444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The PE (Polyethylene) and HDPE (High-Density Polyethylene) cable conduits market is a segment within the broader plastics industry, specializing in providing conduits for cable management and protection. These conduits are essential for safely housing and organizing cables in various applications across industries, including telecommunications, construction, utilities, and transportation. The market’s growth is driven by the increasing demand for efficient cable management solutions, infrastructure development projects, and the expansion of telecommunications networks.

Meaning

PE and HDPE cable conduits are cylindrical tubes made from polyethylene and high-density polyethylene materials, respectively. These conduits are designed to protect cables from environmental factors such as moisture, abrasion, and impact, while also facilitating easy installation and maintenance. PE and HDPE cable conduits come in various sizes, lengths, and configurations to accommodate different types of cables and installation requirements.

Executive Summary

The PE and HDPE cable conduits market is experiencing steady growth globally, fueled by the rising demand for reliable cable management solutions across industries. Key players in the market include manufacturers, distributors, and suppliers of PE and HDPE conduits, as well as companies involved in installation, maintenance, and infrastructure development projects. The market is characterized by innovation, product differentiation, and a focus on sustainability and cost-effectiveness.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The PE and HDPE cable conduits market is influenced by various factors such as technological advancements, infrastructure development projects, regulatory changes, market competition, and customer preferences. Understanding these dynamics is essential for stakeholders to identify opportunities, address challenges, and make informed business decisions.

Regional Analysis

The demand for PE and HDPE cable conduits varies by region due to differences in infrastructure development, regulatory environments, industry verticals, and market maturity. While developed regions like North America and Europe have established markets with stringent quality standards and regulations, emerging markets in Asia-Pacific, Latin America, and Africa offer growth opportunities driven by urbanization, industrialization, and infrastructure investments.

Competitive Landscape

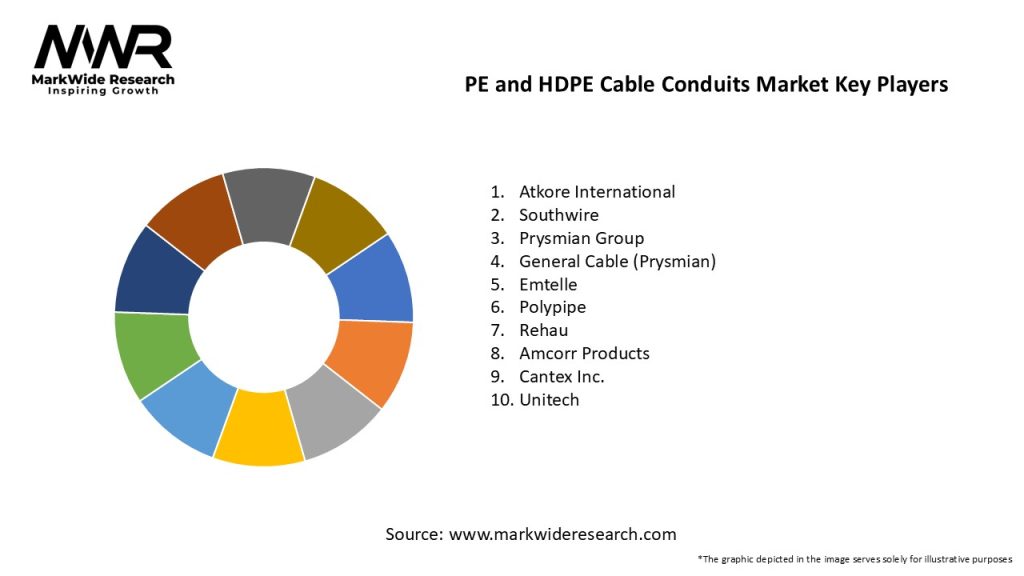

The PE and HDPE cable conduits market is characterized by intense competition among manufacturers, suppliers, and distributors offering a wide range of products and solutions. Key players in the market include:

These players compete based on factors such as product quality, performance, reliability, pricing, distribution network, and brand reputation. Strategic partnerships, mergers and acquisitions, and product innovations are common strategies employed by companies to gain a competitive edge and expand their market presence.

Segmentation

The PE and HDPE cable conduits market can be segmented based on various factors, including:

Segmentation enables companies to target specific customer segments, tailor their marketing strategies, and develop specialized products to meet diverse market needs and preferences.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Understanding the SWOT analysis helps industry participants identify strengths, address weaknesses, capitalize on opportunities, and mitigate threats to maintain competitiveness and drive growth in the PE and HDPE cable conduits market.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has affected the PE and HDPE cable conduits market to varying degrees, depending on factors such as project delays, supply chain disruptions, and changes in demand for construction and infrastructure projects. While some segments experienced slowdowns due to lockdowns and economic uncertainty, others saw increased demand for telecommunications, utilities, and renewable energy projects driven by remote work, digital connectivity, and infrastructure investments.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the PE and HDPE cable conduits market is positive, driven by urbanization, infrastructure development, renewable energy investments, and technological advancements. Continued emphasis on sustainability, innovation, and quality will be key to sustaining growth and competitiveness in a dynamic and evolving market landscape. Collaboration across industry stakeholders, regulatory bodies, and technology providers will be essential to address challenges, seize opportunities, and drive positive change in the PE and HDPE cable conduits market.

Conclusion

PE and HDPE cable conduits market is positive, driven by urbanization, infrastructure development, renewable energy investments, and technological advancements. Continued emphasis on sustainability, innovation, and quality will be key to sustaining growth and competitiveness in a dynamic and evolving market landscape. Collaboration across industry stakeholders, regulatory bodies, and technology providers will be essential to address challenges, seize opportunities, and drive positive change in the PE and HDPE cable conduits market.

PE and HDPE Cable Conduits Market

| Segmentation Details | Description |

|---|---|

| Product Type | Rigid Conduits, Flexible Conduits, Corrugated Conduits, Non-Corrugated Conduits |

| Application | Telecommunications, Power Distribution, Industrial Wiring, Residential Wiring |

| Installation Method | Above Ground, Underground, Direct Burial, Surface Mounted |

| End User | Construction, Telecommunications, Utilities, Manufacturing |

Leading Companies in the PE and HDPE Cable Conduits Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at