444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The nutraceutical contract manufacturing services market has witnessed significant growth in recent years, driven by the increasing demand for personalized and specialized nutraceutical products. Nutraceuticals are products that combine pharmaceutical and nutritional components, offering health benefits beyond basic nutrition. Contract manufacturing services play a crucial role in the nutraceutical industry, providing manufacturers with the necessary expertise, facilities, and resources to develop and produce high-quality products.

Meaning

Nutraceutical contract manufacturing services refer to the outsourcing of manufacturing processes and activities to specialized companies that possess the required infrastructure, technology, and expertise to produce nutraceutical products. These services allow brand owners and product developers to focus on their core competencies while leveraging the capabilities of contract manufacturers to bring their products to market efficiently and cost-effectively.

Executive Summary

The nutraceutical contract manufacturing services market is experiencing rapid growth due to several factors. The increasing consumer demand for personalized health products, coupled with the rising prevalence of chronic diseases, has fueled the need for innovative and functional nutraceuticals. Moreover, the complexity of regulatory compliance and the need for stringent quality control have prompted companies to outsource manufacturing to specialized contract manufacturers.

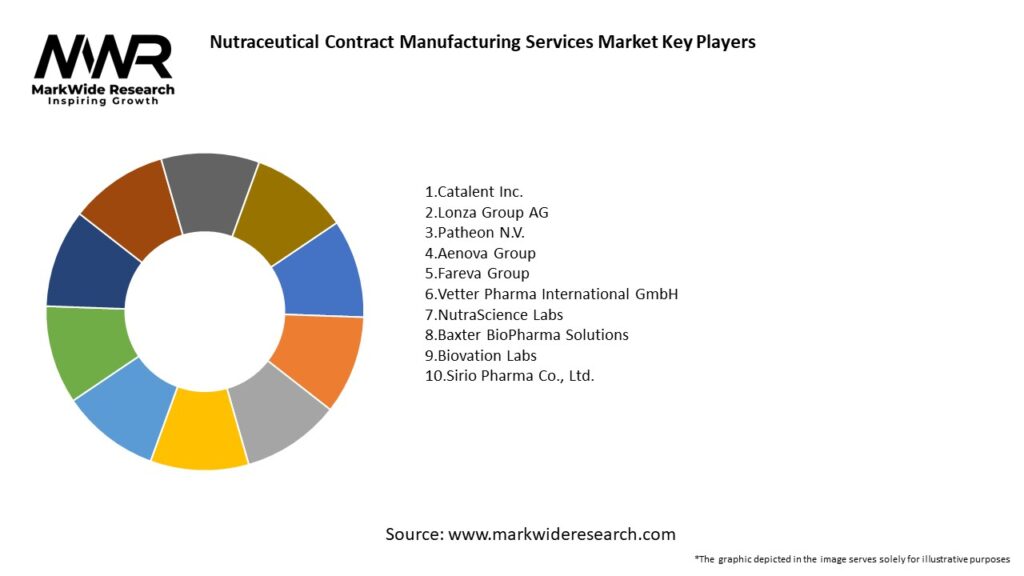

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The nutraceutical contract manufacturing services market is highly dynamic and influenced by various factors. Changing consumer preferences, evolving regulatory landscapes, technological advancements, and market competition all shape the market dynamics. Contract manufacturers must stay updated with the latest trends and adapt to these dynamics to remain competitive and meet customer expectations.

Regional Analysis

The nutraceutical contract manufacturing services market exhibits regional variations, with North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa being key regions of interest. North America and Europe have established markets, driven by the high demand for nutraceuticals and the presence of numerous contract manufacturing companies. Asia Pacific, particularly countries like China, India, and Japan, offers significant growth opportunities due to the expanding middle-class population, rising disposable incomes, and increasing health consciousness.

Competitive Landscape

Leading Companies in the Nutraceutical Contract Manufacturing Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The nutraceutical contract manufacturing services market can be segmented based on service type, product type, end-use application, and region. Service types may include product formulation, encapsulation, tableting, packaging, quality control, and regulatory compliance. Product types encompass vitamins and minerals, herbal extracts, dietary supplements, functional foods, and beverages. End-use applications range from pharmaceuticals to dietary supplements, sports nutrition, and animal health.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a mixed impact on the nutraceutical contract manufacturing services market. While the initial disruption in the global supply chain and manufacturing activities affected the market negatively, the increased focus on health and immunity-boosting products during the pandemic has created opportunities for contract manufacturers. The demand for nutraceutical products, particularly those containing vitamins, minerals, and immune-boosting ingredients, surged during the pandemic, leading to increased production requirements.

However, the pandemic also highlighted the importance of supply chain resilience and the need for contract manufacturers to ensure business continuity. Companies are now incorporating risk mitigation strategies, diversifying sourcing options, and strengthening supply chain relationships to navigate future disruptions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The nutraceutical contract manufacturing services market is poised for continued growth in the coming years. Factors such as the increasing consumer demand for personalized health solutions, the prevalence of chronic diseases, and the need for regulatory compliance will drive market expansion. Contract manufacturers that can adapt to evolving consumer preferences, technological advancements, and sustainability requirements will have a competitive edge. Furthermore, the expansion of the nutraceutical market in emerging economies presents lucrative opportunities for contract manufacturing services.

Conclusion

The nutraceutical contract manufacturing services market plays a vital role in meeting the growing demand for personalized and specialized nutraceutical products. With the increasing consumer focus on health and wellness, contract manufacturers provide brand owners and product developers with the expertise, infrastructure, and resources needed to bring high-quality nutraceuticals to market efficiently. The market offers significant opportunities for expansion in emerging economies, technological advancements, and collaborative partnerships. To thrive in this dynamic market, contract manufacturers should prioritize quality assurance, regulatory compliance, sustainability, and technological innovation. By staying attuned to market trends and customer demands, contract manufacturers can drive industry growth and cater to the evolving needs of consumers in the nutraceutical market.

Nutraceutical Contract Manufacturing Services market

| Segmentation Details | Description |

|---|---|

| Product Type | Vitamins, Minerals, Herbal Extracts, Probiotics |

| Formulation Type | Capsules, Tablets, Powders, Liquids |

| End User | Pharmaceutical Companies, Health Food Stores, Online Retailers, Fitness Centers |

| Packaging Type | Bottles, Blister Packs, Sachets, Pouches |

Leading Companies in the Nutraceutical Contract Manufacturing Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at