444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Mexico masterbatch market represents a dynamic and rapidly evolving segment within the country’s plastics and polymer industry. Masterbatch, a concentrated mixture of pigments, additives, and carrier resins, serves as a crucial component in plastic manufacturing processes across diverse industrial applications. Mexico’s strategic geographic position, robust manufacturing infrastructure, and growing industrial base have positioned the nation as a significant player in the North American masterbatch landscape.

Market dynamics indicate substantial growth potential driven by expanding automotive, packaging, construction, and consumer goods sectors. The country’s proximity to major North American markets, combined with competitive manufacturing costs and established trade relationships, creates favorable conditions for masterbatch market expansion. Industrial growth across key sectors continues to fuel demand for specialized colorants and functional additives.

Manufacturing capabilities within Mexico have evolved significantly, with both domestic and international companies establishing production facilities to serve regional and global markets. The market demonstrates strong growth momentum, with projections indicating a compound annual growth rate of 6.2% through the forecast period. Technological advancement and increasing emphasis on sustainable manufacturing practices further contribute to market development opportunities.

The Mexico masterbatch market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of masterbatch products within Mexican territory. Masterbatch represents a concentrated additive used in plastic manufacturing to impart color, enhance properties, or provide specific functionalities to polymer products during the production process.

Market scope includes various masterbatch types such as color masterbatch, additive masterbatch, filler masterbatch, and specialty formulations designed for specific applications. The market encompasses both domestic production facilities and import operations serving Mexico’s diverse industrial sectors. Value chain participants include raw material suppliers, masterbatch manufacturers, distributors, and end-user industries across automotive, packaging, construction, agriculture, and consumer goods sectors.

Geographic coverage spans Mexico’s major industrial regions, with concentrated activity in manufacturing hubs including the Bajío region, northern border states, and central Mexico. The market serves both domestic consumption requirements and export opportunities to neighboring countries, reflecting Mexico’s role as a regional manufacturing center.

Mexico’s masterbatch market demonstrates robust growth characteristics driven by expanding industrial production and increasing demand for specialized plastic products. The market benefits from Mexico’s strategic position within North American supply chains and its established manufacturing infrastructure. Key growth drivers include automotive industry expansion, packaging sector development, and increasing adoption of advanced polymer technologies.

Market segmentation reveals diverse applications across multiple industries, with automotive and packaging sectors representing the largest consumption segments. Color masterbatch maintains the dominant market share at approximately 45% of total consumption, followed by additive masterbatch applications. Regional distribution shows concentration in major industrial centers, particularly in states with significant automotive and manufacturing presence.

Competitive landscape features a mix of international corporations and domestic manufacturers, creating a dynamic market environment. Technology adoption and product innovation continue to drive market evolution, with increasing focus on sustainable and high-performance formulations. Future prospects remain positive, supported by ongoing industrial development and growing demand for specialized plastic applications.

Strategic market insights reveal several critical factors shaping Mexico’s masterbatch industry development. The market demonstrates strong correlation with broader manufacturing trends and economic indicators, reflecting its integral role in industrial production processes.

Primary market drivers propelling Mexico’s masterbatch industry growth encompass both domestic and international factors. The automotive sector’s continued expansion represents the most significant driver, with Mexico maintaining its position as a leading vehicle production center for North American markets.

Manufacturing growth across diverse industries creates sustained demand for masterbatch products. The packaging industry’s evolution, driven by changing consumer preferences and e-commerce growth, generates increasing requirements for specialized colorants and functional additives. Construction sector development contributes additional demand through applications in pipes, profiles, and building materials.

Trade relationships and proximity to major North American markets provide competitive advantages for Mexican masterbatch manufacturers. The USMCA trade agreement facilitates market access and supply chain integration, supporting industry growth. Cost competitiveness in manufacturing operations attracts both domestic and international investment in production facilities.

Technological advancement drives demand for high-performance masterbatch formulations. Industries increasingly require specialized properties such as UV resistance, flame retardancy, and enhanced durability, creating opportunities for advanced product development. Sustainability initiatives across end-user industries promote adoption of eco-friendly masterbatch solutions.

Market constraints affecting Mexico’s masterbatch industry include raw material price volatility and supply chain dependencies. Fluctuating petroleum-based feedstock costs create pricing pressures and margin challenges for manufacturers. Import dependencies for specialized raw materials and additives expose the market to international supply disruptions and currency fluctuations.

Technical challenges in developing specialized formulations require significant research and development investments. Smaller manufacturers may face difficulties accessing advanced technologies and maintaining competitive product portfolios. Quality standards and certification requirements in export markets create additional compliance costs and operational complexities.

Environmental regulations increasingly impact masterbatch production and application processes. Stricter environmental standards require investments in cleaner technologies and waste management systems. Competition from substitutes and alternative coloring methods may limit market expansion in certain applications.

Economic uncertainties and cyclical industry patterns affect demand stability across key end-user sectors. Automotive and construction industries’ sensitivity to economic conditions creates potential volatility in masterbatch consumption patterns. Skilled labor availability for technical positions remains a constraint for industry expansion and innovation activities.

Significant opportunities exist within Mexico’s masterbatch market across multiple dimensions. The growing emphasis on sustainable manufacturing creates demand for bio-based and recyclable masterbatch formulations. Circular economy initiatives drive interest in products supporting plastic recycling and waste reduction efforts.

Export expansion represents a major growth opportunity, particularly to Central and South American markets. Mexico’s established manufacturing capabilities and competitive cost structure position the country favorably for regional market penetration. Nearshoring trends in North American manufacturing create additional opportunities for domestic masterbatch production.

Technology development in advanced masterbatch formulations offers opportunities for market differentiation and premium pricing. Applications requiring specialized properties such as antimicrobial, conductive, or smart polymer characteristics present growth potential. Digital transformation in manufacturing processes creates opportunities for improved efficiency and product customization.

Industry consolidation trends may create opportunities for strategic partnerships and market expansion. Smaller manufacturers can leverage collaboration opportunities with larger players to access new technologies and markets. Government support for manufacturing sector development provides potential incentives for industry expansion and modernization.

Market dynamics within Mexico’s masterbatch industry reflect complex interactions between supply and demand factors, technological evolution, and competitive pressures. The industry demonstrates cyclical characteristics aligned with broader manufacturing trends and economic conditions.

Supply chain integration continues evolving as manufacturers seek to optimize costs and improve service levels. Vertical integration strategies among larger players create competitive advantages while potentially limiting opportunities for smaller suppliers. Customer relationships increasingly emphasize technical support and customized solutions rather than commodity-based transactions.

Innovation cycles drive continuous product development and market evolution. Companies investing in research and development capabilities gain competitive advantages through superior product performance and customer satisfaction. Market consolidation trends create both challenges and opportunities for industry participants.

Regulatory environment influences market dynamics through environmental standards, safety requirements, and trade policies. Companies must balance compliance costs with competitive positioning while maintaining profitability. International trade patterns affect domestic market dynamics through import competition and export opportunities.

Comprehensive research methodology employed in analyzing Mexico’s masterbatch market incorporates multiple data sources and analytical approaches. Primary research activities include industry interviews, manufacturer surveys, and end-user consultations to gather current market insights and future projections.

Secondary research encompasses analysis of industry publications, government statistics, trade association reports, and company financial statements. Market sizing and segmentation analysis utilize production data, import/export statistics, and consumption patterns across key application sectors. Quantitative analysis incorporates statistical modeling and trend analysis to develop market forecasts and growth projections.

Qualitative research methods include expert interviews, focus groups, and industry roundtables to understand market dynamics, competitive positioning, and emerging trends. Data validation processes ensure accuracy and reliability through cross-referencing multiple sources and expert review procedures.

Market segmentation analysis employs both top-down and bottom-up approaches to ensure comprehensive coverage and accurate sizing. Regional analysis incorporates geographic distribution patterns, industrial concentration, and local market characteristics. Competitive analysis utilizes company profiles, market share estimation, and strategic positioning assessment.

Regional distribution of Mexico’s masterbatch market reflects the country’s industrial geography and manufacturing concentration patterns. Northern Mexico, particularly states bordering the United States, represents the largest consumption region with approximately 40% of total market share.

Bajío region emerges as a significant growth area, driven by automotive industry expansion and manufacturing investment. States including Guanajuato, Querétaro, and San Luis Potosí demonstrate strong masterbatch demand growth, supported by industrial development initiatives. Central Mexico, anchored by Mexico City and surrounding areas, maintains substantial market presence through diverse manufacturing activities.

Coastal regions show growing importance due to port access and export-oriented manufacturing. Pacific coast states benefit from Asian trade relationships and growing industrial development. Southern Mexico represents emerging opportunities as infrastructure development and industrial investment expand into previously underserved regions.

Border states maintain strategic importance due to maquiladora operations and cross-border manufacturing integration. These regions benefit from proximity to U.S. markets and established supply chain relationships. Regional specialization patterns emerge based on dominant industries and local manufacturing capabilities.

Competitive environment within Mexico’s masterbatch market features a diverse mix of international corporations, regional players, and domestic manufacturers. Market leadership positions reflect combinations of production capacity, product portfolio breadth, and customer relationship strength.

Competitive strategies emphasize product innovation, customer service excellence, and operational efficiency. Companies invest in local production capabilities to serve growing domestic demand while maintaining export competitiveness. Strategic partnerships and joint ventures facilitate market access and technology transfer.

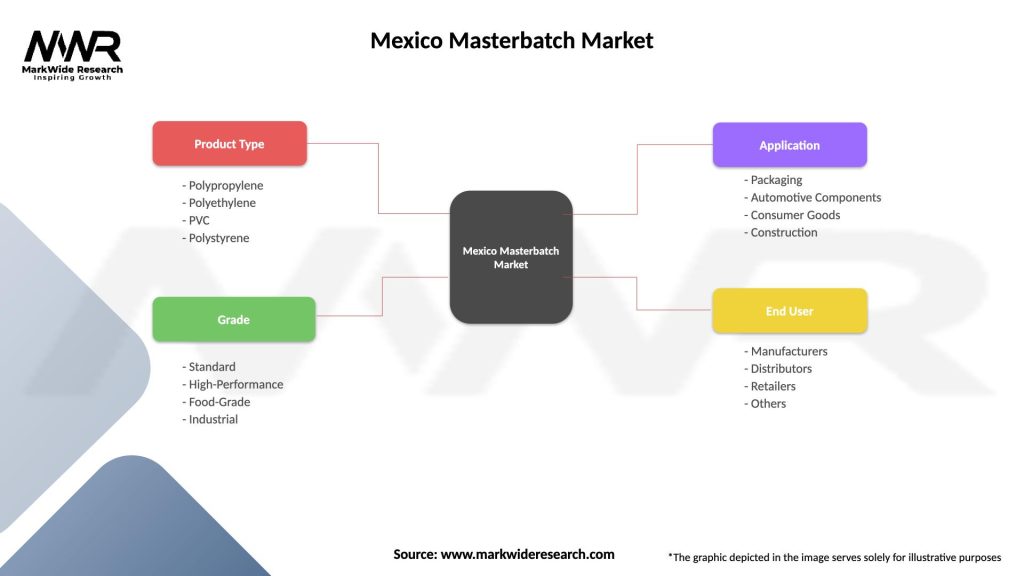

Market segmentation analysis reveals diverse applications and product categories within Mexico’s masterbatch industry. Segmentation approaches include product type, application sector, and end-user industry classifications.

By Product Type:

By Application Sector:

Color masterbatch category maintains market leadership through consistent demand across multiple industries. Automotive applications drive premium color requirements, while packaging applications emphasize food safety and regulatory compliance. Innovation focus includes development of special effects, metallic finishes, and color-matching capabilities.

Additive masterbatch segment demonstrates strong growth potential driven by increasing performance requirements. UV stabilizers show particular strength in outdoor applications, while flame retardant formulations gain importance in construction and electronics. Antimicrobial additives represent emerging opportunities in healthcare and food packaging applications.

Filler masterbatch applications focus on cost optimization and property enhancement. Calcium carbonate-based formulations dominate volume applications, while specialty fillers serve niche performance requirements. Sustainability considerations drive interest in bio-based and recycled filler materials.

Specialty masterbatch category offers highest value opportunities through customized solutions. Conductive masterbatch for electronics applications shows growing demand, while smart polymer formulations create new market possibilities. Technical expertise requirements create competitive advantages for specialized manufacturers.

Industry participants in Mexico’s masterbatch market benefit from multiple value creation opportunities and competitive advantages. Manufacturers gain access to growing domestic demand while leveraging Mexico’s strategic position for regional market expansion.

Cost advantages include competitive labor costs, favorable energy pricing, and proximity to raw material sources. Manufacturing efficiency improvements through modern production technologies and process optimization create additional value. Market access benefits include preferential trade relationships and established supply chain networks.

End-user industries benefit from improved product availability, technical support, and customized solutions. Local production capabilities reduce supply chain risks and enable faster response times to market requirements. Quality improvements through advanced masterbatch formulations enhance final product performance and customer satisfaction.

Economic stakeholders benefit from job creation, technology transfer, and industrial development. Export activities generate foreign currency earnings while domestic production reduces import dependencies. Innovation ecosystem development supports broader industrial competitiveness and technological advancement.

Environmental benefits include reduced transportation emissions through local production and development of sustainable masterbatch formulations. Circular economy initiatives create opportunities for waste reduction and resource efficiency improvements.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability transformation represents the most significant trend shaping Mexico’s masterbatch market. Manufacturers increasingly focus on developing bio-based formulations, recyclable products, and circular economy solutions. Environmental consciousness drives demand for masterbatch products supporting plastic recycling and waste reduction initiatives.

Digitalization trends impact manufacturing processes, customer service, and product development activities. Smart manufacturing technologies enable improved efficiency, quality control, and customization capabilities. Industry 4.0 adoption creates opportunities for predictive maintenance, real-time monitoring, and data-driven optimization.

Customization demand increases as end-user industries seek specialized solutions for unique applications. Mass customization capabilities become competitive differentiators, requiring flexible production systems and technical expertise. Customer collaboration intensifies through co-development projects and technical partnerships.

Regional integration trends strengthen through supply chain optimization and cross-border manufacturing coordination. Nearshoring activities create opportunities for Mexican masterbatch manufacturers to serve relocated production facilities. Trade relationship evolution continues influencing market dynamics and competitive positioning.

Recent industry developments demonstrate the dynamic nature of Mexico’s masterbatch market and ongoing evolution in competitive positioning. Major international companies continue expanding their Mexican operations through facility investments and capacity additions.

Technology partnerships between international and domestic companies facilitate knowledge transfer and capability development. MarkWide Research analysis indicates increasing collaboration between masterbatch manufacturers and end-user industries to develop specialized solutions. Joint development projects focus on sustainable formulations and advanced performance characteristics.

Capacity expansion projects across multiple manufacturers reflect confidence in market growth prospects. New production facilities incorporate advanced technologies and environmental management systems. Product innovation activities intensify with focus on specialty applications and high-performance formulations.

Regulatory developments influence industry practices through updated environmental standards and safety requirements. Companies invest in compliance capabilities while seeking competitive advantages through superior environmental performance. Certification programs gain importance in customer selection processes and market access requirements.

Strategic acquisitions and partnerships reshape competitive landscape dynamics. International companies acquire local capabilities while domestic manufacturers seek technology access through strategic alliances. Market consolidation trends create both challenges and opportunities for industry participants.

Strategic recommendations for Mexico’s masterbatch market participants emphasize diversification, innovation, and operational excellence. Companies should develop comprehensive sustainability strategies addressing environmental concerns while creating competitive advantages.

Market diversification across application sectors and geographic regions reduces cyclical exposure and creates growth opportunities. Manufacturers should explore emerging applications in electronics, healthcare, and renewable energy sectors. Export development strategies should target regional markets with favorable trade relationships and growing industrial demand.

Technology investment priorities should focus on advanced formulations, process automation, and digital capabilities. Research and development activities require increased emphasis on sustainable solutions and specialty applications. Partnership strategies can accelerate technology access and market development through collaboration with international companies and research institutions.

Operational excellence initiatives should emphasize quality management, cost optimization, and customer service enhancement. Supply chain resilience requires diversification of raw material sources and strategic inventory management. Talent development programs support innovation capabilities and operational competitiveness.

Customer relationship strategies should emphasize technical support, customization capabilities, and collaborative development approaches. Long-term partnerships with key customers create competitive advantages and market stability. Brand development activities support premium positioning and customer loyalty in competitive markets.

Future prospects for Mexico’s masterbatch market remain positive, supported by continued industrial growth and expanding application opportunities. MWR projections indicate sustained growth momentum with compound annual growth rates of 6.2% through 2028, driven by automotive sector expansion and packaging industry development.

Sustainability trends will increasingly influence market evolution, creating opportunities for companies developing eco-friendly formulations and circular economy solutions. Bio-based masterbatch products are expected to capture 15% market share by 2027, reflecting growing environmental consciousness and regulatory requirements.

Technology advancement will drive market differentiation through smart polymer applications, advanced colorants, and functional additives. Digital transformation initiatives will enhance manufacturing efficiency and customer service capabilities. Automation adoption is projected to increase by 25% over the next five years, improving competitiveness and operational performance.

Regional market expansion opportunities will emerge through nearshoring trends and trade relationship development. Mexican manufacturers are positioned to benefit from supply chain reconfiguration and regional manufacturing integration. Export growth to Central and South American markets shows potential for annual increases of 10-12%.

Industry consolidation trends will continue reshaping competitive dynamics through mergers, acquisitions, and strategic partnerships. Market leaders will strengthen positions through technology investment and geographic expansion while smaller players seek niche specialization opportunities.

Mexico’s masterbatch market represents a dynamic and growing industry segment with significant potential for continued expansion. The market benefits from strong fundamentals including strategic geographic position, established manufacturing infrastructure, and growing domestic demand across key application sectors.

Growth drivers including automotive industry expansion, packaging sector development, and sustainability trends create favorable conditions for market participants. The industry’s evolution toward specialized formulations and high-performance applications offers opportunities for differentiation and value creation. Competitive advantages through cost competitiveness, market access, and manufacturing capabilities position Mexico favorably within regional and global masterbatch markets.

Future success will depend on companies’ abilities to adapt to changing market requirements, invest in technology development, and build sustainable competitive advantages. The emphasis on environmental responsibility and circular economy principles will increasingly influence product development and market positioning strategies. Strategic focus on innovation, customer relationships, and operational excellence will determine long-term market leadership positions in this evolving industry landscape.

What is Masterbatch?

Masterbatch is a concentrated mixture of pigments and additives encapsulated during a heat process into a carrier resin, which is then cooled and cut into granules. It is used to color or enhance the properties of plastics in various applications, including packaging, automotive, and consumer goods.

What are the key players in the Mexico Masterbatch Market?

Key players in the Mexico Masterbatch Market include companies like Clariant, Ampacet, and PolyOne, which provide a range of masterbatch solutions for different applications. These companies focus on innovation and sustainability to meet the evolving needs of the industry, among others.

What are the growth factors driving the Mexico Masterbatch Market?

The Mexico Masterbatch Market is driven by the increasing demand for lightweight and durable materials in the automotive and packaging sectors. Additionally, the growing emphasis on sustainable and eco-friendly products is encouraging manufacturers to adopt advanced masterbatch solutions.

What challenges does the Mexico Masterbatch Market face?

The Mexico Masterbatch Market faces challenges such as fluctuating raw material prices and stringent environmental regulations. These factors can impact production costs and limit the availability of certain additives used in masterbatch formulations.

What opportunities exist in the Mexico Masterbatch Market?

There are significant opportunities in the Mexico Masterbatch Market due to the rising demand for biodegradable and recyclable materials. Furthermore, advancements in technology are enabling the development of specialized masterbatches for niche applications, enhancing market potential.

What trends are shaping the Mexico Masterbatch Market?

Trends in the Mexico Masterbatch Market include the increasing use of color masterbatches for aesthetic enhancements in consumer products and the growing adoption of functional masterbatches that improve material properties. Additionally, there is a shift towards sustainable practices, with more companies focusing on eco-friendly formulations.

Mexico Masterbatch Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polypropylene, Polyethylene, PVC, Polystyrene |

| Grade | Standard, High-Performance, Food-Grade, Industrial |

| Application | Packaging, Automotive Components, Consumer Goods, Construction |

| End User | Manufacturers, Distributors, Retailers, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Mexico Masterbatch Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at