444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Mexico plastic bottles market represents a dynamic and rapidly evolving sector within the country’s packaging industry, driven by increasing consumer demand, urbanization trends, and expanding beverage consumption patterns. Market dynamics indicate robust growth potential across multiple application segments, with the industry experiencing significant transformation through technological advancements and sustainability initiatives. The market encompasses various plastic bottle types, including PET, HDPE, and PP bottles, serving diverse industries from beverages and personal care to pharmaceuticals and household products.

Growth trajectories in the Mexican plastic bottles market reflect the country’s expanding middle class and changing consumption habits, with urban areas driving approximately 72% of total demand. The market benefits from Mexico’s strategic geographic position, serving as a manufacturing hub for North American distribution while maintaining strong domestic consumption patterns. Industry consolidation has accelerated in recent years, with major players investing heavily in production capacity expansion and sustainable packaging solutions.

Technological innovations continue reshaping the market landscape, particularly in lightweight bottle design and recycling capabilities. The sector demonstrates resilience through diversified application portfolios, with beverage packaging maintaining the largest market share while personal care and pharmaceutical segments show accelerating growth rates of 8.5% annually.

The Mexico plastic bottles market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of plastic bottle containers across various industries within Mexican territory. This market includes manufacturing facilities, raw material suppliers, brand owners, retailers, and end consumers who collectively drive demand for plastic bottle packaging solutions.

Market scope extends beyond simple container production to include value-added services such as custom labeling, specialized closures, and integrated packaging solutions. The definition encompasses both primary packaging applications, where bottles serve as the main product container, and secondary packaging uses in industrial and commercial applications.

Industry boundaries include all plastic bottle types manufactured from various polymer materials, serving sectors ranging from food and beverage to chemicals and pharmaceuticals. The market definition also incorporates the entire value chain from resin procurement through end-of-life recycling processes, reflecting the circular economy approach increasingly adopted by industry participants.

Strategic positioning of Mexico’s plastic bottles market reveals a sector poised for sustained expansion, driven by demographic shifts, economic development, and evolving consumer preferences. The market demonstrates remarkable adaptability to changing regulatory environments while maintaining competitive manufacturing costs that attract international investment and domestic growth.

Key performance indicators highlight the market’s strength across multiple dimensions, with production capacity utilization rates exceeding 78% and export volumes contributing significantly to Mexico’s manufacturing trade balance. The sector benefits from established supply chain networks, skilled workforce availability, and proximity to major consumer markets in North America.

Market differentiation occurs through technological innovation, sustainable packaging solutions, and customized product offerings that meet specific industry requirements. Leading manufacturers have invested substantially in advanced production technologies, enabling higher quality standards and improved operational efficiency. Competitive advantages include lower labor costs compared to developed markets, abundant raw material access, and favorable trade agreements facilitating export growth.

Future prospects indicate continued market expansion supported by infrastructure development, urbanization trends, and increasing per capita consumption of packaged goods. The market’s evolution toward sustainability-focused solutions positions Mexico as a regional leader in environmentally responsible packaging manufacturing.

Market intelligence reveals several critical insights shaping the Mexico plastic bottles market’s trajectory and competitive landscape:

Primary growth drivers propelling the Mexico plastic bottles market include demographic trends, economic development, and changing consumer behavior patterns that collectively create sustained demand for packaging solutions. Population growth and urbanization continue driving increased consumption of packaged beverages, personal care products, and household items requiring plastic bottle packaging.

Economic expansion across Mexico has elevated disposable income levels, enabling consumers to purchase more packaged goods and premium products that utilize advanced plastic bottle designs. The growing middle class demonstrates preferences for convenience packaging, branded products, and quality assurance that plastic bottles provide across various product categories.

Industrial development in sectors such as pharmaceuticals, chemicals, and food processing creates additional demand for specialized plastic bottle applications. These industries require precise specifications, regulatory compliance, and consistent quality standards that established Mexican manufacturers can reliably deliver.

Export opportunities continue expanding as Mexican manufacturers leverage competitive advantages including lower production costs, strategic geographic location, and trade agreement benefits. USMCA provisions particularly enhance market access to North American customers seeking reliable, cost-effective packaging solutions.

Technological advancements in production processes enable manufacturers to offer improved product performance, customization capabilities, and sustainable packaging options that meet evolving customer requirements and regulatory standards.

Environmental concerns represent the most significant challenge facing the Mexico plastic bottles market, with increasing regulatory pressure and consumer awareness driving demand for sustainable alternatives. Plastic waste management issues have prompted government initiatives restricting single-use plastics and mandating recycled content requirements that increase production costs.

Raw material price volatility creates operational challenges for manufacturers, particularly when petroleum-based resin costs fluctuate significantly due to global market conditions. These price variations impact profit margins and require sophisticated hedging strategies to maintain competitive pricing.

Competition from alternative packaging materials including glass, aluminum, and paper-based solutions presents ongoing market share challenges. Some consumer segments demonstrate preferences for perceived environmentally friendly alternatives, potentially limiting plastic bottle adoption in certain applications.

Regulatory complexity across different Mexican states and municipalities creates compliance challenges for manufacturers serving multiple markets. Varying environmental standards, labeling requirements, and waste management regulations increase operational complexity and administrative costs.

Infrastructure limitations in recycling and waste management systems constrain the development of circular economy initiatives that could enhance market sustainability and public perception. Investment requirements for advanced recycling technologies represent significant capital commitments that smaller manufacturers may struggle to afford.

Sustainability innovation presents the most significant growth opportunity for Mexico plastic bottles market participants, with increasing demand for eco-friendly packaging solutions creating new market segments. Biodegradable plastics and enhanced recycling technologies offer pathways for market expansion while addressing environmental concerns.

Export market development provides substantial growth potential, particularly in Central and South American markets where Mexican manufacturers can leverage competitive advantages and established trade relationships. Market penetration in these regions could increase export volumes by an estimated 45% over the next five years.

Value-added services including custom labeling, specialized closures, and integrated packaging solutions create opportunities for higher margin business development. Manufacturers investing in these capabilities can differentiate their offerings and build stronger customer relationships.

E-commerce growth drives demand for specialized packaging solutions that protect products during shipping while maintaining cost effectiveness. This trend creates opportunities for innovative bottle designs and packaging systems tailored to online retail requirements.

Pharmaceutical sector expansion offers premium market opportunities as Mexico’s healthcare industry grows and regulatory standards increase. Specialized pharmaceutical packaging requires higher quality standards and generates superior profit margins compared to commodity applications.

Technology partnerships with international equipment suppliers and material developers can accelerate innovation adoption and enhance competitive positioning in global markets.

Supply chain dynamics in the Mexico plastic bottles market reflect complex interactions between raw material availability, production capacity, and demand fluctuations across diverse end-use sectors. Vertical integration strategies adopted by leading manufacturers have improved supply chain control while reducing costs and enhancing quality consistency.

Competitive dynamics demonstrate increasing consolidation as larger players acquire smaller manufacturers to expand geographic coverage and production capabilities. This consolidation trend has improved operational efficiency while creating more formidable competitors capable of serving large multinational customers.

Innovation dynamics focus heavily on sustainability initiatives, with manufacturers investing in recycled content integration, lightweight designs, and alternative material development. Research and development spending has increased by approximately 22% annually as companies seek competitive advantages through technological advancement.

Regulatory dynamics continue evolving as government agencies implement stricter environmental standards and waste management requirements. These regulatory changes create both challenges and opportunities, driving innovation while potentially increasing compliance costs for market participants.

Customer dynamics reflect growing sophistication in packaging requirements, with brand owners demanding customized solutions, sustainable materials, and supply chain transparency. This evolution requires manufacturers to develop enhanced capabilities and stronger customer relationships.

Comprehensive research approach utilized for analyzing the Mexico plastic bottles market incorporates multiple data collection methodologies and analytical frameworks to ensure accuracy and reliability of market insights. Primary research activities include structured interviews with industry executives, manufacturer surveys, and customer feedback collection across key market segments.

Secondary research encompasses analysis of industry publications, government statistics, trade association reports, and company financial statements to validate primary findings and identify market trends. Data triangulation methods ensure consistency across different information sources while highlighting potential discrepancies requiring further investigation.

Market modeling techniques incorporate statistical analysis, trend extrapolation, and scenario planning to develop realistic market projections and identify key growth drivers. Quantitative analysis focuses on production volumes, capacity utilization rates, and market share calculations across different product categories and geographic regions.

Qualitative assessment includes competitive positioning analysis, regulatory impact evaluation, and technology trend identification that influence market development. Expert validation processes involve industry specialist reviews and peer analysis to ensure research conclusions accurately reflect market realities.

Continuous monitoring systems track market developments, regulatory changes, and competitive activities to maintain current market intelligence and identify emerging opportunities or threats affecting market participants.

Northern Mexico dominates plastic bottle production, with states including Nuevo León, Jalisco, and Estado de México hosting major manufacturing facilities that serve both domestic and export markets. This region benefits from proximity to US markets, established industrial infrastructure, and skilled workforce availability that supports efficient production operations.

Central Mexico represents the largest consumption market, driven by high population density and concentrated urban areas including Mexico City metropolitan region. Market concentration in this region accounts for approximately 42% of total domestic demand, with strong growth in premium packaging applications and specialized bottle designs.

Western regions including Guadalajara and surrounding areas have emerged as important secondary production centers, particularly for beverage and personal care applications. These areas benefit from established supply chain networks and growing local demand from expanding consumer markets.

Border regions along the US-Mexico frontier serve primarily as export-oriented production centers, with manufacturers leveraging maquiladora programs and trade agreement benefits to serve North American customers. Export concentration from these regions represents nearly 65% of total international shipments.

Southern Mexico remains primarily a consumption market with limited local production capacity, creating opportunities for market expansion and regional development initiatives. Growing tourism and agricultural sectors in these areas drive demand for various plastic bottle applications.

Market leadership in Mexico’s plastic bottles sector is characterized by a mix of international corporations and domestic manufacturers, each leveraging distinct competitive advantages to serve different market segments and customer requirements.

Competitive strategies focus on operational efficiency, customer service excellence, and innovation capabilities that enable market share growth and profitability improvement. Strategic partnerships between manufacturers and major brand owners create stable demand relationships while driving collaborative innovation initiatives.

By Material Type:

By Application:

By Capacity:

Beverage Category maintains market leadership with approximately 58% of total volume, driven by Mexico’s hot climate and growing consumption of bottled water, soft drinks, and energy beverages. Innovation trends in this category focus on lightweight designs, enhanced barrier properties, and sustainable materials that meet brand owner requirements while reducing environmental impact.

Personal Care Category demonstrates strong growth potential with increasing consumer spending on beauty and hygiene products. Premium positioning in this segment enables higher margins through specialized designs, custom colors, and advanced closure systems that enhance product differentiation and consumer appeal.

Pharmaceutical Category requires the highest quality standards and regulatory compliance, creating opportunities for specialized manufacturers capable of meeting stringent requirements. Market growth in this segment reflects Mexico’s expanding healthcare sector and increasing pharmaceutical manufacturing activity.

Household Products Category benefits from steady demand growth as urbanization increases consumption of packaged cleaning and maintenance products. Bulk packaging trends in this category drive demand for larger bottle sizes and cost-effective production solutions.

Food Products Category shows emerging growth opportunities as Mexican food manufacturers increasingly adopt plastic bottle packaging for condiments, oils, and liquid food products. Barrier technology advances enable plastic bottles to compete effectively with traditional glass packaging in food applications.

Manufacturers benefit from Mexico’s competitive manufacturing environment, including lower labor costs, abundant raw material access, and favorable trade agreements that enhance export competitiveness. Operational advantages include established supply chains, skilled workforce availability, and proximity to major consumer markets in North America.

Brand Owners gain access to cost-effective packaging solutions, customization capabilities, and reliable supply chain partnerships that support market expansion and product innovation initiatives. Quality assurance programs and regulatory compliance support enable brand owners to maintain product integrity while optimizing packaging costs.

Consumers benefit from improved product availability, enhanced packaging functionality, and competitive pricing that results from efficient manufacturing operations. Sustainability initiatives provide environmentally conscious consumers with recycled content options and improved end-of-life disposal solutions.

Investors find attractive opportunities in a growing market with strong fundamentals, export potential, and increasing demand from diverse end-use sectors. Market consolidation trends create opportunities for strategic acquisitions and partnership development.

Government Stakeholders benefit from increased manufacturing employment, export revenue generation, and industrial development that supports economic growth objectives. Tax revenue and foreign investment attraction contribute to broader economic development goals.

Environmental Stakeholders gain from industry investments in recycling infrastructure, sustainable materials development, and circular economy initiatives that reduce environmental impact while maintaining economic viability.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability Integration represents the most significant trend reshaping the Mexico plastic bottles market, with manufacturers investing heavily in recycled content incorporation, biodegradable materials development, and circular economy initiatives. Consumer awareness drives demand for environmentally responsible packaging solutions that maintain functionality while reducing environmental impact.

Lightweighting Technology continues advancing as manufacturers develop thinner wall designs and optimized bottle shapes that reduce material usage while maintaining structural integrity. Material savings from lightweighting initiatives have achieved reductions of up to 15% in some applications, providing cost benefits and environmental advantages.

Smart Packaging Integration emerges as brands seek enhanced consumer engagement through QR codes, NFC technology, and interactive packaging features. Digital connectivity enables product authentication, promotional campaigns, and consumer feedback collection that adds value beyond basic packaging functionality.

Customization Demand increases as brand owners seek differentiated packaging solutions that support marketing objectives and product positioning strategies. Short-run production capabilities enable manufacturers to serve niche markets and seasonal products with specialized bottle designs.

Automation Advancement accelerates as manufacturers invest in robotic systems, quality control automation, and integrated production lines that improve efficiency while reducing labor dependency. Production optimization through automation has improved output rates by approximately 25% in advanced facilities.

Capacity Expansion Projects across major manufacturers reflect confidence in market growth prospects and demand for increased production capabilities. Investment announcements totaling substantial amounts demonstrate industry commitment to serving growing domestic and export markets through enhanced manufacturing infrastructure.

Sustainability Partnerships between manufacturers and recycling companies create integrated solutions for post-consumer plastic bottle recovery and reprocessing. Circular economy initiatives include bottle-to-bottle recycling programs and closed-loop systems that reduce virgin material requirements.

Technology Acquisitions enable manufacturers to access advanced production capabilities, specialized materials, and innovative packaging solutions that enhance competitive positioning. Strategic partnerships with equipment suppliers and material developers accelerate innovation adoption and market responsiveness.

Regulatory Compliance Initiatives include proactive measures to exceed current environmental standards and prepare for anticipated future regulations. Industry collaboration with government agencies and environmental organizations supports responsible market development and public policy formation.

Export Market Development through trade missions, customer relationship building, and supply chain optimization enables Mexican manufacturers to capture growing international opportunities. Market penetration strategies focus on Central America, Caribbean, and South American markets where competitive advantages are most pronounced.

MarkWide Research analysis indicates that Mexico plastic bottles market participants should prioritize sustainability initiatives as the primary strategic focus, given increasing regulatory pressure and consumer demand for environmentally responsible packaging solutions. Investment priorities should emphasize recycled content integration, alternative material development, and circular economy participation.

Technology modernization represents a critical success factor for maintaining competitiveness in evolving market conditions. Manufacturers should evaluate automation opportunities, quality control enhancements, and production efficiency improvements that reduce costs while improving product consistency and customer satisfaction.

Export market development offers the most significant growth opportunities for Mexican manufacturers, particularly in Central and South American markets where competitive advantages are most pronounced. Market entry strategies should focus on relationship building, local partnership development, and supply chain optimization.

Value-added service development enables differentiation and higher margin opportunities through custom packaging solutions, integrated logistics services, and collaborative innovation programs with major customers. Service expansion should align with customer needs and market trends toward comprehensive packaging partnerships.

Risk management strategies should address raw material price volatility, regulatory compliance requirements, and competitive pressure from alternative packaging materials. Diversification initiatives across multiple end-use sectors and geographic markets can reduce business risk while capturing growth opportunities.

Market projections for Mexico’s plastic bottles sector indicate sustained growth driven by demographic trends, economic development, and expanding export opportunities. Long-term growth expectations reflect continued urbanization, rising disposable incomes, and increasing consumption of packaged goods across diverse product categories.

Sustainability transformation will fundamentally reshape market dynamics over the next decade, with successful companies demonstrating leadership in environmental responsibility while maintaining operational efficiency. Innovation investments in recycled materials, biodegradable alternatives, and circular economy systems will determine competitive positioning and market share development.

Technology integration will accelerate as manufacturers adopt advanced production systems, automation technologies, and digital connectivity solutions that enhance operational efficiency and customer value. Smart manufacturing capabilities will become essential for maintaining competitiveness in global markets.

Export growth potential remains substantial, with Mexican manufacturers well-positioned to capture increasing international demand through competitive advantages and strategic market development initiatives. Market expansion could increase export volumes by an estimated 38% over the next five years through targeted growth strategies.

Regulatory evolution will continue driving industry adaptation toward more sustainable practices while creating opportunities for innovative companies that proactively address environmental concerns. MWR analysis suggests that companies investing early in sustainability solutions will achieve superior market positioning and financial performance.

The Mexico plastic bottles market presents a compelling combination of growth opportunities, competitive advantages, and strategic challenges that require careful navigation and proactive management. Market fundamentals remain strong, supported by demographic trends, economic development, and expanding export potential that create sustained demand across multiple end-use sectors.

Sustainability imperatives will define future market success, with companies demonstrating environmental leadership while maintaining operational efficiency positioned for superior performance. The industry’s evolution toward circular economy principles and innovative materials creates opportunities for differentiation and premium positioning in competitive markets.

Strategic priorities should emphasize technology modernization, export market development, and value-added service expansion that enhance competitive positioning while addressing evolving customer requirements. Companies successfully balancing growth initiatives with sustainability commitments will capture the greatest market opportunities in Mexico’s dynamic plastic bottles sector.

What is Plastic Bottles?

Plastic bottles are containers made from various types of plastic, commonly used for packaging liquids such as beverages, cleaning products, and personal care items. They are lightweight, durable, and can be produced in various shapes and sizes to meet consumer needs.

What are the key players in the Mexico Plastic Bottles Market?

Key players in the Mexico Plastic Bottles Market include companies like PetStar, Grupo Plastilene, and Envases Universales. These companies are involved in the production and distribution of plastic bottles for various applications, including food and beverage packaging, personal care, and household products, among others.

What are the growth factors driving the Mexico Plastic Bottles Market?

The Mexico Plastic Bottles Market is driven by increasing consumer demand for packaged beverages, the convenience of lightweight packaging, and the growth of the e-commerce sector. Additionally, the rising awareness of hygiene and safety in packaging is contributing to market expansion.

What challenges does the Mexico Plastic Bottles Market face?

The Mexico Plastic Bottles Market faces challenges such as environmental concerns regarding plastic waste and stringent regulations on plastic usage. Additionally, competition from alternative packaging materials, such as glass and biodegradable options, poses a challenge to market growth.

What opportunities exist in the Mexico Plastic Bottles Market?

Opportunities in the Mexico Plastic Bottles Market include the development of sustainable packaging solutions and innovations in recycling technologies. The increasing focus on eco-friendly products and the potential for expanding into new markets can also drive growth.

What trends are shaping the Mexico Plastic Bottles Market?

Trends in the Mexico Plastic Bottles Market include the shift towards lightweight and recyclable materials, the adoption of smart packaging technologies, and the growing demand for customized bottle designs. These trends reflect changing consumer preferences and the industry’s response to sustainability challenges.

Mexico Plastic Bottles Market

| Segmentation Details | Description |

|---|---|

| Product Type | PET, HDPE, LDPE, PVC |

| Application | Beverages, Personal Care, Household, Pharmaceuticals |

| End User | Food & Beverage, Cosmetics, Cleaning Products, Healthcare |

| Packaging Type | Single-Serve, Multi-Pack, Bulk, Custom Shapes |

Please note: The segmentation can be entirely customized to align with our client’s needs.

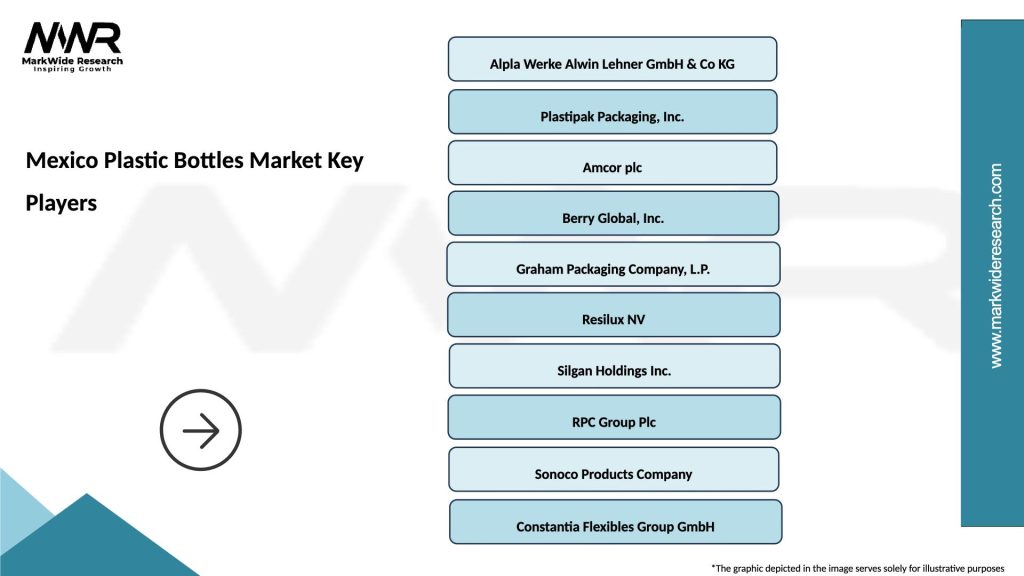

Leading companies in the Mexico Plastic Bottles Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at