444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Panama container glass market represents a dynamic and rapidly evolving sector within the Central American packaging industry. Container glass manufacturing in Panama has experienced substantial growth driven by increasing demand from beverage, food, pharmaceutical, and cosmetic industries. The market demonstrates remarkable resilience and adaptability, with local manufacturers and international players establishing significant presence in the region.

Market dynamics indicate robust expansion across multiple application segments, with the beverage industry leading consumption patterns. Panama’s strategic geographic position as a logistics hub has enhanced its attractiveness for glass container production and distribution throughout Latin America. The sector benefits from growing consumer preference for sustainable packaging solutions and increasing awareness of environmental concerns.

Growth trajectories show consistent upward momentum, with the market experiencing a 6.2% CAGR over recent years. This expansion reflects strong domestic demand coupled with export opportunities to neighboring countries. Manufacturing capabilities have evolved significantly, incorporating advanced technologies and automated production processes to meet international quality standards.

Regional positioning places Panama as an emerging leader in Central American glass container production. The market benefits from favorable government policies, infrastructure development, and strategic trade agreements that facilitate both raw material imports and finished product exports. Investment flows into the sector have increased substantially, indicating strong confidence in long-term market prospects.

The Panama container glass market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of glass containers used for packaging various products within Panama’s borders. This market includes manufacturing facilities, supply chain networks, end-user industries, and supporting infrastructure that collectively contribute to the glass packaging sector’s development.

Container glass specifically denotes hollow glass products designed for packaging applications, including bottles, jars, vials, and specialty containers used across diverse industries. The market encompasses both clear and colored glass containers, ranging from small pharmaceutical vials to large beverage bottles, each serving specific functional and aesthetic requirements.

Market scope extends beyond mere production to include recycling systems, quality control processes, design innovation, and sustainability initiatives. The sector integrates traditional glassmaking techniques with modern manufacturing technologies, creating a balanced approach that meets contemporary market demands while preserving artisanal craftsmanship traditions.

Panama’s container glass market demonstrates exceptional growth potential driven by expanding end-user industries and increasing consumer preference for glass packaging. The market has established itself as a significant player in the Central American region, with production capabilities meeting both domestic demand and export requirements.

Key performance indicators reveal strong market fundamentals, with beverage applications accounting for 68% of total consumption. Food packaging represents the second-largest segment, followed by pharmaceutical and cosmetic applications. The market benefits from Panama’s strategic location, facilitating efficient distribution networks across Latin America.

Technological advancement has become a defining characteristic of the market, with manufacturers investing in energy-efficient furnaces, automated handling systems, and quality control technologies. These improvements have resulted in 23% efficiency gains in production processes while reducing environmental impact.

Competitive landscape features a mix of established international players and emerging local manufacturers. Market consolidation trends indicate strategic partnerships and acquisitions aimed at expanding production capacity and market reach. Sustainability initiatives have gained prominence, with recycling programs achieving 42% glass recovery rates across the country.

Market intelligence reveals several critical insights that shape the Panama container glass industry’s trajectory. Understanding these insights provides stakeholders with strategic advantages in navigating market complexities and identifying growth opportunities.

Primary market drivers propelling the Panama container glass market include robust economic growth, expanding manufacturing sectors, and increasing consumer awareness of sustainable packaging solutions. These fundamental forces create sustained demand across multiple application segments.

Beverage industry expansion serves as the most significant driver, with local breweries and soft drink manufacturers increasing production capacity. The growing tourism sector contributes to beverage consumption, while export opportunities to regional markets amplify demand for quality glass containers.

Environmental consciousness among consumers and businesses drives preference for glass packaging over plastic alternatives. Glass containers offer superior recyclability, chemical inertness, and premium product positioning that appeals to quality-conscious consumers. This trend particularly benefits premium beverage and food segments.

Government initiatives supporting manufacturing sector development provide favorable conditions for glass container production. Tax incentives, infrastructure investments, and trade facilitation measures create an enabling environment for industry growth. Regulatory frameworks promoting environmental sustainability further support glass packaging adoption.

Technological advancement in manufacturing processes enables cost reduction and quality improvement, making glass containers more competitive against alternative packaging materials. Energy-efficient production technologies reduce operational costs while meeting environmental standards.

Market constraints affecting the Panama container glass industry include high energy costs, raw material price volatility, and competition from alternative packaging materials. These challenges require strategic management to maintain market competitiveness.

Energy intensity of glass manufacturing processes creates vulnerability to energy price fluctuations. Glass production requires high-temperature furnaces operating continuously, making energy costs a significant portion of total production expenses. Energy efficiency improvements help mitigate this constraint but require substantial capital investment.

Raw material availability and pricing present ongoing challenges, particularly for specialized glass formulations. Dependence on imported materials for certain applications creates supply chain vulnerabilities and cost pressures. Quality specifications for container glass require consistent raw material properties, limiting sourcing flexibility.

Competition from alternatives such as plastic, aluminum, and flexible packaging materials challenges glass container market share in price-sensitive applications. Alternative materials often offer weight advantages and lower transportation costs, particularly for export markets.

Capital intensity of glass manufacturing creates barriers to entry and limits expansion flexibility. Establishing new production facilities requires significant upfront investment and long payback periods, constraining rapid market response capabilities.

Emerging opportunities in the Panama container glass market span multiple dimensions, from technological innovation to market expansion and sustainability initiatives. These opportunities position the market for sustained growth and competitive advantage.

Export market development represents the most significant opportunity, with Panama’s strategic location enabling efficient access to Central and South American markets. Regional trade agreements and improved logistics infrastructure support export expansion strategies.

Premium packaging segments offer higher margin opportunities, particularly in craft beverages, specialty foods, and luxury cosmetics. These applications value glass containers’ premium positioning and sustainability credentials, supporting price premiums over alternative materials.

Recycling infrastructure development creates opportunities for circular economy business models. Enhanced glass collection and processing capabilities support sustainability goals while reducing raw material costs. Closed-loop systems with major customers can create competitive advantages.

Technology partnerships with equipment manufacturers and research institutions enable access to advanced manufacturing technologies. These collaborations can drive innovation in production processes, product design, and quality control systems.

Pharmaceutical market expansion offers growth potential as Panama’s healthcare sector develops. Pharmaceutical glass containers require specialized manufacturing capabilities and quality certifications, creating barriers to entry and supporting premium pricing.

Market dynamics in Panama’s container glass sector reflect complex interactions between supply-side capabilities, demand-side requirements, and external environmental factors. Understanding these dynamics enables strategic decision-making and competitive positioning.

Supply chain integration has become increasingly important, with manufacturers developing closer relationships with raw material suppliers and end-user customers. Vertical integration strategies help manage cost pressures and ensure quality consistency throughout the value chain.

Demand patterns show seasonal variations aligned with beverage consumption cycles, tourism seasons, and agricultural harvests. Manufacturers adapt production schedules and inventory management strategies to accommodate these fluctuations while maintaining operational efficiency.

Competitive intensity varies across market segments, with commodity applications experiencing price pressure while specialty segments support premium positioning. Market players differentiate through quality, service, innovation, and sustainability credentials.

Regulatory environment influences market dynamics through environmental standards, safety requirements, and trade policies. Compliance with international standards enables export market access while domestic regulations shape competitive conditions.

Innovation cycles drive market evolution through new product development, process improvements, and sustainability initiatives. Companies investing in research and development gain competitive advantages and market leadership positions.

Research approach for analyzing the Panama container glass market employs comprehensive methodologies combining primary research, secondary data analysis, and industry expert insights. This multi-faceted approach ensures accurate market assessment and reliable forecasting.

Primary research includes structured interviews with industry executives, manufacturing facility visits, and customer surveys across key market segments. These direct interactions provide real-time market intelligence and validate secondary research findings.

Secondary research encompasses analysis of government statistics, industry publications, trade association reports, and company financial statements. This data provides historical context and quantitative foundations for market analysis.

Market modeling utilizes econometric techniques to analyze relationships between market drivers, economic indicators, and demand patterns. Statistical models help identify trends and project future market developments under various scenarios.

Expert validation involves consultation with industry specialists, academic researchers, and technology providers to verify findings and assumptions. This validation process ensures research accuracy and credibility.

Data triangulation cross-references multiple information sources to confirm market insights and eliminate potential biases. This rigorous approach enhances research reliability and supports confident decision-making.

Regional market analysis reveals distinct patterns across Panama’s provinces, with industrial concentration in specific areas driving localized market dynamics. Understanding regional variations enables targeted market strategies and investment decisions.

Panama Province dominates container glass consumption, accounting for 52% of national demand. The capital region’s concentration of beverage manufacturers, food processors, and import/export activities creates the largest market opportunity. Industrial infrastructure and logistics capabilities support efficient distribution networks.

Colon Province represents the second-largest market, benefiting from free trade zone activities and port facilities. The region’s strategic importance for international trade creates demand for export-oriented glass container applications. Manufacturing presence in the area supports local market development.

Chiriqui Province shows growing market potential driven by agricultural processing industries and tourism development. The region’s coffee, fruit, and vegetable processing activities create demand for food-grade glass containers. Tourism growth supports beverage market expansion.

Other provinces collectively represent emerging market opportunities, with development projects and infrastructure improvements creating new demand centers. Regional economic diversification initiatives support market expansion beyond traditional industrial centers.

Cross-border trade influences regional market dynamics, with border provinces serving as gateways for export activities. Trade relationships with neighboring countries create additional demand sources and market opportunities.

Competitive environment in Panama’s container glass market features diverse players ranging from multinational corporations to specialized local manufacturers. Market positioning strategies vary based on target segments, geographic focus, and value propositions.

Market share distribution shows concentration among leading players, with the top three companies controlling approximately 71% of production capacity. However, market fragmentation in specialty segments provides opportunities for smaller players to establish competitive positions.

Competitive strategies emphasize operational excellence, customer service, product innovation, and sustainability initiatives. Companies differentiate through quality certifications, technical support, and customized solutions for specific customer requirements.

Market segmentation analysis reveals distinct customer groups, application areas, and product categories that define the Panama container glass market structure. Understanding segmentation patterns enables targeted marketing strategies and product development initiatives.

By Application:

By Product Type:

By Glass Type:

Beverage containers dominate market volume and revenue, with beer bottles representing the largest single category. This segment benefits from consistent demand patterns and established customer relationships. Innovation trends focus on lightweight designs, unique shapes, and enhanced recyclability features.

Food packaging applications show steady growth driven by processed food industry expansion and consumer preference for glass containers. Jam jars, sauce bottles, and specialty food containers create diverse market opportunities. Quality requirements emphasize food safety and preservation capabilities.

Pharmaceutical containers represent a high-value segment with stringent quality standards and regulatory requirements. Growth potential exists as Panama’s healthcare sector develops and pharmaceutical manufacturing expands. Technical specifications require specialized manufacturing capabilities and quality certifications.

Cosmetic packaging offers premium positioning opportunities with emphasis on aesthetic appeal and brand differentiation. This segment values design innovation, surface treatments, and luxury positioning. Market trends favor sustainable packaging solutions and refillable container systems.

Industrial applications provide stable demand from chemical, laboratory, and technical industries. These applications often require specialized glass formulations and custom designs. Growth drivers include industrial development and expanding research activities.

Industry participants in Panama’s container glass market enjoy numerous strategic advantages stemming from market position, operational capabilities, and growth opportunities. These benefits create value for manufacturers, customers, and supporting industries.

Manufacturers benefit from Panama’s strategic geographic location, enabling efficient access to regional markets and cost-effective raw material sourcing. The country’s stable political environment and business-friendly policies support long-term investment planning and operational continuity.

Cost advantages emerge from competitive labor costs, favorable energy pricing, and efficient logistics infrastructure. These factors enhance manufacturing competitiveness and support export market development. Operational efficiency improvements through technology adoption further strengthen cost positions.

Market diversification opportunities reduce dependency on single customer segments or geographic markets. The ability to serve multiple application areas and export to neighboring countries creates revenue stability and growth potential.

Customers benefit from local production capabilities that ensure supply security, reduced transportation costs, and responsive customer service. Quality assurance through proximity to manufacturing facilities enables better communication and faster problem resolution.

Sustainability advantages include reduced transportation emissions, local recycling capabilities, and circular economy opportunities. These benefits align with corporate sustainability goals and regulatory requirements.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability initiatives represent the most significant trend shaping Panama’s container glass market. Manufacturers are implementing comprehensive recycling programs, energy-efficient production technologies, and circular economy business models. Glass recycling rates have improved to 38% collection efficiency across major urban areas.

Lightweighting technologies enable production of containers with reduced glass content while maintaining strength and functionality. These innovations reduce material costs, transportation expenses, and environmental impact. Weight reduction achievements of up to 15% improvement in standard bottle designs demonstrate technological progress.

Customization capabilities are expanding as manufacturers invest in flexible production systems and design technologies. Custom bottle shapes, embossing, and surface treatments enable brand differentiation and premium positioning. Digital printing technologies allow cost-effective small-batch customization.

Smart packaging integration incorporates digital technologies into glass containers through embedded sensors, QR codes, and interactive features. These innovations support product authentication, consumer engagement, and supply chain tracking.

Regional consolidation trends show strategic partnerships and acquisitions aimed at achieving scale economies and market expansion. Market concentration is increasing as companies seek competitive advantages through operational synergies.

Recent industry developments highlight significant investments, technological advancements, and strategic initiatives that shape market evolution. These developments indicate strong confidence in long-term market prospects and commitment to competitive positioning.

Manufacturing capacity expansion projects have been announced by major players, with new production lines incorporating advanced technologies and environmental controls. These investments respond to growing demand and enable market share expansion.

Technology partnerships between glass manufacturers and equipment suppliers drive innovation in production processes, quality control, and automation systems. MarkWide Research indicates that technology investments have resulted in 18% productivity improvements across the industry.

Sustainability certifications are being pursued by leading manufacturers to meet customer requirements and regulatory standards. These certifications cover environmental management, energy efficiency, and recycling practices.

Market entry strategies by international players include joint ventures, acquisitions, and greenfield investments. These activities increase competitive intensity while bringing advanced technologies and best practices to the market.

Product innovation initiatives focus on developing specialized containers for emerging applications, improved barrier properties, and enhanced aesthetic features. Research and development investments support long-term competitiveness and market differentiation.

Strategic recommendations for Panama container glass market participants emphasize sustainable growth, operational excellence, and market diversification. These suggestions address current challenges while positioning companies for future opportunities.

Investment priorities should focus on energy-efficient production technologies that reduce operational costs and environmental impact. MWR analysis suggests that energy optimization investments can achieve 12% cost reduction in manufacturing operations while meeting sustainability goals.

Market expansion strategies should prioritize export development to regional markets, leveraging Panama’s strategic location and trade advantages. Establishing distribution partnerships and customer relationships in neighboring countries creates growth opportunities beyond domestic market limitations.

Product portfolio diversification into higher-value segments such as pharmaceuticals, cosmetics, and specialty applications reduces dependency on commodity markets and improves profitability. These segments offer premium pricing and stable demand patterns.

Sustainability leadership through comprehensive recycling programs, circular economy initiatives, and environmental certifications creates competitive advantages and meets evolving customer requirements. Recycling infrastructure development should be prioritized to support closed-loop systems.

Technology adoption in automation, quality control, and production optimization enables competitive positioning and operational efficiency. Strategic partnerships with technology providers can accelerate implementation and reduce investment risks.

Future market prospects for Panama’s container glass industry appear highly favorable, with multiple growth drivers supporting sustained expansion. The market is positioned to benefit from regional economic development, sustainability trends, and technological advancement.

Growth projections indicate continued market expansion at a 7.1% CAGR over the forecast period, driven by beverage industry growth, export market development, and premium segment expansion. This growth rate reflects strong fundamentals and favorable market conditions.

Export market development represents the primary growth opportunity, with regional trade integration and improved logistics infrastructure supporting market access. Export volumes are projected to increase by 45% growth rate as manufacturers establish regional distribution networks.

Technology evolution will continue driving operational improvements, product innovation, and sustainability achievements. Advanced manufacturing systems, automation technologies, and digital integration will enhance competitiveness and market positioning.

Sustainability requirements will become increasingly important, with circular economy principles, environmental certifications, and recycling capabilities becoming competitive necessities rather than differentiators.

Market consolidation trends are expected to continue, with strategic partnerships and acquisitions creating larger, more efficient operations capable of serving regional markets effectively.

Panama’s container glass market demonstrates exceptional potential for sustained growth and development, supported by favorable geographic positioning, expanding end-user industries, and increasing sustainability awareness. The market has established strong foundations through strategic investments, technological advancement, and operational excellence.

Key success factors include leveraging Panama’s strategic location for regional market access, investing in energy-efficient technologies, and developing comprehensive sustainability programs. Companies that effectively address these priorities will achieve competitive advantages and market leadership positions.

Market outlook remains highly positive, with multiple growth drivers supporting expansion across various segments and applications. Export market development, premium segment growth, and technology adoption create numerous opportunities for industry participants.

Strategic imperatives for market participants include operational excellence, customer focus, innovation leadership, and sustainability commitment. These priorities will determine competitive success and long-term market positioning in Panama’s evolving container glass industry.

What is Container Glass?

Container glass refers to glass products designed for packaging and storing various goods, including beverages, food, and pharmaceuticals. It is known for its durability, recyclability, and ability to preserve the quality of its contents.

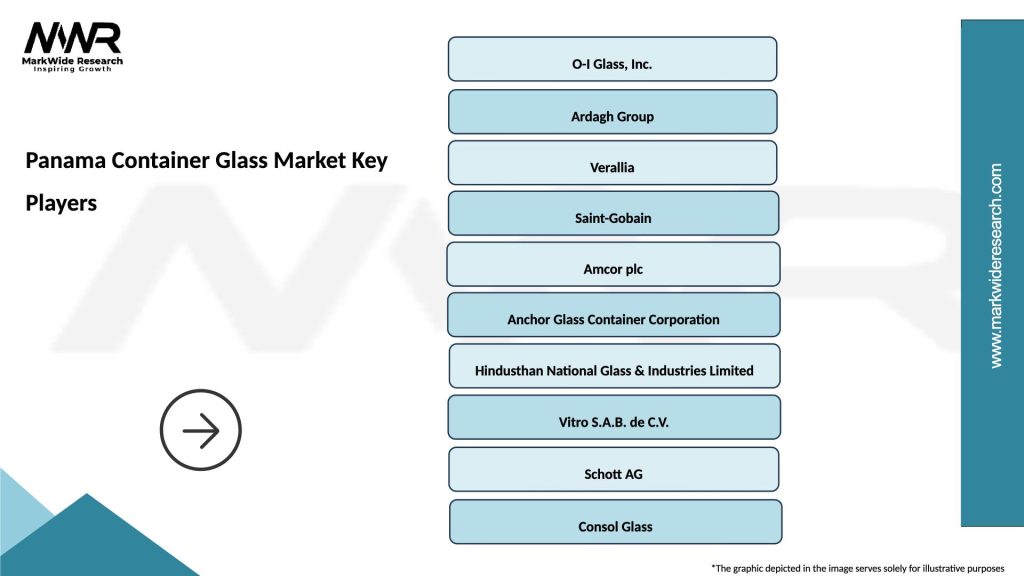

What are the key players in the Panama Container Glass Market?

Key players in the Panama Container Glass Market include companies like Vitro, O-I Glass, and Ardagh Group, which are known for their extensive range of glass packaging solutions. These companies focus on innovation and sustainability in their product offerings, among others.

What are the growth factors driving the Panama Container Glass Market?

The growth of the Panama Container Glass Market is driven by increasing consumer demand for sustainable packaging solutions, the rise in the beverage industry, and the growing trend of premiumization in food and drink products. Additionally, the shift towards eco-friendly materials is influencing market expansion.

What challenges does the Panama Container Glass Market face?

The Panama Container Glass Market faces challenges such as high production costs, competition from alternative packaging materials like plastics, and regulatory pressures regarding environmental impact. These factors can hinder market growth and innovation.

What opportunities exist in the Panama Container Glass Market?

Opportunities in the Panama Container Glass Market include the increasing demand for customized glass packaging solutions and the expansion of e-commerce, which requires innovative packaging designs. Additionally, the focus on recycling and sustainability presents new avenues for growth.

What trends are shaping the Panama Container Glass Market?

Trends in the Panama Container Glass Market include the rise of lightweight glass packaging, advancements in manufacturing technologies, and a growing emphasis on circular economy practices. These trends are influencing product design and consumer preferences.

Panama Container Glass Market

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Jars, Jugs, Vials |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Household |

| Packaging Type | Rigid, Flexible, Bulk, Specialty |

| Grade | Food Grade, Pharmaceutical Grade, Industrial Grade, Recycled |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Panama Container Glass Market

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at