444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The North America Automated Guided Vehicle (AGV) market is witnessing significant growth and is poised for further expansion in the coming years. AGVs are self-operating robotic vehicles that are programmed to perform material handling and transportation tasks in various industries. These vehicles are equipped with advanced sensors, navigation systems, and control software, allowing them to navigate autonomously within predefined areas.

Meaning

Automated Guided Vehicles (AGVs) are revolutionizing the way industries handle material movement and logistics. These vehicles eliminate the need for manual labor in tasks such as loading, unloading, and transporting goods within a facility. AGVs offer increased efficiency, accuracy, and safety, making them an attractive solution for businesses across diverse sectors.

Executive Summary

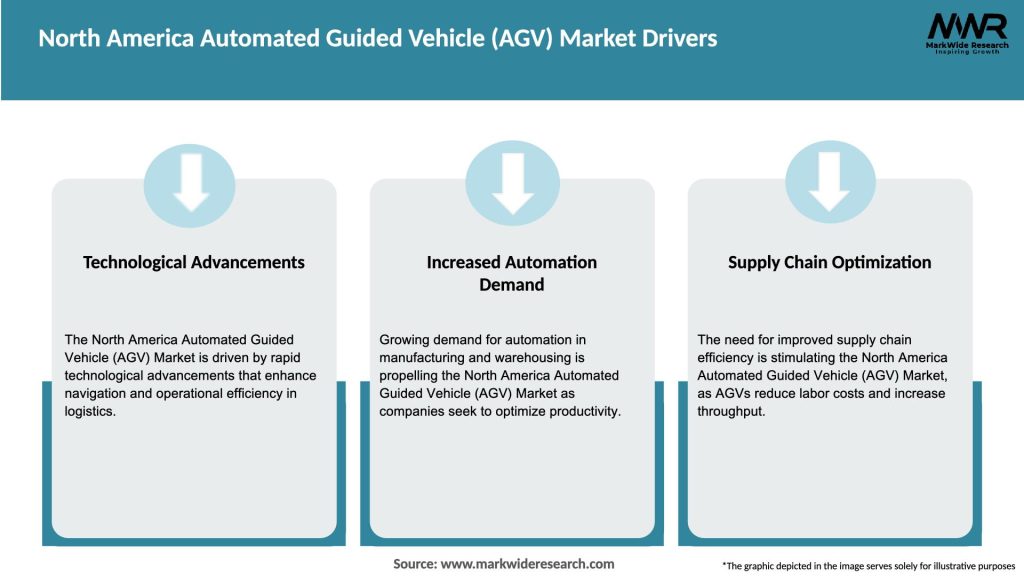

The North America AGV market has been experiencing robust growth due to several factors such as the increasing adoption of automation in industries, the need for cost reduction and process optimization, and the rising demand for efficient and safe material handling solutions. This report provides a comprehensive analysis of the market, including key market insights, drivers, restraints, opportunities, and future outlook.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The North America AGV market is driven by a combination of factors such as increasing automation trends, demand for safe material handling, and technological advancements. While initial costs and limited adoption in SMEs pose challenges, opportunities lie in integrating AGVs with Industry 4.0 principles and expanding their applications in e-commerce and healthcare sectors. The market dynamics indicate a positive growth trajectory for the North America AGV market in the foreseeable future.

Regional Analysis

The North America AGV market can be segmented into several key regions, including the United States, Canada, and Mexico. The United States is currently the largest market in the region, driven by its advanced manufacturing sector, e-commerce growth, and investments in automation. Canada and Mexico are also witnessing significant growth due to increasing industrialization and the adoption of advanced technologies in various industries.

Competitive Landscape

Leading Companies in the North America Automated Guided Vehicle (AGV) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

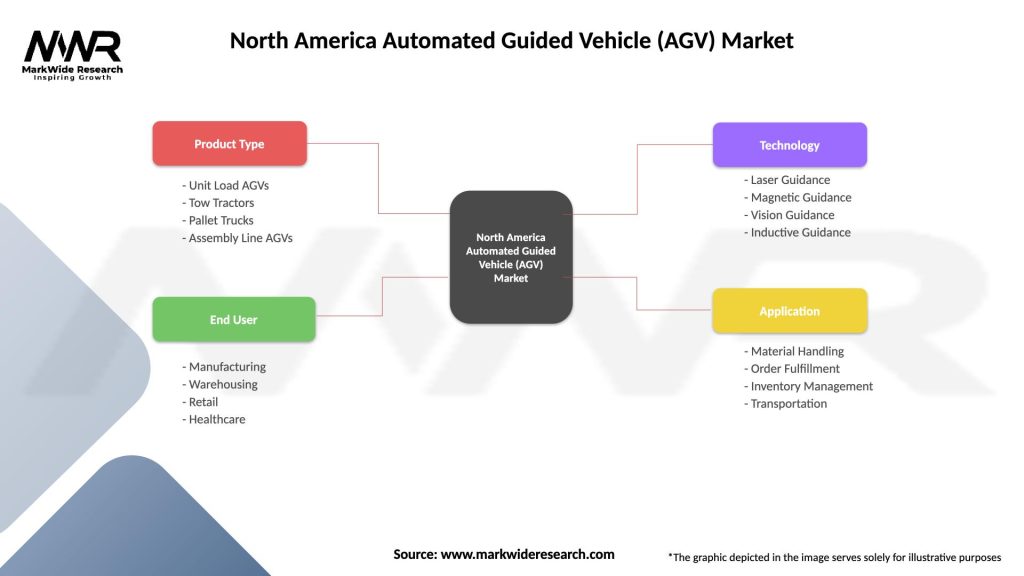

The North America AGV market can be segmented based on various factors, including type, industry vertical, and payload capacity. By type, the market can be divided into tow vehicles, unit load carriers, pallet trucks, and assembly line vehicles. Industry verticals that extensively utilize AGVs include automotive, food and beverage, healthcare, logistics, and manufacturing. Payload capacity categories range from light-duty AGVs (up to 1000 kg) to heavy-duty AGVs (above 1000 kg).

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has significantly impacted various industries, including the AGV market in North America. While some industries experienced a temporary slowdown in demand due to supply chain disruptions and lockdown measures, others witnessed increased demand for automation solutions to mitigate the risks associated with human contact. Overall, the pandemic has highlighted the importance of AGVs in ensuring operational continuity, reducing reliance on manual labor, and maintaining social distancing protocols.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the North America AGV market looks promising, driven by the continuous demand for automation, the need for safe and efficient material handling solutions, and advancements in technology. As industries increasingly embrace digital transformation and seek ways to optimize their processes, the adoption of AGVs is expected to rise. The market will witness further advancements in AI, ML, and sensor technologies, enabling AGVs to handle more complex tasks and operate in diverse environments.

Conclusion

The North America AGV market is experiencing substantial growth, driven by the increasing adoption of automation, the need for safe and efficient material handling, and technological advancements. While initial costs and limited adoption in SMEs pose challenges, opportunities lie in integrating AGVs with Industry 4.0 principles, expanding applications in e-commerce and healthcare sectors, and addressing security concerns. With continuous innovation and strategic partnerships, the future of the AGV market in North America looks promising, offering businesses enhanced efficiency, improved safety, and cost savings in material handling operations.

What is Automated Guided Vehicle (AGV)?

Automated Guided Vehicles (AGVs) are mobile robots used to transport materials within a facility without human intervention. They are commonly utilized in warehouses, manufacturing plants, and distribution centers for tasks such as material handling and inventory management.

What are the key players in the North America Automated Guided Vehicle (AGV) Market?

Key players in the North America Automated Guided Vehicle (AGV) Market include companies like Kiva Systems, Dematic, and Seegrid, which are known for their innovative AGV solutions and technologies, among others.

What are the growth factors driving the North America Automated Guided Vehicle (AGV) Market?

The North America Automated Guided Vehicle (AGV) Market is driven by factors such as the increasing demand for automation in manufacturing, the need for efficient material handling solutions, and advancements in robotics technology.

What challenges does the North America Automated Guided Vehicle (AGV) Market face?

Challenges in the North America Automated Guided Vehicle (AGV) Market include high initial investment costs, the complexity of integrating AGVs with existing systems, and concerns regarding safety and reliability in dynamic environments.

What opportunities exist in the North America Automated Guided Vehicle (AGV) Market?

The North America Automated Guided Vehicle (AGV) Market presents opportunities in sectors such as e-commerce, healthcare, and automotive, where the demand for efficient logistics and automated solutions is rapidly increasing.

What trends are shaping the North America Automated Guided Vehicle (AGV) Market?

Trends in the North America Automated Guided Vehicle (AGV) Market include the rise of collaborative robots, advancements in artificial intelligence for navigation and decision-making, and the growing adoption of AGVs in small and medium-sized enterprises.

North America Automated Guided Vehicle (AGV) Market

| Segmentation Details | Description |

|---|---|

| Product Type | Unit Load AGVs, Tow Tractors, Pallet Trucks, Assembly Line AGVs |

| End User | Manufacturing, Warehousing, Retail, Healthcare |

| Technology | Laser Guidance, Magnetic Guidance, Vision Guidance, Inductive Guidance |

| Application | Material Handling, Order Fulfillment, Inventory Management, Transportation |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the North America Automated Guided Vehicle (AGV) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at