444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Middle East and Africa Machine Control System market is witnessing significant growth and development. Machine control systems are revolutionizing various industries by providing accurate and efficient control over heavy machinery and equipment. These systems utilize advanced technologies such as Global Positioning Systems (GPS), sensors, and telematics to enhance the performance, productivity, and safety of machines in sectors like construction, agriculture, mining, and transportation.

Meaning

Machine control systems refer to the integration of hardware and software technologies that enable precise control and automation of heavy machinery. These systems utilize real-time data and positioning information to optimize machine operations, reduce human error, and enhance productivity. By offering accurate guidance and control, machine control systems ensure higher precision, reduced material wastage, improved safety, and increased operational efficiency.

Executive Summary

The Middle East and Africa Machine Control System market is experiencing substantial growth, driven by factors such as rapid industrialization, infrastructural development projects, and increasing demand for efficient and cost-effective machinery operations. The market is witnessing a surge in adoption due to the benefits provided by machine control systems, such as enhanced productivity, reduced labor costs, improved safety measures, and optimized resource utilization.

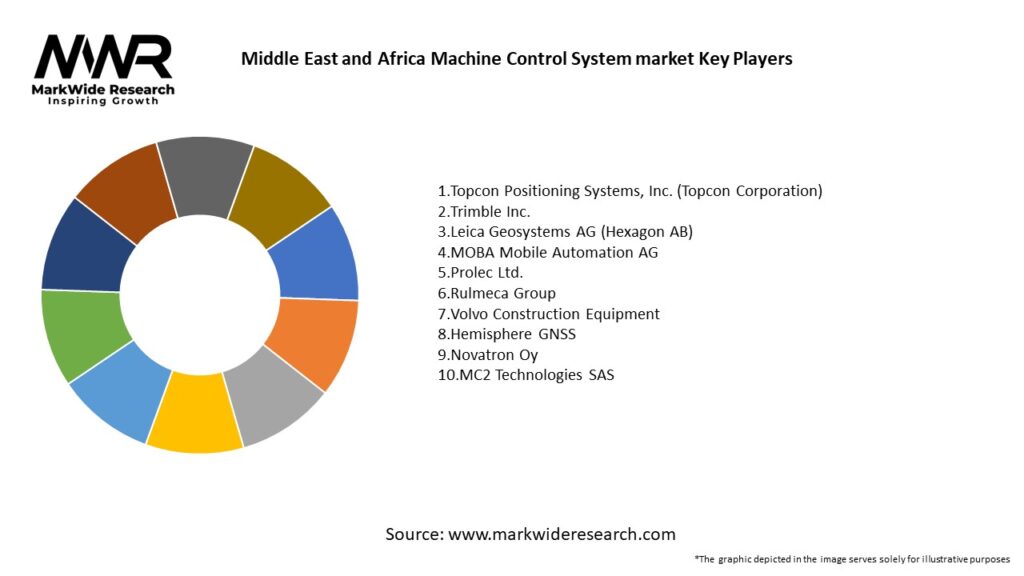

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Middle East and Africa Machine Control System market is driven by dynamic factors that shape its growth and trajectory. The market dynamics are influenced by market drivers, restraints, opportunities, and various external factors such as government regulations, technological advancements, and industry trends.

Organizations operating in this market need to adapt to the changing dynamics and leverage the opportunities to stay competitive. Continuous innovation, strategic partnerships, and investments in research and development are key to navigating the evolving landscape of the machine control system market in the Middle East and Africa.

Regional Analysis

The Middle East and Africa Machine Control System market can be segmented into sub-regions for a detailed analysis of market trends, opportunities, and challenges. The region encompasses countries such as Saudi Arabia, UAE, South Africa, Egypt, Nigeria, and Kenya, among others.

Each sub-region has its own market dynamics and requirements, and understanding the specific needs and preferences of different countries can help market players formulate effective strategies to cater to the demand.

Competitive Landscape

Leading Companies in Middle East and Africa Machine Control System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Middle East and Africa Machine Control System market can be segmented based on various factors, including:

Segmenting the market based on these factors provides a comprehensive understanding of the market landscape, enabling market players to identify target segments and customize their strategies accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis of the Middle East and Africa Machine Control System market provides an overview of the market’s strengths, weaknesses, opportunities, and threats.

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these factors helps market participants to capitalize on strengths, address weaknesses, explore opportunities, and mitigate threats to their business operations in the Middle East and Africa Machine Control System market.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the Middle East and Africa Machine Control System market. The pandemic disrupted global supply chains, leading to delays in equipment procurement and project execution. Lockdown measures and travel restrictions affected the construction, mining, and transportation sectors, reducing the demand for machine control systems.

However, the pandemic also highlighted the importance of automation and remote operations. Machine control systems proved crucial in maintaining productivity and safety in industries that were allowed to operate. The need for social distancing and reduced human intervention accelerated the adoption of machine control systems in various sectors.

As the region recovers from the pandemic, the market is expected to rebound, driven by government initiatives to boost economic growth, infrastructure development projects, and the growing need for efficient machinery operations in a post-pandemic environment.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Middle East and Africa Machine Control System market is promising. The market is expected to witness steady growth, driven by factors such as infrastructural development projects, the need for improved productivity and efficiency, and the integration of advanced technologies.

The construction, agriculture, mining, and transportation sectors will continue to be major contributors to the market growth. Increasing investments in infrastructure development, government initiatives, and the adoption of digital technologies will further boost the demand for machine control systems.

The market will see a shift towards advanced features such as AI integration, IoT connectivity, cloud-based solutions, and mobile applications. These features will enable real-time monitoring, predictive maintenance, remote control, and data analytics, leading to enhanced operational efficiency and improved decision-making.

While challenges such as high initial investment and skilled workforce shortage exist, market players can overcome these challenges through strategic collaborations, innovation, and customized solutions.

Conclusion

In conclusion, the Middle East and Africa Machine Control System market is poised for growth, driven by increasing demand for efficient machinery operations, infrastructure development, and technological advancements. Market players should adapt to the evolving market dynamics, focus on customer needs, and embrace emerging technologies to capitalize on the opportunities and ensure long-term success in the market.

What is Machine Control System?

Machine Control Systems are advanced technologies used in construction and mining to enhance the precision and efficiency of machinery operations. They integrate GPS, sensors, and software to automate tasks such as grading, excavation, and surveying.

What are the key players in the Middle East and Africa Machine Control System market?

Key players in the Middle East and Africa Machine Control System market include Topcon Positioning Systems, Trimble Inc., Leica Geosystems, and Caterpillar Inc., among others.

What are the growth factors driving the Middle East and Africa Machine Control System market?

The growth of the Middle East and Africa Machine Control System market is driven by increasing infrastructure development, the rising demand for automation in construction, and advancements in technology such as IoT and AI.

What challenges does the Middle East and Africa Machine Control System market face?

Challenges in the Middle East and Africa Machine Control System market include high initial investment costs, a lack of skilled workforce, and varying regulatory standards across different countries.

What opportunities exist in the Middle East and Africa Machine Control System market?

Opportunities in the Middle East and Africa Machine Control System market include the expansion of smart city projects, increased adoption of green technologies, and the potential for partnerships with local firms to enhance market penetration.

What trends are shaping the Middle East and Africa Machine Control System market?

Trends in the Middle East and Africa Machine Control System market include the integration of machine learning for predictive maintenance, the use of drones for site surveying, and the growing emphasis on sustainability in construction practices.

Middle East and Africa Machine Control System market

| Segmentation Details | Description |

|---|---|

| Product Type | GPS, Laser, Ultrasonic, Optical |

| Technology | 2D, 3D, GNSS, Robotics |

| End User | Construction, Mining, Agriculture, Forestry |

| Installation | Fixed, Portable, Integrated, Standalone |

Leading Companies in Middle East and Africa Machine Control System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at