444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Microfibrillated Cellulose (MFC) is a versatile nanomaterial that is gaining significant traction in various industries due to its unique properties and eco-friendly nature. MFC is derived from cellulose, which is the most abundant organic polymer on Earth and is commonly found in plant cell walls. Microfibrillated Cellulose offers excellent mechanical strength, high aspect ratio, large surface area, and exceptional rheological properties, making it suitable for a wide range of applications.

Meaning

Microfibrillated Cellulose (MFC) refers to cellulose fibers that have been mechanically disintegrated into micro-scale fibrils. The disintegration process involves the separation of cellulose fibers and the breakdown of the hydrogen bonds holding them together. This results in the formation of a network of interconnected cellulose fibrils with a high aspect ratio.

Executive Summary

The global Microfibrillated Cellulose (MFC) market is experiencing robust growth, driven by the increasing demand for sustainable and eco-friendly materials across various industries. The unique properties of MFC, such as its high strength, lightweight nature, and biodegradability, have propelled its adoption in applications such as packaging, composites, coatings, and personal care products. Additionally, the growing focus on reducing carbon emissions and the shift towards renewable materials are further fueling the market growth.

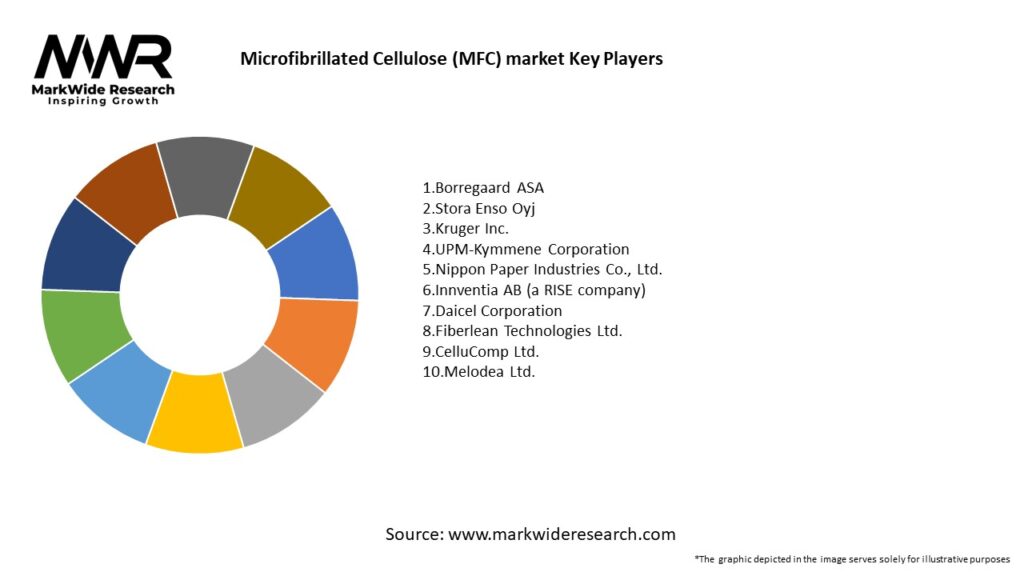

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Microfibrillated Cellulose market is highly dynamic and is influenced by various factors, including technological advancements, environmental regulations, consumer preferences, and industry collaborations. The market is characterized by intense competition among key players, driving continuous innovation and product development. The demand for Microfibrillated Cellulose is expected to witness steady growth, driven by the increasing emphasis on sustainable materials and the shift towards a circular economy.

Regional Analysis

The Microfibrillated Cellulose market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America and Europe currently dominate the market, owing to the presence of well-established industries and favorable government regulations promoting the use of sustainable materials. The Asia Pacific region is expected to witness significant growth, driven by the rapid industrialization, growing population, and increasing environmental awareness.

Competitive Landscape

leading companies in the Microfibrillated Cellulose (MFC) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Microfibrillated Cellulose market can be segmented based on the following criteria:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The outbreak of the Covid-19 pandemic had a mixed impact on the Microfibrillated Cellulose market. While certain industries faced disruptions in their operations and a decline in demand, others witnessed an increased need for sustainable materials. The packaging industry, in particular, experienced a surge in demand for Microfibrillated Cellulose-based materials, driven by the growing e-commerce sector and the increased focus on hygiene and safety.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Microfibrillated Cellulose market is expected to witness significant growth in the coming years. The increasing demand for sustainable materials, the rising awareness about environmental conservation, and the shift towards a circular economy are the key factors driving market expansion. Technological advancements and continuous investments in research and development will further enhance the properties and applications of Microfibrillated Cellulose, opening up new opportunities for market players. However, overcoming challenges such as high production costs and the lack of standardized testing methods will be crucial for the widespread adoption of MFC across industries.

In terms of market growth, the packaging industry is expected to remain a significant driver for the Microfibrillated Cellulose market. The increasing consumer demand for sustainable and eco-friendly packaging solutions, coupled with stringent regulations on single-use plastics, will fuel the adoption of MFC-based packaging materials. The versatility of Microfibrillated Cellulose allows it to be integrated into various packaging formats, including films, trays, and coatings, offering improved barrier properties, moisture resistance, and biodegradability.

Additionally, the composites industry is poised to witness substantial growth in the utilization of Microfibrillated Cellulose. MFC-reinforced composites offer excellent mechanical strength, lightweight characteristics, and improved sustainability compared to traditional materials. The automotive, aerospace, and construction sectors, in particular, are expected to drive the demand for MFC-based composites due to their potential for weight reduction, increased fuel efficiency, and enhanced structural integrity.

Another emerging area of application for Microfibrillated Cellulose is in the electronics and energy storage sectors. With the rising demand for flexible electronics, wearable devices, and energy storage systems, the unique properties of MFC, such as its electrical conductivity and thermal stability, make it an attractive material for these applications. The integration of Microfibrillated Cellulose into electronic devices and energy storage technologies can contribute to the development of more sustainable and efficient systems.

Geographically, the Asia Pacific region is anticipated to exhibit significant growth in the Microfibrillated Cellulose market. The region’s rapid industrialization, growing population, and increasing environmental awareness are driving the demand for sustainable materials. Countries like China, Japan, and South Korea are investing in research and development activities focused on nanocellulose and its applications, providing growth opportunities for MFC manufacturers and suppliers.

However, it is important to address the challenges and limitations faced by the Microfibrillated Cellulose market. The high production costs associated with MFC production can hinder its widespread adoption, especially in price-sensitive industries. Manufacturers need to explore cost-effective production methods and establish economies of scale to make Microfibrillated Cellulose more competitive in the market.

Moreover, the lack of standardized testing methods and quality control parameters for Microfibrillated Cellulose poses a challenge for both manufacturers and end-users. Establishing standardized protocols for characterizing and evaluating the properties of MFC will ensure consistency in product quality and facilitate wider acceptance in various industries.

Conclusion

In conclusion, the Microfibrillated Cellulose market is witnessing significant growth driven by the increasing demand for sustainable and eco-friendly materials across industries. The unique properties of Microfibrillated Cellulose, such as its high strength, lightweight nature, and biodegradability, make it a desirable choice for a wide range of applications. The packaging, composites, personal care, paints and coatings, and food and beverages industries are key drivers of market growth. Continued investments in research and development, collaborations, and education about the benefits of Microfibrillated Cellulose will further propel the market forward. As companies strive to meet environmental regulations and consumer demand for sustainable products, the Microfibrillated Cellulose market is expected to expand significantly in the coming years, offering immense opportunities for industry participants and stakeholders.

Microfibrillated Cellulose (MFC) market

| Segmentation Details | Description |

|---|---|

| Product Type | Wood-based, Cotton-based, Bacterial cellulose, Others |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Paper & Pulp |

| Application | Thickening Agent, Stabilizer, Reinforcement, Coating |

| Form | Powder, Gel, Suspension, Fiber |

leading companies in the Microfibrillated Cellulose (MFC) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at