444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Biomanufacturing, the process of producing biomaterials, therapeutic proteins, and other biological products using living organisms, has witnessed a significant transformation in recent years. The advent of Next-Generation Biomanufacturing has revolutionized the industrial landscape, offering advanced technologies and methodologies for enhanced production efficiency, reduced costs, and improved sustainability. This comprehensive guide provides insights into the Next-Generation Biomanufacturing market, its key trends, market dynamics, regional analysis, competitive landscape, and future outlook.

Meaning

Next-Generation Biomanufacturing refers to the integration of cutting-edge technologies, such as automation, artificial intelligence (AI), machine learning (ML), and advanced analytics, into the biomanufacturing process. It aims to overcome the limitations of traditional biomanufacturing methods by optimizing production processes, reducing human intervention, and increasing overall productivity. This innovative approach holds tremendous potential for various industries, including pharmaceuticals, biotechnology, agriculture, and environmental sectors.

Executive Summary

The Next-Generation Biomanufacturing market has experienced rapid growth due to the increasing demand for biopharmaceuticals, personalized medicine, and sustainable industrial processes. The market is driven by advancements in automation and digital technologies, coupled with the rising need for efficient and cost-effective manufacturing methods. However, several challenges, such as regulatory complexities, high initial investments, and limited awareness, pose restraints to market growth. Nonetheless, the market presents lucrative opportunities for players who can capitalize on the growing demand for innovative biomanufacturing solutions.

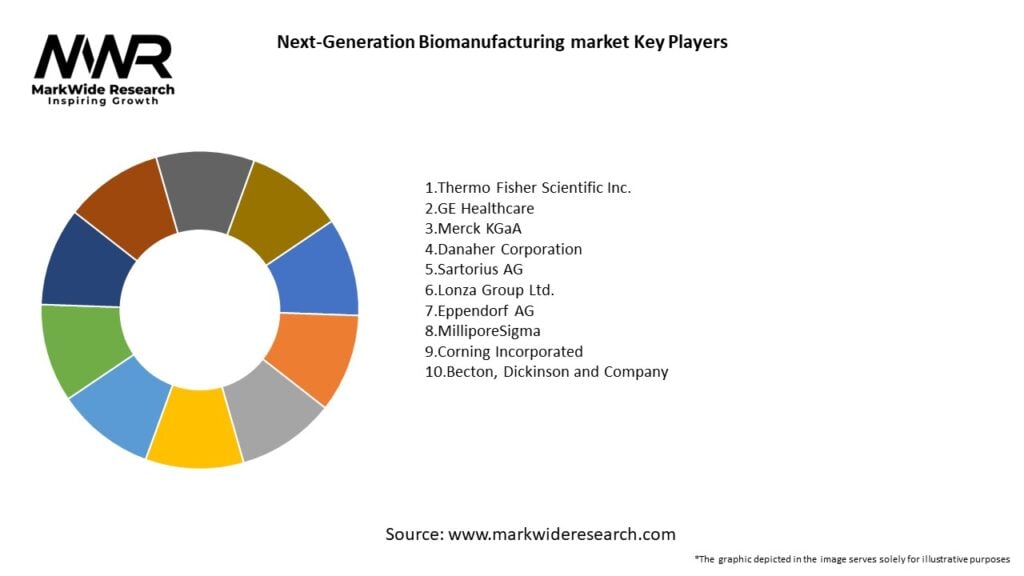

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

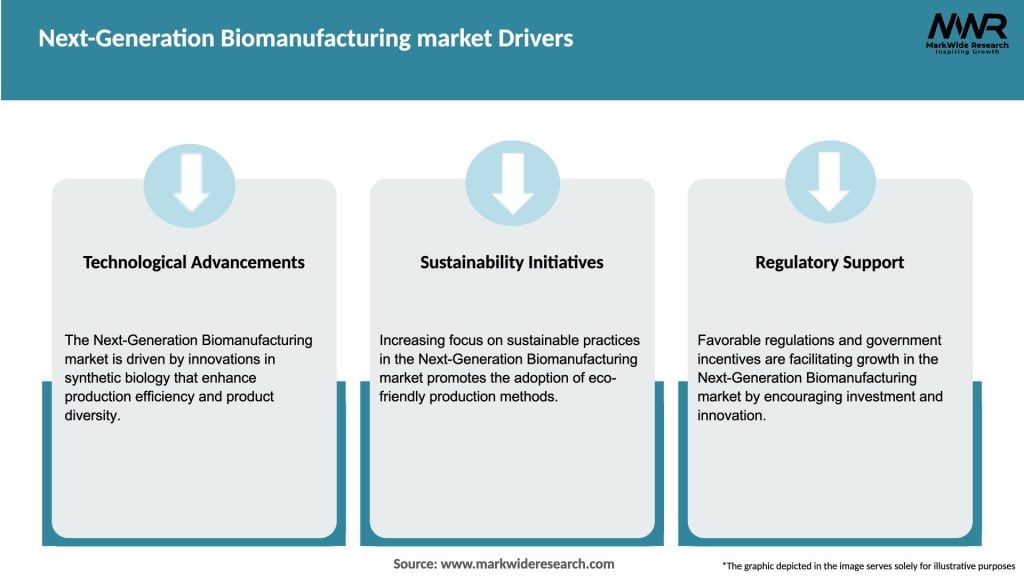

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Next-Generation Biomanufacturing market is characterized by dynamic factors such as technological advancements, evolving regulatory landscape, strategic collaborations, and shifting consumer preferences. The market is driven by the need for efficient and sustainable manufacturing methods, while challenges such as high initial investments and regulatory complexities impact its growth. However, the continuous development of advanced technologies and increasing awareness about the benefits of Next-Generation Biomanufacturing create opportunities for market expansion.

Regional Analysis

North America: The North American market dominates the Next-Generation Biomanufacturing landscape, primarily driven by the presence of major pharmaceutical and biotechnology companies, advanced infrastructure, and favorable government initiatives. The region is witnessing significant investments in research and development, further fostering market growth.

Europe: Europe is a key market for Next-Generation Biomanufacturing, with established biopharmaceutical and biotechnology industries. The region’s focus on sustainability and technological advancements contributes to market growth, with countries like Germany, the UK, and Switzerland leading the way.

Asia-Pacific: The Asia-Pacific region is poised for substantial growth in the Next-Generation Biomanufacturing market. Factors such as rapid industrialization, rising investments in research and development, and favorable government initiatives are propelling market expansion in countries like China, Japan, and South Korea.

Competitive Landscape

Leading companies in the Global Next-Generation Biomanufacturing market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

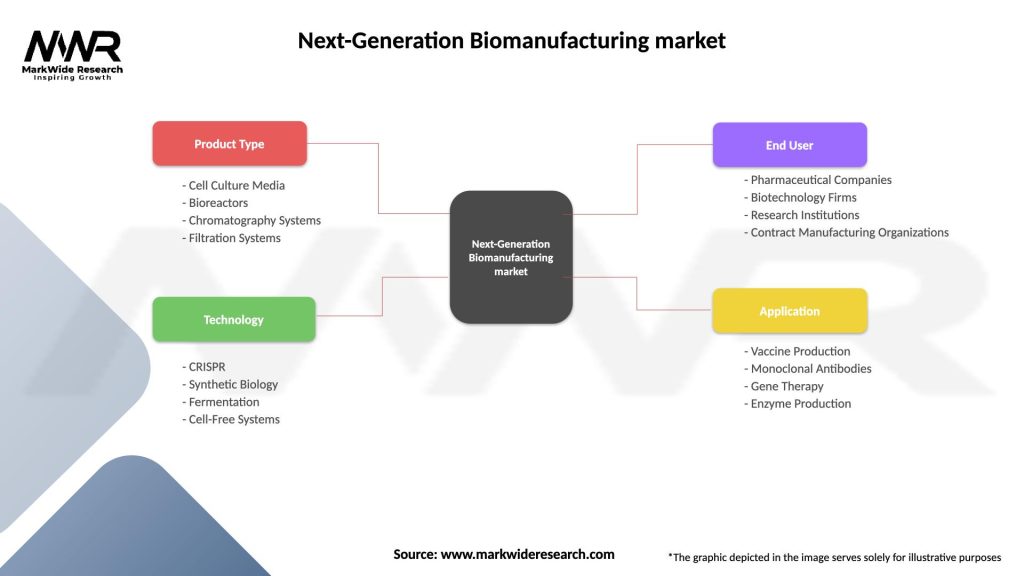

The Next-Generation Biomanufacturing market can be segmented based on:

Category-wise Insights

Biopharmaceuticals: Next-Generation Biomanufacturing has revolutionized the production of biopharmaceuticals, enabling increased efficiency, reduced costs, and improved product quality. Advanced technologies such as single-use systems, continuous bioprocessing, and process analytical technology (PAT) are driving innovation in this category.

Personalized Medicine: Next-Generation Biomanufacturing plays a pivotal role in the production of personalized medicine and therapies. The ability to customize treatments according to patients’ genetic profiles and individual needs is a key advantage of Next-Generation Biomanufacturing methods.

Industrial Chemicals and Enzymes: Next-Generation Biomanufacturing is being increasingly utilized in the production of industrial chemicals and enzymes. The use of microbial fermentation, metabolic engineering, and bioconversion processes helps enhance production efficiency, reduce environmental impact, and optimize resource utilization.

Agriculture and Food Products: Next-Generation Biomanufacturing offers sustainable solutions for the agriculture and food industry, including the production of bio-based fertilizers, biopesticides, and genetically modified organisms (GMOs). These technologies contribute to enhanced crop yield, reduced chemical usage, and improved food security.

Environmental Solutions: Next-Generation Biomanufacturing plays a vital role in environmental conservation and remediation. The production of biofuels, bioplastics, and bio-based materials helps reduce greenhouse gas emissions and fosters the transition towards a circular economy.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has accelerated the need for advanced biomanufacturing solutions. The production of vaccines, therapeutics, and diagnostic tools has highlighted the significance of scalable and flexible manufacturing processes. Next-Generation Biomanufacturing has played a crucial role in enabling rapid vaccine development, process optimization, and increased production capacity during the pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Next-Generation Biomanufacturing market is poised for significant growth in the coming years. Advancements in automation, AI, and analytics, coupled with the rising demand for biopharmaceuticals and personalized medicine, will continue to drive market expansion. The market is expected to witness increased collaboration, technological innovations, and a shift towards sustainable manufacturing practices.

Conclusion

Next-Generation Biomanufacturing represents a paradigm shift in industrial processes, offering advanced technologies and methodologies to enhance production efficiency, reduce costs, and promote sustainability. The market is driven by the increasing demand for biopharmaceuticals, personalized medicine, and eco-friendly production practices. While challenges exist, such as high initial investments and regulatory complexities, the market presents significant opportunities for industry participants and stakeholders. By embracing Next-Generation Biomanufacturing, companies can transform their operations, meet evolving market demands, and contribute to a more sustainable and innovative future.

What is Next-Generation Biomanufacturing?

Next-Generation Biomanufacturing refers to advanced methods of producing biological products using innovative technologies such as synthetic biology, automation, and bioprocess optimization. This approach enhances efficiency, sustainability, and scalability in the production of pharmaceuticals, biofuels, and other bioproducts.

Who are the key players in the Next-Generation Biomanufacturing market?

Key players in the Next-Generation Biomanufacturing market include companies like Amgen, Genomatica, and Ginkgo Bioworks, which are known for their contributions to biopharmaceuticals and sustainable production methods. These companies leverage cutting-edge technologies to improve biomanufacturing processes, among others.

What are the main drivers of growth in the Next-Generation Biomanufacturing market?

The main drivers of growth in the Next-Generation Biomanufacturing market include the increasing demand for sustainable production methods, advancements in genetic engineering, and the rising need for efficient drug development processes. These factors are pushing industries to adopt biomanufacturing technologies.

What challenges does the Next-Generation Biomanufacturing market face?

Challenges in the Next-Generation Biomanufacturing market include regulatory hurdles, high initial investment costs, and the complexity of scaling up bioprocesses. These factors can hinder the widespread adoption of innovative biomanufacturing techniques.

What opportunities exist in the Next-Generation Biomanufacturing market?

Opportunities in the Next-Generation Biomanufacturing market include the potential for developing personalized medicine, the use of biomanufacturing in sustainable agriculture, and the creation of novel bio-based materials. These areas present significant growth potential for companies in the sector.

What trends are shaping the Next-Generation Biomanufacturing market?

Trends shaping the Next-Generation Biomanufacturing market include the integration of artificial intelligence in bioprocess optimization, the rise of cell-free systems for production, and increased collaboration between academia and industry. These trends are driving innovation and efficiency in biomanufacturing.

Next-Generation Biomanufacturing market

| Segmentation Details | Description |

|---|---|

| Product Type | Cell Culture Media, Bioreactors, Chromatography Systems, Filtration Systems |

| Technology | CRISPR, Synthetic Biology, Fermentation, Cell-Free Systems |

| End User | Pharmaceutical Companies, Biotechnology Firms, Research Institutions, Contract Manufacturing Organizations |

| Application | Vaccine Production, Monoclonal Antibodies, Gene Therapy, Enzyme Production |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Global Next-Generation Biomanufacturing market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at