444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The Malaysia Adhesives Market has been experiencing steady growth, driven by increasing demand across various end-use industries such as automotive, construction, packaging, and textiles. Adhesives are essential in these industries for bonding materials, enhancing product performance, and improving manufacturing efficiency. With rising industrial activities and growing awareness of the benefits of adhesive products, the market is poised for continued expansion. The market is also influenced by the shift toward environmentally friendly products, such as bio-based adhesives, in response to sustainability demands.

Meaning

Adhesives are substances used for joining materials together by forming a bond at the interface of two surfaces. These materials, commonly referred to as glue or paste, can be in various forms such as liquid, powder, or film. Adhesives are commonly used in various industries, including automotive, construction, packaging, and electronics. The function of adhesives extends beyond bonding, providing properties such as heat resistance, electrical conductivity, and moisture resistance, depending on the formulation.

Executive Summary

The Malaysia Adhesives Market is expected to witness steady growth over the forecast period, driven by increased demand in packaging, automotive, and construction sectors. Technological advancements in adhesive formulations, such as the development of eco-friendly adhesives, are also contributing to market expansion. The demand for packaging materials, particularly in the food and beverage industry, is expected to remain a key growth driver. However, challenges such as fluctuating raw material costs and environmental regulations may impact market dynamics. With a focus on innovation, key players in the market are positioning themselves to capitalize on the growing demand for high-performance and sustainable adhesives.

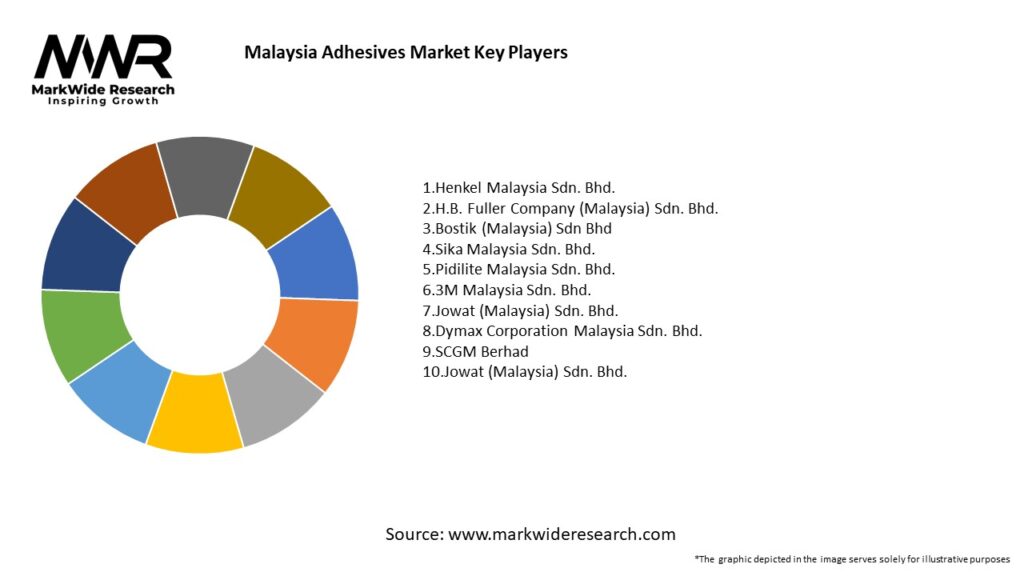

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

Regional Analysis

The Malaysia Adhesives Market is primarily driven by strong demand from packaging, automotive, and construction industries. Malaysia’s strategic location in Southeast Asia, along with its robust manufacturing base, makes it an ideal market for adhesive products. The demand for adhesives in packaging materials, particularly for the food and beverage sector, is rising, while the automotive and construction sectors continue to be key contributors to market growth. Additionally, government initiatives promoting sustainability are encouraging the adoption of eco-friendly adhesives in various applications.

Competitive Landscape

Leading Companies in the Malaysia Adhesives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

By Type

By End-Use Industry

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic affected the Malaysia Adhesives Market by disrupting supply chains and temporarily halting manufacturing activities. However, the demand for adhesives in packaging materials for essential goods, particularly food and healthcare products, remained strong. The pandemic accelerated the adoption of e-commerce, which led to increased demand for packaging adhesives. As industries recover and adapt, the role of adhesives in packaging and other sectors is expected to strengthen.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Malaysia Adhesives Market is expected to grow steadily as demand for adhesives continues to rise in key sectors such as packaging, automotive, and construction. With technological innovations and increasing adoption of sustainable adhesives, the market is likely to see significant expansion over the next few years. The future outlook section presents a forecast of the Malaysia adhesives market’s growth prospects and emerging trends. It takes into account various factors, including market dynamics, technological advancements, and regulatory landscape, to provide insights into the market’s future trajectory.

Conclusion

In conclusion, the Malaysia adhesives market offers immense growth potential, driven by the demand from key industries and the increasing focus on eco-friendly solutions. While challenges such as raw material price volatility and regulatory compliance exist, market players can leverage opportunities in the construction industry and emerging technologies to foster growth. By staying abreast of market trends and adopting strategic approaches, industry participants can thrive in this dynamic and evolving market landscape.

Malaysia Adhesives Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polyurethane, Epoxy, Acrylic, Silicone |

| End User | Construction, Automotive, Electronics, Packaging |

| Application | Bonding, Coating, Sealing, Insulating |

| Form | Liquid, Paste, Film, Granule |

Leading Companies in the Malaysia Adhesives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at