444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The machine tool maintenance service market serves as a linchpin within the industrial landscape, offering critical maintenance and repair services for machine tools across diverse sectors. It ensures optimal operational efficiency, longevity, and performance of machinery, thereby underpinning seamless industrial operations and productivity enhancement.

Meaning

Machine tool maintenance services encompass a gamut of activities aimed at preserving, repairing, and optimizing the functionality of machine tools utilized across various industrial domains. These services encompass preventive maintenance, corrective repairs, and predictive maintenance strategies, ensuring uninterrupted machinery operation and mitigating downtime risks.

Executive Summary

The machine tool maintenance service market witnesses robust growth propelled by burgeoning industrial automation, escalating demand for precision machining, and imperative adherence to stringent quality standards. While presenting abundant growth prospects, the market is beset by challenges such as skilled labor shortages and technological complexities, necessitating innovative service delivery models and strategic partnerships.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The machine tool maintenance service market operates within a dynamic landscape characterized by technological dynamism, evolving industrial requirements, and regulatory imperatives. Adroit navigation of these dynamics mandates strategic foresight, innovation, and adaptability on the part of service providers to sustain competitiveness and capitalize on emergent opportunities.

Regional Analysis

The machine tool maintenance service market exhibits regional variances predicated on factors such as industrial maturity, technological adoption rates, and regulatory frameworks. A granular regional analysis elucidates distinctive market dynamics, informing targeted market penetration strategies and service delivery models.

Competitive Landscape

Leading Companies in the Machine Tool Maintenance Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

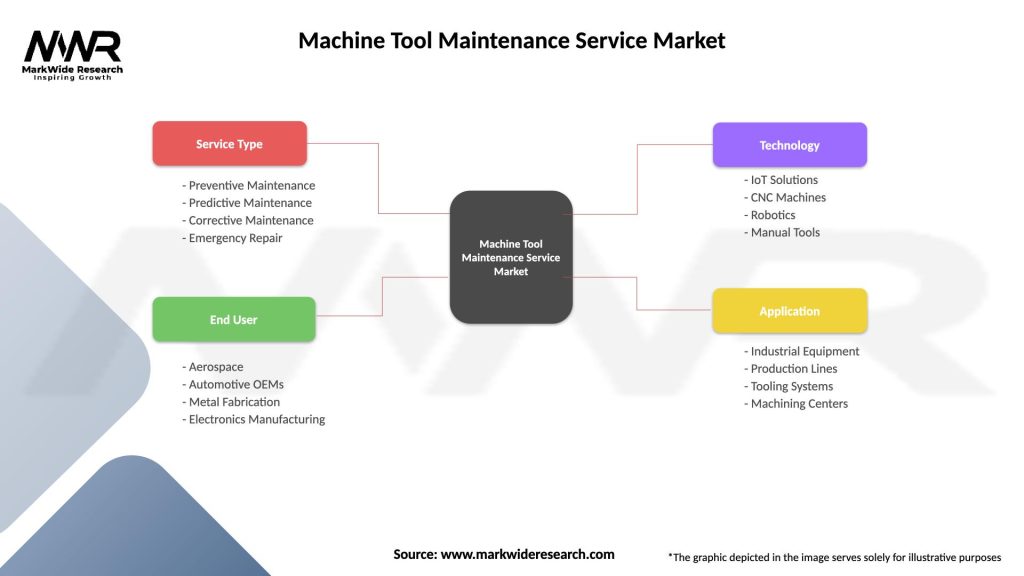

Segmentation

Segmentation constitutes a potent strategy for market segmentation, facilitating targeted service offerings tailored to diverse industrial requirements and customer preferences. Key segmentation parameters encompass machinery type, industrial verticals, maintenance service types, and geographic considerations, empowering service providers to cater to specialized market segments and augment revenue streams.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic engendered profound ramifications within the machine tool maintenance service market, characterized initially by disruptions in service provision and logistical challenges. However, the sector exhibited resilience, adapting to dynamic exigencies and pivoting towards remote service delivery modalities. Key impacts of the pandemic include:

Key Industry Developments

Analyst Suggestions

Future Outlook

The machine tool maintenance service market is poised for sustained growth driven by escalating industrial automation, burgeoning demand for predictive maintenance solutions, and imperatives for operational continuity. However, persistent challenges such as skilled labor shortages and technological complexities necessitate strategic interventions. The industry’s future trajectory is shaped by technological innovations, collaborative partnerships, and adept navigation of evolving market dynamics.

Conclusion

The machine tool maintenance service market assumes paramount importance within the industrial landscape, serving as a linchpin for operational continuity and productivity enhancement across diverse industrial sectors. Amidst escalating demand for precision machining and stringent quality imperatives, the market presents abundant growth opportunities tempered by challenges such as skilled labor shortages and technological complexities. By embracing technological innovations, fostering collaborative partnerships, and prioritizing service excellence, machine tool maintenance service providers can navigate dynamic market dynamics and emerge as key enablers of industrial efficiency and competitiveness.

What is Machine Tool Maintenance Service?

Machine Tool Maintenance Service refers to the systematic upkeep and repair of machine tools to ensure optimal performance and longevity. This includes routine inspections, preventive maintenance, and corrective actions to address any operational issues.

What are the key players in the Machine Tool Maintenance Service Market?

Key players in the Machine Tool Maintenance Service Market include companies like Siemens, Fanuc, and Mazak, which provide comprehensive maintenance solutions and support for various machine tools, among others.

What are the main drivers of growth in the Machine Tool Maintenance Service Market?

The growth of the Machine Tool Maintenance Service Market is driven by the increasing demand for precision manufacturing, the need for reducing downtime in production, and advancements in maintenance technologies such as predictive analytics.

What challenges does the Machine Tool Maintenance Service Market face?

Challenges in the Machine Tool Maintenance Service Market include the high cost of advanced maintenance technologies, a shortage of skilled technicians, and the complexity of modern machine tools that require specialized knowledge for effective maintenance.

What opportunities exist in the Machine Tool Maintenance Service Market?

Opportunities in the Machine Tool Maintenance Service Market include the growing trend of automation in manufacturing, the rise of smart factories, and the increasing adoption of IoT technologies that enable real-time monitoring and maintenance.

What trends are shaping the Machine Tool Maintenance Service Market?

Trends in the Machine Tool Maintenance Service Market include the shift towards predictive maintenance, the integration of AI and machine learning for diagnostics, and the increasing focus on sustainability practices in maintenance operations.

Machine Tool Maintenance Service Market

| Segmentation Details | Description |

|---|---|

| Service Type | Preventive Maintenance, Predictive Maintenance, Corrective Maintenance, Emergency Repair |

| End User | Aerospace, Automotive OEMs, Metal Fabrication, Electronics Manufacturing |

| Technology | IoT Solutions, CNC Machines, Robotics, Manual Tools |

| Application | Industrial Equipment, Production Lines, Tooling Systems, Machining Centers |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Machine Tool Maintenance Service Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at