444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The NIR (Near-Infrared) meat analyzer market is witnessing steady growth due to advancements in food safety regulations, increased demand for quality control in meat processing, and technological innovations in spectroscopy. NIR meat analyzers provide rapid and non-destructive analysis of meat composition, including moisture, protein, fat, and collagen content, ensuring product quality and consistency in the food industry. These analyzers are essential for optimizing production processes, enhancing product shelf-life, and meeting consumer expectations for safe and nutritious meat products.

Meaning

NIR meat analyzers utilize near-infrared spectroscopy to analyze meat samples without damaging them, providing accurate measurements of key compositional parameters. By emitting and detecting light waves, these analyzers can assess moisture, protein, fat, and other components in meat products within seconds. This technology is crucial for meat processors to maintain quality standards, comply with regulatory requirements, and improve operational efficiency in production facilities.

Executive Summary

The NIR meat analyzer market is expanding due to the growing emphasis on food quality and safety, coupled with the rising adoption of automated inspection systems in meat processing plants. Key market players are focusing on developing advanced spectroscopy technologies, integrating artificial intelligence for data analysis, and expanding their product portfolios to cater to diverse applications in the meat industry. Despite challenges such as initial investment costs and regulatory complexities, the market presents lucrative opportunities for innovation and market expansion.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The NIR meat analyzer market dynamics are shaped by:

Regional Analysis

Competitive Landscape

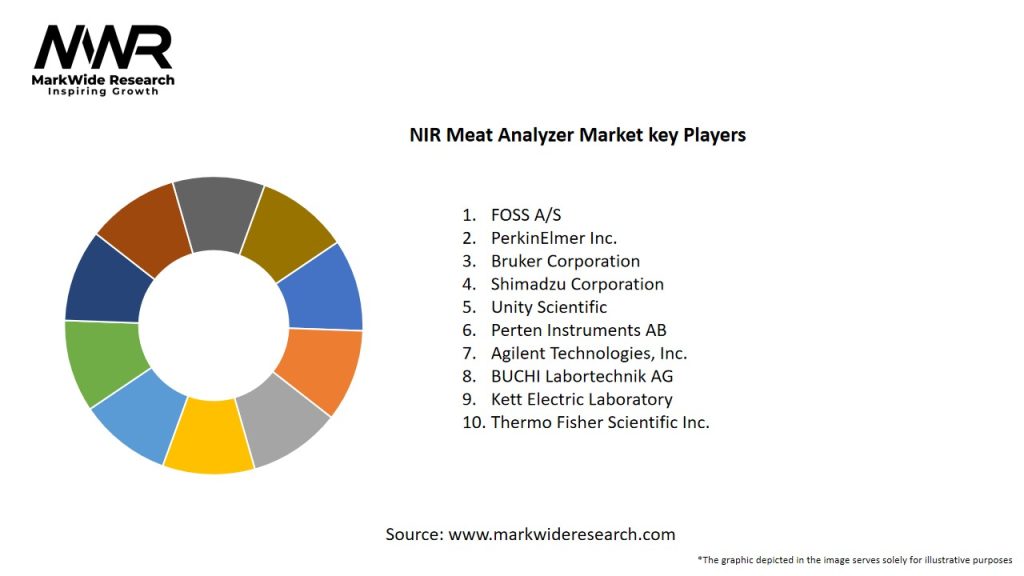

Key players in the NIR meat analyzer market include:

Segmentation

The NIR meat analyzer market can be segmented based on:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

COVID-19 Impact

The COVID-19 pandemic underscored the importance of food safety and quality assurance, driving demand for NIR meat analyzers to ensure hygienic and contamination-free meat products. Supply chain disruptions initially affected market growth but accelerated adoption of automated inspection systems and remote monitoring solutions. Post-pandemic recovery is expected with continued investments in food safety technologies and regulatory compliance.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the NIR meat analyzer market is optimistic, driven by increasing meat consumption, stringent food safety regulations, and technological advancements in spectroscopy. Continued focus on quality assurance, operational efficiency, and sustainability will drive market growth and innovation in the global meat processing industry.

Conclusion

In conclusion, the NIR meat analyzer market plays a crucial role in ensuring food safety, quality control, and operational efficiency in meat processing facilities worldwide. Despite challenges such as high initial costs and technical complexities, the market offers significant opportunities for growth through technological innovation, market expansion into emerging economies, and strategic partnerships. By leveraging advanced NIR spectroscopy solutions, industry stakeholders can meet evolving consumer demands for safe, nutritious, and high-quality meat products while driving sustainable growth and competitive advantage in the global market.

What is NIR Meat Analyzer?

NIR Meat Analyzer refers to a device that utilizes Near-Infrared Spectroscopy technology to assess the quality and composition of meat products. It provides rapid and non-destructive analysis of parameters such as fat content, protein levels, and moisture, which are crucial for quality control in the meat industry.

What are the key companies in the NIR Meat Analyzer Market?

Key companies in the NIR Meat Analyzer Market include Foss Analytical, Bruker Corporation, and PerkinElmer, which are known for their innovative solutions in meat analysis. These companies focus on enhancing the accuracy and efficiency of meat quality assessments, among others.

What are the drivers of growth in the NIR Meat Analyzer Market?

The growth of the NIR Meat Analyzer Market is driven by increasing demand for high-quality meat products, the need for efficient quality control processes, and advancements in spectroscopy technology. Additionally, the rising consumer awareness regarding meat safety and nutritional content further fuels market expansion.

What challenges does the NIR Meat Analyzer Market face?

The NIR Meat Analyzer Market faces challenges such as the high initial investment costs associated with advanced analyzers and the need for skilled personnel to operate these devices. Furthermore, variations in meat composition can affect the accuracy of NIR measurements, posing a challenge for consistent results.

What opportunities exist in the NIR Meat Analyzer Market?

Opportunities in the NIR Meat Analyzer Market include the development of portable analyzers for on-site testing and the integration of artificial intelligence for enhanced data analysis. Additionally, expanding applications in the poultry and seafood industries present new avenues for growth.

What trends are shaping the NIR Meat Analyzer Market?

Trends in the NIR Meat Analyzer Market include the increasing adoption of automation in meat processing facilities and the growing emphasis on sustainability in meat production. Moreover, innovations in sensor technology are leading to more precise and faster analysis methods.

NIR Meat Analyzer Market

| Segmentation Details | Description |

|---|---|

| Product Type | Portable Analyzers, Benchtop Analyzers, Inline Analyzers, Handheld Devices |

| Application | Meat Quality Assessment, Fat Content Analysis, Protein Content Measurement, Moisture Content Evaluation |

| End User | Meat Processing Plants, Quality Control Laboratories, Research Institutions, Food Safety Agencies |

| Technology | Near-Infrared Spectroscopy, Chemometrics, Data Analysis Software, Calibration Techniques |

Leading Companies in the NIR Meat Analyzer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at