444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Machine bench vices are essential tools for securing workpieces during machining operations. They provide a stable and reliable means of clamping and holding materials in place, allowing for accurate and precise cuts and drilling. As a result, the machine bench vices market is an essential part of the wider metalworking industry, with significant demand from both industrial and DIY customers.

In this article, we will provide an overview of the machine bench vices market, including market analysis, key trends, and future outlook. We will also examine the impact of COVID-19 on the market, key industry developments, and the competitive landscape.

Machine bench vices are mechanical tools designed to hold and clamp workpieces securely in place during machining operations. They consist of two jaws that can be adjusted to grip materials of different sizes and shapes. The jaws are operated by a screw mechanism that tightens or loosens the grip. Machine bench vices are commonly used in metalworking, woodworking, and other industries that require precise cutting, drilling, and shaping of materials.

Executive Summary

The global machine bench vices market is expected to grow at a steady pace over the next few years, driven by increasing demand from the metalworking industry. Key factors driving the market include the growing adoption of advanced machining technologies, rising demand for precision manufacturing, and increasing awareness of the benefits of using machine bench vices.

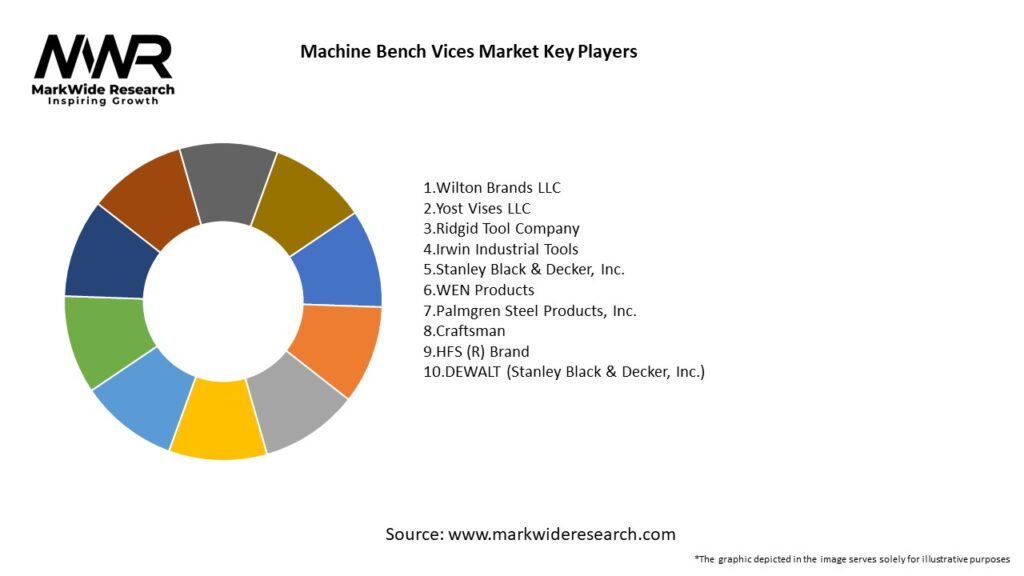

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the Machine Bench Vices Market:

Demand for Precision: The growing need for precision machining in industries like automotive, aerospace, and electronics is a major factor driving the demand for reliable machine bench vices.

Industrial Automation: The rise of industrial automation and the use of CNC machines in manufacturing processes require advanced clamping tools such as machine bench vices to ensure smooth, precise, and secure operations.

Technological Advancements: Continuous improvements in vice design and materials, including the introduction of multi-functional, ergonomic, and easy-to-use vices, are contributing to the market’s growth.

Industry 4.0: The shift toward Industry 4.0 and the increasing integration of smart factory technologies are driving the need for more efficient clamping tools, such as advanced machine bench vices, in automated and connected production systems.

Rising Manufacturing Activities: Increased manufacturing activities in emerging economies, particularly in Asia-Pacific and Latin America, are driving the demand for machine bench vices in various industries, including metalworking, machinery, and heavy equipment production.

Market Restraints

Despite its growth, the Machine Bench Vices Market faces several challenges:

High Costs: The cost of advanced machine bench vices, especially those with specialized features like precision clamping and multifunctionality, can be a barrier to adoption for small and medium-sized enterprises (SMEs) with limited budgets.

Availability of Alternative Clamping Solutions: The availability of alternative clamping solutions, such as hydraulic and pneumatic vices, may limit the market share of traditional mechanical machine bench vices in certain applications.

Supply Chain Issues: Disruptions in the global supply chain, particularly in raw materials like cast iron and steel, can lead to delays in production and increased costs for manufacturers of machine bench vices.

Technological Limitations: Some older machine bench vices may lack the precision and flexibility required by modern manufacturing operations, which could hinder their adoption in advanced industries.

Market Opportunities

The Machine Bench Vices Market offers several opportunities for growth:

Growth in Emerging Markets: The increasing industrialization and manufacturing activities in emerging markets, such as India, China, and Brazil, present significant growth opportunities for machine bench vice manufacturers.

Technological Innovations: The development of smart machine bench vices integrated with sensors and IoT technology offers an opportunity to provide more efficient, automated clamping solutions for advanced manufacturing processes.

Customization and Specialization: Manufacturers can capitalize on the growing demand for customized and specialized machine bench vices for specific applications, such as automotive, aerospace, and electronics manufacturing.

Energy-Efficient Solutions: The demand for energy-efficient and sustainable manufacturing processes is increasing. Machine bench vices that incorporate sustainable materials and energy-saving features present a growth opportunity for market players.

Aftermarket Services: Offering maintenance services, spare parts, and upgrades for existing machine bench vices can provide a profitable revenue stream for manufacturers.

Market Dynamics

The Machine Bench Vices Market is shaped by several key dynamics:

Technological Advancements: Innovations in material science, design, and automation are leading to the development of more advanced, durable, and cost-effective machine bench vices.

Consumer Preferences: The increasing preference for multifunctional and ergonomic tools is influencing the design and features of machine bench vices. Manufacturers are focusing on providing ease of use, enhanced clamping capabilities, and improved precision.

Regulatory Compliance: Increasing regulations related to workplace safety and manufacturing standards are driving the demand for high-quality and reliable machine bench vices that meet safety and operational requirements.

Customization Trends: The rise of niche applications in various industries, such as aerospace and electronics, is driving the demand for customized machine bench vices with specialized features.

Regional Analysis

The Machine Bench Vices Market shows varied growth across different regions:

North America: The market in North America is driven by high demand from manufacturing and automotive industries, with a focus on precision machining and automation. The U.S. is a significant consumer of machine bench vices in industrial operations.

Europe: Europe is witnessing strong growth in machine bench vice demand, particularly in countries like Germany and Italy, where precision engineering and automotive manufacturing are key industries.

Asia-Pacific: The Asia-Pacific region holds the largest share of the market due to rapid industrialization, particularly in China and India, where manufacturing and heavy industries are booming. The growing adoption of automation in these countries is further driving demand.

Latin America: Latin America is seeing steady growth, driven by increasing industrial activities, particularly in Brazil and Mexico, which are expanding their manufacturing capabilities.

Middle East & Africa: The market in the Middle East & Africa is expected to grow as industrialization progresses, particularly in the UAE and South Africa, where manufacturing and infrastructure projects are on the rise.

Competitive Landscape

Leading companies in the Machine Bench Vices Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

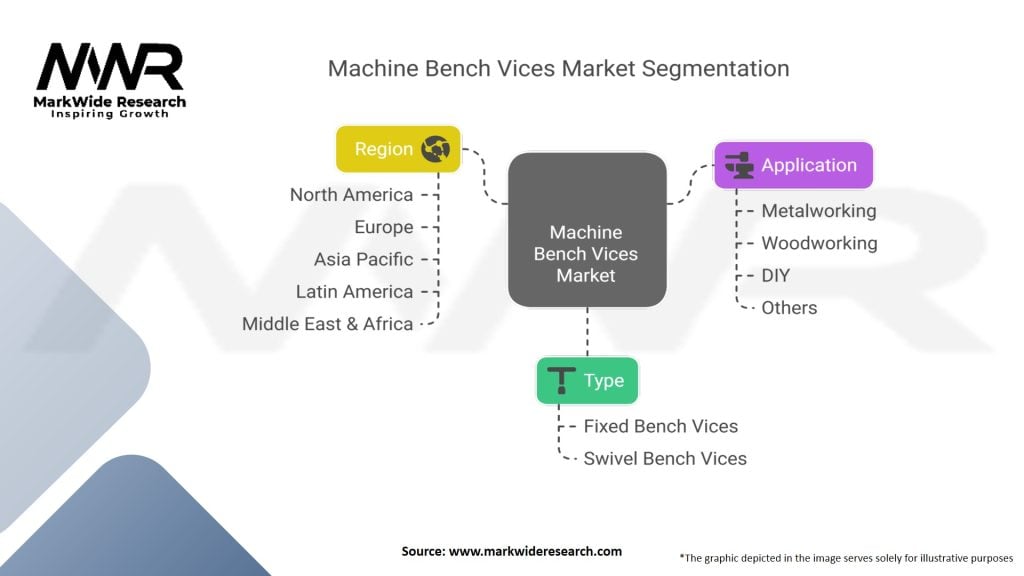

Segmentation

The Machine Bench Vices Market can be segmented based on several factors:

By Type: Manual Machine Bench Vices, Hydraulic Machine Bench Vices, Pneumatic Machine Bench Vices.

By Material: Cast Iron, Steel, Aluminum, Others.

By Application: Automotive, Aerospace, Electronics, Industrial Manufacturing, Metalworking.

By End-User: Manufacturing Companies, Automotive Manufacturers, Aerospace Companies, Metalworking Shops, DIY Enthusiasts.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Enhanced Precision: Machine bench vices ensure that workpieces are securely held in place, which enhances precision during machining and other operations.

Operational Efficiency: By reducing the need for manual clamping and repositioning, machine bench vices increase productivity and reduce time spent on each task.

Cost Savings: High-quality, durable machine bench vices reduce maintenance costs and ensure long-term performance in industrial operations.

Improved Safety: Machine bench vices ensure that workpieces are firmly held, preventing accidents and improving workplace safety.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Automation and Smart Vices: The growing adoption of automation and smart manufacturing processes is leading to the development of machine bench vices with integrated sensors and automated features for precise clamping and monitoring.

Customization: Increasing demand for customized machine bench vices for specific industrial applications, particularly in high-precision sectors like aerospace and electronics.

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the machine bench vices market. The lockdowns and restrictions imposed by governments worldwide have resulted in a decline in demand for machine bench vices in the short term. However, the increasing adoption of remote work and digitalization is expected to drive the demand for precision manufacturing in the long term, which in turn is expected to drive the growth of the machine bench vices market.

Key Industry Developments

Analyst Suggestions

Focus on Emerging Markets: Companies should target emerging markets, particularly in Asia-Pacific and Latin America, where industrialization is rapidly growing.

Invest in Product Innovation: Companies should invest in developing machine bench vices with advanced features such as automation and smart connectivity to meet evolving customer needs.

Future Outlook

Looking ahead, the future outlook for the machine bench vices market is positive, driven by several factors. Firstly, the demand for precision manufacturing is expected to continue to grow, fueled by factors such as increasing industrialization, rising consumer demand for high-quality products, and the need for greater efficiency and productivity in manufacturing processes.

Secondly, the adoption of advanced machining technologies such as CNC machines and 3D printing is expected to increase, providing manufacturers with more options for precision manufacturing. As a result, the demand for machine bench vices that are compatible with these technologies is also expected to grow. Thirdly, the increasing adoption of Industry 4.0 technologies such as IoT, AI, and automation is expected to revolutionize the manufacturing industry and enhance the capabilities of machine bench vices. These technologies are expected to enable manufacturers to achieve higher levels of efficiency, productivity, and precision in their manufacturing processes.

Conclusion

The machine bench vices market is an essential part of the wider metalworking industry, providing a reliable and efficient means of clamping and holding workpieces in place during machining operations. The market is highly competitive, with numerous small and medium-sized players competing for market share. However, the market offers several growth opportunities, driven by factors such as the growing demand for precision manufacturing, increasing adoption of advanced machining technologies, and increasing awareness of the benefits of using machine bench vices.

What are machine bench vices?

Machine bench vices are tools used to securely hold workpieces in place during machining operations. They are essential in various applications, including metalworking, woodworking, and assembly tasks.

Who are the key players in the machine bench vices market?

Key players in the machine bench vices market include Wilton Tools, JET Tools, and Bessey Tools, among others. These companies are known for their innovative designs and high-quality products.

What are the main drivers of growth in the machine bench vices market?

The growth of the machine bench vices market is driven by the increasing demand for precision tools in manufacturing and the rise of DIY projects. Additionally, advancements in materials and technology are enhancing product performance.

What challenges does the machine bench vices market face?

The machine bench vices market faces challenges such as competition from alternative clamping solutions and fluctuations in raw material prices. These factors can impact production costs and pricing strategies.

What opportunities exist in the machine bench vices market?

Opportunities in the machine bench vices market include the expansion of e-commerce platforms and the growing trend of automation in manufacturing. These trends can lead to increased sales and product innovation.

What trends are shaping the machine bench vices market?

Current trends in the machine bench vices market include the development of ergonomic designs and the integration of smart technology. These innovations aim to improve user experience and enhance operational efficiency.

Machine Bench Vices Market

| Segmentation | Details |

|---|---|

| Type | Fixed Bench Vices, Swivel Bench Vices |

| Application | Metalworking, Woodworking, DIY, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Machine Bench Vices Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at