444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Mexico container glass market represents a dynamic and rapidly evolving sector within the country’s manufacturing landscape. This market encompasses the production and distribution of glass containers used across various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals. Mexico’s strategic location and robust manufacturing capabilities have positioned it as a significant player in the North American container glass industry.

Market dynamics indicate substantial growth potential driven by increasing consumer demand for sustainable packaging solutions and the expansion of key end-user industries. The market benefits from Mexico’s proximity to major consumer markets in the United States and Canada, creating opportunities for export-oriented growth. Manufacturing excellence and technological advancement have enabled Mexican container glass producers to compete effectively in both domestic and international markets.

Industry consolidation and modernization efforts have strengthened the market’s competitive position, with leading manufacturers investing heavily in advanced production technologies and environmental sustainability initiatives. The market demonstrates resilience through diversified applications and strong relationships with major beverage and food companies. Growth projections suggest the market will expand at a compound annual growth rate of 4.2% over the forecast period, driven by increasing urbanization and changing consumer preferences.

The Mexico container glass market refers to the comprehensive ecosystem of glass container manufacturing, distribution, and consumption within Mexican territory. This market encompasses all types of glass packaging solutions, including bottles, jars, vials, and specialty containers designed for various industrial applications. Container glass represents a critical component of the packaging industry, providing durable, recyclable, and chemically inert storage solutions for consumer and industrial products.

Market participants include glass manufacturers, raw material suppliers, equipment providers, and end-user industries that rely on glass packaging for product protection and brand presentation. The market’s scope extends beyond simple container production to include specialized services such as custom design, decoration, and logistics support. Technological innovation continues to drive market evolution, with manufacturers developing lightweight containers, enhanced barrier properties, and improved manufacturing efficiency.

Sustainability considerations play an increasingly important role in market definition, as container glass offers superior recyclability compared to alternative packaging materials. The market’s environmental benefits align with growing consumer awareness and regulatory requirements for sustainable packaging solutions across multiple industries.

Mexico’s container glass market demonstrates robust growth potential supported by favorable demographic trends, industrial expansion, and increasing export opportunities. The market benefits from established manufacturing infrastructure, skilled workforce, and strategic geographic positioning that facilitates trade with North American partners. Key growth drivers include expanding beverage consumption, pharmaceutical industry growth, and increasing demand for premium packaging solutions.

Market segmentation reveals diverse applications across food and beverage, pharmaceutical, cosmetic, and chemical industries, with the beverage segment maintaining the largest market share at approximately 68% of total demand. Manufacturing capabilities have evolved significantly, incorporating advanced technologies such as automated production lines, quality control systems, and energy-efficient furnaces that enhance productivity and reduce environmental impact.

Competitive dynamics feature both domestic and international players, with market leaders focusing on capacity expansion, product innovation, and strategic partnerships to strengthen market position. MarkWide Research analysis indicates that technological advancement and sustainability initiatives will continue driving market transformation, creating opportunities for companies that invest in modern manufacturing capabilities and environmental stewardship.

Strategic insights reveal several critical factors shaping the Mexico container glass market’s trajectory and competitive landscape:

Primary market drivers propelling growth in Mexico’s container glass market stem from multiple interconnected factors that create sustained demand across various industry segments. Beverage industry expansion remains the most significant driver, with increasing consumption of bottled water, soft drinks, alcoholic beverages, and specialty drinks creating consistent demand for glass containers.

Consumer preference shifts toward premium packaging and sustainable materials have elevated glass containers’ market position relative to alternative packaging solutions. The material’s superior barrier properties, chemical inertness, and complete recyclability align with evolving consumer values and regulatory requirements. Health consciousness trends have particularly benefited glass packaging, as consumers increasingly associate glass containers with product purity and safety.

Export market opportunities continue expanding as Mexican manufacturers leverage competitive production costs and strategic geographic positioning to serve North American markets. Trade agreements and established logistics networks facilitate efficient cross-border commerce, enabling Mexican producers to compete effectively with domestic manufacturers in target export markets.

Industrial diversification has created new demand sources beyond traditional beverage applications. The pharmaceutical industry’s growth, cosmetic sector expansion, and specialty chemical applications have generated higher-value market segments that support premium pricing and improved profit margins for container glass manufacturers.

Market constraints present significant challenges that container glass manufacturers must navigate to maintain competitive positioning and sustainable growth. Energy cost volatility represents a primary concern, as glass manufacturing requires substantial energy input for furnace operations, making producers vulnerable to fluctuating natural gas and electricity prices.

Raw material availability and cost fluctuations create ongoing operational challenges, particularly for silica sand, soda ash, and limestone that comprise the primary glass formulation. Supply chain disruptions and transportation costs can significantly impact manufacturing economics and product pricing strategies.

Environmental regulations continue tightening, requiring substantial investments in emission control systems, waste management infrastructure, and energy efficiency improvements. Compliance costs can strain smaller manufacturers and create competitive advantages for companies with greater financial resources to invest in environmental technologies.

Alternative packaging competition from plastic, aluminum, and flexible packaging solutions presents ongoing market share pressure. These alternatives often offer lower weight, reduced transportation costs, and simplified handling characteristics that appeal to certain customer segments and applications.

Capital intensity requirements for modern glass manufacturing facilities create barriers to entry and limit expansion opportunities for existing players. The substantial investment required for furnace construction, forming equipment, and quality control systems can constrain market growth and competitive dynamics.

Emerging opportunities within Mexico’s container glass market present substantial potential for growth and market expansion across multiple dimensions. Sustainability initiatives create significant opportunities as corporations and consumers increasingly prioritize environmentally responsible packaging solutions, positioning glass containers advantageously due to their infinite recyclability and reduced environmental impact.

Premium market segments offer enhanced profitability through specialized applications in craft beverages, luxury cosmetics, and high-end food products. These segments typically accept higher pricing for superior packaging quality, unique designs, and enhanced brand presentation capabilities that glass containers provide.

Technological advancement opportunities include lightweight container development, smart packaging integration, and advanced decoration techniques that can differentiate products and create competitive advantages. Investment in research and development can yield proprietary technologies that command premium pricing and strengthen customer relationships.

Geographic expansion potential extends beyond traditional North American export markets to include Central and South American countries where economic development is driving increased demand for packaged goods. Strategic market entry can establish first-mover advantages in emerging markets with growing consumer purchasing power.

Circular economy initiatives present opportunities for manufacturers to develop closed-loop recycling systems, create value-added services, and strengthen relationships with environmentally conscious customers. These initiatives can generate additional revenue streams while supporting sustainability objectives.

Market dynamics in Mexico’s container glass industry reflect complex interactions between supply-side capabilities, demand-side requirements, and external environmental factors. Production capacity utilization currently operates at approximately 78% efficiency, indicating room for growth without requiring substantial new capital investment in manufacturing infrastructure.

Demand patterns demonstrate seasonal variations aligned with beverage consumption cycles, with peak demand occurring during summer months and holiday periods. This seasonality requires manufacturers to maintain flexible production scheduling and inventory management strategies to optimize capacity utilization and customer service levels.

Competitive intensity varies across market segments, with commodity glass containers experiencing price-based competition while specialty applications support value-based pricing strategies. Market leaders leverage economies of scale, technological capabilities, and customer relationships to maintain competitive advantages.

Innovation cycles drive continuous product development and manufacturing process improvements, with successful companies investing consistently in research and development activities. Customer collaboration plays an increasingly important role in product development, with manufacturers working closely with end-users to develop customized solutions that meet specific application requirements.

Regulatory influences shape market dynamics through environmental standards, food safety requirements, and trade policies that affect both domestic operations and export opportunities. Companies that proactively address regulatory requirements often gain competitive advantages through enhanced market access and customer confidence.

Comprehensive research methodology employed in analyzing Mexico’s container glass market incorporates multiple data sources and analytical approaches to ensure accuracy and reliability of market insights. Primary research activities include extensive interviews with industry executives, manufacturing personnel, and key customers to gather firsthand perspectives on market trends, challenges, and opportunities.

Secondary research components encompass analysis of industry publications, government statistics, trade association reports, and company financial disclosures to establish quantitative market parameters and validate primary research findings. This multi-source approach ensures comprehensive market coverage and reduces potential bias from individual data sources.

Quantitative analysis techniques include statistical modeling, trend analysis, and comparative benchmarking to identify market patterns and project future developments. These analytical methods provide objective foundations for market assessments and strategic recommendations.

Qualitative research methods incorporate expert interviews, focus group discussions, and observational studies to understand market dynamics that quantitative data alone cannot capture. This approach provides deeper insights into customer behavior, competitive strategies, and emerging market trends.

Data validation processes ensure research accuracy through cross-referencing multiple sources, conducting follow-up interviews, and applying statistical significance testing to key findings. These validation steps enhance confidence in research conclusions and recommendations.

Regional market distribution across Mexico reveals distinct patterns of container glass production and consumption that reflect industrial concentration, population density, and economic development levels. Central Mexico dominates manufacturing activity, accounting for approximately 52% of total production capacity, with major facilities located in states including Mexico, Puebla, and Hidalgo.

Northern border regions have experienced significant growth due to proximity to U.S. markets and established manufacturing infrastructure supporting export-oriented production. States such as Nuevo León, Chihuahua, and Baja California have attracted substantial investment in container glass manufacturing facilities designed primarily for cross-border trade.

Western Mexico represents an emerging growth region, with Jalisco and Michoacán states developing container glass capabilities to serve regional beverage and food processing industries. This region benefits from agricultural production that generates demand for food packaging applications and growing urban populations that consume packaged beverages.

Southern regions remain underdeveloped in container glass manufacturing but present opportunities for market expansion as economic development progresses and infrastructure improvements enhance market access. These regions may become increasingly important as manufacturers seek to diversify geographic risk and access new customer segments.

Coastal areas offer strategic advantages for manufacturers serving both domestic and international markets, with port access facilitating raw material imports and finished product exports. These locations may become increasingly valuable as global trade patterns evolve and supply chain optimization becomes more critical.

Competitive dynamics within Mexico’s container glass market feature a mix of established multinational corporations, domestic manufacturers, and specialized producers serving niche market segments. Market leadership is concentrated among several key players who have achieved significant scale advantages and technological capabilities.

Competitive strategies emphasize operational excellence, customer service, product innovation, and strategic partnerships to maintain market position and drive growth. Leading companies invest heavily in manufacturing technology, quality systems, and environmental sustainability initiatives to differentiate their offerings and strengthen customer relationships.

Market consolidation trends continue as companies seek to achieve greater economies of scale and operational efficiency through strategic acquisitions and partnerships. This consolidation creates opportunities for remaining independent manufacturers to serve specialized market niches or develop strategic alliances with larger players.

Market segmentation analysis reveals diverse applications and customer requirements that drive demand for container glass products across multiple industry verticals. By Application: The market divides into several key segments with distinct characteristics and growth patterns.

Beverage Applications:

Food Applications:

Pharmaceutical Applications:

Category analysis provides detailed understanding of performance variations across different container glass market segments, revealing opportunities for growth and optimization. Beverage containers maintain market dominance with consistent demand growth driven by population expansion, urbanization, and increasing per-capita consumption of packaged beverages.

Premium beverage segments demonstrate particularly strong growth potential, with craft beer, premium spirits, and specialty water categories showing annual growth rates exceeding 8%. These segments support higher pricing and enhanced profit margins while requiring specialized manufacturing capabilities and customer service approaches.

Pharmaceutical packaging represents the fastest-growing category, benefiting from Mexico’s expanding healthcare sector and increasing pharmaceutical manufacturing activity. This segment requires stringent quality standards, regulatory compliance, and specialized production capabilities that create barriers to entry and support premium pricing.

Food packaging applications show steady growth aligned with processed food consumption trends and export market development. MWR analysis indicates that specialty food segments, including organic products and gourmet foods, offer particular growth opportunities for manufacturers capable of providing customized packaging solutions.

Industrial applications including chemical containers and laboratory glassware represent smaller but stable market segments that provide diversification benefits and specialized revenue streams. These applications often require unique specifications and technical expertise that support differentiated market positioning.

Industry participants and stakeholders derive multiple strategic advantages from engagement in Mexico’s container glass market, creating value across the entire supply chain ecosystem. Manufacturers benefit from established market demand, diversified customer base, and opportunities for operational scale that support sustainable profitability and growth.

Cost advantages include competitive labor costs, favorable energy pricing, and strategic geographic positioning that reduces transportation expenses for key markets. These factors enable Mexican manufacturers to compete effectively in both domestic and international markets while maintaining healthy profit margins.

Customer benefits encompass reliable supply chains, high-quality products, and responsive customer service that support their business objectives and market positioning. Long-term partnerships with glass manufacturers provide supply security and collaborative product development opportunities that enhance competitive advantages.

Investor advantages include exposure to growing markets, stable cash flows, and opportunities for value creation through operational improvements and market expansion. The industry’s essential nature and high barriers to entry provide defensive characteristics that appeal to risk-conscious investors.

Economic development benefits extend to local communities through employment creation, tax revenue generation, and supply chain development that supports broader economic growth. Container glass manufacturing typically provides well-paying jobs and contributes to industrial development in host regions.

Environmental benefits include support for circular economy principles through glass recycling, reduced packaging waste, and lower carbon footprint compared to alternative packaging materials. These benefits align with growing environmental consciousness and regulatory requirements.

Strengths:

Weaknesses:

Opportunities:

Threats:

Transformative trends shaping Mexico’s container glass market reflect broader industry evolution and changing customer requirements across multiple dimensions. Sustainability integration has become a dominant trend, with manufacturers investing heavily in recycling infrastructure, energy efficiency improvements, and circular economy initiatives that reduce environmental impact while creating competitive advantages.

Lightweighting initiatives continue gaining momentum as manufacturers develop thinner-walled containers that maintain structural integrity while reducing material usage and transportation costs. These innovations require advanced engineering capabilities and precise manufacturing control but offer significant value propositions for customers seeking cost reduction and environmental benefits.

Digital transformation is revolutionizing manufacturing operations through implementation of Industry 4.0 technologies including predictive maintenance, real-time quality monitoring, and automated production optimization. These technologies improve operational efficiency while reducing waste and enhancing product consistency.

Customization demand is increasing as customers seek unique packaging solutions that differentiate their products and strengthen brand positioning. This trend requires flexible manufacturing capabilities and collaborative customer relationships but supports premium pricing and enhanced customer loyalty.

Supply chain localization trends are driving manufacturers to establish regional production capabilities that reduce transportation costs and improve customer responsiveness. This localization strategy requires careful market analysis and investment planning but can create sustainable competitive advantages.

Recent industry developments demonstrate the dynamic nature of Mexico’s container glass market and the strategic initiatives driving market evolution. Capacity expansion projects by major manufacturers reflect confidence in long-term market growth and commitment to serving increasing customer demand across multiple market segments.

Technology partnerships between glass manufacturers and equipment suppliers have accelerated adoption of advanced manufacturing technologies that improve productivity, quality, and environmental performance. These collaborations often result in proprietary capabilities that create competitive differentiation.

Sustainability certifications and environmental management system implementations have become standard practice among leading manufacturers, reflecting customer requirements and regulatory expectations. These initiatives often generate operational improvements while enhancing market positioning.

Strategic acquisitions and joint ventures continue reshaping competitive dynamics as companies seek to achieve greater scale, access new markets, or acquire specialized capabilities. These transactions often create synergies that benefit customers through improved service and expanded product offerings.

Research and development investments in new glass formulations, manufacturing processes, and product designs are generating innovations that address evolving customer needs and market requirements. These investments position companies for future growth while strengthening competitive advantages.

Strategic recommendations for Mexico container glass market participants emphasize the importance of balanced growth strategies that leverage existing strengths while addressing market challenges and opportunities. MarkWide Research analysis suggests that companies should prioritize operational excellence initiatives that improve manufacturing efficiency and product quality while reducing environmental impact.

Investment priorities should focus on technologies that enable lightweighting, improve energy efficiency, and enhance manufacturing flexibility to serve diverse customer requirements. These investments typically generate positive returns through reduced operating costs and enhanced customer value propositions.

Market expansion strategies should emphasize high-growth segments including pharmaceuticals, premium beverages, and specialty applications that support higher margins and customer loyalty. Success in these segments requires specialized capabilities and dedicated customer service approaches.

Partnership development with key customers, suppliers, and technology providers can create competitive advantages through improved supply chain integration, innovation acceleration, and market access enhancement. These partnerships often generate mutual benefits that strengthen long-term business relationships.

Sustainability leadership should become a core strategic priority, with companies investing in recycling infrastructure, renewable energy adoption, and circular economy initiatives that address customer requirements while reducing operational costs and regulatory risks.

Future market prospects for Mexico’s container glass industry appear favorable, supported by demographic trends, economic development, and evolving consumer preferences that favor sustainable packaging solutions. Long-term growth projections indicate sustained market expansion with projected annual growth rates of 4.5% over the next decade, driven by increasing urbanization and rising disposable incomes.

Technology evolution will continue transforming manufacturing capabilities, with advanced automation, artificial intelligence, and sustainable production technologies becoming standard industry practices. Companies that invest proactively in these technologies will likely achieve competitive advantages through improved efficiency and product differentiation.

Market consolidation trends are expected to continue as companies seek economies of scale and operational synergies through strategic combinations. This consolidation may create opportunities for specialized manufacturers serving niche markets while strengthening the competitive position of industry leaders.

Export market development presents significant growth opportunities as Mexican manufacturers leverage competitive advantages to serve expanding international markets. Success in export markets will require continued investment in quality systems, customer service capabilities, and logistics infrastructure.

Regulatory evolution toward stricter environmental standards and sustainability requirements will likely accelerate industry transformation while creating competitive advantages for companies that proactively address these requirements through innovative solutions and operational improvements.

Mexico’s container glass market represents a dynamic and growing industry with substantial opportunities for sustainable growth and value creation. The market benefits from strong fundamental drivers including demographic trends, industrial diversification, and increasing focus on sustainable packaging solutions that position glass containers advantageously relative to alternative materials.

Strategic positioning of Mexican manufacturers leverages competitive advantages in manufacturing costs, geographic location, and raw material access while addressing challenges related to energy costs, environmental compliance, and competitive pressures. Success in this market requires balanced strategies that emphasize operational excellence, customer service, and sustainable business practices.

Future success will depend on companies’ ability to adapt to evolving market requirements, invest in advanced technologies, and develop strong customer partnerships that create mutual value and competitive differentiation. The industry’s essential nature and high barriers to entry provide stability while growth opportunities in premium segments and export markets offer potential for enhanced profitability and market expansion.

What is Container Glass?

Container glass refers to glass products designed for packaging and storing various goods, including beverages, food, and pharmaceuticals. It is known for its durability, recyclability, and ability to preserve the quality of its contents.

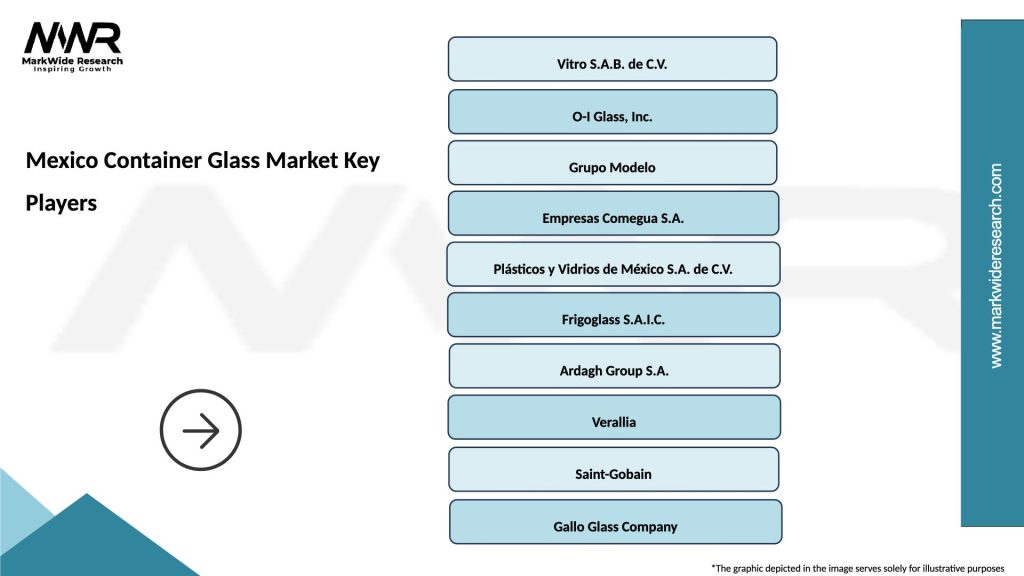

What are the key players in the Mexico Container Glass Market?

Key players in the Mexico Container Glass Market include Vitro, O-I Glass, and Grupo Modelo, which are known for their extensive production capabilities and innovative glass packaging solutions, among others.

What are the growth factors driving the Mexico Container Glass Market?

The Mexico Container Glass Market is driven by increasing demand for sustainable packaging solutions, the growth of the beverage industry, and rising consumer preferences for glass over plastic due to health and environmental concerns.

What challenges does the Mexico Container Glass Market face?

Challenges in the Mexico Container Glass Market include high production costs, competition from alternative packaging materials, and the need for significant energy consumption during manufacturing processes.

What opportunities exist in the Mexico Container Glass Market?

Opportunities in the Mexico Container Glass Market include the expansion of e-commerce, which increases demand for safe packaging, and innovations in glass recycling technologies that enhance sustainability efforts.

What trends are shaping the Mexico Container Glass Market?

Trends in the Mexico Container Glass Market include the rise of personalized packaging solutions, increased focus on eco-friendly production methods, and the growing popularity of premium glass containers in the food and beverage sectors.

Mexico Container Glass Market

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Jars, Containers, Vials |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Household |

| Grade | Recycled, Soda-Lime, Borosilicate, Lead Glass |

| Packaging Type | Bulk, Retail, Custom, Standard |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Mexico Container Glass Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at