444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Nitrile Coated Gloves Market is witnessing substantial growth driven by the increasing awareness of workplace safety standards and the rising demand for durable and versatile hand protection solutions. Nitrile coated gloves offer superior resistance to chemicals, punctures, and abrasions, making them ideal for a wide range of industries such as manufacturing, construction, healthcare, and automotive. With stringent regulations and growing emphasis on employee welfare, the market for nitrile coated gloves is experiencing significant expansion globally.

Meaning

Nitrile coated gloves are gloves made of synthetic rubber known as nitrile, which are coated with a layer of nitrile material on the palm and fingers. This coating enhances the gloves‘ resistance to punctures, cuts, abrasions, and chemicals while maintaining flexibility and dexterity. Nitrile coated gloves are widely used in industries where hand protection is essential, including oil and gas, automotive, pharmaceuticals, food processing, and janitorial services. They provide reliable protection against various workplace hazards, ensuring the safety and well-being of workers.

Executive Summary

The Nitrile Coated Gloves Market is experiencing steady growth driven by factors such as increasing awareness of occupational safety, stringent regulations mandating the use of personal protective equipment (PPE), and the growing adoption of nitrile gloves over latex and vinyl alternatives. Key players in the market are focusing on product innovation, quality assurance, and expansion of distribution channels to capitalize on the rising demand for nitrile coated gloves across diverse industries. With the ongoing emphasis on workplace safety and hygiene, the market is poised for continued expansion in the coming years.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Nitrile Coated Gloves Market is driven by a combination of regulatory requirements, industry trends, technological advancements, and consumer preferences. Key market dynamics shaping growth include the increasing demand for PPE in response to occupational hazards and infectious diseases, the growing importance of ergonomic design and user comfort, and the emergence of new application areas and end-user industries. Market players are adapting their strategies to meet evolving customer needs, expand their product portfolios, and explore untapped market segments for growth opportunities.

Regional Analysis

The Nitrile Coated Gloves Market varies regionally based on factors such as industrial activity, regulatory frameworks, and economic conditions. Developed regions such as North America, Europe, and Asia-Pacific are major consumers of nitrile coated gloves, driven by stringent safety regulations, advanced manufacturing industries, and growing healthcare infrastructure. Emerging markets in Latin America, Africa, and the Middle East offer significant growth potential due to increasing industrialization, urbanization, and awareness of occupational safety standards.

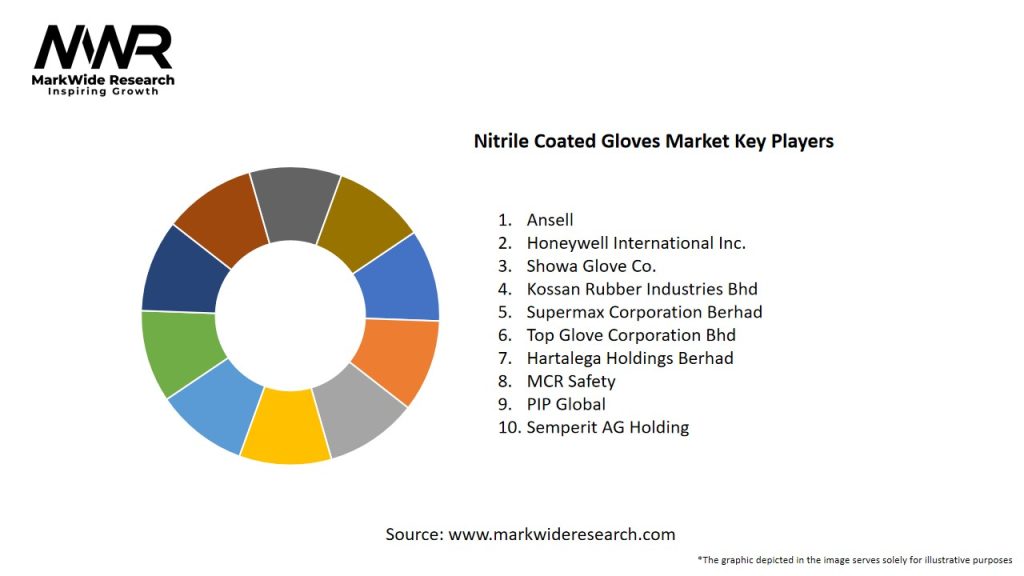

Competitive Landscape

The Nitrile Coated Gloves Market is highly competitive, with a mix of multinational corporations, regional players, and niche manufacturers vying for market share. Key players in the market include Ansell Limited, Top Glove Corporation Bhd, Hartalega Holdings Berhad, Kimberly-Clark Corporation, and Semperit AG Holding. These companies offer a wide range of nitrile coated gloves catering to different industries and applications, with a focus on quality, performance, and compliance with regulatory standards. Strategic partnerships, acquisitions, and investments in research and development are common strategies employed by market players to strengthen their market position and gain a competitive advantage.

Segmentation

The Nitrile Coated Gloves Market can be segmented based on product type, application, end-user industry, and region. By product type, the market includes disposable and reusable nitrile coated gloves in various sizes, thicknesses, and textures. By application, the market covers industrial work, healthcare, laboratory testing, food handling, and janitorial services. By end-user industry, the market encompasses manufacturing, construction, healthcare, automotive, oil and gas, and others. By region, the market spans North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has led to a surge in demand for nitrile coated gloves as essential PPE for frontline workers, healthcare professionals, and essential service providers. Key trends observed include the shortage of gloves due to supply chain disruptions, price fluctuations, and increased demand from healthcare and industrial sectors. The pandemic has underscored the importance of occupational safety, hygiene, and infection control measures, driving greater awareness and adoption of nitrile coated gloves in various industries worldwide.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Nitrile Coated Gloves Market is expected to continue its growth trajectory in the coming years, driven by factors such as increasing awareness of occupational safety, stringent regulations mandating the use of PPE, and the growing adoption of nitrile gloves over latex and vinyl alternatives. Industry participants that invest in innovation, quality assurance, and sustainability will be well-positioned to capitalize on emerging opportunities and address evolving challenges in the global market landscape.

Conclusion

In conclusion, the Nitrile Coated Gloves Market presents significant opportunities for manufacturers, suppliers, and distributors to meet the growing demand for durable, versatile, and reliable hand protection solutions across industries. With the increasing emphasis on workplace safety, hygiene, and regulatory compliance, nitrile coated gloves play a crucial role in safeguarding the health and well-being of workers worldwide. By leveraging innovation, collaboration, and strategic investments, industry stakeholders can contribute to the advancement of occupational safety standards and the resilience of supply chains in the dynamic landscape of glove manufacturing and distribution.

What is Nitrile Coated Gloves?

Nitrile coated gloves are protective handwear made from synthetic rubber, designed to provide resistance to chemicals, punctures, and abrasions. They are commonly used in various industries, including healthcare, automotive, and food processing.

What are the key players in the Nitrile Coated Gloves Market?

Key players in the Nitrile Coated Gloves Market include Ansell Limited, Showa Group, and Kimberly-Clark Corporation, among others. These companies are known for their innovative products and extensive distribution networks.

What are the growth factors driving the Nitrile Coated Gloves Market?

The growth of the Nitrile Coated Gloves Market is driven by increasing awareness of workplace safety, rising demand in the healthcare sector, and the expansion of the food service industry. Additionally, the need for high-quality protective gear in various applications contributes to market growth.

What challenges does the Nitrile Coated Gloves Market face?

The Nitrile Coated Gloves Market faces challenges such as fluctuating raw material prices and competition from alternative glove materials. Additionally, regulatory compliance and environmental concerns regarding disposal can impact market dynamics.

What opportunities exist in the Nitrile Coated Gloves Market?

Opportunities in the Nitrile Coated Gloves Market include the development of eco-friendly gloves and the expansion into emerging markets. Innovations in glove technology, such as enhanced grip and comfort, also present significant growth potential.

What trends are shaping the Nitrile Coated Gloves Market?

Trends in the Nitrile Coated Gloves Market include the increasing adoption of disposable gloves in various industries and the rise of smart gloves with integrated technology. Additionally, there is a growing focus on sustainability and the use of biodegradable materials.

Nitrile Coated Gloves Market

| Segmentation Details | Description |

|---|---|

| Product Type | Disposable, Reusable, Heavy-Duty, Light-Duty |

| Application | Medical, Industrial, Food Handling, Cleaning |

| End User | Healthcare, Manufacturing, Food Service, Janitorial |

| Size | Small, Medium, Large, Extra Large |

Leading Companies in Nitrile Coated Gloves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at