444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The mobile concrete mixer market is a dynamic and rapidly growing industry that caters to the construction sector’s need for on-site concrete production. This market segment has gained significant traction in recent years due to its flexibility, convenience, and cost-effectiveness. Mobile concrete mixers are specifically designed to provide a portable and efficient solution for concrete mixing and delivery, eliminating the need for traditional stationary mixers.

Meaning

A mobile concrete mixer is a self-contained unit that combines cement, sand, water, and aggregates to produce concrete on-site. It is equipped with a mixing drum, which rotates to ensure proper blending of the ingredients. These mixers are mounted on trucks, trailers, or skids, enabling easy transportation to various construction sites. The mobility factor allows contractors to save time and resources by producing concrete where it is needed, reducing the dependency on batch plants.

Executive Summary

The mobile concrete mixer market has experienced significant growth in recent years, driven by the rising demand for efficient and cost-effective concrete production solutions. The market is characterized by intense competition, with several key players striving to innovate and provide technologically advanced mobile concrete mixers. Factors such as urbanization, infrastructure development, and the need for on-site concrete production are fueling the market’s growth.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

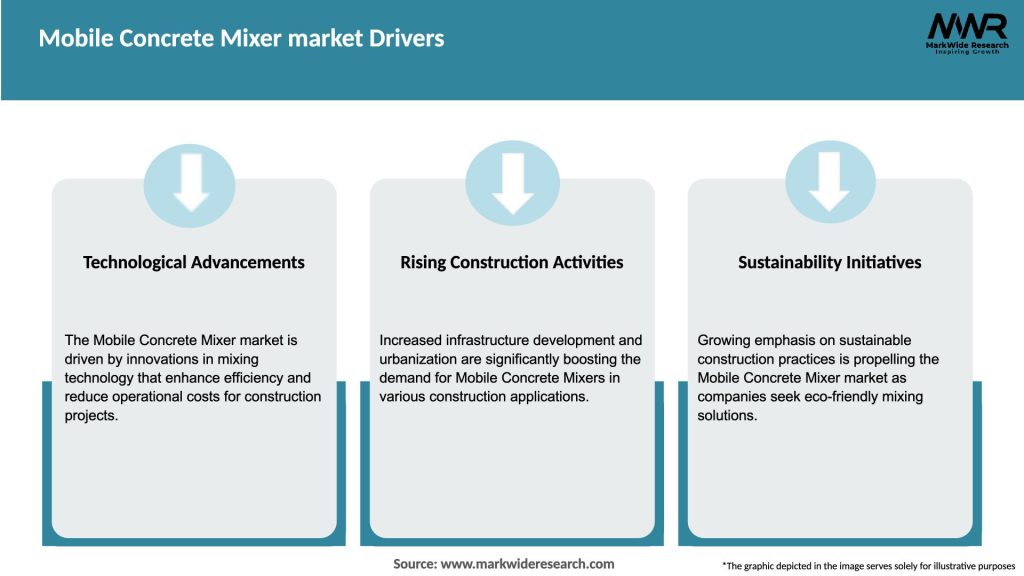

The mobile concrete mixer market is propelled by several key drivers:

Market Restraints

While the mobile concrete mixer market showcases substantial growth potential, it also faces certain challenges:

Market Opportunities

The mobile concrete mixer market presents several opportunities for growth and expansion:

Market Dynamics

The mobile concrete mixer market is driven by a combination of factors, including the demand for on-site concrete production, technological advancements, and the growth of the construction industry. The market is highly competitive, with key players striving to gain a larger market share through product innovations, mergers and acquisitions, and strategic collaborations. Additionally, stringent regulations related to emissions and environmental impact are influencing manufacturers to develop more sustainable and energy-efficient mobile concrete mixers.

Regional Analysis

The mobile concrete mixer market exhibits regional variations based on construction activity, infrastructure development, and economic factors. Some key regional insights include:

Competitive Landscape

Leading Companies in the Mobile Concrete Mixer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The mobile concrete mixer market can be segmented based on various factors, including:

Segmenting the market allows manufacturers and industry participants to target specific customer segments, cater to their unique requirements, and devise appropriate marketing strategies.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the construction industry and, consequently, the mobile concrete mixer market. The initial lockdowns and restrictions disrupted construction activities, leading to project delays and cancellations. However, as the industry gradually recovered, the demand for mobile concrete mixers increased.

The pandemic highlighted the importance of on-site concrete production and the need for flexible solutions. Mobile concrete mixers gained prominence as they allowed construction projects to continue with reduced reliance on external suppliers and batch plants. The market witnessed increased adoption of mobile mixers for smaller projects and those with limited access to traditional concrete supply chains.

Furthermore, the focus on hygiene and safety protocols during the pandemic accelerated the demand for mobile mixers. Contractors preferred on-site production to ensure the quality and cleanliness of concrete, reducing the risk of contamination and ensuring compliance with health guidelines.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the mobile concrete mixer market looks promising, driven by the construction industry’s growth, the demand for on-site concrete production, and the focus on sustainable construction practices. The market is expected to witness continued technological advancements, including automation, digitalization, and integration with telematics. Electric-powered mobile concrete mixers are likely to gain traction as environmental regulations become stricter.

Emerging markets in Asia Pacific, Latin America, and Africa are expected to offer significant growth opportunities due to rapid urbanization and infrastructure development. Rental services for mobile concrete mixers are also expected to grow in popularity, providing a cost-effective solution for contractors with intermittent equipment needs.

Overall, the mobile concrete mixer market is poised for steady growth, driven by the need for efficient, flexible, and sustainable concrete production solutions in the construction industry.

Conclusion

The mobile concrete mixer market is witnessing robust growth, driven by the demand for on-site concrete production, cost-effectiveness, and flexibility. Mobile mixers offer several advantages, including increased efficiency, cost savings, and time efficiency. However, the market also faces challenges such as initial investment costs, maintenance requirements, andlimited mixing capacity for large-scale projects.

To stay competitive, manufacturers need to focus on technological advancements, customization options, and safety features. They should also explore opportunities in emerging markets, emphasize sustainability, and provide excellent customer support. The Covid-19 pandemic highlighted the importance of mobile concrete mixers for on-site production and hygiene considerations.

What is Mobile Concrete Mixer?

A Mobile Concrete Mixer is a type of equipment used for mixing concrete on-site, allowing for the production of fresh concrete as needed. These mixers are designed for mobility, enabling them to be transported easily to various construction locations.

What are the key players in the Mobile Concrete Mixer market?

Key players in the Mobile Concrete Mixer market include companies like Cemen Tech, Terex Corporation, and Liebherr Group, which are known for their innovative mixing solutions and robust product offerings in the construction industry, among others.

What are the growth factors driving the Mobile Concrete Mixer market?

The Mobile Concrete Mixer market is driven by the increasing demand for on-site concrete production, the growth of the construction industry, and the need for efficient and flexible mixing solutions. Additionally, the rise in infrastructure projects globally contributes to market expansion.

What challenges does the Mobile Concrete Mixer market face?

Challenges in the Mobile Concrete Mixer market include the high initial investment costs and the need for skilled operators to ensure proper mixing and operation. Furthermore, fluctuating raw material prices can impact production costs.

What opportunities exist in the Mobile Concrete Mixer market?

Opportunities in the Mobile Concrete Mixer market include advancements in technology, such as automation and IoT integration, which can enhance operational efficiency. Additionally, the growing trend towards sustainable construction practices presents new avenues for innovation.

What trends are shaping the Mobile Concrete Mixer market?

Trends in the Mobile Concrete Mixer market include the increasing adoption of electric and hybrid models to reduce emissions, as well as the integration of smart technology for real-time monitoring and control. These innovations are aimed at improving efficiency and sustainability in construction projects.

Mobile Concrete Mixer market

| Segmentation Details | Description |

|---|---|

| Product Type | Stationary Mixers, Portable Mixers, Towable Mixers, Volumetric Mixers |

| End User | Construction Companies, Ready-Mix Suppliers, Contractors, DIY Enthusiasts |

| Technology | Hydraulic, Electric, Diesel, Hybrid |

| Capacity | Small (1-3 cu yd), Medium (3-6 cu yd), Large (6-10 cu yd), Extra Large (10+ cu yd) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Mobile Concrete Mixer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at