444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Oxy-fuel welding and cutting is a widely used industrial process that involves the combination of fuel gases and oxygen to generate a high-temperature flame for various applications such as welding, cutting, brazing, and heating. This process has been in existence for several decades and continues to be a fundamental technique in many industries. Oxy-fuel welding and cutting equipment are essential tools in industries such as automotive, construction, manufacturing, and metal fabrication. The market for oxy-fuel welding and cutting is driven by the need for efficient and precise metalworking techniques.

Meaning

Oxy-fuel welding and cutting, also known as gas welding and cutting, is a process that uses the combustion of oxygen and a fuel gas, typically acetylene, to create a high-temperature flame. The flame produced by the combination of oxygen and fuel gas can reach temperatures as high as 6,330 degrees Fahrenheit (3,500 degrees Celsius). This intense heat is used to melt and join metal parts together during welding or to cut through metal plates or structures. Oxy-fuel welding and cutting is widely recognized for its versatility and ability to work with various metals, making it a popular choice in many industries.

Executive Summary

The oxy-fuel welding and cutting market has witnessed steady growth in recent years. This growth can be attributed to the increasing demand for metal fabrication and construction activities across the globe. Oxy-fuel welding and cutting offer several advantages, including cost-effectiveness, ease of use, and versatility in working with different metal types. These factors have contributed to the widespread adoption of oxy-fuel welding and cutting techniques in various industries. The market is expected to continue its upward trajectory, driven by technological advancements and the expanding scope of application areas.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

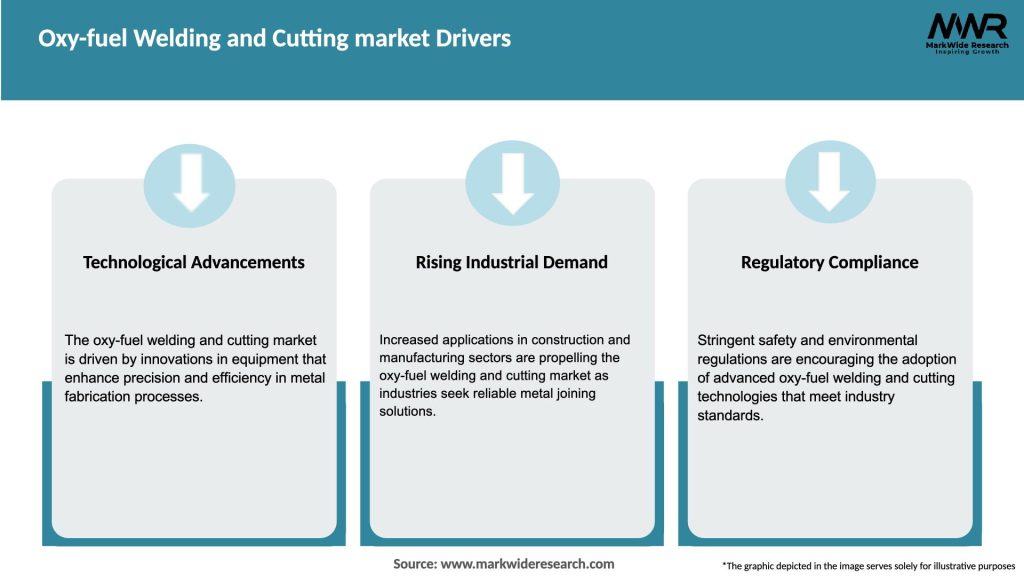

The oxy-fuel welding and cutting market is driven by several key factors:

Market Restraints

Despite the positive growth factors, the oxy-fuel welding and cutting market faces some challenges:

Market Opportunities

The oxy-fuel welding and cutting market offers several opportunities for growth and innovation:

Market Dynamics

The oxy-fuel welding and cutting market is characterized by dynamic factors that influence its growth and direction. These dynamics include technological advancements, changing market trends, regulatory developments, and economic factors. Understanding and adapting to these dynamics are crucial for businesses operating in this market to stay competitive and seize growth opportunities.

Technological advancements drive market growth by improving the efficiency, precision, and safety of oxy-fuel welding and cutting processes. Innovations such as automated systems, computer-controlled equipment, and advanced safety features have significantly impacted the market. Manufacturers and suppliers need to keep pace with technological advancements to meet customer expectations and stay ahead of the competition.

Market trends play a vital role in shaping the oxy-fuel welding and cutting market. Emerging trends such as the integration of automation and robotics, the adoption of eco-friendly fuel gases, and the development of portable oxy-fuel systems influence market demand and customer preferences. Businesses must monitor and adapt to these trends to stay relevant and cater to evolving customer needs.

Regulatory developments related to worker safetyand environmental sustainability also impact the oxy-fuel welding and cutting market. Governments and regulatory bodies impose stringent regulations and standards to ensure the safety of workers and reduce environmental impact. Compliance with these regulations is essential for businesses to operate legally and gain the trust of customers.

Economic factors, such as GDP growth, industrial output, and investment in infrastructure development, significantly influence the demand for oxy-fuel welding and cutting equipment. A thriving economy with increased industrial activities creates a favorable market environment, driving the demand for metal fabrication and construction, which in turn boosts the demand for oxy-fuel welding and cutting processes.

Regional Analysis

The oxy-fuel welding and cutting market can be analyzed based on regional segments, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique characteristics and market dynamics.

North America holds a significant share in the oxy-fuel welding and cutting market due to the presence of well-established industries, including automotive, aerospace, and construction. The region’s strong emphasis on safety regulations and technological advancements drive the adoption of oxy-fuel welding and cutting processes.

Europe is another prominent market for oxy-fuel welding and cutting, driven by the demand for metal fabrication in industries such as automotive, shipbuilding, and infrastructure development. The region’s focus on reducing emissions and promoting sustainable practices also encourages the use of oxy-fuel systems that produce lower greenhouse gas emissions.

The Asia Pacific region is experiencing rapid industrialization and infrastructure development, creating substantial opportunities for the oxy-fuel welding and cutting market. Countries like China and India have a robust manufacturing sector, which drives the demand for metal fabrication and welding processes. The growing automotive and construction industries in the region further contribute to market growth.

Latin America and the Middle East and Africa regions show promising growth prospects for the oxy-fuel welding and cutting market. These regions are witnessing increasing investments in infrastructure development, construction projects, and industrial growth. As these economies expand, the demand for oxy-fuel welding and cutting equipment is expected to rise.

Competitive Landscape

Leading Companies in the Oxy-fuel Welding and Cutting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The oxy-fuel welding and cutting market can be segmented based on equipment type, end-use industry, and region.

By equipment type, the market can be segmented into:

By end-use industry, the market can be segmented into:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The oxy-fuel welding and cutting market offers several benefits for industry participants and stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the oxy-fuel welding and cutting market. The global lockdowns and restrictions imposed to curb the spread of the virus disrupted industrial activities and led to a temporary decline in demand for welding and cutting processes. Many construction projects were put on hold, and manufacturing activities faced disruptions due to supply chain challenges.

However, as the world gradually recovers from the pandemic, the oxy-fuel welding and cutting market is expected to rebound. Governments are implementing stimulus packages and infrastructure development plans to revive economies, leading to increased demand for welding and cutting processes. The construction sector is witnessing a resurgence, and the need for metal fabrication and repair is growing.

Furthermore, the emphasis on worker safety and hygiene practices in the post-pandemic era is likely to drive the adoption of oxy-fuel welding and cutting processes. The market is expected to witness a gradual recovery as industries resume operations and invest in infrastructure development projects.

Key Industry Developments

Analyst Suggestions

Future Outlook

The oxy-fuel welding and cutting market is expected to witness steady growth in the coming years. The increasing demand for metal fabrication, infrastructure development, and construction activities will drive the market. Technological advancements, such as automation, robotics, and digital integration, will further enhance the efficiency and productivity of oxy-fuel welding and cutting processes. Environmental sustainability will continue to be a focus, leading to the development of eco-friendly oxy-fuel systems and the adoption of alternative fuel gases. The market is expected to witness significant opportunities in emerging economies, where industrial growth and infrastructure development projects are on the rise.

However, the market will also face challenges, including competition from advanced welding and cutting techniques and the volatility of fuel gas prices. Skilled labor shortage in certain regions can also pose challenges to market growth. To stay competitive, manufacturers need to focus on innovation, strategic partnerships, and expanding their presence in emerging markets.

Conclusion

The oxy-fuel welding and cutting market plays a vital role in various industries, offering versatile solutions for metal fabrication, construction, and manufacturing processes. Technological advancements, safety regulations, and environmental concerns are driving the market’s growth and shaping its future direction. Despite challenges such as competition from advanced techniques and limited applicability to certain materials, the oxy-fuel welding and cutting market presents significant opportunities for manufacturers and stakeholders. The development of advanced oxy-fuel systems, expansion into emerging economies, integration of automation and robotics, and collaboration with industry verticals are key strategies for success in the market.

With the gradual recovery from the COVID-19 pandemic and the increasing emphasis on worker safety and environmental sustainability, the oxy-fuel welding and cutting market is poised for growth. By staying abreast of market trends, investing in research and development, and fostering strategic partnerships, companies can thrive in this dynamic and evolving market.

What is Oxy-fuel Welding and Cutting?

Oxy-fuel Welding and Cutting refers to a process that uses a flame produced by burning a fuel gas, typically acetylene, with oxygen to weld or cut metals. This technique is widely used in various industries for its effectiveness in joining and shaping metal components.

What are the key players in the Oxy-fuel Welding and Cutting market?

Key players in the Oxy-fuel Welding and Cutting market include Air Products and Chemicals, Inc., Linde plc, and Messer Group GmbH, among others. These companies are known for their innovative solutions and extensive product offerings in welding and cutting technologies.

What are the growth factors driving the Oxy-fuel Welding and Cutting market?

The growth of the Oxy-fuel Welding and Cutting market is driven by the increasing demand for metal fabrication in construction, automotive, and manufacturing industries. Additionally, advancements in welding technologies and the rising need for repair and maintenance services contribute to market expansion.

What challenges does the Oxy-fuel Welding and Cutting market face?

The Oxy-fuel Welding and Cutting market faces challenges such as safety concerns related to the handling of flammable gases and the competition from alternative welding technologies like MIG and TIG welding. These factors can hinder market growth and adoption.

What opportunities exist in the Oxy-fuel Welding and Cutting market?

Opportunities in the Oxy-fuel Welding and Cutting market include the growing trend of automation in welding processes and the increasing use of oxy-fuel systems in renewable energy projects. These developments can enhance efficiency and open new avenues for market players.

What trends are shaping the Oxy-fuel Welding and Cutting market?

Current trends in the Oxy-fuel Welding and Cutting market include the integration of digital technologies for better precision and control, as well as the development of eco-friendly fuel alternatives. These trends are influencing how companies approach welding and cutting applications.

Oxy-fuel Welding and Cutting market

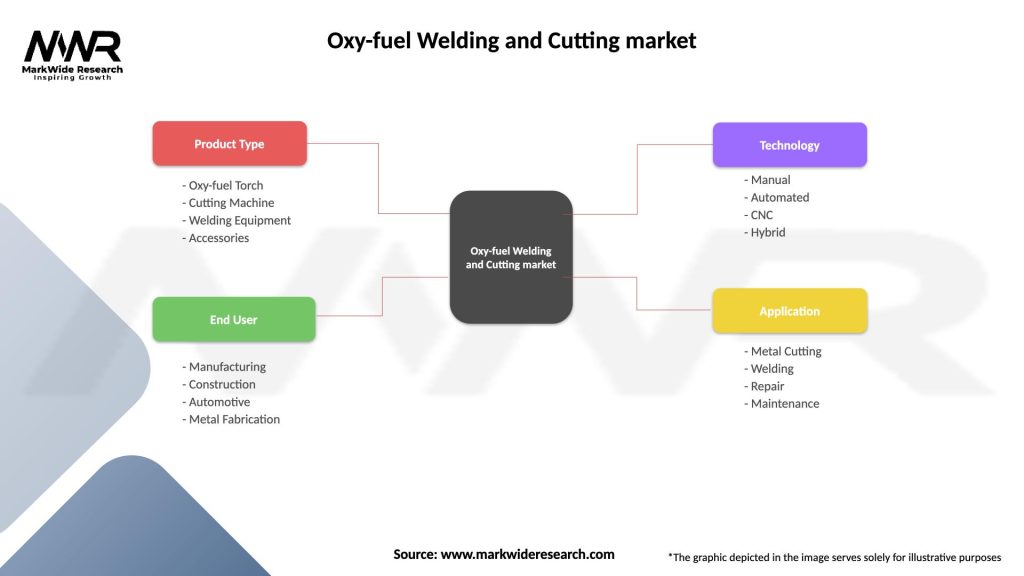

| Segmentation Details | Description |

|---|---|

| Product Type | Oxy-fuel Torch, Cutting Machine, Welding Equipment, Accessories |

| End User | Manufacturing, Construction, Automotive, Metal Fabrication |

| Technology | Manual, Automated, CNC, Hybrid |

| Application | Metal Cutting, Welding, Repair, Maintenance |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Oxy-fuel Welding and Cutting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at