444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Motorized decoiler machines have become an integral part of modern manufacturing industries, revolutionizing the way coil handling is carried out. These machines are designed to efficiently unwind and feed metal coils, allowing seamless operations in various applications such as automotive, construction, aerospace, and electrical industries. With their ability to handle heavy-duty coils and enhance productivity, motorized decoiler machines have witnessed significant demand globally.

Meaning

A motorized decoiler machine, also known as a motorized uncoiler, is a mechanical device used to unwind metal coils and supply them to the processing line. It comprises a motorized spindle, which rotates to uncoil the metal coil, along with a range of supporting components like loop control systems, coil guides, and safety measures. These machines are available in different sizes and capacities to cater to diverse coil handling requirements.

Executive Summary

The motorized decoiler machine market has experienced substantial growth in recent years, driven by the increasing demand for efficient coil handling solutions across various industries. Manufacturers are increasingly adopting motorized decoiler machines to streamline their production processes, reduce material wastage, and enhance overall productivity. This market is expected to witness continued expansion, fueled by technological advancements and the need for automation in coil handling operations.

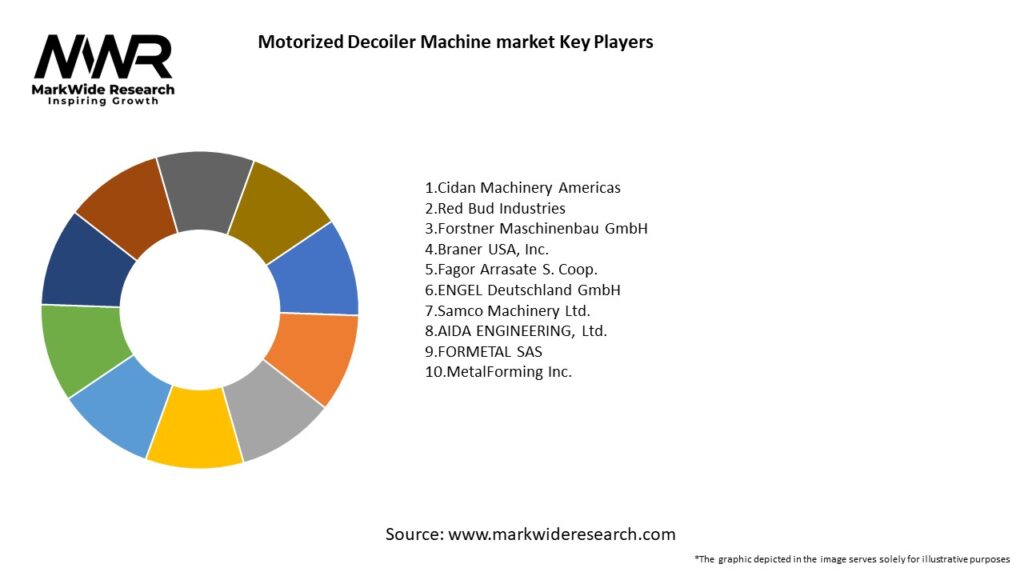

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The motorized decoiler machine market is driven by a combination of factors, including industry-specific demands, technological advancements, and the overall economic landscape. The increasing focus on automation and productivity improvement, along with the need for efficient coil handling solutions, has fueled market growth. However, challenges related to initial investment and maintenance can impact market expansion. Despite these challenges, emerging economies and continuous technological innovations present significant opportunities for market players.

Regional Analysis

The motorized decoiler machine market exhibits a strong presence across regions, with key players catering to diverse geographical markets. North America and Europe have been early adopters of motorized decoiler machines, owing to the presence of established manufacturing industries and technological advancements. Asia Pacific is witnessing rapid growth, fueled by increasing industrialization and infrastructure development. Additionally, the Middle East and Africa and Latin America regions are showing promising growth due to ongoing industrial expansion.

Competitive Landscape

Leading Companies in the Motorized Decoiler Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The motorized decoiler machine market can be segmented based on various factors, including:

Category-wise Insights

Single Spindle Decoiler Machines: These machines are designed with a single spindle to handle and unwind metal coils. They are commonly used in industries with medium to heavy coil handling requirements. Single spindle decoiler machines offer ease of operation, compact design, and efficient coil feeding.

Double Spindle Decoiler Machines: Double spindle decoiler machines feature two spindles to handle multiple coils simultaneously. They are ideal for industries requiring high-speed and continuous coil processing. Double spindle decoilers offer enhanced productivity and reduced downtime during coil changeovers.

Pallet Decoiler Machines: Pallet decoiler machines are specifically designed to handle large and heavy coils. They incorporate pallet systems that support the coil during unwinding, ensuring stability and safety. Pallet decoilers are widely used in industries where coil size and weight are significant factors.

Up to 5 Tons: Decoiler machines with a capacity of up to 5 tons are suitable for small to medium-scale applications. They are commonly used in industries with lighter coil handling requirements or for initial processing stages.

5-10 Tons: Decoiler machines with a capacity of 5 to 10 tons are well-suited for industries with moderate coil sizes and weights. They offer versatility and can handle a wide range of coils, making them suitable for various applications.

Above 10 Tons: Decoiler machines with a capacity of above 10 tons are designed for heavy-duty coil handling in industries such as steel manufacturing, shipbuilding, and heavy machinery production. They provide robust performance and high load-bearing capabilities.

Automotive: The automotive industry extensively utilizes motorized decoiler machines for coil handling in the manufacturing of car bodies, chassis, and various components. These machines ensure efficient processing of metal coils and contribute to streamlined production.

Construction: In the construction industry, motorized decoiler machines find applications in steel fabrication, roofing, and structural element manufacturing. They enable precise coil unwinding, leading to accurate and consistent product quality.

Aerospace: The aerospace industry requires motorized decoiler machines for manufacturing aircraft components and structures. These machines ensure precise coil feeding and contribute to the production of high-quality aerospace parts.

Electrical and Electronics: Motorized decoiler machines play a vital role in the electrical and electronics industry for coil handling in the production of transformers, motors, and electrical components. They facilitate efficient unwinding and feeding of coils, ensuring smooth manufacturing processes.

Others: Motorized decoiler machines are also used in various other industries such as energy, machinery, and consumer goods manufacturing, where coil handling is an essential part of the production process.

Direct Sales: Many motorized decoiler machine manufacturers offer their products directly to end-users. Direct sales channels allow for better customer engagement, customization options, and after-sales support.

Distributors/Wholesalers: Some manufacturers choose to work with distributors or wholesalers to reach a broader customer base. This sales channel enables wider market coverage and access to existing distribution networks.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the motorized decoiler machine market can expect several key benefits:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the motorized decoiler machine market. While the initial phase witnessed disruptions in manufacturing activities due to lockdowns and supply chain challenges, the market gradually recovered as industries resumed operations and adopted new safety measures.

The pandemic accelerated the need for automation in manufacturing processes to minimize human contact and ensure social distancing. This led to increased demand for motorized decoiler machines as manufacturers sought efficient and automated solutions for coil handling.

Additionally, the shift towards remote work and digitalization drove the integration of advanced technologies like IIoT and remote monitoring capabilities in motorized decoiler machines. This allowed for remote machine monitoring, predictive maintenance, and reduced reliance on on-site personnel.

Key Industry Developments

Analyst Suggestions

Future Outlook

The motorized decoiler machine market is poised for significant growth in the coming years. The increasing demand for automation, the need for efficient coil handling solutions, and the integration of advanced technologies are expected to drive market expansion. Emerging economies and the ongoing technological advancements present favorable opportunities for market players. However, challenges related to initial investment and maintenance should be addressed to ensure sustained growth.

Conclusion

The motorized decoiler machine market is witnessing robust growth driven by the need for efficient coil handling solutions across various industries. Manufacturers are adopting these machines to enhance productivity, reduce material wastage, and improve overall operational efficiency. The market is characterized by continuous technological advancements, integration of automation and control systems, and a focus on safety and ergonomic design. Collaboration, customization, and after-sales services are key strategies for market players to maintain a competitive edge. Despite challenges, the motorized decoiler machine market is expected to experience sustained growth, fueled by emerging economies and the continuous demand for optimized coil handling in manufacturing industries.

What is Motorized Decoiler Machine?

A Motorized Decoiler Machine is a device used in manufacturing processes to unwind coils of material, such as metal or plastic, automatically. It enhances efficiency by reducing manual labor and ensuring a steady supply of material for further processing.

What are the key companies in the Motorized Decoiler Machine market?

Key companies in the Motorized Decoiler Machine market include Tishken, Akyapak, and A.J. Machine among others. These companies are known for their innovative designs and reliable machinery that cater to various industrial applications.

What are the growth factors driving the Motorized Decoiler Machine market?

The growth of the Motorized Decoiler Machine market is driven by increasing automation in manufacturing, rising demand for precision in production processes, and the expansion of industries such as automotive and construction.

What challenges does the Motorized Decoiler Machine market face?

Challenges in the Motorized Decoiler Machine market include high initial investment costs, the need for skilled operators, and competition from alternative material handling solutions that may offer lower costs.

What opportunities exist in the Motorized Decoiler Machine market?

Opportunities in the Motorized Decoiler Machine market include advancements in technology that improve machine efficiency, the growing trend of smart manufacturing, and the increasing adoption of eco-friendly materials in production.

What trends are shaping the Motorized Decoiler Machine market?

Trends in the Motorized Decoiler Machine market include the integration of IoT for real-time monitoring, the development of energy-efficient models, and a shift towards modular designs that allow for customization in various manufacturing setups.

Motorized Decoiler Machine market

| Segmentation Details | Description |

|---|---|

| Product Type | Hydraulic Decoiler, Electric Decoiler, Manual Decoiler, Automatic Decoiler |

| End User | Manufacturing, Construction, Automotive, Aerospace |

| Technology | Servo Motor, Pneumatic, Mechanical, Electromechanical |

| Application | Metal Processing, Coil Handling, Sheet Metal Fabrication, Wire Production |

Leading Companies in the Motorized Decoiler Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at