444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global oil-free screw compressors market has witnessed a steady growth rate over the past few years. Oil-free screw compressors are used extensively in various industries, including food and beverage, pharmaceutical, chemical, and oil and gas. The key advantage of oil-free screw compressors is that they eliminate the need for oil lubrication, making them more environmentally friendly and reducing maintenance costs. The global oil-free screw compressors market is expected to grow at a CAGR of 8.2% from 2021 to 2028, reaching USD 10.4 billion by 2028.

An oil-free screw compressor is a type of compressor that does not require any lubricating oil for the compression process. This type of compressor uses a pair of rotors, one with male lobes and the other with female lobes, that rotate in opposite directions to compress the air. The compression process is achieved by the meshing of the rotors and the reduction in volume between them. The absence of oil in the compression process makes oil-free screw compressors more environmentally friendly and reduces maintenance costs.

Executive Summary of Oil-Free Screw Compressors Market

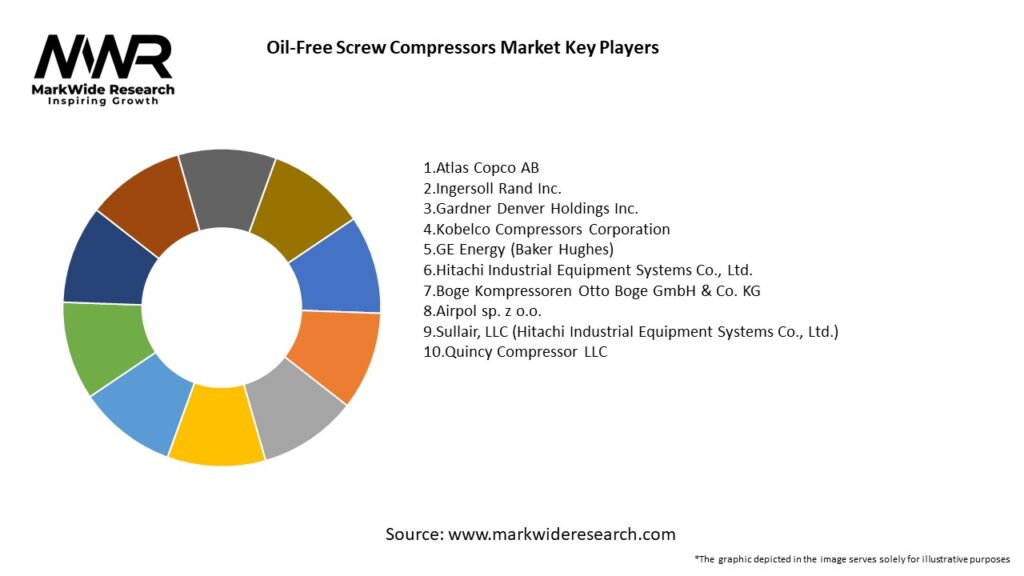

The global oil-free screw compressors market is expected to grow at a CAGR of 8.2% from 2021 to 2028, reaching USD 10.4 billion by 2028. The key drivers of this growth include the increasing demand for oil-free compressors in various industries, the stringent regulations on emissions and energy efficiency, and the growing awareness of the environmental benefits of oil-free compressors. However, the market is also facing certain challenges, such as the high initial costs of oil-free compressors and the lack of awareness about their benefits in certain regions. The key players in the market include Atlas Copco, Ingersoll Rand, Gardner Denver, Fusheng, and Sullair.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Oil-Free Screw Compressors Market is influenced by several factors:

Regional Analysis

Competitive Landscape

Leading Companies in the Oil-Free Screw Compressors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

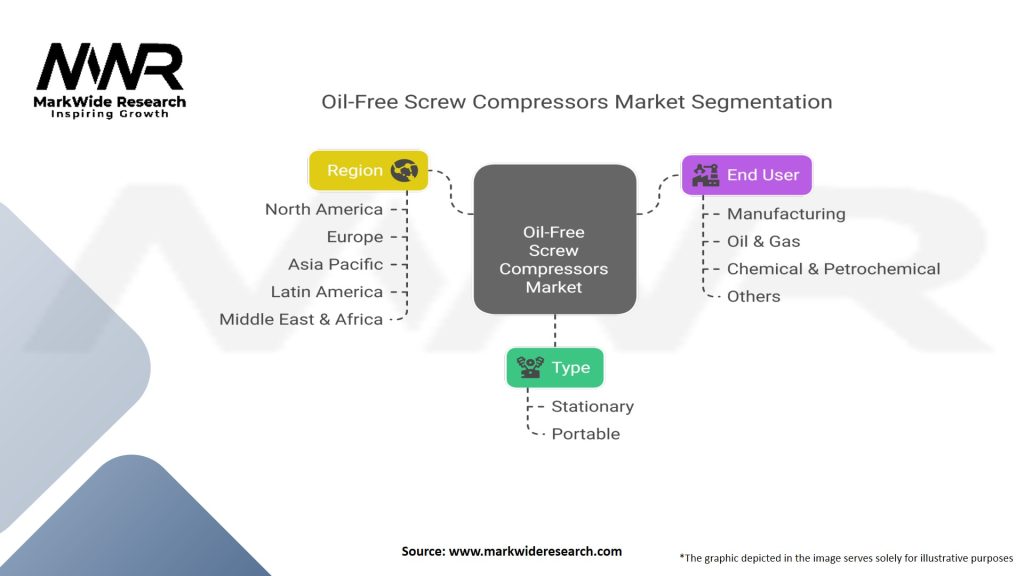

Segmentation

The Oil-Free Screw Compressors Market can be segmented by the following:

By Type:

By Application:

By Region:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the oil-free screw compressors market. The pandemic led to a decline in industrial activity and demand for compressors in 2020. However, the market is expected to recover in 2021 and beyond as industrial activity resumes and the demand for air compressors increases. Additionally, the pandemic has led to a greater focus on hygiene and air purity in various industries, which is expected to drive the adoption of oil-free compressors.

Key Industry Developments

Analyst Suggestions

Future Outlook

The oil-free screw compressors market is expected to continue to grow in the coming years, driven by the increasing demand for oil-free compressors in various industries and the focus on energy efficiency and sustainability. The development of new technologies and materials that improve the efficiency and reliability of oil-free compressors is also expected to create opportunities for the market. However, the high initial costs of oil-free compressors and the availability of alternative compressor technologies can be a challenge for the market. Overall, the global oil-free screw compressors market is expected to reach USD 10.4 billion by 2028, growing at a CAGR of 8.2% from 2021 to 2028.

Conclusion

The global oil-free screw compressors market is witnessing steady growth, driven by the increasing demand for oil-free compressors in various industries and the focus on energy efficiency and sustainability. The key players in the market are focusing on product innovation, partnerships, and acquisitions to strengthen their market position. The Asia-Pacific region is expected to dominate the market during the forecast period, driven by the rapid industrialization and urbanization in the region. However, the high initial costs of oil-free compressors and the availability of alternative compressor technologies can be a challenge for the market.

Overall, the market is expected to continue to grow in the coming years, driven by the increasing demand for air compressors and the growing awareness of the environmental benefits of oil-free compressors. The oil-free screw compressors market is witnessing steady growth, driven by the increasing demand for oil-free compressors in various industries and the focus on energy efficiency and sustainability.

What are oil-free screw compressors?

Oil-free screw compressors are a type of air compressor that utilizes a pair of helical rotors to compress air without the use of oil, making them ideal for applications requiring clean air, such as food processing, pharmaceuticals, and electronics manufacturing.

Which companies are leading in the Oil-Free Screw Compressors Market?

Leading companies in the Oil-Free Screw Compressors Market include Atlas Copco, Ingersoll Rand, Gardner Denver, and Kaeser Compressors, among others.

What are the key drivers of growth in the Oil-Free Screw Compressors Market?

Key drivers of growth in the Oil-Free Screw Compressors Market include the increasing demand for energy-efficient solutions, the rising need for clean air in various industries, and advancements in compressor technology that enhance performance and reliability.

What challenges does the Oil-Free Screw Compressors Market face?

The Oil-Free Screw Compressors Market faces challenges such as high initial investment costs, competition from alternative compressor technologies, and the need for regular maintenance to ensure optimal performance.

What opportunities exist in the Oil-Free Screw Compressors Market?

Opportunities in the Oil-Free Screw Compressors Market include the growing trend towards sustainability and energy efficiency, the expansion of industrial applications, and the increasing adoption of automation in manufacturing processes.

What trends are shaping the Oil-Free Screw Compressors Market?

Trends shaping the Oil-Free Screw Compressors Market include the integration of smart technology for monitoring and control, the development of compact and lightweight designs, and a focus on reducing noise levels in industrial environments.

Oil-Free Screw Compressors Market

| Segmentation Details | Details |

|---|---|

| Type | Stationary Oil-Free Screw Compressors, Portable Oil-Free Screw Compressors |

| End User | Manufacturing, Oil & Gas, Chemical & Petrochemical, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Oil-Free Screw Compressors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at