Market Overview

The monolayer cast film line market encompasses the production, distribution, and utilization of machinery and equipment used for manufacturing monolayer cast films. These films are widely utilized in various industries such as packaging, agriculture, construction, and healthcare for applications including food packaging, agricultural mulching, geomembranes, and medical packaging. Monolayer cast film lines offer advantages such as versatility, cost-effectiveness, and ease of operation, making them essential equipment in the production of flexible packaging solutions.

Meaning

Monolayer cast film lines are extrusion systems designed to produce thin, uniform plastic films from polymer resins. The process involves melting polymer pellets, extruding the molten material through a flat die, and casting the film onto a chilled roller to solidify and form a continuous sheet. Monolayer cast films offer properties such as clarity, strength, barrier protection, and printability, making them suitable for a wide range of packaging and industrial applications.

Executive Summary

The monolayer cast film line market is experiencing steady growth driven by the demand for flexible packaging solutions, sustainability initiatives, and technological advancements in film extrusion technology. As industries seek lightweight, recyclable, and cost-effective packaging materials, the market for monolayer cast film lines presents opportunities for manufacturers, suppliers, and service providers. Understanding key market trends, customer requirements, and competitive dynamics is crucial for stakeholders to capitalize on emerging opportunities and sustain growth in a competitive landscape.

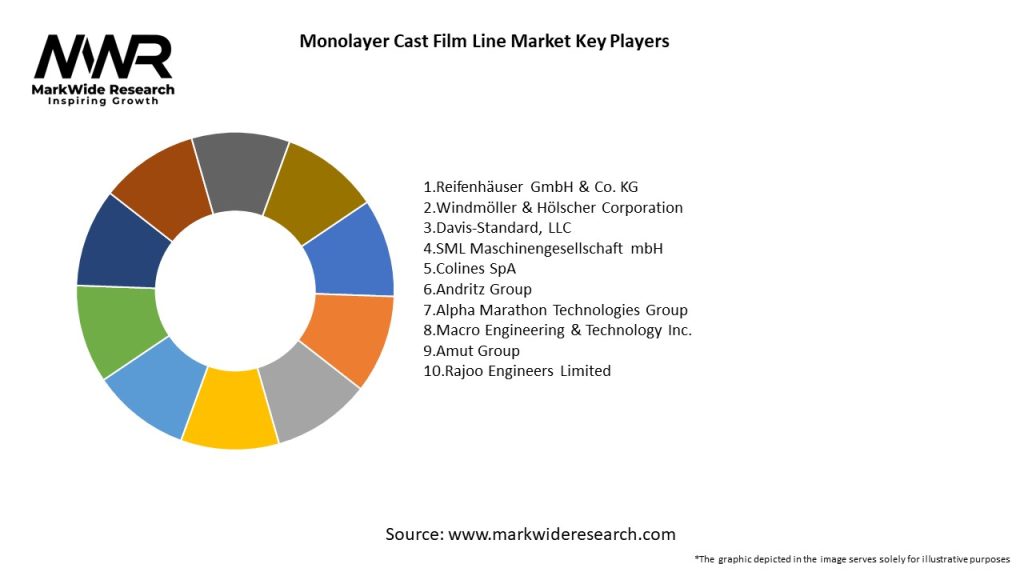

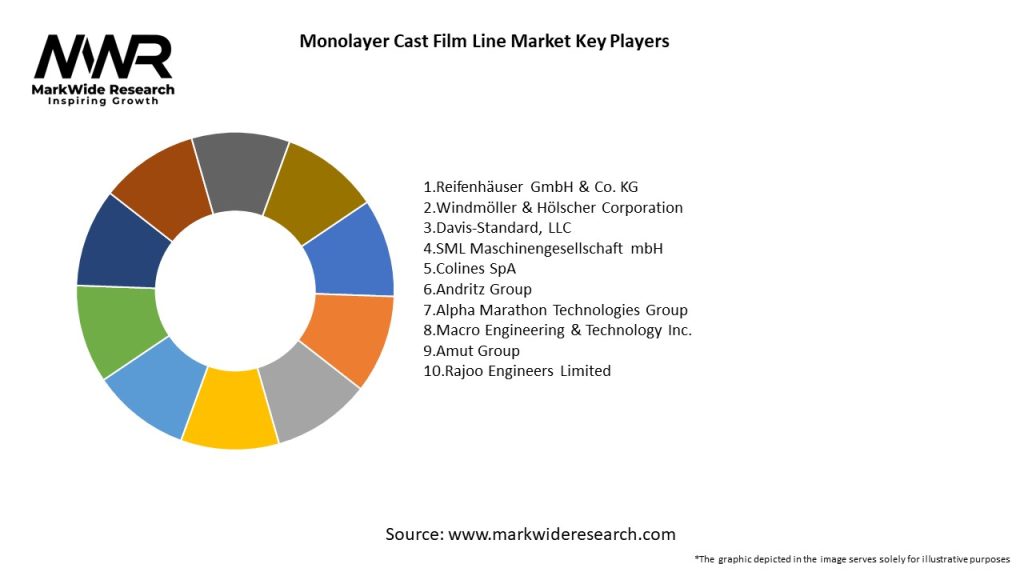

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Flexible Packaging Demand: The growing demand for flexible packaging solutions in industries such as food and beverage, pharmaceuticals, and consumer goods drives the market for monolayer cast film lines, as manufacturers seek efficient and versatile equipment to produce a wide range of packaging materials.

- Sustainability Trends: Increasing focus on sustainability, recyclability, and circular economy principles in packaging drives demand for monolayer cast films made from bio-based, compostable, and recyclable materials, encouraging investments in eco-friendly film extrusion technology.

- Technological Advancements: Innovations in film extrusion technology, process automation, and material formulations improve the productivity, efficiency, and quality of monolayer cast film lines, enabling manufacturers to meet stringent product specifications and customer requirements.

- Market Expansion: The expansion of end-user industries, geographical markets, and application segments creates opportunities for monolayer cast film line manufacturers to diversify their product offerings, enter new markets, and establish strategic partnerships to enhance market penetration and customer reach.

Market Drivers

- Rise in Flexible Packaging: The shift from rigid to flexible packaging solutions in industries such as food and beverage, healthcare, and personal care drives demand for monolayer cast film lines capable of producing high-quality, lightweight films with barrier properties and printability for packaging applications.

- Consumer Convenience: Consumer preferences for convenient, portable, and resealable packaging formats drive innovation in flexible packaging solutions, prompting investments in monolayer cast film lines capable of producing films with enhanced functionalities such as easy-open seals and tear resistance.

- Cost-Effectiveness: The cost-effectiveness of monolayer cast film lines compared to other film extrusion technologies such as blown film and multilayer coextrusion attracts manufacturers seeking efficient and economical equipment for producing mono-layered films for packaging and industrial applications.

- Customization and Flexibility: The ability of monolayer cast film lines to produce films with customizable properties such as thickness, width, and additives enables manufacturers to meet specific customer requirements and adapt to changing market demands for specialized packaging solutions.

Market Restraints

- Competition from Other Technologies: Competition from alternative film extrusion technologies such as blown film and multilayer coextrusion poses a challenge to the monolayer cast film line market, particularly in applications requiring complex structures, barrier properties, and high-performance films.

- Raw Material Price Volatility: Volatility in raw material prices, supply chain disruptions, and fluctuations in resin availability impact the cost of production for monolayer cast film manufacturers, affecting profit margins and pricing competitiveness in the market.

- Regulatory Compliance: Compliance with regulatory requirements, quality standards, and industry certifications imposes additional costs and administrative burdens on monolayer cast film line manufacturers, particularly in highly regulated sectors such as food packaging and medical applications.

- Technological Limitations: Technological limitations such as film thickness variability, gauge uniformity, and web handling challenges may limit the performance and capabilities of monolayer cast film lines, requiring continuous innovation and process optimization to overcome technical constraints.

Market Opportunities

- Bio-based Films: Growing consumer awareness and regulatory initiatives promoting sustainable packaging solutions create opportunities for manufacturers to develop monolayer cast film lines capable of processing bio-based resins, biodegradable polymers, and compostable materials for eco-friendly packaging applications.

- Functional Additives: Incorporation of functional additives such as antimicrobial agents, oxygen scavengers, and UV stabilizers into monolayer films enhances their performance, shelf life, and product differentiation, driving demand for film extrusion equipment capable of processing specialty resins and additives.

- Smart Packaging Solutions: Integration of smart packaging technologies such as RFID tags, NFC sensors, and QR codes into flexible packaging solutions creates opportunities for monolayer cast film line manufacturers to produce films with embedded functionalities for traceability, authentication, and consumer engagement.

- Customized Solutions: Offering customized film solutions tailored to specific end-user requirements, application needs, and market preferences enables manufacturers to differentiate their product offerings, build brand loyalty, and capture niche market segments with specialized packaging solutions.

Market Dynamics

The monolayer cast film line market operates within a dynamic ecosystem influenced by factors such as technological innovation, market trends, competitive pressures, and regulatory developments. Understanding the market dynamics enables stakeholders to identify opportunities, address challenges, and formulate strategies to navigate the evolving landscape effectively.

Regional Analysis

The monolayer cast film line market exhibits regional variations in demand, market maturity, and growth potential influenced by factors such as industrialization, economic development, consumer preferences, and regulatory frameworks. Let’s explore key regions:

- North America: The North American market for monolayer cast film lines is characterized by the presence of established packaging manufacturers, technological innovation hubs, and stringent regulatory requirements driving investments in sustainable packaging solutions and advanced film extrusion technology.

- Europe: Europe is a mature market for monolayer cast film lines, characterized by a strong emphasis on environmental sustainability, circular economy principles, and product quality standards driving demand for eco-friendly packaging materials, recyclable films, and bio-based resins.

- Asia Pacific: Asia Pacific is the largest and fastest-growing market for monolayer cast film lines, driven by rapid industrialization, urbanization, and rising consumer demand for packaged goods, prompting investments in packaging machinery, automation solutions, and film extrusion technology.

- Latin America: Latin America offers growth opportunities for monolayer cast film line manufacturers, driven by expanding consumer markets, urbanization trends, and investments in food processing, agriculture, and pharmaceutical industries requiring flexible packaging solutions for diverse applications.

- Middle East and Africa: The Middle East and Africa represent emerging markets for monolayer cast film lines, driven by infrastructure development, urbanization, and investments in manufacturing sectors such as construction, automotive, and healthcare requiring packaging solutions for product protection and brand differentiation.

Competitive Landscape

Leading Companies in the Monolayer Cast Film Line Market:

- Reifenhäuser GmbH & Co. KG

- Windmöller & Hölscher Corporation

- Davis-Standard, LLC

- SML Maschinengesellschaft mbH

- Colines SpA

- Andritz Group

- Alpha Marathon Technologies Group

- Macro Engineering & Technology Inc.

- Amut Group

- Rajoo Engineers Limited

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The monolayer cast film line market can be segmented based on various factors such as machine type, application, end-user industry, and geographical region, enabling targeted analysis, market segmentation, and customization to meet specific customer needs and market demands.

Category-wise Insights

- Food Packaging Films: Monolayer cast film lines are widely used to produce food packaging films with properties such as barrier protection, sealability, and printability for applications including fresh produce, snacks, frozen foods, and ready-to-eat meals.

- Agricultural Films: Monolayer cast film lines are utilized to manufacture agricultural films for applications such as mulching, greenhouse covering, silage storage, and crop protection, providing benefits such as soil moisture retention, weed control, and crop yield enhancement.

- Industrial films: Monolayer cast film lines produce industrial films for applications such as surface protection, laminating, adhesive tapes, and construction membranes, offering properties such as tear resistance, puncture strength, and weatherability for demanding industrial applications.

- Medical Packaging Films: Monolayer cast film lines are employed to produce medical packaging films for applications such as sterile barrier packaging, medical device packaging, and pharmaceutical blister packs, requiring properties such as sterility, barrier protection, and compatibility with sterilization processes.

Key Benefits for Industry Participants and Stakeholders

- Efficiency and Productivity: Monolayer cast film lines offer high throughput, consistent quality, and operational reliability, enabling manufacturers to meet production targets, minimize downtime, and optimize resource utilization for cost-effective film production.

- Versatility and Customization: Monolayer cast film lines provide flexibility, adaptability, and customization options to produce films with specific properties, thicknesses, widths, and additives tailored to customer requirements and market preferences.

- Quality and Consistency: Monolayer cast film lines deliver uniform film thickness, excellent optical clarity, and mechanical properties, ensuring product quality, consistency, and performance for packaging and industrial applications.

- Innovation and Differentiation: Monolayer cast film lines facilitate innovation, process optimization, and product differentiation through the integration of advanced technologies, material formulations, and process controls to meet evolving market demands and customer expectations.

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the monolayer cast film line market:

- Strengths:

- Versatility and flexibility in film production.

- Cost-effectiveness compared to other technologies.

- Customization options and process control.

- Established market presence and customer base.

- Weaknesses:

- Dependency on raw material prices and availability.

- Technological limitations and process constraints.

- Competition from alternative film extrusion technologies.

- Regulatory compliance and quality assurance challenges.

- Opportunities:

- Growth in flexible packaging applications.

- Innovation in bio-based and sustainable films.

- Expansion into emerging markets and applications.

- Adoption of digitalization and smart technologies.

- Threats:

- Competition from alternative film extrusion technologies.

- Raw material price volatility and supply chain disruptions.

- Regulatory changes and compliance requirements.

- Technological disruptions and market consolidation.

Market Key Trends

- Sustainable Packaging Solutions: Increasing demand for sustainable packaging solutions drives innovation in bio-based resins, compostable films, and recyclable materials, influencing the adoption of monolayer cast film lines for eco-friendly packaging applications.

- Digitalization and Industry 4.0: Integration of digital technologies, automation solutions, and data analytics into film extrusion processes enables real-time monitoring, predictive maintenance, and process optimization for improved productivity and efficiency.

- Material Innovation and Additives: Development of specialty resins, functional additives, and barrier coatings enhances the performance, functionality, and value proposition of monolayer cast films, expanding their applications in diverse end-user industries.

- Circular Economy Initiatives: Focus on circular economy principles, waste reduction, and resource efficiency drives initiatives for closed-loop recycling, post-consumer recycling, and end-of-life management of plastic films, shaping the future of sustainable film production.

Covid-19 Impact

The COVID-19 pandemic has had significant impacts on the monolayer cast film line market, influencing market dynamics, supply chains, and customer behavior. Key impacts include:

- Demand Fluctuations: Disruptions in supply chains, changes in consumer behavior, and economic uncertainties lead to fluctuations in demand for flexible packaging solutions, affecting sales volumes and production schedules for monolayer cast film lines.

- Supply Chain Disruptions: Disruptions in raw material supply, logistics operations, and international trade pose challenges for manufacturers of monolayer cast film lines, impacting production lead times, inventory management, and delivery schedules.

- Operational Challenges: Adapting to remote work practices, social distancing measures, and health protocols poses operational challenges for film extrusion facilities, affecting workforce availability, production efficiency, and overall business continuity.

- Shift in Consumer Preferences: Changes in consumer preferences, lifestyle trends, and purchasing behavior influence demand for packaged goods, prompting adjustments in packaging formats, materials, and design requirements for monolayer cast film applications.

Key Industry Developments

- Remote Monitoring and Service: Adoption of remote monitoring systems, IoT platforms, and predictive analytics enables manufacturers to offer remote diagnostics, troubleshooting, and maintenance services for monolayer cast film lines, enhancing equipment reliability and uptime.

- Energy Efficiency Solutions: Implementation of energy management systems, process optimization strategies, and energy-efficient components reduces energy consumption, operating costs, and environmental footprint of monolayer cast film production processes.

- Material Recycling Technologies: Development of advanced recycling technologies, chemical recycling processes, and mechanical recycling equipment enables the recycling of post-consumer and post-industrial plastic waste into high-quality resins for film extrusion applications.

- Smart Packaging Innovations: Integration of smart packaging technologies, digital printing solutions, and anti-counterfeiting measures into flexible packaging designs enhances product differentiation, brand protection, and consumer engagement in monolayer cast film applications.

Analyst Suggestions

- Investment in Sustainability: Prioritize investments in sustainable materials, eco-friendly processes, and circular economy initiatives to meet regulatory requirements, customer expectations, and market trends for sustainable packaging solutions.

- Adoption of Digital Technologies: Embrace digitalization, automation, and data analytics tools to improve operational efficiency, process optimization, and predictive maintenance for monolayer cast film lines, enabling real-time decision-making and performance optimization.

- Collaboration and Partnerships: Foster collaborations with raw material suppliers, technology providers, and end-user industries to co-develop innovative solutions, address market needs, and create value-added products and services for the packaging market.

- Focus on Product Differentiation: Differentiate product offerings through innovation, customization, and value-added services such as material formulations, additive solutions, and process optimizations tailored to specific customer requirements and market segments.

Future Outlook

The monolayer cast film line market is poised for growth and innovation, driven by trends such as sustainability, digitalization, material innovation, and smart packaging solutions. As industries seek eco-friendly, cost-effective, and high-performance packaging solutions, demand for monolayer cast film lines will continue to grow, offering opportunities for manufacturers to innovate, differentiate, and capture market share in a dynamic and evolving landscape.

Conclusion

The monolayer cast film line market plays a vital role in the production of flexible packaging solutions for diverse end-user industries, offering efficiency, versatility, and sustainability in film extrusion processes. Despite challenges such as raw material price volatility, competition from alternative technologies, and regulatory compliance requirements, the market presents opportunities for growth, innovation, and market expansion driven by trends such as sustainable packaging, digitalization, and material innovation. By embracing technology, sustainability, and collaboration, stakeholders can navigate the evolving market landscape, meet customer demands, and achieve long-term success in the monolayer cast film line market.

Leading Companies in the Monolayer Cast Film Line Market:

- Reifenhäuser GmbH & Co. KG

- Windmöller & Hölscher Corporation

- Davis-Standard, LLC

- SML Maschinengesellschaft mbH

- Colines SpA

- Andritz Group

- Alpha Marathon Technologies Group

- Macro Engineering & Technology Inc.

- Amut Group

- Rajoo Engineers Limited

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA