444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The Middle East and Africa pharmaceutical blister packaging market represents a rapidly expanding segment within the global pharmaceutical packaging industry. This market encompasses the production, distribution, and utilization of specialized packaging solutions designed to protect pharmaceutical products while ensuring optimal shelf life and patient safety. The region’s pharmaceutical blister packaging sector has experienced remarkable growth, driven by increasing healthcare investments, expanding pharmaceutical manufacturing capabilities, and rising demand for advanced packaging technologies.

Market dynamics in the Middle East and Africa region reflect a complex interplay of factors including regulatory harmonization, technological advancement, and growing pharmaceutical consumption. The market demonstrates significant potential for expansion, with industry analysts projecting a compound annual growth rate (CAGR) of 8.2% over the forecast period. This growth trajectory is supported by increasing healthcare expenditure, expanding pharmaceutical manufacturing facilities, and rising awareness of medication safety and efficacy.

Regional characteristics of the Middle East and Africa pharmaceutical blister packaging market include diverse regulatory environments, varying levels of technological adoption, and distinct consumer preferences. The market serves multiple pharmaceutical segments including prescription medications, over-the-counter drugs, and specialty pharmaceuticals. Key growth drivers include urbanization trends, aging populations in certain regions, and increasing prevalence of chronic diseases requiring long-term medication management.

The Middle East and Africa pharmaceutical blister packaging market refers to the comprehensive ecosystem encompassing the design, manufacturing, and distribution of specialized packaging solutions for pharmaceutical products across the MEA region. This market involves the production of thermoformed plastic cavities sealed with backing materials to create individual dose packaging for tablets, capsules, and other solid dosage forms.

Blister packaging technology represents a critical component of pharmaceutical product protection, offering superior barrier properties against moisture, oxygen, and light while providing tamper-evident features and dose accuracy. The market encompasses various packaging formats including unit-dose blisters, multi-dose packaging, and specialized child-resistant designs. These packaging solutions serve essential functions in maintaining drug stability, extending shelf life, and ensuring patient compliance through clear dosage identification and convenient administration.

Market scope extends beyond traditional packaging to include innovative solutions such as smart packaging technologies, sustainable materials, and integrated patient information systems. The pharmaceutical blister packaging market in the Middle East and Africa addresses diverse therapeutic areas including cardiovascular medications, antibiotics, pain management drugs, and chronic disease treatments, reflecting the region’s evolving healthcare landscape and pharmaceutical consumption patterns.

Strategic market analysis reveals that the Middle East and Africa pharmaceutical blister packaging market is positioned for substantial growth driven by multiple convergent factors. The market benefits from increasing pharmaceutical manufacturing investments, regulatory modernization efforts, and growing consumer awareness of medication safety and quality. Regional pharmaceutical companies are increasingly adopting advanced blister packaging technologies to meet international quality standards and expand their market reach.

Key market trends include the adoption of sustainable packaging materials, integration of smart packaging technologies, and development of specialized packaging solutions for temperature-sensitive medications. The market demonstrates strong growth potential across various pharmaceutical segments, with particular strength in generic drug packaging and over-the-counter medication solutions. Industry participants are focusing on technological innovation, capacity expansion, and strategic partnerships to capitalize on emerging opportunities.

Competitive landscape analysis indicates a dynamic market environment with both international packaging companies and regional players competing for market share. The market shows increasing consolidation trends as companies seek to achieve economies of scale and expand their technological capabilities. Growth strategies include vertical integration, geographic expansion, and development of specialized packaging solutions for emerging therapeutic areas.

Market intelligence reveals several critical insights that define the Middle East and Africa pharmaceutical blister packaging landscape:

Primary growth drivers propelling the Middle East and Africa pharmaceutical blister packaging market include expanding healthcare infrastructure, increasing pharmaceutical consumption, and rising quality standards. The region’s growing population, particularly in urban areas, creates sustained demand for pharmaceutical products requiring advanced packaging solutions. Healthcare sector investments by governments and private entities contribute to market expansion through improved pharmaceutical distribution networks and enhanced quality requirements.

Technological advancement serves as a crucial market driver, with pharmaceutical companies increasingly adopting automated packaging lines and advanced materials to improve product protection and reduce manufacturing costs. The integration of Industry 4.0 technologies, including IoT sensors and data analytics, enhances packaging line efficiency and enables real-time quality monitoring. These technological improvements result in approximately 25% efficiency gains in packaging operations while reducing material waste and improving product quality.

Regulatory harmonization across the region creates opportunities for standardized packaging solutions and facilitates market entry for international pharmaceutical companies. The implementation of serialization requirements and anti-counterfeiting measures drives demand for sophisticated blister packaging technologies. Additionally, growing awareness of medication safety and patient compliance issues encourages pharmaceutical companies to invest in advanced packaging solutions that improve drug stability and ease of use.

Significant challenges facing the Middle East and Africa pharmaceutical blister packaging market include high initial capital investments required for advanced packaging equipment and technology implementation. The cost of establishing modern packaging facilities with automated production lines and quality control systems can be prohibitive for smaller pharmaceutical companies, limiting market participation and technological adoption rates.

Regulatory complexity presents ongoing challenges as pharmaceutical companies must navigate diverse regulatory requirements across different MEA countries. Varying standards for packaging materials, labeling requirements, and quality certifications create compliance burdens that increase operational costs and complexity. The lack of harmonized regulations across the region can impede market expansion and increase time-to-market for new pharmaceutical products.

Supply chain constraints including limited availability of specialized packaging materials and equipment in certain regions create operational challenges. Dependence on imported raw materials and packaging machinery can result in supply disruptions and increased costs. Additionally, skilled workforce shortages in advanced packaging technologies and quality control procedures limit the industry’s ability to fully capitalize on growth opportunities and maintain consistent quality standards.

Emerging opportunities in the Middle East and Africa pharmaceutical blister packaging market include the development of sustainable packaging solutions using biodegradable and recyclable materials. Growing environmental consciousness among consumers and regulatory bodies creates demand for eco-friendly packaging alternatives. Companies investing in sustainable packaging technologies can gain competitive advantages while addressing environmental concerns and regulatory requirements.

Digital transformation presents significant opportunities through the integration of smart packaging technologies and digital health solutions. The incorporation of QR codes, NFC chips, and blockchain technology enables enhanced product authentication, patient engagement, and supply chain transparency. These innovations can improve medication adherence rates by approximately 35% while providing valuable data insights for pharmaceutical companies and healthcare providers.

Market expansion opportunities exist in underserved regions and therapeutic areas where advanced packaging solutions can address specific healthcare challenges. The growing prevalence of chronic diseases requiring long-term medication management creates demand for specialized packaging solutions including multi-dose blisters and compliance packaging. Additionally, the expansion of pharmaceutical manufacturing capabilities in the region creates opportunities for local packaging suppliers to establish strategic partnerships and capture market share.

Complex market dynamics characterize the Middle East and Africa pharmaceutical blister packaging sector, with multiple interconnected factors influencing growth patterns and competitive positioning. The market demonstrates cyclical patterns related to pharmaceutical product launches, regulatory changes, and healthcare spending fluctuations. Understanding these dynamics is crucial for stakeholders seeking to optimize their market strategies and investment decisions.

Demand-supply equilibrium in the market reflects the balance between growing pharmaceutical consumption and packaging production capacity. Regional capacity utilization rates average approximately 72%, indicating opportunities for expansion while maintaining operational efficiency. The market experiences seasonal variations related to healthcare campaigns, disease outbreaks, and pharmaceutical product launches that influence packaging demand patterns.

Competitive dynamics involve both price competition and differentiation strategies as companies seek to establish market leadership. Innovation cycles in packaging technology create opportunities for early adopters to gain competitive advantages through superior product offerings. Market consolidation trends reflect the industry’s evolution toward larger, more technologically advanced operations capable of serving diverse customer requirements and geographic markets.

Comprehensive research methodology employed in analyzing the Middle East and Africa pharmaceutical blister packaging market incorporates multiple data collection and analysis techniques to ensure accuracy and reliability. Primary research involves extensive interviews with industry executives, pharmaceutical manufacturers, packaging suppliers, and regulatory officials across key MEA markets. This approach provides firsthand insights into market trends, challenges, and opportunities from diverse stakeholder perspectives.

Secondary research encompasses analysis of industry reports, regulatory filings, company financial statements, and trade publications to establish market baselines and identify emerging trends. Data triangulation techniques validate findings across multiple sources to ensure research accuracy and minimize potential biases. Statistical analysis methods including regression analysis and trend extrapolation support market forecasting and scenario development.

Market segmentation analysis utilizes both top-down and bottom-up approaches to accurately assess market size and growth potential across different product categories, applications, and geographic regions. Quality assurance protocols ensure data accuracy through multiple validation checkpoints and expert review processes. The methodology incorporates feedback from MarkWide Research industry specialists to enhance analysis depth and market understanding.

Geographic market distribution across the Middle East and Africa reveals distinct regional characteristics and growth patterns. The Gulf Cooperation Council (GCC) countries represent approximately 45% of regional market share, driven by advanced healthcare infrastructure, high pharmaceutical consumption, and significant healthcare investments. These markets demonstrate strong demand for premium packaging solutions and advanced technologies.

North African markets including Egypt, Morocco, and Tunisia show robust growth potential supported by expanding pharmaceutical manufacturing capabilities and increasing healthcare access. These regions benefit from strategic geographic positioning for serving both regional and international markets. Local pharmaceutical companies are increasingly investing in advanced packaging technologies to meet international quality standards and expand export opportunities.

Sub-Saharan Africa presents emerging opportunities with growing pharmaceutical markets and increasing healthcare investments. Countries such as South Africa, Nigeria, and Kenya demonstrate strong growth potential driven by expanding middle-class populations and improving healthcare infrastructure. Regional market share distribution shows approximately 30% concentration in South Africa, reflecting the country’s advanced pharmaceutical sector and manufacturing capabilities.

Market competition in the Middle East and Africa pharmaceutical blister packaging sector involves a diverse mix of international corporations and regional specialists competing across different market segments and geographic areas. The competitive environment demonstrates increasing consolidation as companies seek to achieve economies of scale and expand their technological capabilities.

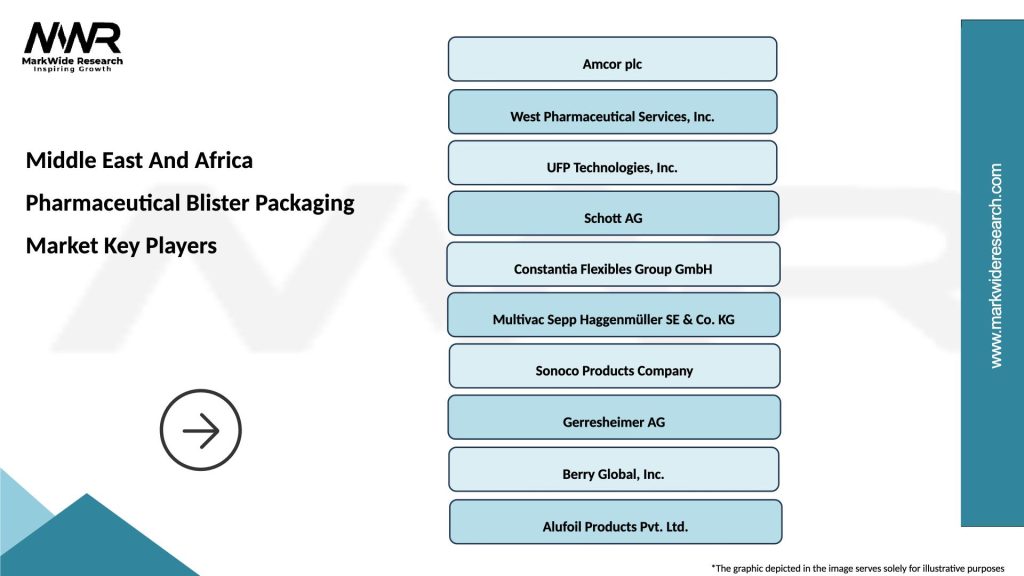

Leading market participants include:

Competitive strategies focus on technological innovation, geographic expansion, and strategic partnerships to capture market opportunities. Companies are investing in research and development to create next-generation packaging solutions while expanding manufacturing capabilities in key regional markets.

Market segmentation analysis reveals diverse application areas and product categories within the Middle East and Africa pharmaceutical blister packaging market. Understanding these segments is crucial for identifying growth opportunities and developing targeted market strategies.

By Material Type:

By Product Type:

By Application:

Prescription medications represent the largest category within the Middle East and Africa pharmaceutical blister packaging market, accounting for approximately 65% of total market volume. This segment demonstrates consistent growth driven by increasing prevalence of chronic diseases and expanding pharmaceutical formularies. Prescription drug packaging requires stringent quality standards and specialized barrier properties to ensure medication stability and efficacy.

Over-the-counter (OTC) medications constitute a rapidly growing category with significant packaging innovation opportunities. OTC products require attractive packaging designs that combine product protection with consumer appeal and brand differentiation. This segment benefits from increasing consumer self-medication trends and expanding retail pharmacy networks across the region.

Specialty pharmaceuticals including biologics and high-value medications represent a premium market segment with specialized packaging requirements. These products often require advanced barrier properties, temperature control features, and enhanced security measures. The specialty pharmaceutical category shows strong growth potential as regional pharmaceutical companies expand their product portfolios to include innovative therapeutic solutions.

Generic medications form a substantial market category driven by cost-containment pressures and increasing generic drug adoption. Generic pharmaceutical packaging focuses on cost-effectiveness while maintaining quality standards and regulatory compliance. This segment demonstrates steady growth as healthcare systems seek to reduce medication costs while ensuring patient access to essential treatments.

Pharmaceutical manufacturers benefit from advanced blister packaging solutions through improved product protection, extended shelf life, and enhanced brand differentiation. Modern packaging technologies enable manufacturers to reduce product losses, minimize contamination risks, and ensure consistent product quality throughout the distribution chain. These benefits translate to improved profitability and reduced liability risks.

Healthcare providers and pharmacists gain advantages through improved medication management, reduced dispensing errors, and enhanced patient safety. Blister packaging provides clear dose identification, tamper-evident features, and convenient storage solutions that streamline pharmacy operations. Unit-dose packaging reduces medication errors by approximately 40% while improving inventory management and reducing waste.

Patients and consumers benefit from improved medication adherence, enhanced safety features, and convenient dosing solutions. Blister packaging provides clear visual cues for medication identification, dose tracking, and compliance monitoring. Child-resistant features protect vulnerable populations while maintaining accessibility for intended users. These benefits contribute to better health outcomes and reduced healthcare costs.

Regulatory authorities benefit from enhanced product traceability, improved anti-counterfeiting measures, and standardized packaging formats that facilitate market oversight. Serialization capabilities enable effective product recalls and supply chain monitoring. Advanced packaging technologies support regulatory compliance efforts while reducing administrative burdens associated with product safety monitoring.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability initiatives represent a dominant trend in the Middle East and Africa pharmaceutical blister packaging market, with companies increasingly adopting recyclable materials and reducing packaging waste. Environmental consciousness among consumers and regulatory bodies drives demand for eco-friendly packaging solutions. Companies implementing sustainable packaging strategies report approximately 20% improvement in brand perception and customer loyalty.

Smart packaging integration emerges as a transformative trend incorporating digital technologies to enhance patient engagement and medication management. QR codes, NFC chips, and smartphone connectivity enable real-time medication tracking, adherence monitoring, and patient education. These technologies create new revenue streams while improving health outcomes and reducing healthcare costs.

Serialization and traceability requirements drive adoption of advanced tracking technologies throughout the pharmaceutical supply chain. Regulatory mandates for product authentication and anti-counterfeiting measures create demand for sophisticated packaging solutions. Companies investing in serialization capabilities gain competitive advantages through enhanced supply chain visibility and regulatory compliance.

Personalized packaging solutions address individual patient needs through customized dosing schedules, multi-drug packaging, and patient-specific labeling. This trend reflects the broader movement toward personalized medicine and patient-centric healthcare delivery. Personalized packaging solutions demonstrate potential for improving medication adherence rates and reducing healthcare costs.

Recent industry developments highlight the dynamic nature of the Middle East and Africa pharmaceutical blister packaging market. Major packaging companies are establishing regional manufacturing facilities to serve growing local demand and reduce supply chain dependencies. These investments demonstrate confidence in regional market potential and commitment to serving MEA pharmaceutical companies.

Technology partnerships between packaging companies and pharmaceutical manufacturers create opportunities for innovative packaging solutions tailored to specific therapeutic areas. Collaborative research and development efforts focus on developing next-generation materials and packaging formats that address emerging healthcare challenges. According to MarkWide Research analysis, these partnerships result in approximately 30% faster time-to-market for new packaging innovations.

Regulatory harmonization efforts across the region create opportunities for standardized packaging solutions and improved market access. Regional pharmaceutical authorities are working toward aligned quality standards and mutual recognition agreements that facilitate trade and reduce compliance burdens. These developments support market expansion and encourage investment in advanced packaging technologies.

Acquisition activities in the packaging industry reflect consolidation trends as companies seek to expand their geographic reach and technological capabilities. Strategic acquisitions enable companies to access new markets, acquire specialized expertise, and achieve economies of scale. These developments reshape competitive dynamics and create opportunities for market leadership.

Strategic recommendations for market participants include focusing on technological innovation and sustainable packaging solutions to differentiate their offerings and capture premium market segments. Companies should invest in research and development capabilities to create next-generation packaging solutions that address emerging healthcare challenges and regulatory requirements.

Geographic expansion strategies should prioritize high-growth markets while building local partnerships to navigate regulatory complexities and cultural preferences. Establishing regional manufacturing capabilities can reduce costs, improve supply chain resilience, and enhance customer relationships. Companies should consider joint ventures or strategic alliances to accelerate market entry and reduce investment risks.

Digital transformation initiatives should integrate smart packaging technologies and data analytics capabilities to create value-added services for pharmaceutical customers. Investment in IoT sensors, blockchain technology, and mobile applications can enhance supply chain visibility and patient engagement. These capabilities create competitive advantages and new revenue opportunities.

Sustainability programs should address environmental concerns while meeting regulatory requirements and customer expectations. Companies should develop comprehensive sustainability strategies including material selection, manufacturing processes, and end-of-life considerations. Collaboration with suppliers and customers can accelerate sustainability initiatives and create shared value.

Long-term market prospects for the Middle East and Africa pharmaceutical blister packaging market remain highly positive, supported by sustained healthcare investments, expanding pharmaceutical manufacturing, and increasing quality standards. The market is projected to maintain robust growth momentum with a compound annual growth rate exceeding 8% over the next decade. This growth trajectory reflects the region’s evolving healthcare landscape and increasing pharmaceutical consumption patterns.

Technology evolution will continue driving market transformation through advanced materials, smart packaging integration, and automated manufacturing processes. Artificial intelligence and machine learning applications will optimize packaging design, quality control, and supply chain management. These technological advances will create new market opportunities while improving operational efficiency and product quality.

Market maturation will bring increased consolidation, standardization, and specialization as the industry evolves toward more sophisticated and efficient operations. Regional pharmaceutical companies will increasingly adopt international quality standards and advanced packaging technologies to compete in global markets. MWR projections indicate that market concentration among leading players will increase to approximately 60% over the forecast period.

Regulatory evolution will continue shaping market dynamics through enhanced quality requirements, serialization mandates, and sustainability standards. Harmonization efforts across the region will facilitate market access and reduce compliance complexities. These regulatory developments will support market growth while ensuring patient safety and product quality.

The Middle East and Africa pharmaceutical blister packaging market represents a dynamic and rapidly expanding sector with significant growth potential driven by healthcare infrastructure development, increasing pharmaceutical consumption, and advancing packaging technologies. The market demonstrates resilience and adaptability in addressing diverse regional requirements while maintaining international quality standards.

Key success factors for market participants include technological innovation, sustainability focus, regulatory compliance, and strategic geographic positioning. Companies that invest in advanced packaging technologies, develop sustainable solutions, and build strong regional partnerships will be best positioned to capitalize on emerging opportunities and achieve long-term success.

Future market development will be characterized by continued technological advancement, increasing consolidation, and growing emphasis on patient-centric packaging solutions. The integration of digital technologies, sustainable materials, and personalized packaging approaches will define the next phase of market evolution. Stakeholders who embrace these trends and invest in capabilities development will drive industry leadership and create sustainable competitive advantages in this promising market.

What is Pharmaceutical Blister Packaging?

Pharmaceutical blister packaging refers to a type of packaging that consists of a pre-formed plastic cavity or pocket, typically used to contain tablets, capsules, or other pharmaceutical products. This packaging method is designed to protect the contents from moisture, light, and contamination, ensuring product integrity and safety.

What are the key players in the Middle East And Africa Pharmaceutical Blister Packaging Market?

Key players in the Middle East And Africa Pharmaceutical Blister Packaging Market include Amcor plc, West Pharmaceutical Services, and UFP Technologies, among others. These companies are known for their innovative packaging solutions and commitment to quality in the pharmaceutical sector.

What are the growth factors driving the Middle East And Africa Pharmaceutical Blister Packaging Market?

The growth of the Middle East And Africa Pharmaceutical Blister Packaging Market is driven by increasing demand for pharmaceutical products, rising healthcare expenditures, and a growing focus on patient safety and compliance. Additionally, advancements in packaging technology are enhancing the efficiency and effectiveness of blister packaging.

What challenges does the Middle East And Africa Pharmaceutical Blister Packaging Market face?

The Middle East And Africa Pharmaceutical Blister Packaging Market faces challenges such as regulatory compliance, high production costs, and the need for sustainable packaging solutions. These factors can impact the overall growth and innovation within the market.

What opportunities exist in the Middle East And Africa Pharmaceutical Blister Packaging Market?

Opportunities in the Middle East And Africa Pharmaceutical Blister Packaging Market include the increasing adoption of smart packaging technologies and the expansion of the pharmaceutical industry in emerging markets. Additionally, there is a growing trend towards eco-friendly packaging solutions that can attract environmentally conscious consumers.

What trends are shaping the Middle East And Africa Pharmaceutical Blister Packaging Market?

Trends shaping the Middle East And Africa Pharmaceutical Blister Packaging Market include the rise of personalized medicine, the integration of digital technologies in packaging, and a shift towards more sustainable materials. These trends are influencing how pharmaceutical products are packaged and delivered to consumers.

Middle East And Africa Pharmaceutical Blister Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | Cold Formed, Thermoformed, Aluminum Foil, PVC |

| End User | Pharmaceutical Companies, Contract Packaging Organizations, Hospitals, Retail Pharmacies |

| Packaging Type | Blister Packs, Strip Packs, Sachets, Pouches |

| Material | Plastic, Aluminum, Paper, Composite |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Middle East And Africa Pharmaceutical Blister Packaging Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at