444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview The North America stud welding machine market is a significant segment of the welding industry, providing efficient and reliable solutions for joining metal components. Stud welding machines are used to weld studs, pins, or fasteners to metal surfaces, creating strong and durable connections. The market is driven by factors such as the growth of the construction and automotive industries, increasing demand for high-quality welding equipment, and advancements in welding technology. As the manufacturing sector in North America continues to evolve, the demand for stud welding machines is expected to grow, offering new opportunities for market players.

Meaning Stud welding machines are specialized welding equipment used to weld studs or fasteners to metal surfaces. The process involves placing a stud or fastener against the workpiece and using an arc to weld the two together. Stud welding machines are used in a variety of industries, including construction, automotive, aerospace, and shipbuilding, to create strong and reliable connections.

Executive Summary The North America stud welding machine market is experiencing steady growth, driven by factors such as the increasing demand for welding equipment in the construction and automotive industries, growing emphasis on automation and efficiency, and technological advancements in welding technology. Stud welding machines offer several advantages over traditional welding methods, including faster welding speeds, reduced material distortion, and improved weld quality. As the market continues to evolve, companies are focusing on product innovation and strategic partnerships to capitalize on the growing demand for stud welding machines in North America.

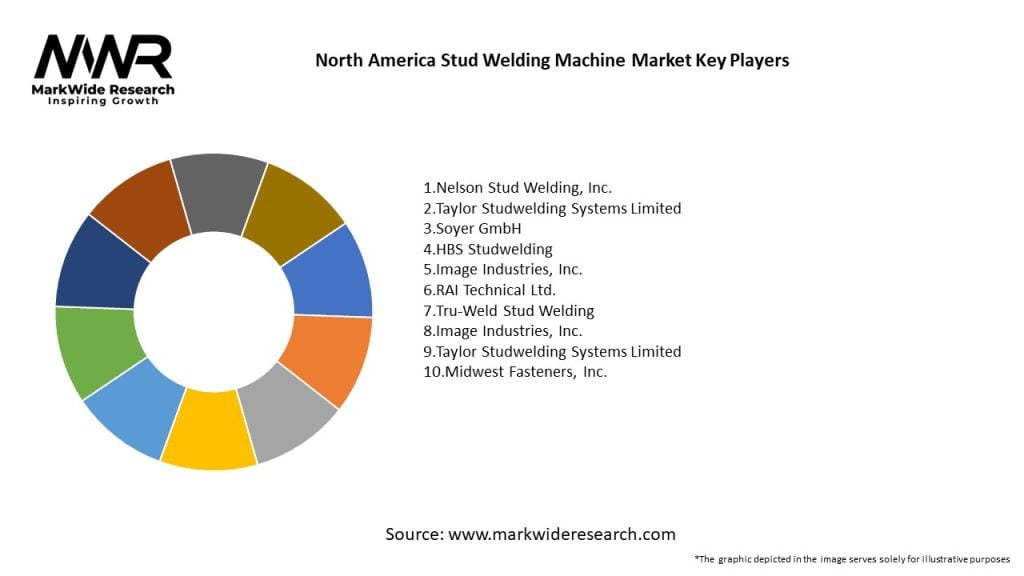

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics The North America stud welding machine market is characterized by dynamic factors such as technological advancements, changing customer preferences, and regulatory changes. These dynamics are shaping the market landscape and driving companies to innovate and adapt to meet the evolving needs of the welding industry in the region.

Regional Analysis The North America stud welding machine market is a mature market with a strong presence of established players and a robust infrastructure. The United States and Canada are the key markets in the region, driven by factors such as industrialization, infrastructure development, and technological advancements in welding technology.

Competitive Landscape

Leading Companies in North America Stud Welding Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

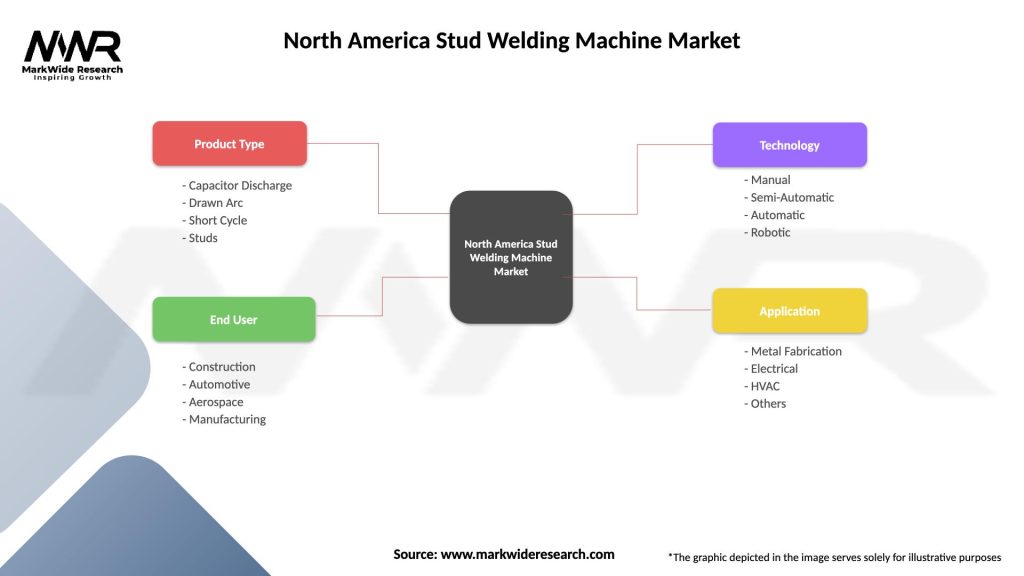

Segmentation The North America stud welding machine market can be segmented based on various factors such as:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis A SWOT analysis of the North America stud welding machine market reveals the following:

Market Key Trends

Covid-19 Impact The Covid-19 pandemic had a significant impact on the North America stud welding machine market, leading to disruptions in supply chains, manufacturing operations, and demand for welding equipment. However, the market quickly recovered as industries resumed operations and adapted to the new normal.

Key Industry Developments

Analyst Suggestions

Future Outlook The future outlook for the North America stud welding machine market is positive, with steady growth expected in the coming years. Factors such as the growth of end-use industries, technological advancements, and the focus on automation and efficiency will continue to drive market growth. However, challenges such as high initial investment, competition from substitutes, and regulatory hurdles need to be addressed to unlock the full potential of the market.

Conclusion The North America stud welding machine market is a dynamic and growing segment of the welding industry, driven by factors such as the growth of end-use industries, technological advancements, and the focus on automation and efficiency. Companies in the market are focusing on product innovation and strategic partnerships to capitalize on the growing demand for stud welding machines in North America. By understanding the market dynamics and trends, companies can position themselves for success and contribute to the growth of the welding industry in the region.

What is Stud Welding Machine?

A stud welding machine is a device used to join metal studs to a base material through a welding process. This technique is commonly employed in construction, automotive, and manufacturing industries for its efficiency and strength in creating durable connections.

What are the key players in the North America Stud Welding Machine Market?

Key players in the North America Stud Welding Machine Market include companies like Nelson Stud Welding, T.J. Snow Company, and TWI Ltd. These companies are known for their innovative technologies and extensive product offerings in stud welding solutions, among others.

What are the growth factors driving the North America Stud Welding Machine Market?

The North America Stud Welding Machine Market is driven by the increasing demand for efficient welding solutions in construction and automotive sectors. Additionally, advancements in welding technology and the growing trend of automation in manufacturing processes contribute to market growth.

What challenges does the North America Stud Welding Machine Market face?

Challenges in the North America Stud Welding Machine Market include the high initial investment costs and the need for skilled labor to operate advanced welding machines. Furthermore, fluctuations in raw material prices can impact production costs and profitability.

What opportunities exist in the North America Stud Welding Machine Market?

Opportunities in the North America Stud Welding Machine Market include the rising adoption of automation and robotics in manufacturing, which can enhance productivity. Additionally, the growing focus on sustainable construction practices presents avenues for innovative welding solutions.

What trends are shaping the North America Stud Welding Machine Market?

Trends in the North America Stud Welding Machine Market include the integration of smart technologies and IoT in welding machines, improving efficiency and monitoring. There is also a shift towards lightweight materials in automotive manufacturing, influencing the design and application of stud welding machines.

North America Stud Welding Machine Market

| Segmentation Details | Description |

|---|---|

| Product Type | Capacitor Discharge, Drawn Arc, Short Cycle, Studs |

| End User | Construction, Automotive, Aerospace, Manufacturing |

| Technology | Manual, Semi-Automatic, Automatic, Robotic |

| Application | Metal Fabrication, Electrical, HVAC, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in North America Stud Welding Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at