444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The metal 3D printing service market represents a revolutionary shift in manufacturing, where traditional processes are being augmented or replaced by advanced additive manufacturing techniques. Metal 3D printing, also known as metal additive manufacturing, allows for the creation of complex metal parts through layer-by-layer deposition. This market is growing rapidly due to the demand for customized solutions, shorter lead times, reduced waste, and enhanced design flexibility. This comprehensive report explores key aspects of the metal 3D printing service market, including its definition, market drivers, restraints, opportunities, dynamics, and competitive landscape. Additionally, we will delve into key trends, the impact of Covid-19, regional analysis, and future outlook.

Meaning

Metal 3D printing, in its most basic form, involves using various additive manufacturing techniques to create metal objects from digital models. Unlike traditional subtractive manufacturing, where material is removed to create a part, metal 3D printing adds material layer by layer. This process allows for complex geometries and intricate designs that would be difficult or impossible to achieve with conventional manufacturing methods. Metal 3D printing services encompass a range of applications, including aerospace, automotive, healthcare, industrial tooling, and consumer products, providing customized solutions to meet diverse industry needs.

Executive Summary

The metal 3D printing service market is witnessing rapid growth, driven by technological advancements, the demand for customized manufacturing, and the need for sustainable practices. This report provides an in-depth analysis of the market, examining key market insights, drivers, restraints, and opportunities. The competitive landscape, regional analysis, segmentation, and category-wise insights are explored to understand the market’s complexity. The report also covers the impact of Covid-19, key industry developments, analyst suggestions, and a future outlook for the metal 3D printing service market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Key market insights offer a snapshot of the current state of the metal 3D printing service market and its growth trajectory. These insights help businesses understand the trends and factors driving market growth.

Market Drivers

Market drivers are the factors that contribute to the growth and expansion of the metal 3D printing service market. These drivers can be economic, technological, or industry-specific, each playing a role in shaping the market’s trajectory.

Market Restraints

Market restraints refer to factors that may hinder the growth of the metal 3D printing service market or present challenges to businesses. Understanding these restraints is essential for developing effective risk mitigation strategies.

Market Opportunities

Despite the market restraints, there are ample opportunities for growth and expansion in the metal 3D printing service market. Identifying these opportunities can help businesses capitalize on emerging trends and market needs.

Market Dynamics

Market dynamics refer to the complex interactions between various factors that influence the behavior of the metal 3D printing service market. Understanding these dynamics helps businesses adapt to changing conditions and make informed decisions.

Regional Analysis

The metal 3D printing service market is a global market with regional variations in demand and industry trends. Conducting a regional analysis helps businesses understand the unique characteristics of different markets and tailor their strategies accordingly.

Competitive Landscape

Leading Companies in Metal 3D Printing Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

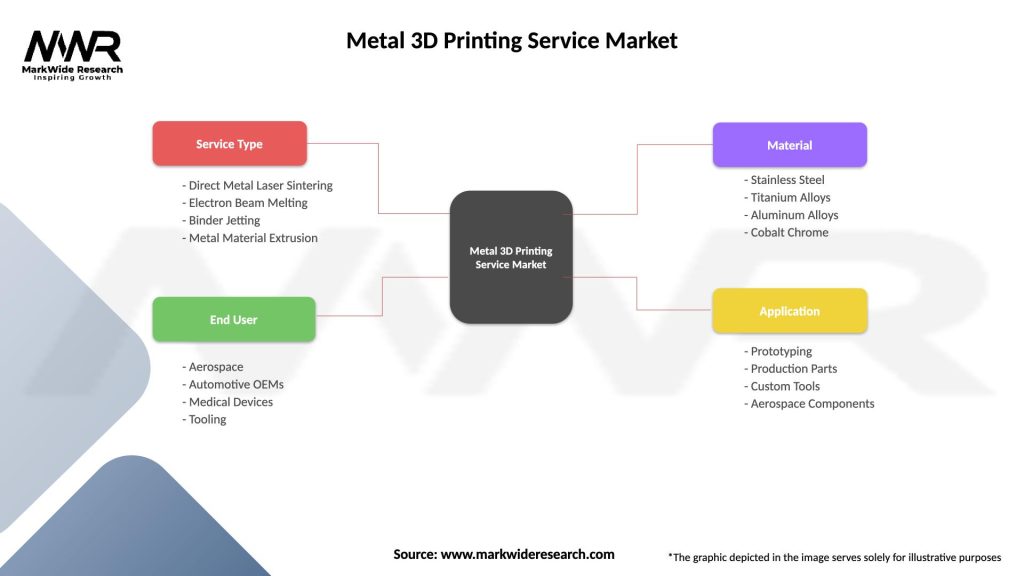

Segmentation

Market segmentation involves dividing the metal 3D printing service market into distinct categories based on specific characteristics or criteria. This approach allows businesses to target specific customer groups and tailor their products or services accordingly.

Category-wise Insights

Category-wise insights provide a deeper understanding of specific market segments or product categories within the metal 3D printing service market. This section explores various categories and their unique characteristics, offering valuable information for businesses seeking to target these segments.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the metal 3D printing service market stand to gain significant benefits from market analysis and insights. Understanding these benefits can help businesses identify opportunities and create value for their stakeholders.

SWOT Analysis

A SWOT analysis is a strategic tool used to identify a business’s strengths, weaknesses, opportunities, and threats in the metal 3D printing service market. It provides a comprehensive view of the internal and external factors that influence market success.

Market Key Trends

Identifying key market trends is essential for businesses seeking to stay ahead of the curve in the metal 3D printing service market. Trends can indicate shifts in industry requirements, technological advancements, or changing market dynamics.

Covid-19 Impact

The Covid-19 pandemic has had a profound impact on the metal 3D printing service market, affecting industries, businesses, and supply chains. This section explores the key effects of the pandemic and how businesses have adapted to the changing landscape.

Key Industry Developments

Key industry developments refer to significant events or trends that have shaped the metal 3D printing service market. These developments can include mergers and acquisitions, regulatory changes, and technological advancements.

Analyst Suggestions

Analysts provide expert insights and suggestions based on market analysis and trends. These suggestions can help businesses make informed decisions and develop effective strategies for success in the metal 3D printing service market.

Future Outlook

The future outlook for the metal 3D printing service market is shaped by various factors, including economic trends, technological advancements, and industry developments. This section explores the key aspects of the market’s future outlook and what businesses can expect.

Conclusion

In conclusion, the metal 3D printing service market represents a transformative shift in manufacturing, driven by technological advancements, customization, and sustainability. Understanding the market’s key drivers, restraints, opportunities, and dynamics is crucial for businesses seeking to navigate this industry effectively. The competitive landscape and regional variations provide additional insights into market behavior, while category-wise insights offer a deeper understanding of specific market segments. As the market continues to evolve, businesses must stay informed about key trends, regulatory changes, and industry developments. By embracing advanced technologies, focusing on customization, and strengthening industry partnerships, businesses can position themselves for success in the metal 3D printing service market’s future.

What is Metal 3D Printing Service?

Metal 3D Printing Service refers to the process of creating three-dimensional objects from metal materials using additive manufacturing techniques. This technology is widely used in industries such as aerospace, automotive, and medical for producing complex parts with high precision.

What are the key players in the Metal 3D Printing Service Market?

Key players in the Metal 3D Printing Service Market include companies like Stratasys, 3D Systems, and EOS, which are known for their advanced additive manufacturing technologies. These companies provide a range of services and solutions for various industrial applications, among others.

What are the growth factors driving the Metal 3D Printing Service Market?

The Metal 3D Printing Service Market is driven by factors such as the increasing demand for lightweight and complex components in aerospace and automotive industries, as well as advancements in printing technologies. Additionally, the growing trend of customization in manufacturing is contributing to market growth.

What challenges does the Metal 3D Printing Service Market face?

Challenges in the Metal 3D Printing Service Market include high material costs and the need for specialized equipment and expertise. Furthermore, regulatory compliance and quality assurance in critical applications like aerospace can pose significant hurdles.

What opportunities exist in the Metal 3D Printing Service Market?

Opportunities in the Metal 3D Printing Service Market include the potential for innovation in materials and processes, as well as the expansion of applications in sectors like healthcare and energy. The increasing adoption of Industry Four-point-oh technologies also presents new avenues for growth.

What trends are shaping the Metal 3D Printing Service Market?

Trends in the Metal 3D Printing Service Market include the rise of hybrid manufacturing techniques that combine traditional and additive methods, as well as the development of new metal alloys specifically designed for 3D printing. Sustainability initiatives are also influencing the market as companies seek to reduce waste and improve efficiency.

Metal 3D Printing Service Market

| Segmentation Details | Description |

|---|---|

| Service Type | Direct Metal Laser Sintering, Electron Beam Melting, Binder Jetting, Metal Material Extrusion |

| End User | Aerospace, Automotive OEMs, Medical Devices, Tooling |

| Material | Stainless Steel, Titanium Alloys, Aluminum Alloys, Cobalt Chrome |

| Application | Prototyping, Production Parts, Custom Tools, Aerospace Components |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Metal 3D Printing Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at