444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The machinery safety fences market encompasses a wide range of safety barriers and guarding systems designed to protect workers, equipment, and assets in industrial environments. These safety solutions serve as physical barriers to prevent access to hazardous machinery and production areas, ensuring compliance with safety regulations and standards while promoting a safe work environment.

Meaning

Machinery safety fences refer to physical barriers, enclosures, and guarding systems installed around machinery, equipment, and production areas to restrict access, control pedestrian traffic, and prevent accidents and injuries in industrial settings. These safety solutions play a crucial role in creating a safe work environment by minimizing the risk of contact with moving parts, pinch points, and other potential hazards.

Executive Summary

The machinery safety fences market is witnessing steady growth driven by increasing emphasis on workplace safety, regulatory compliance, and automation in industrial sectors. As companies prioritize worker safety and invest in advanced safety solutions, the demand for machinery safety fences continues to rise globally.

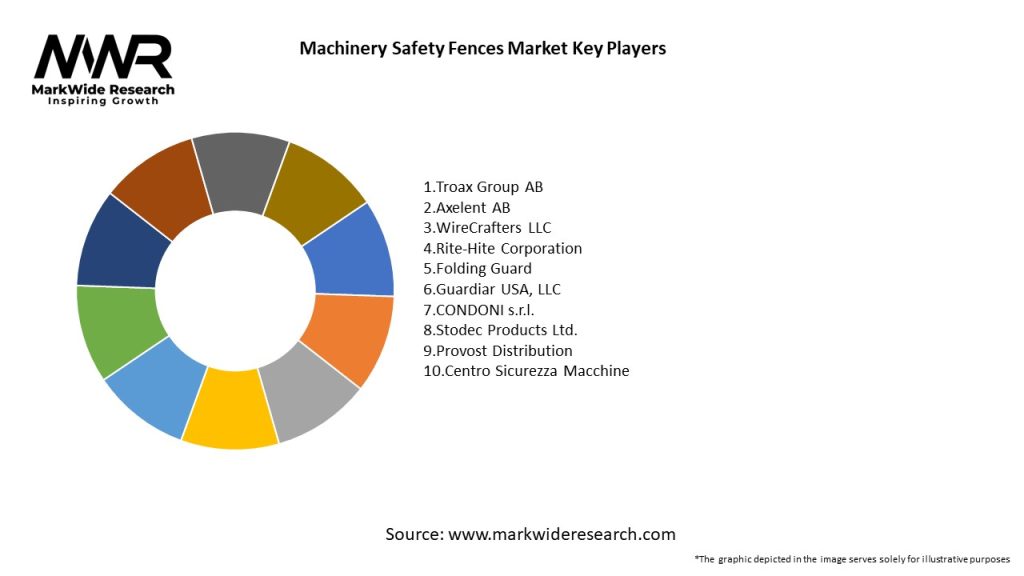

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The machinery safety fences market operates within a dynamic landscape influenced by factors such as technological advancements, regulatory changes, industry trends, and economic conditions. These dynamics shape market demand, competitive strategies, and innovation among market players, requiring agility, adaptability, and foresight to succeed in the market.

Regional Analysis

The adoption and demand for machinery safety fences vary across regions due to differences in industrialization levels, regulatory environments, safety standards, and market maturity. Understanding regional market dynamics, customer needs, and competitive landscapes is essential for market players to devise targeted strategies and enhance market penetration and growth.

Competitive Landscape

Leading Companies in the Machinery Safety Fences Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The machinery safety fences market can be segmented based on various factors, including product type, material, application, end-user industry, and geography. Segmentation enables market players to target specific customer segments, address diverse market needs, and tailor their product offerings, marketing strategies, and distribution channels accordingly to maximize market penetration and revenue growth.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths

• The machinery safety fences market benefits from stringent regulatory standards that mandate safety measures in industrial environments, driving consistent demand.

• High levels of customization available in safety fence designs allow businesses to tailor solutions to specific machinery and operational needs, enhancing user satisfaction.

• Established relationships with manufacturers and suppliers provide a competitive edge through improved access to high-quality materials and innovative safety technologies.

• Increasing awareness of workplace safety and accident prevention promotes the adoption of safety fences, thereby reinforcing market growth and stability.

Weaknesses

• The high initial investment required for installing advanced safety fencing systems can deter small to medium-sized enterprises from upgrading their safety measures.

• Limited awareness among some sectors about the importance of machinery safety fences may hinder market penetration in less regulated industries.

• The reliance on traditional materials for safety fences can restrict innovation and adaptability in meeting evolving safety standards and customer expectations.

• Maintenance and compliance costs associated with safety fencing systems can pose financial burdens, particularly for companies with tight budgets.

Opportunities

• The growing trend of automation in manufacturing presents opportunities for integrating advanced safety fencing solutions that enhance worker protection alongside automated machinery.

• Expanding industries such as construction and logistics are increasingly prioritizing safety, creating a larger market for machinery safety fences tailored to diverse applications.

• Advances in smart technology and IoT integration offer potential for developing intelligent safety fences that provide real-time monitoring and alerts, appealing to tech-savvy customers.

• The rising focus on sustainability can drive innovation in eco-friendly materials for safety fences, aligning with corporate social responsibility initiatives and attracting environmentally conscious clients.

Threats

• Intense competition from low-cost alternatives in the market may pressure pricing strategies, potentially undermining profit margins for established manufacturers.

• Rapid technological advancements could render existing safety fencing solutions obsolete, necessitating continuous innovation to maintain market relevance.

• Economic downturns or fluctuations in industrial activity can lead to reduced capital expenditure on safety improvements, impacting overall market growth.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has highlighted the importance of workplace safety and hygiene, accelerating demand for machinery safety fences to implement physical distancing measures, access controls, and hygiene protocols in industrial facilities to mitigate the risk of virus transmission among workers.

Key Industry Developments

Analyst Suggestions

Future Outlook

The machinery safety fences market is poised for growth driven by increasing awareness of workplace safety, regulatory compliance requirements, and technological advancements in automation and digitalization. The market’s future will be shaped by trends such as digitalization, customization, sustainability, and collaboration, offering opportunities for innovation, market differentiation, and strategic partnerships.

Conclusion

Machinery safety fences play a critical role in ensuring workplace safety, regulatory compliance, and risk mitigation in industrial environments. As companies prioritize worker safety and invest in advanced safety solutions, the demand for machinery safety fences continues to rise globally. By embracing innovation, compliance, customer education, and strategic partnerships, market players can capitalize on growth opportunities, differentiate their offerings, and contribute to safer and more productive industrial workplaces.

What is Machinery Safety Fences?

Machinery safety fences are protective barriers designed to prevent unauthorized access to hazardous areas around machinery, ensuring the safety of workers and compliance with safety regulations.

What are the key players in the Machinery Safety Fences Market?

Key players in the Machinery Safety Fences Market include companies like Rockford Systems, A-Safe, and Ametek, among others.

What are the main drivers of growth in the Machinery Safety Fences Market?

The growth of the Machinery Safety Fences Market is driven by increasing workplace safety regulations, rising awareness of employee safety, and the expansion of manufacturing sectors requiring enhanced safety measures.

What challenges does the Machinery Safety Fences Market face?

Challenges in the Machinery Safety Fences Market include high installation costs, the need for regular maintenance, and potential resistance from companies due to perceived operational disruptions.

What opportunities exist in the Machinery Safety Fences Market?

Opportunities in the Machinery Safety Fences Market include advancements in materials technology, the integration of smart safety solutions, and the growing demand for customized safety solutions in various industries.

What trends are shaping the Machinery Safety Fences Market?

Trends in the Machinery Safety Fences Market include the adoption of modular fencing systems, increased use of transparent materials for visibility, and the incorporation of IoT technology for enhanced safety monitoring.

Machinery Safety Fences Market

| Segmentation Details | Description |

|---|---|

| Product Type | Fixed Fences, Adjustable Fences, Modular Fences, Portable Fences |

| Material | Steel, Aluminum, Plastic, Composite |

| Application | Manufacturing, Construction, Warehousing, Agriculture |

| End User | OEMs, Contractors, Facility Managers, Safety Inspectors |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Machinery Safety Fences Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at