Care and Cosmetics:

Demand high-quality PET containers for lotions, shampoos, and beauty products.

Other Industrial Applications:

Including applications in chemical packaging and consumer goods.

By Distribution Channel:

Direct Sales:

Manufacturer sales to large, integrated production facilities.

Distributors and Dealers:

Third-party networks that facilitate access to a wider range of customers.

Online Platforms:

E-commerce channels that cater to small and medium-scale operators.

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Category-wise Insights

Extrusion vs. Injection Molding:

Extrusion machines are often preferred for their continuous production process, while injection molding machines offer high precision for complex preform designs. Hybrid systems provide versatility by combining the advantages of both methods.

Production Capacity:

High-capacity machines are typically employed by large-scale, integrated bottle manufacturers, while low to medium capacity machines are suitable for niche and specialized operations.

End-User Applications:

The food and beverage industry drives the bulk of PET preform demand, but significant growth opportunities exist in the pharmaceutical and personal care sectors, where premium quality and customization are paramount.

Key Benefits for Industry Participants and Stakeholders

Increased Operational Efficiency:

Advanced preform machines enable higher production speeds, consistent product quality, and lower waste, which are crucial for competitive manufacturing.

Cost Reduction:

Energy-efficient designs and automation reduce operational costs, making PET preform production more cost-effective.

Enhanced Product Quality:

High-precision machinery ensures the production of uniform, high-quality preforms, enhancing the overall quality of PET containers.

Sustainable Production:

Innovations in PET processing and reduced energy consumption contribute to environmentally friendly manufacturing practices.

Market Expansion and Diversification:

The ability to produce a wide range of preform designs caters to diverse consumer needs and opens up new revenue streams in various end-user sectors.

SWOT Analysis

Strengths:

Advanced Manufacturing Technology:

Continuous innovations in extrusion, injection molding, and hybrid systems drive efficiency and product quality.

High Demand Across Industries:

The extensive use of PET packaging in food, beverages, pharmaceuticals, and consumer goods ensures robust market demand.

Scalability and Customization:

A wide range of machine capacities and customizable solutions cater to different production scales and industry requirements.

Weaknesses:

High Capital Investment:

Initial costs for state-of-the-art PET preform machines and installation can be significant, potentially limiting access for smaller players.

Maintenance and Technical Expertise:

Advanced machinery requires specialized maintenance and skilled operators, which can lead to higher operating costs.

Dependence on Raw Material Prices:

Fluctuations in the cost of PET resin directly impact production costs and profit margins.

Opportunities:

Expansion in Emerging Markets:

Rapid industrial growth and increasing demand for PET packaging in emerging economies offer significant growth potential.

Sustainable Innovation:

Development of energy-efficient and low-waste production technologies can improve sustainability and attract eco-conscious customers.

Digital Integration:

Incorporating IoT, AI, and real-time monitoring systems enhances production efficiency and product quality.

Product Diversification:

Expanding the range of preform designs and exploring niche applications in pharmaceuticals and personal care can unlock new revenue streams.

Threats:

Economic Fluctuations:

Global economic instability and fluctuations in industrial investments may affect production capacity and consumer demand.

Regulatory Pressures:

Stricter environmental and safety regulations could increase manufacturing costs and operational complexity.

Competitive Intensity:

Intense competition from established machinery manufacturers and emerging technology innovators may lead to pricing pressures and reduced market share.

Market Key Trends

Automation and Digitalization:

The integration of digital control systems and IoT-driven monitoring is revolutionizing PET preform production, enhancing efficiency and predictive maintenance.

Sustainable Manufacturing:

Environmental concerns are driving innovations in energy efficiency and waste reduction, leading to the adoption of greener production technologies.

Customization and Innovation:

Trends toward personalized packaging and flexible production lines are fueling the development of customizable preform machines.

Global Expansion:

Increased demand in emerging markets and international trade opportunities are driving the expansion of PET preform machine capabilities worldwide.

Technological Convergence:

Collaborations between automation, materials science, and digital technology sectors are resulting in next-generation production systems.

Covid-19 Impact

Operational Disruptions:

The pandemic temporarily affected production schedules and supply chains, prompting manufacturers to invest in more resilient processes.

Increased E-Commerce Adoption:

Digital sales channels for machinery have grown as face-to-face interactions declined during lockdowns.

Focus on Efficiency:

Economic pressures emphasized the need for cost-effective and efficient production methods, driving investments in automation and energy-saving technologies.

Supply Chain Diversification:

Manufacturers have diversified their raw material sourcing strategies to mitigate disruptions experienced during the pandemic.

Long-Term Digital Transformation:

The acceleration of digital transformation in manufacturing has further cemented the role of advanced, IoT-enabled PET preform machines.

Key Industry Developments

Technological Breakthroughs:

Recent advancements in injection molding precision and continuous extrusion processes have significantly improved production rates and product quality.

Strategic Alliances:

Collaborations between major machinery manufacturers and technology providers have accelerated digital integration and enhanced system interoperability.

Capacity Expansion:

Investments in new production facilities in key regions, particularly Asia-Pacific and Latin America, are boosting global output.

Sustainability Initiatives:

Firms are increasingly adopting green manufacturing practices, including energy-efficient machinery and waste-recycling technologies.

Market Consolidation:

Mergers and acquisitions within the industry are streamlining supply chains and fostering innovation through shared R&D efforts.

Analyst Suggestions

Enhance R&D Investments:

Focus on developing next-generation preform machines with improved automation, energy efficiency, and process integration.

Leverage Digital Technologies:

Integrate IoT, AI, and data analytics into production lines to enhance machine performance, predictive maintenance, and overall efficiency.

Expand Geographic Reach:

Target emerging markets by establishing local production centers or forming strategic partnerships to increase market penetration.

Invest in Sustainable Manufacturing:

Prioritize energy-efficient technologies and eco-friendly production practices to meet growing environmental standards and consumer expectations.

Strengthen After-Sales Support:

Develop robust technical support and maintenance services to ensure smooth operation and prolong equipment lifespan, thereby boosting customer satisfaction.

Future Outlook

The future of the PET Preform Machine Market is highly promising, driven by continued technological innovation, growing global demand for PET packaging, and the increasing emphasis on sustainable production processes. Key trends include:

Advanced Automation:

Further integration of robotics, IoT, and digital monitoring will enhance production efficiency and reduce operational costs.

Sustainability Focus:

A growing commitment to eco-friendly manufacturing will drive innovations in energy efficiency and waste reduction.

Market Expansion:

Emerging economies and expanding international trade will offer significant opportunities for growth.

Customization and Innovation:

Demand for customized packaging solutions will encourage further innovation in machine versatility and performance.

Industry Consolidation:

Ongoing mergers and strategic partnerships will streamline production processes and foster a more integrated global supply chain.

Conclusion

The PET Preform Machine Market is set for robust growth, driven by increasing global demand for PET packaging, advancements in automation and digital integration, and a strategic focus on sustainable manufacturing. With substantial opportunities in emerging markets and a strong drive toward innovation, the market offers significant potential for industry stakeholders.

The PET preform machine market presents immense opportunities for manufacturers and stakeholders involved in the production of PET bottles and containers. With the increasing demand for sustainable packaging solutions, technological advancements in machine design, and evolving consumer preferences, the market is poised for significant growth. By understanding the market dynamics, regional variations, competitive landscape, and key trends, industry participants can navigate the market successfully and unlock the potential for growth and profitability in the PET preform machine market.

What is a PET preform machine?

A PET preform machine is a specialized piece of equipment used to produce preforms from PET (polyethylene terephthalate) resin, which are then molded into bottles and containers for various applications, including beverages and personal care products.

Who are the key players in the PET Preform Machine Market?

Key players in the PET Preform Machine Market include Husky Injection Molding Systems, Sidel, Krones AG, and Nissei ASB Machine Co., Ltd., among others.

What are the main drivers of growth in the PET Preform Machine Market?

The main drivers of growth in the PET Preform Machine Market include the increasing demand for lightweight packaging solutions, the rise in beverage consumption, and the growing trend towards sustainable packaging options.

What challenges does the PET Preform Machine Market face?

Challenges in the PET Preform Machine Market include fluctuations in raw material prices, the need for technological advancements to improve efficiency, and competition from alternative packaging materials.

What opportunities exist in the PET Preform Machine Market?

Opportunities in the PET Preform Machine Market include the expansion of the food and beverage industry, innovations in recycling technologies, and the increasing adoption of eco-friendly packaging solutions.

What trends are shaping the PET Preform Machine Market?

Trends shaping the PET Preform Machine Market include the integration of automation and smart technologies, the development of lightweight preforms, and a growing focus on reducing carbon footprints in manufacturing processes.

PET Preform Machine Market

| Segmentation | Details |

|---|---|

| Machine Type | Injection Molding Machine, Stretch Blow Molding Machine, Others |

| End User | Beverages, Personal Care, Pharmaceuticals, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the PET Preform Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at