444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The microbial bioreactors market is experiencing significant growth due to the rising demand for biopharmaceuticals, advancements in genetic engineering, and the need for sustainable solutions in various industries. Microbial bioreactors are essential tools in biotechnology and industrial microbiology, enabling the cultivation and maintenance of microbial cells under controlled conditions. These bioreactors provide a controlled environment for microorganisms to grow and produce valuable products such as enzymes, vaccines, antibodies, and biofuels.

Meaning

Microbial bioreactors are specialized devices or systems designed to support the growth and propagation of microorganisms in a controlled environment. These bioreactors are used in various applications, including pharmaceuticals, biotechnology, agriculture, environmental engineering, and biofuel production. They provide optimal conditions for microorganisms to thrive, allowing for the efficient production of desired products or biomass.

Executive Summary

The microbial bioreactors market is poised for substantial growth in the coming years. Factors such as increasing investments in biopharmaceutical research and development, advancements in bioprocessing technologies, and the growing demand for sustainable and eco-friendly solutions are driving market expansion. Additionally, the COVID-19 pandemic has highlighted the importance of biomanufacturing capabilities, further boosting the demand for microbial bioreactors.

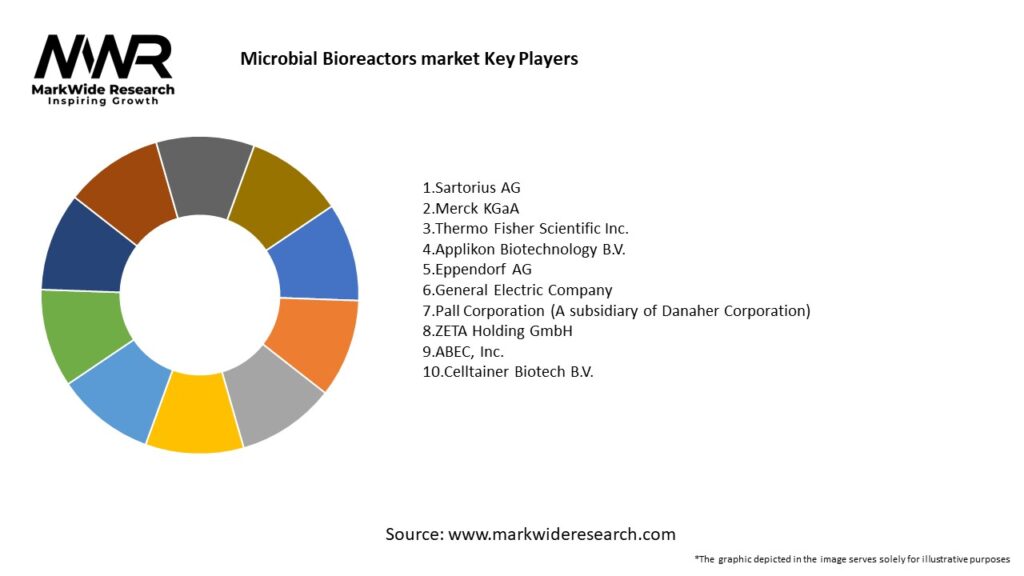

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

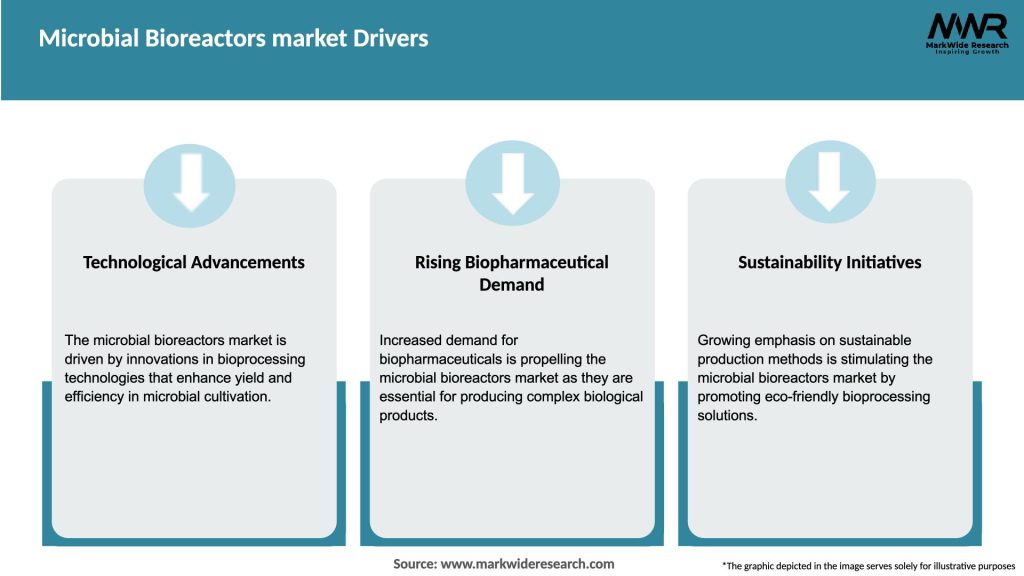

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The microbial bioreactors market is dynamic and influenced by several factors. Technological advancements, changing regulatory landscape, and market consolidation through mergers and acquisitions are some of the key dynamics shaping the market.

Technological advancements, such as the development of single-use bioreactors and advanced process control systems, are enhancing the efficiency and scalability of microbial bioreactors. These advancements are enabling higher productivity, reducing operational costs, and improving the overall manufacturing process.

The regulatory landscape plays a crucial role in the microbial bioreactors market, as the biopharmaceutical industry is subject to stringent regulations to ensure product safety and efficacy. Market players must navigate complex regulatory frameworks and comply with guidelines from regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

The market is also witnessing consolidation through mergers and acquisitions, as companies aim to expand their product portfolios, geographic presence, and technological capabilities. Strategic collaborations and partnerships are becoming common, allowing companies to leverage each other’s strengths and enhance their market position.

Regional Analysis

The microbial bioreactors market can be analyzed based on regional segments, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

North America dominates the market due to the presence of a well-established biopharmaceutical industry and significant investments in research and development. Europe is also a prominent market, supported by favorable government initiatives and a strong focus on sustainable solutions. The Asia Pacific region is witnessing rapid growth, driven by the increasing demand for biopharmaceuticals, rising healthcare expenditure, and favorable regulatory policies in countries like China and India.

Latin America and the Middle East and Africa are emerging markets, with growing investments in the healthcare and biotechnology sectors. These regions offer untapped opportunities for microbial bioreactor manufacturers, as governments aim to strengthen their healthcare infrastructure and attract investments.

Competitive Landscape

Leading Companies in the Microbial Bioreactors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The microbial bioreactors market can be segmented based on product type, application, end-user, and region.

Based on product type, the market can be divided into benchtop bioreactors, pilot-scale bioreactors, and industrial-scale bioreactors. Benchtop bioreactors are small-scale systems used for research and development purposes, while pilot-scale and industrial-scale bioreactors are designed for large-scale production.

The application segment includes pharmaceuticals, biotechnology, agriculture, environmental engineering, and biofuel production. Microbial bioreactors find extensive application in the production of biopharmaceuticals, enzymes, vaccines, and biofuels.

End-users of microbial bioreactors encompass pharmaceutical and biotechnology companies, research institutes, contract manufacturing organizations, and academic and research organizations.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the microbial bioreactors market can benefit in several ways:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis of the microbial bioreactors market provides insights into the internal and external factors influencing the market’s performance.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The microbial bioreactors market is characterized by several key trends:

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the microbial bioreactors market. The global healthcare crisis and the urgent need for vaccines and therapeutics have underscored the importance of biomanufacturing capabilities.

The demand for microbial bioreactors has surged due to the need for large-scale production of COVID-19 vaccines and other biologics. Biopharmaceutical companies and contract manufacturing organizations have ramped up their production capacities, leading to increased investments in microbial bioreactors.

The pandemic has also accelerated research and development in the field of biotechnology, creating opportunities for microbial bioreactor manufacturers. The focus on developing novel therapies and vaccines has spurred innovation in bioprocessing technologies, driving the adoption of advanced microbial bioreactors.

However, the pandemic has also posed challenges in terms of disrupted supply chains, restricted mobility, and reduced funding for research and development. Companies have had to adapt to remote work environments and implement stringent safety protocols to ensure business continuity.

Overall, the COVID-19 pandemic has highlighted the critical role of microbial bioreactors in biomanufacturing and has further underscored the importance of sustainable and efficient production methods.

Key Industry Developments

The microbial bioreactors market has witnessed several key industry developments:

Analyst Suggestions

Based on the analysis of the microbial bioreactors market, industry analysts suggest the following:

Future Outlook

The future outlook for the microbial bioreactors market is highly promising. The market is expected to witness significant growth in the coming years, driven by factors such as increasing demand for biopharmaceuticals, technological advancements, and the focus on sustainable manufacturing.

Advancements in genetic engineering, process automation, and continuous bioprocessing will continue to shape the market. Additionally, the increasing adoption of personalized medicine, growing demand for biofuels, and expansion in emerging markets will create new opportunities for market players.

However, challenges such as high initial investment costs, complex regulatory landscape, and the shortage of skilled professionals need to be addressed. Companies that successfully navigate these challenges and adapt to changing market dynamics are poised to thrive in the microbial bioreactors market.

Conclusion

The microbial bioreactors market is witnessing significant growth, driven by the rising demand for biopharmaceuticals, advancements in genetic engineering, and the need for sustainable solutions. These bioreactors play a critical role in biotechnology and industrial microbiology, enabling the production of valuable products such as enzymes, vaccines, antibodies, and biofuels.

Technological advancements, favorable government support, and the focus on personalized medicine and sustainable manufacturing are key drivers for market expansion. The COVID-19 pandemic has further emphasized the importance of microbial bioreactors in biomanufacturing, particularly in the production of vaccines and therapeutics.

What is Microbial Bioreactors?

Microbial bioreactors are systems that provide a controlled environment for the growth of microorganisms, facilitating processes such as fermentation and bioconversion. They are essential in various applications, including pharmaceuticals, food production, and waste treatment.

What are the key players in the Microbial Bioreactors market?

Key players in the Microbial Bioreactors market include Thermo Fisher Scientific, Sartorius AG, and Eppendorf AG, among others. These companies are known for their innovative technologies and solutions that enhance bioprocessing efficiency.

What are the growth factors driving the Microbial Bioreactors market?

The Microbial Bioreactors market is driven by the increasing demand for biopharmaceuticals, advancements in biotechnology, and the growing focus on sustainable production methods. Additionally, the rise in research activities in microbiology contributes to market growth.

What challenges does the Microbial Bioreactors market face?

Challenges in the Microbial Bioreactors market include high initial investment costs, the complexity of bioprocess optimization, and regulatory hurdles. These factors can hinder the adoption of microbial bioreactor technologies in various industries.

What opportunities exist in the Microbial Bioreactors market?

The Microbial Bioreactors market presents opportunities in the development of novel bioprocessing techniques and the integration of automation and digital technologies. Additionally, the increasing focus on renewable energy sources and biofuels opens new avenues for growth.

What trends are shaping the Microbial Bioreactors market?

Trends in the Microbial Bioreactors market include the shift towards single-use bioreactors, advancements in bioprocess monitoring technologies, and the growing interest in microbial consortia for enhanced production. These trends are influencing how bioprocesses are designed and implemented.

Microbial Bioreactors market

| Segmentation Details | Description |

|---|---|

| Product Type | Stirred Tank, Airlift, Membrane, Photo-bioreactor |

| End User | Pharmaceuticals, Food & Beverages, Wastewater Treatment, Biofuels |

| Technology | Batch, Continuous, Fed-batch, Hybrid |

| Application | Biopharmaceutical Production, Enzyme Production, Fermentation, Cell Culture |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Microbial Bioreactors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at