444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The Middle East and Africa pharmaceutical packaging market represents a dynamic and rapidly expanding sector driven by increasing healthcare demands, growing pharmaceutical manufacturing capabilities, and rising awareness of medication safety. This region encompasses diverse economies ranging from oil-rich Gulf states to emerging African markets, each contributing unique growth drivers to the pharmaceutical packaging landscape.

Market dynamics in the Middle East and Africa are characterized by substantial investments in healthcare infrastructure, expanding pharmaceutical manufacturing facilities, and increasing regulatory compliance requirements. The region experiences a compound annual growth rate (CAGR) of 8.2%, significantly outpacing global averages due to demographic shifts, urbanization trends, and improving healthcare accessibility.

Regional diversity plays a crucial role in market development, with the Gulf Cooperation Council (GCC) countries leading in advanced packaging technologies while African markets focus on essential medication packaging and accessibility solutions. The pharmaceutical packaging sector benefits from increasing local production capabilities, reducing dependency on imports and creating opportunities for specialized packaging solutions.

Technological advancement drives innovation across the region, with smart packaging, serialization technologies, and sustainable packaging materials gaining significant traction. The market demonstrates strong potential for growth as governments prioritize healthcare sector development and pharmaceutical companies establish regional manufacturing hubs to serve both local and export markets.

The Middle East and Africa pharmaceutical packaging market refers to the comprehensive ecosystem of packaging materials, technologies, and services specifically designed for pharmaceutical products across the MEA region. This market encompasses primary packaging solutions that directly contact medications, secondary packaging for protection and branding, and tertiary packaging for distribution and logistics.

Pharmaceutical packaging in this context includes various materials such as blister packs, bottles, vials, ampoules, prefilled syringes, and specialized containers designed to maintain drug efficacy, ensure patient safety, and comply with regulatory requirements. The market serves diverse pharmaceutical segments including prescription medications, over-the-counter drugs, biologics, and medical devices.

Regional characteristics define the market scope, addressing unique challenges such as extreme climate conditions, diverse regulatory frameworks, varying healthcare infrastructure levels, and different economic development stages across Middle Eastern and African countries. The market focuses on solutions that ensure medication stability, prevent counterfeiting, and enhance patient compliance while meeting international quality standards.

Strategic positioning of the Middle East and Africa pharmaceutical packaging market reflects significant growth opportunities driven by expanding healthcare sectors, increasing pharmaceutical manufacturing investments, and rising demand for advanced packaging solutions. The region demonstrates remarkable potential with pharmaceutical packaging adoption rates increasing by 12.5% annually across key markets.

Market segmentation reveals diverse opportunities across material types, with plastic packaging commanding the largest market share, followed by glass and metal packaging solutions. Primary packaging applications dominate the market, accounting for approximately 65% of total demand, while secondary and tertiary packaging segments show strong growth potential.

Competitive landscape features a mix of international packaging giants and regional specialists, with companies focusing on technological innovation, regulatory compliance, and sustainable packaging solutions. The market benefits from increasing foreign direct investment in pharmaceutical manufacturing facilities and growing emphasis on local production capabilities.

Future prospects indicate sustained growth driven by demographic trends, healthcare infrastructure development, and increasing pharmaceutical consumption. The market is expected to benefit from digital transformation initiatives, smart packaging adoption, and enhanced supply chain efficiency across the region.

Market intelligence reveals several critical insights shaping the Middle East and Africa pharmaceutical packaging landscape:

Demographic transformation serves as a primary market driver, with the region experiencing significant population growth, aging demographics, and increasing prevalence of chronic diseases requiring long-term medication management. These demographic shifts create sustained demand for diverse pharmaceutical packaging solutions tailored to different patient populations and medication types.

Healthcare infrastructure development accelerates market growth through government investments in hospitals, clinics, and healthcare facilities across the region. Major infrastructure projects, particularly in Gulf countries and emerging African markets, create substantial demand for pharmaceutical packaging solutions to support expanding healthcare services and medication distribution networks.

Pharmaceutical manufacturing expansion drives packaging demand as companies establish regional production facilities to serve local markets and export opportunities. The trend toward pharmaceutical localization, supported by government incentives and regulatory frameworks, creates significant opportunities for packaging suppliers and technology providers.

Regulatory compliance requirements increasingly drive demand for advanced packaging solutions that meet international standards for drug safety, traceability, and quality assurance. Harmonization with global regulatory frameworks necessitates sophisticated packaging technologies and materials that ensure medication integrity throughout the supply chain.

Digital health initiatives promote smart packaging adoption, with governments and healthcare providers implementing digital solutions for medication management, patient compliance monitoring, and supply chain visibility. These initiatives create opportunities for innovative packaging technologies that integrate digital capabilities with traditional protective functions.

Economic volatility across the region creates challenges for pharmaceutical packaging market growth, with currency fluctuations, oil price dependencies, and varying economic development levels affecting investment decisions and market expansion strategies. Economic uncertainties can delay infrastructure projects and reduce healthcare spending in some markets.

Regulatory complexity presents significant challenges as pharmaceutical packaging companies navigate diverse regulatory frameworks across different countries within the region. Varying standards, approval processes, and compliance requirements increase operational complexity and market entry barriers for packaging suppliers.

Infrastructure limitations in certain markets constrain packaging distribution and supply chain efficiency, particularly in remote areas and developing economies. Limited transportation networks, storage facilities, and cold chain capabilities affect the deployment of advanced packaging solutions and market penetration strategies.

Skilled workforce shortage impacts market development as the pharmaceutical packaging industry requires specialized technical expertise for advanced packaging technologies, quality control, and regulatory compliance. Limited availability of trained professionals constrains industry growth and technology adoption rates.

Import dependencies for specialized packaging materials and technologies create supply chain vulnerabilities and cost pressures, particularly during global disruptions or trade restrictions. Heavy reliance on imported packaging components affects market stability and pricing dynamics across the region.

Pharmaceutical localization initiatives create substantial opportunities for packaging suppliers as governments promote domestic pharmaceutical manufacturing through incentives, regulatory support, and infrastructure development. These initiatives drive demand for comprehensive packaging solutions and technology transfer partnerships that support local industry development.

Sustainable packaging innovation presents significant market opportunities as environmental consciousness increases across the region. Companies developing biodegradable materials, recyclable packaging solutions, and reduced-waste technologies can capture growing demand from environmentally conscious pharmaceutical manufacturers and healthcare providers.

Digital transformation offers extensive opportunities for smart packaging solutions that integrate IoT technologies, blockchain verification, and digital authentication systems. The growing emphasis on supply chain transparency and patient safety creates demand for innovative packaging technologies that provide real-time monitoring and verification capabilities.

Biologics and specialty pharmaceuticals represent high-growth opportunities requiring specialized packaging solutions for temperature-sensitive medications, complex delivery systems, and personalized medicine applications. The expanding biologics market creates demand for advanced packaging technologies that ensure product stability and efficacy.

Export market development provides opportunities for regional pharmaceutical manufacturers to serve international markets, driving demand for packaging solutions that meet global regulatory standards and facilitate international trade. Strategic positioning as a regional pharmaceutical hub creates packaging supply chain opportunities.

Supply chain evolution transforms market dynamics as pharmaceutical companies optimize distribution networks, implement advanced logistics technologies, and enhance supply chain visibility. These changes drive demand for packaging solutions that support efficient distribution, reduce handling costs, and improve inventory management across diverse regional markets.

Technology convergence creates dynamic market conditions as traditional packaging solutions integrate with digital technologies, creating hybrid solutions that combine physical protection with digital capabilities. This convergence enables new business models, service offerings, and value propositions for packaging suppliers and pharmaceutical companies.

Competitive intensity increases as international packaging companies establish regional presence while local suppliers enhance capabilities through technology partnerships and capacity expansion. Market dynamics reflect increasing competition across price points, technology offerings, and service capabilities.

Customer expectations evolve toward comprehensive packaging solutions that address multiple requirements including product protection, regulatory compliance, sustainability, and digital integration. These changing expectations drive innovation and differentiation strategies among packaging suppliers serving the pharmaceutical industry.

Regulatory evolution continuously shapes market dynamics as authorities update standards, implement new requirements, and harmonize regulations with international frameworks. According to MarkWide Research analysis, regulatory compliance costs account for approximately 15% of total packaging expenses across the region, influencing supplier selection and technology adoption decisions.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable insights into the Middle East and Africa pharmaceutical packaging market. The research approach combines quantitative data analysis with qualitative insights from industry experts, regulatory authorities, and market participants across the region.

Primary research activities include structured interviews with pharmaceutical packaging manufacturers, pharmaceutical companies, regulatory officials, and healthcare providers across key markets. These interviews provide firsthand insights into market trends, challenges, opportunities, and future outlook from diverse stakeholder perspectives.

Secondary research encompasses analysis of industry reports, regulatory documents, trade publications, and company financial statements to validate primary research findings and provide comprehensive market context. This approach ensures data accuracy and provides historical perspective on market development trends.

Market segmentation analysis utilizes statistical modeling and data analysis techniques to identify market segments, growth patterns, and competitive dynamics. The methodology incorporates regional variations, economic factors, and industry-specific considerations to provide accurate market sizing and forecasting.

Validation processes include cross-referencing multiple data sources, expert review panels, and statistical verification to ensure research accuracy and reliability. The methodology addresses regional diversity, market complexity, and data availability challenges specific to the Middle East and Africa pharmaceutical packaging market.

Gulf Cooperation Council (GCC) countries lead the regional pharmaceutical packaging market with advanced healthcare infrastructure, substantial healthcare investments, and growing pharmaceutical manufacturing capabilities. The GCC market demonstrates strong demand for premium packaging solutions, smart packaging technologies, and specialized applications for biologics and specialty pharmaceuticals. Market share distribution shows 42% concentration in GCC countries, driven by high healthcare spending and regulatory sophistication.

North African markets including Egypt, Morocco, and Tunisia represent significant growth opportunities with expanding pharmaceutical manufacturing sectors and increasing healthcare accessibility. These markets focus on cost-effective packaging solutions, generic medication packaging, and essential drug applications. The region benefits from strategic geographic positioning for European and African market access.

Sub-Saharan Africa presents substantial long-term growth potential driven by demographic trends, healthcare infrastructure development, and increasing pharmaceutical access initiatives. The market emphasizes affordable packaging solutions, climate-resistant materials, and distribution-friendly formats suitable for challenging logistics environments.

Levant region markets including Jordan, Lebanon, and Iraq demonstrate resilience despite economic and political challenges, with pharmaceutical packaging demand driven by healthcare needs and regional pharmaceutical manufacturing. These markets focus on essential medication packaging and cost-effective solutions that address local market requirements.

East African markets including Kenya, Ethiopia, and Tanzania show strong growth potential with expanding healthcare sectors, increasing pharmaceutical investments, and growing middle-class populations. The region demonstrates 18% annual growth in pharmaceutical packaging adoption, driven by healthcare infrastructure development and improved medication access programs.

Market leadership in the Middle East and Africa pharmaceutical packaging sector features a diverse competitive landscape combining international packaging giants with regional specialists and emerging local players. The competitive environment reflects varying market maturity levels, regulatory requirements, and customer preferences across different regional markets.

International players maintain strong market positions through advanced technology offerings, comprehensive product portfolios, and established relationships with multinational pharmaceutical companies. These companies focus on premium packaging solutions, innovative technologies, and regulatory compliance capabilities that serve sophisticated market segments.

Regional specialists leverage local market knowledge, cost advantages, and specialized capabilities to serve specific market segments and geographic areas. These companies often focus on high-volume, cost-effective packaging solutions for generic medications and essential drugs.

Emerging competitors include local manufacturers developing capabilities through technology partnerships, joint ventures, and capacity expansion initiatives. These players increasingly compete in standard packaging segments while building expertise in specialized applications and regulatory compliance.

By Material Type:

By Packaging Type:

By Drug Type:

Solid Dosage Packaging represents the largest market category, encompassing tablets, capsules, and powder medications requiring diverse packaging solutions from blister packs to bottles. This category benefits from high-volume production, standardized packaging processes, and growing generic medication markets across the region. Innovation focuses on child-resistant closures, moisture protection, and patient compliance features.

Injectable Packaging demonstrates strong growth driven by increasing biologics adoption, vaccine distribution programs, and specialty pharmaceutical development. This category requires sophisticated packaging solutions including prefilled syringes, vials, and ampoules that ensure sterility, stability, and ease of administration. The segment shows 22% growth rate annually, reflecting expanding healthcare capabilities.

Liquid Medication Packaging serves diverse applications from oral suspensions to topical preparations, requiring specialized barrier properties and dispensing solutions. This category emphasizes child safety, accurate dosing, and extended shelf life through advanced packaging materials and closure systems.

Specialty Packaging addresses unique requirements for controlled substances, temperature-sensitive medications, and personalized medicine applications. This high-value category focuses on advanced features including tamper evidence, serialization, and smart packaging technologies that enhance security and traceability.

Medical Device Packaging represents a growing category encompassing diagnostic devices, surgical instruments, and combination products requiring sterile packaging solutions. This segment benefits from increasing medical device manufacturing and healthcare technology adoption across the region.

Pharmaceutical Manufacturers benefit from comprehensive packaging solutions that ensure product integrity, regulatory compliance, and market differentiation. Advanced packaging technologies enable extended shelf life, improved patient compliance, and enhanced brand recognition while reducing total cost of ownership through supply chain efficiency and reduced product losses.

Healthcare Providers gain advantages through packaging solutions that improve medication management, reduce administration errors, and enhance patient safety. Smart packaging technologies provide real-time information, dosing guidance, and authentication capabilities that support clinical decision-making and patient care quality.

Patients and Consumers benefit from packaging innovations that improve medication accessibility, enhance safety features, and provide clear usage instructions. Child-resistant packaging, easy-open features for elderly patients, and compliance monitoring capabilities contribute to better health outcomes and medication adherence.

Regulatory Authorities benefit from advanced packaging technologies that enhance drug safety, prevent counterfeiting, and improve supply chain traceability. Serialization systems, tamper-evident features, and digital authentication capabilities support regulatory oversight and public health protection objectives.

Supply Chain Partners gain efficiency improvements through packaging solutions that optimize storage, transportation, and handling processes. Standardized packaging formats, improved durability, and enhanced identification systems reduce logistics costs and improve inventory management across distribution networks.

Strengths:

Weaknesses:

Opportunities:

Threats:

Smart Packaging Integration emerges as a dominant trend with pharmaceutical companies increasingly adopting IoT-enabled packaging solutions that provide real-time monitoring, patient compliance tracking, and supply chain visibility. These technologies integrate sensors, QR codes, and NFC chips to create connected packaging ecosystems that enhance medication management and patient outcomes.

Sustainability Focus drives significant market transformation as companies prioritize eco-friendly packaging materials, recyclable solutions, and reduced environmental impact. MWR data indicates that 38% of pharmaceutical companies in the region have implemented sustainability initiatives in their packaging strategies, reflecting growing environmental consciousness and regulatory pressure.

Serialization and Anti-Counterfeiting technologies gain widespread adoption as regulatory authorities implement track-and-trace requirements and pharmaceutical companies invest in product authentication systems. These technologies include unique identifiers, blockchain integration, and tamper-evident features that enhance supply chain security and consumer protection.

Personalized Medicine Packaging responds to growing demand for customized pharmaceutical solutions, requiring flexible packaging systems that accommodate small batch sizes, variable dosing, and patient-specific requirements. This trend drives innovation in packaging automation, labeling systems, and distribution logistics.

Cold Chain Optimization becomes increasingly critical as biologics and temperature-sensitive medications expand market presence. Advanced packaging solutions incorporate temperature monitoring, insulation technologies, and cold chain logistics integration to ensure product integrity throughout distribution networks.

Manufacturing Capacity Expansion across the region reflects growing pharmaceutical production capabilities and packaging demand. Major pharmaceutical companies have announced significant investments in regional manufacturing facilities, creating opportunities for local packaging suppliers and technology providers to establish strategic partnerships and supply relationships.

Technology Transfer Initiatives facilitate knowledge sharing and capability development as international packaging companies establish regional operations and partner with local manufacturers. These initiatives enhance technical expertise, quality standards, and innovation capabilities across the pharmaceutical packaging value chain.

Regulatory Harmonization Efforts progress toward standardizing pharmaceutical packaging requirements across regional markets, reducing compliance complexity and facilitating market access for packaging suppliers. These developments create opportunities for scalable packaging solutions and streamlined regulatory processes.

Digital Health Integration accelerates as healthcare systems adopt digital technologies for medication management, patient monitoring, and supply chain optimization. Packaging companies respond by developing solutions that integrate with electronic health records, mobile applications, and digital therapeutics platforms.

Sustainability Partnerships emerge as pharmaceutical companies collaborate with packaging suppliers to develop environmentally responsible solutions that reduce waste, improve recyclability, and minimize carbon footprint. These partnerships drive innovation in biodegradable materials, reusable packaging systems, and circular economy approaches.

Strategic Market Entry requires comprehensive understanding of regional diversity, regulatory requirements, and local market dynamics. Companies should prioritize market research, regulatory compliance, and partnership development to establish successful market presence and sustainable competitive advantages in diverse regional markets.

Technology Investment should focus on smart packaging capabilities, sustainability solutions, and digital integration features that address evolving customer requirements and regulatory expectations. Companies investing in advanced technologies position themselves for long-term growth and market leadership in high-value segments.

Partnership Development with local pharmaceutical manufacturers, regulatory authorities, and distribution partners creates strategic advantages and market access opportunities. Collaborative approaches enable knowledge sharing, risk mitigation, and accelerated market penetration across diverse regional markets.

Regulatory Compliance requires proactive engagement with regulatory authorities, continuous monitoring of requirement changes, and investment in compliance capabilities that ensure market access and operational continuity. Companies should prioritize regulatory expertise and quality systems that support multiple market requirements.

Sustainability Integration should become a core business strategy rather than an add-on consideration, with companies developing comprehensive environmental programs that address material selection, manufacturing processes, and end-of-life management. Sustainability leadership creates competitive differentiation and market positioning advantages.

Market expansion prospects remain highly positive for the Middle East and Africa pharmaceutical packaging market, driven by demographic trends, healthcare infrastructure development, and increasing pharmaceutical manufacturing capabilities. The market is projected to maintain strong growth momentum with CAGR exceeding 8% through the forecast period, supported by diverse growth drivers across regional markets.

Technology evolution will continue transforming the pharmaceutical packaging landscape with advanced materials, smart packaging solutions, and digital integration capabilities becoming standard market requirements. Companies that invest in innovation and technology development will capture significant market opportunities and establish competitive leadership positions.

Regional integration initiatives will create larger, more efficient markets with harmonized regulatory frameworks and streamlined supply chains. These developments will benefit packaging suppliers through economies of scale, reduced compliance complexity, and enhanced market access opportunities across the region.

Sustainability transformation will accelerate as environmental regulations strengthen and customer expectations evolve toward eco-friendly packaging solutions. The market will increasingly favor suppliers that demonstrate environmental leadership and provide comprehensive sustainability solutions that address circular economy principles.

Digital transformation will reshape pharmaceutical packaging through IoT integration, blockchain authentication, and AI-powered supply chain optimization. According to MarkWide Research projections, digital packaging adoption rates will reach 55% by 2028, creating substantial opportunities for technology-enabled packaging solutions and services.

The Middle East and Africa pharmaceutical packaging market presents exceptional growth opportunities driven by expanding healthcare sectors, increasing pharmaceutical manufacturing capabilities, and evolving customer requirements for advanced packaging solutions. Regional diversity creates multiple market opportunities across different economic development levels, regulatory frameworks, and healthcare infrastructure capabilities.

Market dynamics favor companies that demonstrate technological innovation, regulatory compliance expertise, and sustainability leadership while addressing diverse regional requirements and customer preferences. The competitive landscape rewards suppliers that provide comprehensive solutions, maintain quality standards, and establish strong local partnerships across key markets.

Future success in this market requires strategic investment in technology development, regulatory compliance capabilities, and sustainability initiatives that address evolving market requirements and customer expectations. Companies that position themselves as innovation leaders and trusted partners will capture significant market opportunities and establish sustainable competitive advantages in this dynamic and growing market.

What is Pharmaceutical Packaging?

Pharmaceutical packaging refers to the process of enclosing and protecting pharmaceutical products, including medications and medical devices, to ensure their safety, efficacy, and quality. This includes various materials and technologies used to package drugs for distribution and use in healthcare settings.

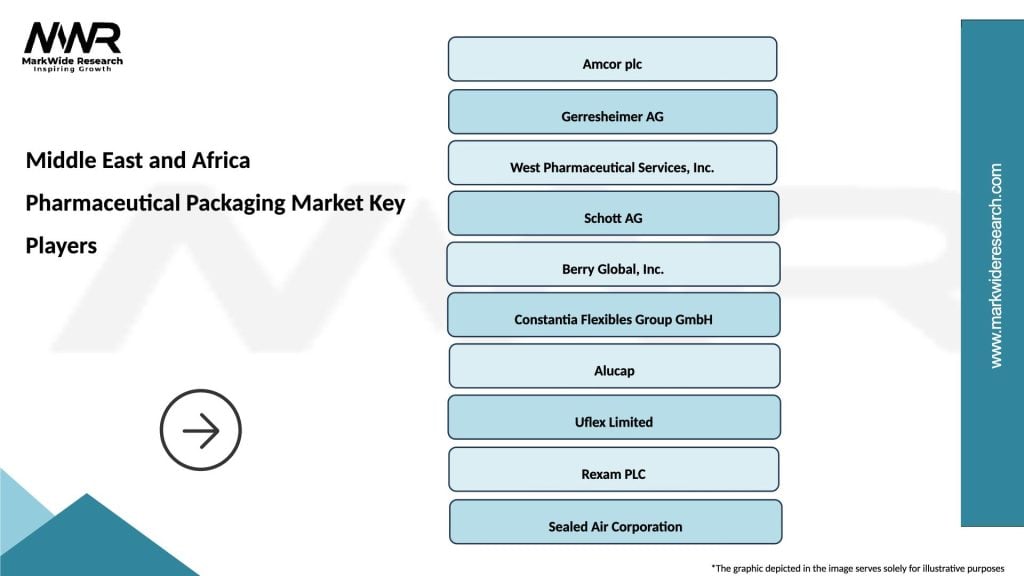

What are the key players in the Middle East and Africa Pharmaceutical Packaging Market?

Key players in the Middle East and Africa Pharmaceutical Packaging Market include companies like Amcor, West Pharmaceutical Services, and Schott AG, which provide innovative packaging solutions for pharmaceuticals. These companies focus on enhancing product safety and compliance with regulatory standards, among others.

What are the growth factors driving the Middle East and Africa Pharmaceutical Packaging Market?

The growth of the Middle East and Africa Pharmaceutical Packaging Market is driven by increasing demand for advanced packaging solutions, rising healthcare expenditures, and the expansion of the pharmaceutical industry in the region. Additionally, the need for improved drug safety and patient compliance is influencing packaging innovations.

What challenges does the Middle East and Africa Pharmaceutical Packaging Market face?

Challenges in the Middle East and Africa Pharmaceutical Packaging Market include regulatory compliance issues, the high cost of advanced packaging technologies, and the need for sustainable packaging solutions. These factors can hinder market growth and innovation.

What opportunities exist in the Middle East and Africa Pharmaceutical Packaging Market?

Opportunities in the Middle East and Africa Pharmaceutical Packaging Market include the growing trend towards personalized medicine, the rise of e-commerce in pharmaceuticals, and advancements in smart packaging technologies. These trends are expected to create new avenues for growth and innovation.

What trends are shaping the Middle East and Africa Pharmaceutical Packaging Market?

Trends shaping the Middle East and Africa Pharmaceutical Packaging Market include the increasing adoption of eco-friendly materials, the integration of technology in packaging solutions, and the focus on child-resistant and tamper-evident packaging. These trends aim to enhance safety and sustainability in pharmaceutical packaging.

Middle East and Africa Pharmaceutical Packaging Market

| Segmentation Details | Description |

|---|---|

| Packaging Type | Blister Packs, Bottles, Vials, Pouches |

| Material | Glass, Plastic, Aluminum, Paper |

| End User | Pharmaceutical Companies, Contract Manufacturers, Hospitals, Retail Pharmacies |

| Technology | Child-Resistant, Tamper-Evident, Smart Packaging, Eco-Friendly |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Middle East and Africa Pharmaceutical Packaging Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at