444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The Middle East and Africa pharmaceutical plastic packaging market represents a rapidly expanding sector driven by increasing healthcare demands, growing pharmaceutical manufacturing capabilities, and rising awareness of medication safety across the region. This dynamic market encompasses various plastic packaging solutions including bottles, vials, blister packs, pouches, and specialized containers designed to protect pharmaceutical products throughout their lifecycle.

Regional pharmaceutical industries are experiencing unprecedented growth, with countries like South Africa, UAE, Saudi Arabia, and Egypt leading the transformation. The market demonstrates robust expansion patterns, with growth rates reaching 8.2% CAGR across key segments. Healthcare infrastructure development and increasing local pharmaceutical production are primary catalysts driving demand for advanced plastic packaging solutions.

Market dynamics reveal significant opportunities in both established and emerging markets within the region. The pharmaceutical plastic packaging sector benefits from favorable regulatory environments, increasing foreign direct investment in healthcare, and growing consumer awareness regarding medication quality and safety. Sustainability initiatives are also reshaping packaging preferences, with 65% of manufacturers exploring eco-friendly plastic alternatives.

Innovation trends include smart packaging technologies, child-resistant closures, tamper-evident features, and specialized barrier properties for sensitive medications. The market serves diverse pharmaceutical categories including generic drugs, branded medications, biologics, and over-the-counter products, each requiring specific packaging characteristics to ensure product integrity and patient safety.

The Middle East and Africa pharmaceutical plastic packaging market refers to the comprehensive ecosystem of plastic-based packaging solutions specifically designed, manufactured, and utilized for pharmaceutical products across the MEA region. This market encompasses primary packaging that directly contacts medications, secondary packaging for protection and branding, and tertiary packaging for distribution and logistics.

Pharmaceutical plastic packaging includes various container types such as bottles for tablets and capsules, vials for injectable medications, blister packs for unit-dose presentations, pouches for powders and granules, and specialized containers for biologics and temperature-sensitive drugs. These packaging solutions must comply with stringent regulatory requirements while providing optimal protection against environmental factors including moisture, light, oxygen, and contamination.

Market scope extends beyond traditional packaging to include innovative solutions like smart packaging with embedded sensors, child-resistant designs for safety compliance, and sustainable materials addressing environmental concerns. The sector serves pharmaceutical manufacturers, contract packaging organizations, healthcare providers, and ultimately patients across diverse therapeutic areas including cardiovascular, diabetes, oncology, and infectious diseases.

Strategic market positioning reveals the Middle East and Africa pharmaceutical plastic packaging market as a high-growth sector benefiting from expanding healthcare access, increasing pharmaceutical manufacturing, and evolving regulatory frameworks. The market demonstrates strong fundamentals with pharmaceutical production growth reaching 12.5% annually in key regional markets, directly driving packaging demand.

Key growth drivers include rising chronic disease prevalence, expanding generic drug manufacturing, increasing healthcare expenditure, and growing pharmaceutical exports from regional production hubs. The market benefits from favorable demographics with young populations requiring diverse medication categories and aging populations driving demand for chronic disease treatments.

Technology adoption accelerates across the region, with manufacturers implementing advanced packaging technologies including barrier coatings, moisture control systems, and serialization capabilities for supply chain security. Sustainability trends influence material selection, with 45% of packaging companies investing in recyclable and bio-based plastic alternatives.

Competitive landscape features both international packaging giants and regional specialists, creating dynamic market conditions that foster innovation and competitive pricing. Market consolidation trends indicate strategic partnerships between pharmaceutical manufacturers and packaging suppliers to optimize supply chain efficiency and ensure regulatory compliance across diverse market requirements.

Market intelligence reveals several critical insights shaping the Middle East and Africa pharmaceutical plastic packaging landscape:

According to MarkWide Research analysis, these insights collectively indicate a market transformation toward more sophisticated, sustainable, and technology-enabled packaging solutions that meet evolving pharmaceutical industry requirements while addressing regional market characteristics and consumer preferences.

Healthcare infrastructure development serves as a primary market driver, with governments across the Middle East and Africa investing substantially in healthcare facilities, pharmaceutical manufacturing capabilities, and medical supply chains. These investments create sustained demand for pharmaceutical products and corresponding packaging solutions.

Population demographics strongly favor market growth, with young populations requiring preventive medications and vaccines, while aging demographics drive demand for chronic disease treatments. The region’s population growth rate of 2.1% annually ensures expanding pharmaceutical consumption and packaging requirements.

Regulatory modernization accelerates market development through improved quality standards, streamlined approval processes, and enhanced intellectual property protection. These regulatory improvements attract international pharmaceutical investments and encourage local manufacturing expansion, directly benefiting the packaging sector.

Economic diversification initiatives across oil-dependent economies prioritize healthcare and pharmaceutical manufacturing as strategic sectors. Government support through incentives, infrastructure development, and regulatory frameworks creates favorable conditions for pharmaceutical plastic packaging market growth.

Disease burden evolution drives pharmaceutical demand, with increasing prevalence of diabetes, cardiovascular diseases, and cancer requiring specialized medications and corresponding packaging solutions. Chronic disease prevalence affects 28% of the regional population, creating sustained pharmaceutical packaging demand.

Technology accessibility improvements enable advanced packaging solutions including smart packaging, serialization, and anti-counterfeiting measures. These technological capabilities enhance medication safety and supply chain security while creating new market opportunities for innovative packaging providers.

Economic volatility presents significant challenges for the pharmaceutical plastic packaging market, with currency fluctuations, oil price dependencies, and political instabilities affecting investment decisions and market stability. These factors can delay pharmaceutical projects and reduce packaging demand in affected regions.

Regulatory complexity across diverse markets creates compliance challenges for packaging manufacturers serving multiple countries. Varying standards, approval processes, and quality requirements increase operational costs and complexity, particularly for smaller packaging companies lacking regulatory expertise.

Infrastructure limitations in certain regions constrain market development, with inadequate transportation networks, unreliable power supply, and limited cold chain capabilities affecting pharmaceutical distribution and packaging requirements. These infrastructure gaps limit market accessibility and growth potential.

Raw material dependencies expose the market to supply chain vulnerabilities, with most plastic resins imported from international suppliers. Price volatility and supply disruptions can significantly impact packaging costs and availability, affecting pharmaceutical manufacturers’ operations.

Skilled workforce shortages limit market development, particularly in specialized areas like pharmaceutical packaging design, regulatory compliance, and quality assurance. The shortage of qualified professionals constrains industry growth and innovation capabilities across the region.

Environmental concerns regarding plastic packaging create regulatory pressures and consumer resistance, requiring investments in sustainable alternatives and waste management systems. These environmental considerations increase operational costs and complexity for packaging manufacturers while driving innovation requirements.

Pharmaceutical manufacturing expansion creates substantial opportunities for packaging suppliers, with several countries developing pharmaceutical hubs to serve regional and international markets. These manufacturing investments require comprehensive packaging solutions and long-term supplier partnerships.

Generic drug production offers significant growth potential, with patent expirations creating opportunities for local manufacturers to produce cost-effective alternatives. Generic drug packaging requires efficient, affordable solutions that maintain quality standards while optimizing costs.

Biologics and biosimilars represent emerging opportunities requiring specialized packaging with enhanced barrier properties, temperature control, and contamination prevention. The growing biologics market demands innovative packaging solutions that protect sensitive medications throughout the supply chain.

E-commerce pharmaceutical sales create new packaging requirements optimized for direct-to-consumer delivery, including tamper-evident features, patient information integration, and shipping durability. Online pharmaceutical sales are growing at 18% annually across major regional markets.

Sustainability initiatives drive demand for eco-friendly packaging alternatives, creating opportunities for companies developing recyclable, biodegradable, or bio-based plastic solutions. Environmental consciousness among consumers and regulators creates market demand for sustainable packaging innovations.

Technology integration opportunities include smart packaging with embedded sensors, NFC chips for authentication, and IoT connectivity for supply chain monitoring. These advanced packaging solutions command premium pricing while providing enhanced value to pharmaceutical manufacturers and patients.

Supply chain evolution significantly influences market dynamics, with pharmaceutical companies optimizing packaging supplier relationships to ensure quality, reliability, and cost-effectiveness. Strategic partnerships between pharmaceutical manufacturers and packaging suppliers create stable demand patterns while fostering innovation and customization.

Competitive pressures drive continuous improvement in packaging solutions, with suppliers investing in advanced technologies, quality systems, and customer service capabilities. Market competition benefits pharmaceutical manufacturers through improved packaging options, competitive pricing, and enhanced service levels.

Regulatory dynamics shape market development through evolving standards, compliance requirements, and quality expectations. Regulatory harmonization across the region facilitates market access while increasing quality standards, benefiting established packaging suppliers with strong compliance capabilities.

Innovation cycles accelerate market transformation, with new materials, technologies, and design concepts regularly entering the market. Packaging innovation adoption rates reach 22% annually among leading pharmaceutical manufacturers, driving demand for advanced packaging solutions.

Customer relationship dynamics emphasize long-term partnerships, technical support, and collaborative development programs. Pharmaceutical manufacturers increasingly seek packaging suppliers capable of providing comprehensive solutions including design, regulatory support, and supply chain management.

Market consolidation trends create opportunities for strategic acquisitions, partnerships, and market expansion. Larger packaging companies acquire regional specialists to expand market coverage while smaller companies seek partnerships to access advanced technologies and regulatory expertise.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable market insights. Primary research includes extensive interviews with pharmaceutical manufacturers, packaging suppliers, regulatory officials, and industry experts across key markets in the Middle East and Africa region.

Secondary research encompasses analysis of industry reports, regulatory documents, company financial statements, trade publications, and academic studies. This comprehensive approach ensures thorough coverage of market dynamics, competitive landscapes, and emerging trends affecting the pharmaceutical plastic packaging sector.

Data validation processes include cross-referencing multiple sources, expert consultations, and statistical analysis to ensure accuracy and reliability. Market sizing methodologies employ bottom-up and top-down approaches, incorporating pharmaceutical production data, packaging consumption patterns, and regional market characteristics.

Regional market analysis covers major markets including Saudi Arabia, UAE, South Africa, Egypt, Nigeria, Kenya, and other significant pharmaceutical markets. Country-specific analysis considers local regulations, market conditions, competitive landscapes, and growth opportunities.

Industry expert consultations provide qualitative insights into market trends, challenges, and opportunities. Expert interviews include pharmaceutical executives, packaging engineers, regulatory specialists, and industry association representatives to ensure comprehensive market understanding.

Quantitative analysis incorporates statistical modeling, trend analysis, and forecasting methodologies to project market development patterns. Data analysis considers historical trends, current market conditions, and future growth drivers to provide accurate market projections and strategic insights.

Saudi Arabia leads the regional pharmaceutical plastic packaging market with advanced healthcare infrastructure, substantial pharmaceutical investments, and strong regulatory frameworks. The kingdom’s Vision 2030 initiative prioritizes healthcare sector development, creating sustained demand for pharmaceutical packaging solutions with local pharmaceutical production growing at 15% annually.

United Arab Emirates serves as a regional pharmaceutical hub with Dubai and Abu Dhabi hosting major pharmaceutical manufacturing and distribution facilities. The UAE’s strategic location, advanced logistics infrastructure, and business-friendly environment attract international pharmaceutical companies requiring sophisticated packaging solutions.

South Africa represents the largest pharmaceutical market in sub-Saharan Africa, with established manufacturing capabilities and growing generic drug production. The country’s pharmaceutical industry benefits from skilled workforce, regulatory expertise, and established supply chains, driving demand for diverse packaging solutions.

Egypt demonstrates significant market potential with large population, expanding healthcare access, and growing pharmaceutical manufacturing sector. Government initiatives supporting local pharmaceutical production create opportunities for packaging suppliers while addressing domestic healthcare needs.

Nigeria offers substantial growth opportunities driven by large population, increasing healthcare investments, and expanding pharmaceutical manufacturing. The market benefits from government policies encouraging local production and reducing import dependencies, creating demand for packaging solutions.

Other regional markets including Kenya, Morocco, Algeria, and Qatar contribute to overall market growth through expanding healthcare systems, increasing pharmaceutical consumption, and developing manufacturing capabilities. These markets collectively represent 25% of regional packaging demand.

Market leadership features a combination of international packaging giants and regional specialists, creating dynamic competitive conditions that drive innovation and market development. Leading companies demonstrate strong technical capabilities, regulatory expertise, and comprehensive service offerings.

Competitive strategies emphasize technological innovation, regulatory compliance, customer service excellence, and strategic partnerships. Companies invest in advanced manufacturing capabilities, quality systems, and regional presence to serve diverse pharmaceutical packaging requirements effectively.

Market positioning varies from premium technology providers offering advanced packaging solutions to cost-effective suppliers serving generic drug manufacturers. This competitive diversity ensures comprehensive market coverage while fostering innovation and competitive pricing across different market segments.

By Product Type:

By Material Type:

By Application:

Solid Dosage Packaging dominates the market with 55% market share, driven by high consumption of tablets and capsules across therapeutic categories. This segment benefits from standardized packaging formats, established manufacturing processes, and cost-effective production methods that support both branded and generic pharmaceutical products.

Injectable Packaging represents the fastest-growing segment with increasing biologics adoption, vaccine programs, and chronic disease treatments requiring parenteral administration. This category demands specialized packaging with enhanced barrier properties, sterility maintenance, and chemical compatibility for sensitive medications.

Liquid Medication Packaging serves diverse pharmaceutical applications including pediatric formulations, geriatric medications, and specialty drugs requiring liquid delivery. This segment emphasizes leak prevention, chemical resistance, and accurate dosing capabilities while maintaining product stability throughout shelf life.

Specialty Packaging addresses niche applications including controlled-release medications, combination products, and personalized medicines. This category commands premium pricing while requiring advanced materials, specialized manufacturing processes, and regulatory expertise to meet unique pharmaceutical requirements.

Generic Drug Packaging focuses on cost optimization while maintaining quality standards and regulatory compliance. This segment drives volume growth through efficient packaging designs, standardized formats, and competitive pricing that supports affordable healthcare access across the region.

Biologics Packaging emerges as a high-value segment requiring sophisticated packaging solutions with enhanced barrier properties, temperature stability, and contamination prevention. This category represents significant growth opportunities as biologics adoption accelerates across therapeutic areas.

Pharmaceutical Manufacturers benefit from comprehensive packaging solutions that ensure product integrity, regulatory compliance, and market differentiation. Advanced packaging technologies provide enhanced product protection, improved patient compliance, and supply chain security while supporting brand positioning and market access strategies.

Packaging Suppliers gain access to expanding market opportunities driven by pharmaceutical industry growth, technological advancement, and increasing quality requirements. The market offers stable demand patterns, long-term customer relationships, and premium pricing for innovative packaging solutions that address evolving pharmaceutical needs.

Healthcare Providers benefit from improved medication safety, enhanced patient compliance, and reduced medication errors through advanced packaging features. Smart packaging technologies provide valuable information for patient monitoring, inventory management, and clinical decision-making while supporting healthcare quality initiatives.

Patients and Consumers receive enhanced medication safety through tamper-evident packaging, improved dosing accuracy, and better product information. Advanced packaging features support medication adherence, reduce administration errors, and provide confidence in product authenticity and quality.

Regulatory Authorities benefit from improved pharmaceutical supply chain security, enhanced traceability, and reduced counterfeit medications through advanced packaging technologies. Serialization and authentication features support regulatory oversight while protecting public health and safety.

Investors and Financial Stakeholders gain exposure to a growing market with stable demand drivers, technological innovation opportunities, and expanding regional pharmaceutical industries. The market offers attractive investment prospects through established companies and emerging technology providers serving pharmaceutical packaging needs.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability Integration emerges as a dominant trend with pharmaceutical companies and packaging suppliers investing in recyclable materials, reduced packaging waste, and circular economy principles. Sustainable packaging adoption reaches 40% among leading pharmaceutical brands, driving innovation in bio-based plastics and recyclable designs.

Smart Packaging Technologies gain momentum through embedded sensors, NFC chips, and IoT connectivity that provide real-time information about medication conditions, authenticity, and patient compliance. These technologies enhance supply chain visibility while supporting personalized healthcare initiatives and medication management programs.

Serialization and Traceability become standard requirements across the region, with pharmaceutical manufacturers implementing track-and-trace capabilities to combat counterfeiting and ensure supply chain security. These systems require specialized packaging features and integration with digital platforms for comprehensive product monitoring.

Personalized Medicine Packaging addresses growing demand for customized medications and patient-specific dosing requirements. This trend drives innovation in small-batch packaging, variable printing technologies, and flexible packaging formats that support personalized healthcare delivery.

Cold Chain Optimization becomes critical for biologics and temperature-sensitive medications, requiring advanced packaging with enhanced thermal protection, temperature monitoring, and cold chain integrity maintenance throughout distribution networks.

Patient-Centric Design emphasizes packaging features that improve medication adherence, reduce administration errors, and enhance patient experience. These designs include easy-open closures, clear dosing instructions, and accessibility features for elderly and disabled patients.

Manufacturing Capacity Expansion accelerates across the region with major pharmaceutical companies establishing production facilities and packaging suppliers investing in regional manufacturing capabilities. These investments reduce supply chain dependencies while supporting local pharmaceutical industry development.

Regulatory Harmonization Initiatives progress through regional cooperation agreements and alignment with international standards. These developments facilitate pharmaceutical trade, reduce compliance costs, and improve market access for packaging suppliers serving multiple countries.

Technology Transfer Programs bring advanced packaging technologies to regional markets through partnerships between international suppliers and local manufacturers. These programs enhance local capabilities while providing cost-effective access to sophisticated packaging solutions.

Sustainability Commitments drive industry transformation with major pharmaceutical companies setting ambitious environmental goals and packaging suppliers developing eco-friendly alternatives. MWR data indicates that 70% of pharmaceutical manufacturers have established sustainability targets for packaging materials.

Digital Integration Projects connect packaging systems with digital health platforms, enabling comprehensive medication management and patient monitoring capabilities. These projects represent significant investments in technology infrastructure and data management systems.

Strategic Partnerships between pharmaceutical manufacturers and packaging suppliers create integrated supply chain solutions that optimize costs, improve quality, and enhance service levels. These partnerships often include long-term agreements and collaborative development programs.

Investment Prioritization should focus on sustainable packaging technologies, smart packaging capabilities, and regional manufacturing capacity to capitalize on market growth opportunities. Companies should balance innovation investments with operational efficiency improvements to maintain competitive positioning.

Market Entry Strategies for new participants should emphasize regulatory expertise, local partnerships, and specialized capabilities that address unmet market needs. Successful market entry requires understanding of regional requirements, customer preferences, and competitive dynamics.

Technology Adoption recommendations include gradual implementation of smart packaging features, serialization capabilities, and sustainability initiatives that align with customer requirements and regulatory trends. Companies should prioritize technologies that provide clear value propositions and competitive advantages.

Partnership Development strategies should focus on long-term relationships with pharmaceutical manufacturers, technology providers, and regulatory consultants. Strategic partnerships can provide market access, technical expertise, and risk mitigation while supporting sustainable growth.

Risk Management approaches should address supply chain vulnerabilities, regulatory changes, and economic volatility through diversification strategies, contingency planning, and flexible operational capabilities. Companies should maintain adaptability while ensuring consistent quality and service levels.

Innovation Focus should align with market trends including sustainability, digitalization, and patient-centricity while maintaining cost-effectiveness and regulatory compliance. Innovation investments should address both current market needs and future growth opportunities.

Market trajectory indicates sustained growth driven by expanding pharmaceutical industries, increasing healthcare access, and evolving patient needs across the Middle East and Africa region. The market is expected to maintain robust growth rates with pharmaceutical packaging demand increasing at 9.5% CAGR over the forecast period.

Technology evolution will continue transforming the market through smart packaging adoption, sustainability innovations, and digital integration capabilities. These technological advances will create new market segments while enhancing value propositions for pharmaceutical manufacturers and patients.

Regulatory development will drive quality improvements, standardization, and international alignment that facilitate market growth and pharmaceutical trade. Regulatory harmonization will reduce compliance costs while improving market access for packaging suppliers and pharmaceutical manufacturers.

Sustainability transformation will reshape material selection, packaging design, and waste management practices throughout the industry. Environmental considerations will become increasingly important in purchasing decisions and regulatory requirements, driving innovation in eco-friendly packaging solutions.

Market consolidation trends will continue through strategic acquisitions, partnerships, and capacity expansion initiatives. Larger companies will acquire specialized capabilities while smaller companies will seek partnerships to access advanced technologies and market opportunities.

Regional integration will enhance market connectivity through improved trade agreements, infrastructure development, and regulatory cooperation. These developments will create larger addressable markets while reducing operational complexity for packaging suppliers serving multiple countries.

The Middle East and Africa pharmaceutical plastic packaging market represents a dynamic and rapidly expanding sector with substantial growth opportunities driven by increasing healthcare demands, expanding pharmaceutical manufacturing, and evolving regulatory frameworks. Market fundamentals remain strong with sustained pharmaceutical industry growth, technological advancement, and favorable demographic trends supporting long-term market expansion.

Strategic market positioning reveals significant opportunities for packaging suppliers that can provide comprehensive solutions addressing quality, sustainability, and innovation requirements. The market rewards companies with strong regulatory expertise, technological capabilities, and customer service excellence while maintaining competitive pricing and operational efficiency.

Future market development will be shaped by sustainability initiatives, technology integration, and regulatory harmonization that create new opportunities while transforming traditional packaging approaches. Companies that successfully adapt to these trends while maintaining operational excellence will capture disproportionate market share and value creation opportunities.

The pharmaceutical plastic packaging market in the Middle East and Africa region offers compelling investment prospects for stakeholders across the value chain, from raw material suppliers to end-user pharmaceutical manufacturers. Market success requires strategic focus on innovation, sustainability, and customer partnership while maintaining the operational capabilities necessary to serve this demanding and rapidly evolving market effectively.

What is Pharmaceutical Plastic Packaging?

Pharmaceutical Plastic Packaging refers to the use of plastic materials for packaging pharmaceutical products, ensuring their safety, integrity, and efficacy. This includes various forms such as bottles, blisters, and pouches designed to protect medications from environmental factors.

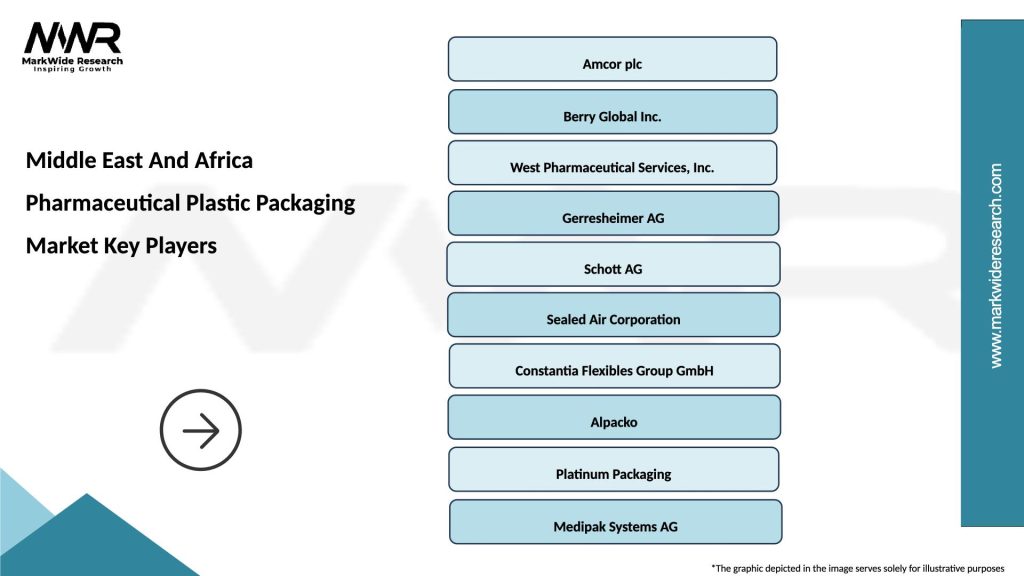

What are the key players in the Middle East And Africa Pharmaceutical Plastic Packaging Market?

Key players in the Middle East And Africa Pharmaceutical Plastic Packaging Market include Amcor, West Pharmaceutical Services, and Berry Global, among others. These companies are known for their innovative packaging solutions and commitment to quality.

What are the growth factors driving the Middle East And Africa Pharmaceutical Plastic Packaging Market?

The growth of the Middle East And Africa Pharmaceutical Plastic Packaging Market is driven by increasing healthcare expenditures, a rise in chronic diseases, and the demand for advanced packaging solutions that enhance drug safety and shelf life.

What challenges does the Middle East And Africa Pharmaceutical Plastic Packaging Market face?

Challenges in the Middle East And Africa Pharmaceutical Plastic Packaging Market include regulatory compliance issues, the high cost of advanced materials, and competition from alternative packaging solutions such as glass and metal.

What opportunities exist in the Middle East And Africa Pharmaceutical Plastic Packaging Market?

Opportunities in the Middle East And Africa Pharmaceutical Plastic Packaging Market include the growing trend towards sustainable packaging solutions, advancements in smart packaging technologies, and the increasing demand for personalized medicine packaging.

What trends are shaping the Middle East And Africa Pharmaceutical Plastic Packaging Market?

Trends in the Middle East And Africa Pharmaceutical Plastic Packaging Market include the shift towards eco-friendly materials, the integration of digital technologies for tracking and authentication, and the development of child-resistant and senior-friendly packaging designs.

Middle East And Africa Pharmaceutical Plastic Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Blisters, Pouches, Jars |

| Material | Polyethylene, Polypropylene, PVC, PET |

| End User | Pharmaceutical Companies, Contract Manufacturers, Research Institutions, Distributors |

| Packaging Type | Primary Packaging, Secondary Packaging, Tertiary Packaging, Labels |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Middle East And Africa Pharmaceutical Plastic Packaging Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at