444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The North America Pharmaceutical Isolator Market is experiencing steady growth, driven by the increasing demand for contamination-free environments in pharmaceutical manufacturing and research. Pharmaceutical isolators are specialized enclosures that are used in sterile drug manufacturing processes to maintain aseptic conditions and protect both the operator and the product from contamination. These isolators are essential in ensuring the quality and safety of pharmaceutical products. The North American market is primarily influenced by strict regulatory standards, technological advancements in isolator design, and the rising need for biopharmaceutical manufacturing.

Meaning

Pharmaceutical isolators are controlled environments used to provide a contamination-free area for the production and handling of pharmaceuticals, especially in sterile processes. These isolators are designed to provide physical barriers between the product and the outside environment, protecting both the product from contamination and the operators from hazardous materials or drugs. Pharmaceutical isolators are primarily used in the production of high-potency drugs, biologics, and other sterile pharmaceutical products. The design and functionality of these isolators are critical to maintaining the required sterile conditions and ensuring the safety of pharmaceutical manufacturing processes.

Executive Summary

The North America Pharmaceutical Isolator Market is forecasted to grow at a healthy pace during the forecast period (2023-2028). With increasing focus on ensuring contamination control in pharmaceutical production, isolators are being adopted extensively by manufacturers and researchers in the region. Regulatory pressures from agencies like the U.S. Food and Drug Administration (FDA) and Health Canada, combined with the growth of biologics and biopharmaceuticals, are further propelling the demand for pharmaceutical isolators in North America. Additionally, technological innovations such as the development of more efficient isolator designs and automation are expected to drive market growth. However, the high cost of installation and maintenance may act as a restraint to market growth.

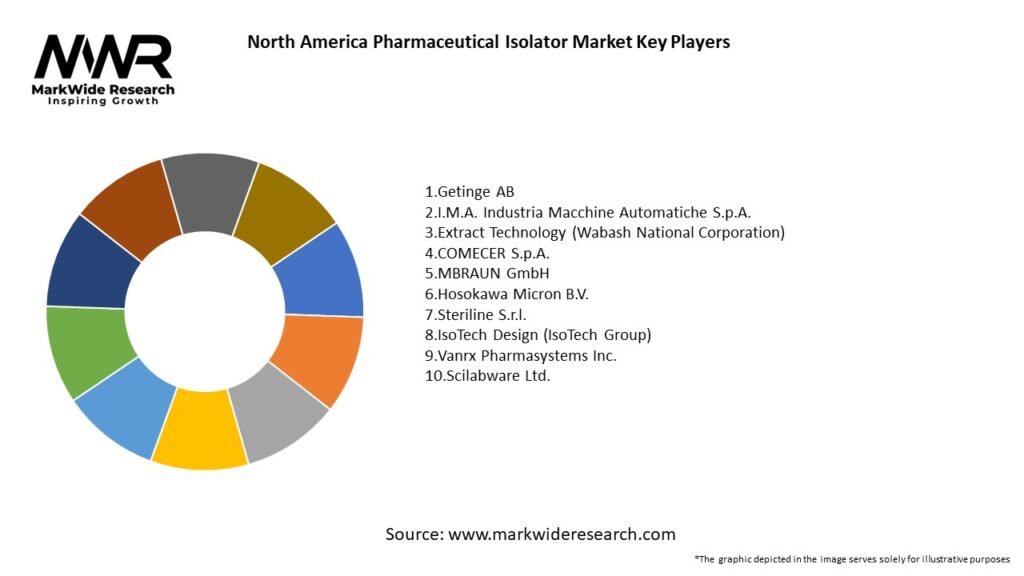

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

Regional Analysis

The North American Pharmaceutical Isolator Market is dominated by the United States and Canada, both of which have well-established pharmaceutical industries and regulatory frameworks. The U.S. is home to the largest pharmaceutical market globally, with a significant number of pharmaceutical manufacturers and research institutions. The FDA plays a crucial role in regulating pharmaceutical manufacturing, and its stringent standards for aseptic production continue to drive the demand for pharmaceutical isolators. Canada also follows strict health and safety regulations under Health Canada, which further supports the adoption of isolators. The growing number of biologics and high-potency drug production facilities in both countries is expected to continue to drive market demand.

Competitive Landscape

Leading Companies in North America Pharmaceutical Isolator Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

By Product Type

By Application

By End-User

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic accelerated the demand for pharmaceutical isolators as manufacturers raced to meet the growing need for vaccines and other critical drugs. The pandemic highlighted the importance of maintaining sterile environments in drug production, which further fueled market growth. The pandemic also led to increased investments in biotechnology and contract manufacturing, leading to higher demand for pharmaceutical isolators in the region.

Key Industry Developments

Analyst Suggestions

Future Outlook:

The North America Pharmaceutical Isolator Market is poised for continued growth, driven by the ongoing rise in biologics production, regulatory pressures, and technological advancements. As the demand for high-potency and sterile drugs continues to rise, pharmaceutical isolators will play an essential role in ensuring product safety and maintaining regulatory compliance. The North America Pharmaceutical Isolator market is expected to witness continued growth, driven by the increasing focus on patient safety and the adoption of aseptic manufacturing processes. Advancements in technology and customization of isolator solutions are likely to further fuel market growth.

Conclusion:

The North America Pharmaceutical Isolator market is experiencing significant growth, driven by the growing emphasis on patient safety and regulatory compliance in pharmaceutical manufacturing. Pharmaceutical isolators play a crucial role in maintaining a sterile and contamination-free environment during drug production. While initial investment costs and limited adoption in small-scale facilities may pose challenges, opportunities lie in advancements in technology and the rise in pharmaceutical R&D. As companies invest in research and development and focus on marketing and awareness, the future outlook for the pharmaceutical isolator market remains positive.

What is Pharmaceutical Isolator?

Pharmaceutical isolators are controlled environments designed to provide a sterile and contamination-free space for the handling of sensitive pharmaceutical products. They are commonly used in the production of sterile drugs, compounding, and research applications.

What are the key players in the North America Pharmaceutical Isolator market?

Key players in the North America Pharmaceutical Isolator market include companies such as Getinge AB, STERIS plc, and Fedegari S.r.l., which specialize in manufacturing isolators for pharmaceutical applications, among others.

What are the growth factors driving the North America Pharmaceutical Isolator market?

The growth of the North America Pharmaceutical Isolator market is driven by increasing demand for sterile pharmaceuticals, advancements in isolator technology, and the rising focus on contamination control in drug manufacturing processes.

What challenges does the North America Pharmaceutical Isolator market face?

Challenges in the North America Pharmaceutical Isolator market include high initial investment costs, the complexity of regulatory compliance, and the need for regular maintenance and validation of isolator systems.

What opportunities exist in the North America Pharmaceutical Isolator market?

Opportunities in the North America Pharmaceutical Isolator market include the growing trend of personalized medicine, increasing investments in biopharmaceuticals, and the expansion of contract manufacturing organizations that require advanced isolator solutions.

What trends are shaping the North America Pharmaceutical Isolator market?

Trends in the North America Pharmaceutical Isolator market include the integration of automation and digital technologies, the development of modular isolators, and a shift towards more sustainable manufacturing practices.

North America Pharmaceutical Isolator market

| Segmentation Details | Description |

|---|---|

| Product Type | Compounding Isolators, Sterile Isolators, Biohazard Isolators, Aseptic Isolators |

| End User | Pharmaceutical Companies, Biotechnology Firms, Research Laboratories, Contract Manufacturing Organizations |

| Technology | Negative Pressure, Positive Pressure, Hybrid Systems, Robotic Systems |

| Application | Drug Manufacturing, Vaccine Production, Laboratory Research, Sterilization Processes |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in North America Pharmaceutical Isolator Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at