444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Metal fabrication is the process of creating metal structures by cutting, bending, and assembling metal pieces. The metal fabrication service market is a rapidly growing industry due to the increasing demand for customized metal products across various end-use industries. In this article, we will analyze the global metal fabrication service market, including its meaning, executive summary, market analysis, market drivers, market restraints, market opportunities, regional analysis, competitive landscape, market segmentation, SWOT analysis, market key trends, COVID-19 impact, key industry developments, future outlook, and conclusion.

Metal fabrication services are offered by companies that specialize in designing, engineering, and manufacturing metal products. These services include custom fabrication, welding, cutting, and metal finishing. Metal fabrication services are widely used in various industries, including automotive, aerospace, construction, and energy.

Executive Summary

The global metal fabrication service market is expected to grow at a CAGR of 3.9% from 2021 to 2028. The key factors driving the market growth are increasing demand for customized metal products, growing industrialization, and rising infrastructure development. The Asia-Pacific region is expected to dominate the market due to the high demand for metal fabrication services in the region.

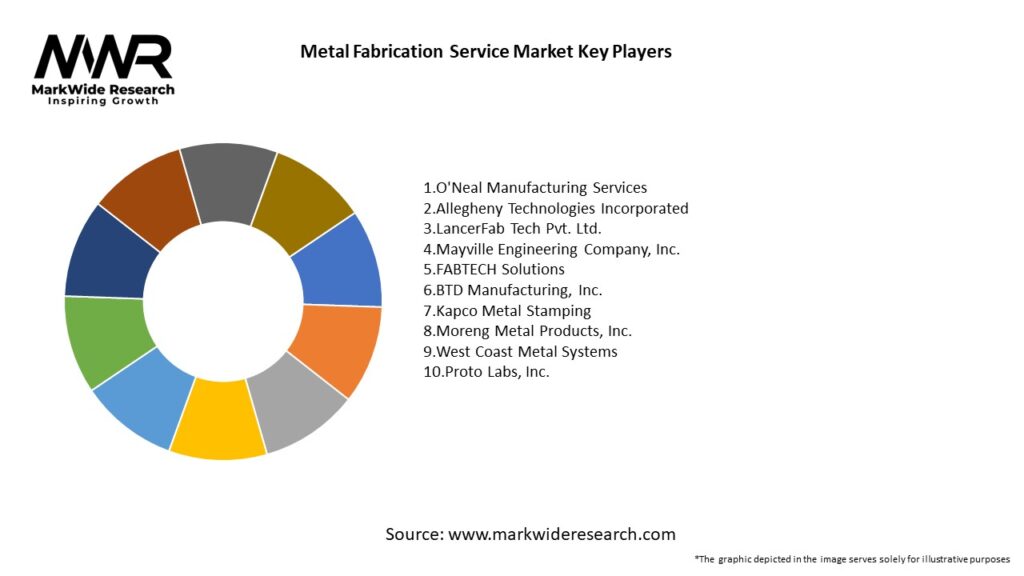

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

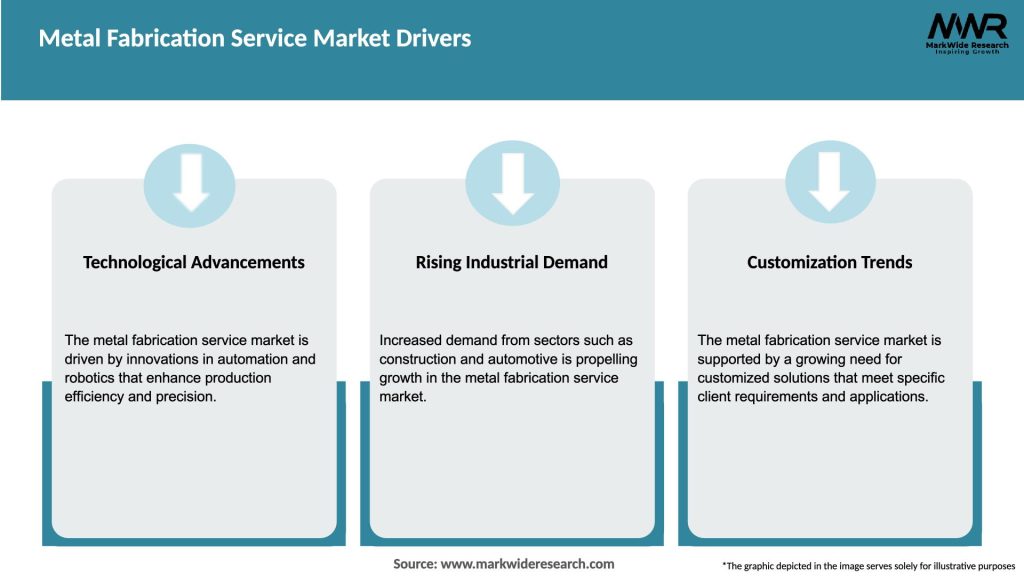

Market Drivers

Several key factors are driving the growth of the Metal Fabrication Service Market:

Industrial Growth: As industrial activities, particularly in the automotive, aerospace, and construction sectors, continue to grow, the demand for metal parts and components produced through fabrication services is rising.

Technological Advancements: The increasing adoption of automated systems, robotics, and AI in fabrication processes is enabling faster, more accurate, and cost-effective production, contributing to the market’s expansion.

Custom Manufacturing Demand: Many industries require bespoke metal products that can only be produced through advanced metal fabrication techniques, driving demand for these services.

Growth in Infrastructure Projects: The rise in infrastructure development across the globe, particularly in emerging economies, is increasing the demand for fabricated metal parts for construction and engineering applications.

Sustainability and Efficiency: The push for energy-efficient and sustainable manufacturing practices is encouraging the adoption of precision fabrication technologies, reducing waste, and improving energy efficiency.

Market Restraints

Despite the strong growth prospects, the Metal Fabrication Service Market faces several challenges:

High Initial Costs: The high investment required in advanced equipment, machinery, and skilled labor for metal fabrication services can be a barrier, particularly for small and medium-sized enterprises (SMEs).

Skilled Labor Shortage: There is a growing shortage of skilled workers trained in advanced metal fabrication techniques such as welding, machining, and CNC operations, which could hamper growth in certain regions.

Fluctuating Raw Material Prices: The price volatility of raw materials such as steel, aluminum, and copper can impact the profitability of metal fabrication services, making it difficult for businesses to offer competitive prices.

Environmental Regulations: Stricter environmental regulations related to manufacturing and waste disposal may increase operational costs for metal fabrication companies, affecting their profitability.

Market Opportunities

The Metal Fabrication Service Market presents several opportunities for growth and innovation:

Emerging Markets: The rapid industrialization in emerging markets, particularly in Asia-Pacific, Latin America, and Africa, presents significant opportunities for metal fabrication service providers to expand their operations and capture new business.

Sustainable Practices: As demand for sustainable manufacturing practices grows, companies that can offer environmentally friendly fabrication services, such as reducing material waste and energy consumption, will have a competitive edge.

Adoption of 3D Printing: The adoption of 3D printing for metal fabrication is opening up new opportunities for businesses to produce highly complex parts that were previously difficult or expensive to manufacture using traditional methods.

Automotive and Aerospace Demand: The growing need for lightweight, high-strength metal components in the automotive and aerospace industries is driving demand for advanced fabrication services capable of producing precision-engineered parts.

Market Dynamics

The Metal Fabrication Service Market is influenced by several dynamic factors:

Technological Innovation: Continuous advancements in automation, robotics, and digital manufacturing technologies are reshaping the metal fabrication landscape, enabling faster production and enhanced precision.

Regulatory Environment: Compliance with environmental regulations related to emissions, waste management, and recycling is shaping the operational strategies of metal fabrication companies.

Global Supply Chains: The interconnected global supply chains and trade policies, particularly in raw materials and fabricated parts, are having an impact on the cost and availability of key components used in metal fabrication.

Customization Trends: Increasing demand for customized solutions in industries such as automotive, aerospace, and industrial equipment is driving innovation in fabrication processes and the development of more specialized services.

Regional Analysis

The Metal Fabrication Service Market is geographically diverse, with key regions contributing to the market growth:

North America: The market in North America, particularly the United States and Canada, is driven by a strong manufacturing base in automotive, aerospace, and construction sectors, and a high demand for customized metal products.

Europe: Europe is home to some of the world’s largest automotive and manufacturing industries, which fuels the demand for metal fabrication services. Germany, Italy, and the UK are leading players in the market.

Asia-Pacific: Asia-Pacific is expected to see the highest growth in the metal fabrication services market, with China and India leading the demand due to the rapid industrialization and growth in sectors like automotive, construction, and electronics.

Latin America: The growing infrastructure development in countries like Brazil and Mexico is contributing to an increased demand for fabricated metal components in construction and energy sectors.

Middle East & Africa: The demand for metal fabrication services is rising in the Middle East, particularly in the construction and oil and gas sectors, due to ongoing infrastructure projects.

Competitive Landscape

Leading companies in the Metal Fabrication Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

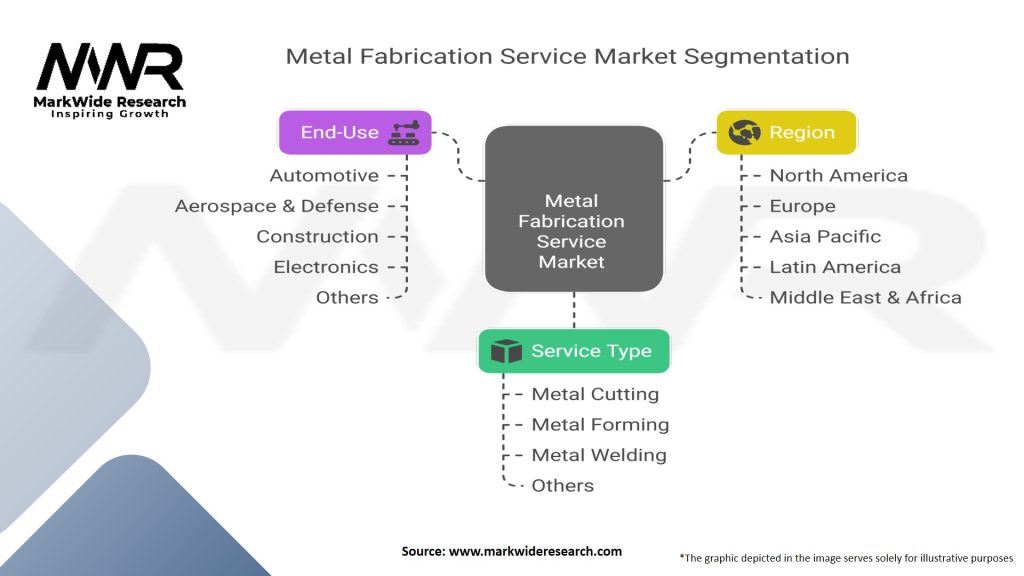

Segmentation

The Metal Fabrication Service Market can be segmented based on various factors:

Type of Service: Cutting, Bending, Welding, Assembling, Machining.

Application: Automotive, Aerospace, Construction, Industrial Equipment, Consumer Goods.

End-User Industry: Automotive, Construction, Aerospace, Heavy Machinery, Consumer Electronics.

Category-wise Insights

Automotive: The automotive industry is one of the largest consumers of metal fabrication services, requiring precise and customized parts for vehicles.

Aerospace: Aerospace companies require lightweight and high-strength metal components, making the aerospace industry a key driver of the metal fabrication market.

Key Benefits for Industry Participants and Stakeholders

Customization: Metal fabrication services provide highly customized solutions for industries requiring specific part specifications and precision.

Cost-Effective Solutions: Metal fabrication helps businesses reduce manufacturing costs by providing tailored, efficient, and cost-effective metal parts.

Enhanced Product Quality: The advanced technologies in metal fabrication, including CNC machining and laser cutting, ensure high-quality components that meet industry standards.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Automation: Increasing use of automation and robotics in fabrication processes to improve production speed and reduce human error.

Sustainability: Growing demand for sustainable manufacturing processes in metal fabrication, including energy-efficient systems and waste reduction.

COVID-19 Impact

The COVID-19 pandemic has had a significant impact on the global metal fabrication service market. The pandemic has disrupted the global supply chain, leading to shortages of raw materials and delays in shipments. The closure of manufacturing facilities and construction sites has also affected the demand for metal fabrication services. However, the market is expected to recover in the post-pandemic period due to the increasing demand for infrastructure development and the growing trend of localization of supply chains.

Key Industry Developments

Technological Innovation: The adoption of advanced technologies such as laser cutting and AI-driven systems for precision and efficiency.

Strategic Partnerships: Increasing collaborations between fabrication service providers and technology companies to enhance service offerings.

Analyst Suggestions

Invest in Automation: Companies should invest in automated systems and robotics to enhance production efficiency and meet growing demand.

Focus on Sustainability: Implementing sustainable practices and energy-efficient technologies can help businesses comply with environmental regulations and appeal to eco-conscious consumers.

Future Outlook

The global metal fabrication service market is expected to grow at a steady rate in the coming years, driven by the increasing demand for customized metal products and the growing industrialization and infrastructure development. The market is also expected to benefit from the increasing adoption of automation and robotics in metal fabrication services. The Asia-Pacific region is expected to dominate the market due to the high demand for metal fabrication services in the region. However, the market is expected to face challenges from low-cost alternatives and fluctuations in raw material prices.

Conclusion

The global metal fabrication service market is a rapidly growing industry that offers customized metal products to various end-use industries. The market is expected to grow at a steady rate in the coming years due to the increasing demand for customized metal products and the growing industrialization and infrastructure development. The key players in the market are adopting strategies such as mergers and acquisitions, partnerships, and collaborations to strengthen their position in the market. The market is also witnessing key trends such as the increasing use of advanced technologies and sustainable practices. Despite challenges such as high costs and fluctuations in raw material prices, the metal fabrication service market is expected to offer significant opportunities in the future.

What is metal fabrication service?

Metal fabrication service refers to the process of creating metal structures and components through cutting, bending, and assembling various metal materials. This service is essential in industries such as construction, automotive, and aerospace, where precision and durability are critical.

Who are the key players in the metal fabrication service market?

Key players in the metal fabrication service market include companies like Steelcase, Inc., ArcelorMittal, and Thyssenkrupp AG, which provide a range of fabrication services for various applications, including structural steel and custom metal parts, among others.

What are the main drivers of growth in the metal fabrication service market?

The main drivers of growth in the metal fabrication service market include the increasing demand for customized metal products, advancements in fabrication technologies, and the expansion of industries such as construction and manufacturing that rely heavily on metal components.

What challenges does the metal fabrication service market face?

The metal fabrication service market faces challenges such as fluctuating raw material prices, skilled labor shortages, and the need for compliance with stringent environmental regulations, which can impact operational costs and project timelines.

What opportunities exist in the metal fabrication service market?

Opportunities in the metal fabrication service market include the growing trend towards automation and digitalization in manufacturing processes, the rise of sustainable practices in metalworking, and the increasing demand for lightweight materials in industries like automotive and aerospace.

What trends are shaping the metal fabrication service market?

Trends shaping the metal fabrication service market include the adoption of advanced technologies such as laser cutting and CNC machining, the integration of Industry Four-point-oh practices, and a focus on sustainability through recycling and eco-friendly materials.

Metal Fabrication Service Market

| Segmentation | Details |

|---|---|

| Service Type | Metal Cutting, Metal Forming, Metal Welding, Others |

| End-Use | Automotive, Aerospace & Defense, Construction, Electronics, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Metal Fabrication Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at