444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The North America butterfly valve market is witnessing significant growth and is expected to expand at a steady pace in the coming years. Butterfly valves are widely used in various industries due to their excellent sealing capabilities, low-pressure drop, and ease of operation. These valves find extensive applications in the oil and gas, water and wastewater, power generation, chemical, and food and beverage sectors, among others.

Meaning

Butterfly valves are quarter-turn valves that are primarily used to regulate or isolate the flow of fluids in a pipeline. They consist of a circular disc or vane, which is mounted on a rod in the center of the valve body. When the valve is open, the disc allows fluid to flow freely, and when closed, it creates a tight seal to prevent any leakage.

Executive Summary

The North America butterfly valve market is experiencing steady growth due to the rising demand for reliable and efficient flow control solutions across industries. The market is driven by factors such as increasing investments in infrastructure development, growing focus on water and wastewater treatment, and expanding industrial activities. Additionally, technological advancements in valve design and materials are further fueling market growth.

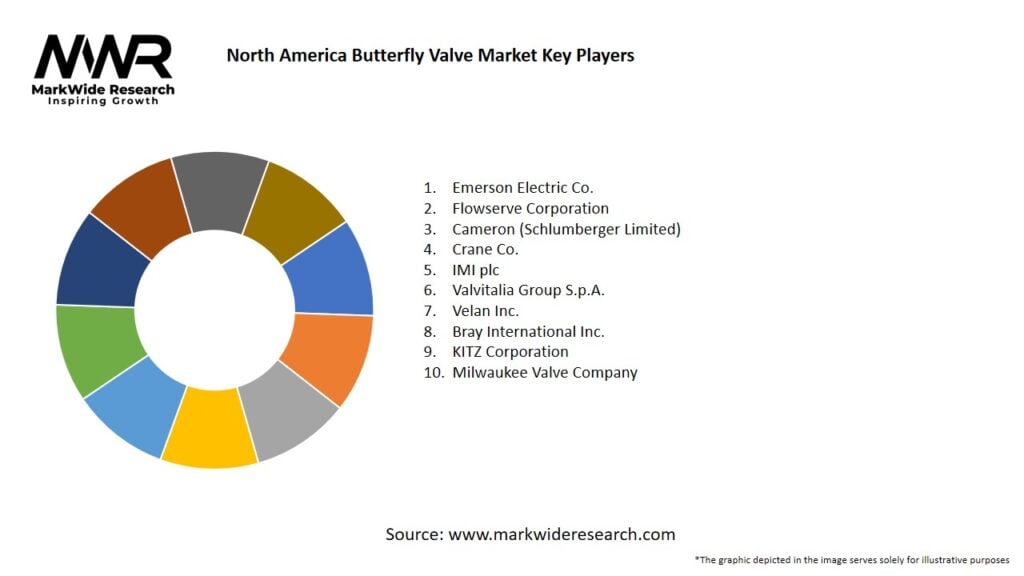

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The North America butterfly valve market is influenced by various dynamic factors:

Regional Analysis

The North America butterfly valve market is segmented into the United States, Canada, and Mexico.

Competitive Landscape

Leading companies in the North America Butterfly Valve Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

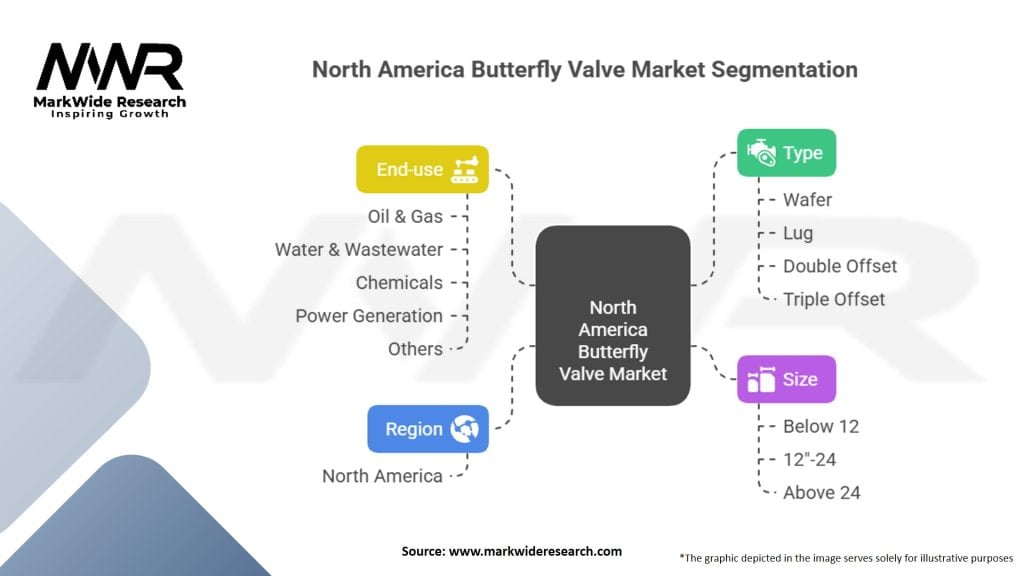

The North America butterfly valve market can be segmented based on valve type, material, end-user industry, and region.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the North America butterfly valve market. The initial phase of the pandemic led to disruptions in the supply chain, manufacturing operations, and project delays across industries. However, as the situation gradually improved, industries resumed operations, leading to the recovery of the market. The demand for butterfly valves in essential sectors such as water and wastewater treatment, pharmaceuticals, and food and beverage remained relatively stable during the pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The North America butterfly valve market is expected to witness steady growth in the coming years. The market will be driven by factors such as infrastructure development projects, increasing focus on water and wastewater treatment, and the growing demand for efficient flow control solutions. Technological advancements and the integration of smart features will further enhance the performance and capabilities of butterfly valves. However, manufacturers need to address challenges related to high installation and maintenance costs and comply with stringent regulations to capitalize on the market opportunities.

Conclusion

The North America butterfly valve market is poised for steady growth, driven by the demand for reliable and efficient flow control solutions across industries. The market offers numerous opportunities for manufacturers to innovate and develop advanced valve solutions. With increasing investments in infrastructure development and the focus on environmental sustainability, butterfly valve manufacturers need to adapt to changing industry requirements and leverage technological advancements to maintain a competitive edge in the market.

What is a butterfly valve in the context of the North America Butterfly Valve Market?

A butterfly valve is a type of flow control device that consists of a rotating disc to regulate fluid flow. In the North America Butterfly Valve Market, these valves are commonly used in various applications, including water supply systems, chemical processing, and HVAC systems.

Who are the key players in the North America Butterfly Valve Market?

Key players in the North America Butterfly Valve Market include Emerson Electric Co., Flowserve Corporation, and Valmet Corporation, among others. These companies are known for their innovative valve solutions and extensive distribution networks.

What are the main drivers of growth in the North America Butterfly Valve Market?

The growth of the North America Butterfly Valve Market is driven by increasing demand for efficient fluid control systems in industries such as oil and gas, water treatment, and power generation. Additionally, the push for infrastructure upgrades and modernization contributes to market expansion.

What challenges does the North America Butterfly Valve Market face?

The North America Butterfly Valve Market faces challenges such as fluctuating raw material prices and stringent regulatory requirements. These factors can impact production costs and compliance for manufacturers in the region.

What opportunities exist in the North America Butterfly Valve Market?

Opportunities in the North America Butterfly Valve Market include the growing adoption of automation and smart technologies in industrial applications. Additionally, the increasing focus on sustainable practices and energy efficiency presents avenues for innovation.

What trends are shaping the North America Butterfly Valve Market?

Trends in the North America Butterfly Valve Market include the development of lightweight and corrosion-resistant materials, as well as the integration of IoT technology for enhanced monitoring and control. These innovations are aimed at improving performance and reliability in various applications.

North America Butterfly Valve Market

| Segmentation | Details |

|---|---|

| Type | Wafer, Lug, Double Offset, Triple Offset |

| Size | Below 12″, 12″-24″, Above 24″ |

| End-use | Oil & Gas, Water & Wastewater, Chemicals, Power Generation, Others |

| Region | North America |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the North America Butterfly Valve Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at