444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Laminated fabrics have gained significant popularity in various industries due to their exceptional durability and performance-enhancing properties. These fabrics are created by bonding multiple layers of materials together, typically combining a woven or non-woven fabric with a polymer film. The lamination process enhances the fabric’s strength, water resistance, breathability, and overall performance. Laminated fabrics find extensive applications across sectors such as automotive, healthcare, sports and outdoor apparel, industrial protective clothing, and home furnishings. This comprehensive market analysis delves into the key aspects of the laminated fabrics market, including market drivers, restraints, opportunities, and regional analysis, to provide valuable insights to industry participants and stakeholders.

Meaning

Laminated fabrics refer to textiles composed of multiple layers fused together through lamination techniques. The lamination process involves bonding a polymer film onto a fabric substrate, creating a robust and versatile material. The resulting laminated fabric exhibits improved properties such as strength, flexibility, waterproofing, and breathability, depending on the specific requirements of the application. The lamination process can be achieved through various methods, including hot melt, adhesive, and extrusion, each offering unique advantages based on the desired end use.

Executive Summary

The global laminated fabrics market has witnessed steady growth in recent years, driven by the increasing demand for durable and high-performance materials in various industries. The market is expected to continue its positive trajectory, fueled by advancements in manufacturing technologies and growing applications across sectors such as automotive, healthcare, and sports and outdoor apparel. Additionally, the rising awareness about the benefits of laminated fabrics, such as enhanced durability, protection, and comfort, is further propelling market growth. However, the market is not without its challenges, including the high cost of production and the limited availability of raw materials. Addressing these concerns and capitalizing on emerging opportunities will be crucial for industry participants to thrive in the competitive laminated fabrics market.

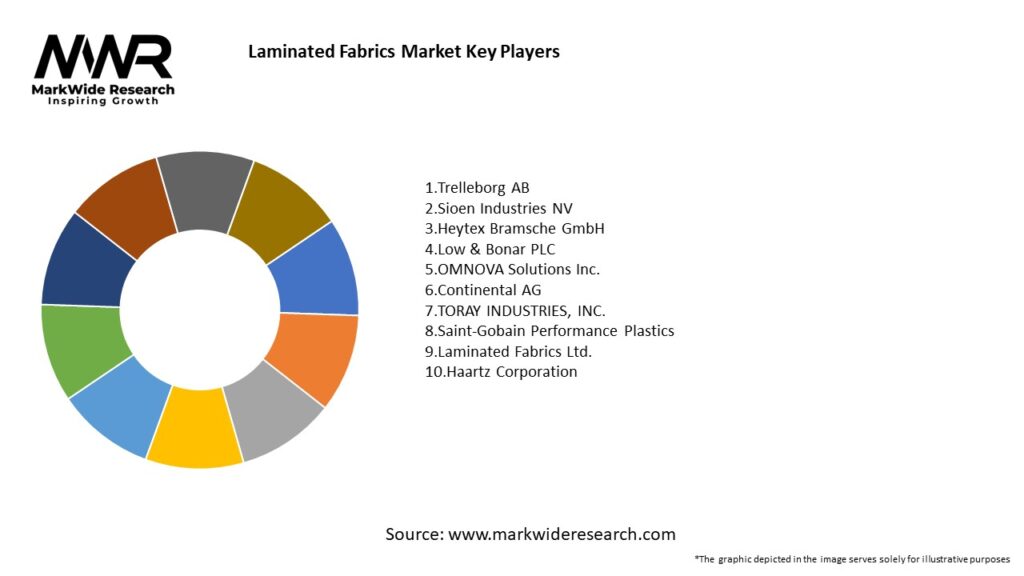

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The laminated fabrics market offers numerous key insights that shed light on its current status and future prospects. Some of the key market insights include:

Market Drivers

Several key drivers are fueling the growth of the laminated fabrics market:

Market Restraints

Despite the positive market outlook, a few challenges may hinder the growth of the laminated fabrics market:

Market Opportunities

The laminated fabrics market presents several opportunities for growth and expansion:

Market Dynamics

The laminated fabrics market is characterized by dynamic factors that influence its growth and development. These market dynamics include:

Regional Analysis

The laminated fabrics market exhibits a global presence, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique market dynamics and growth opportunities:

Competitive Landscape

Leading companies in the Laminated Fabrics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

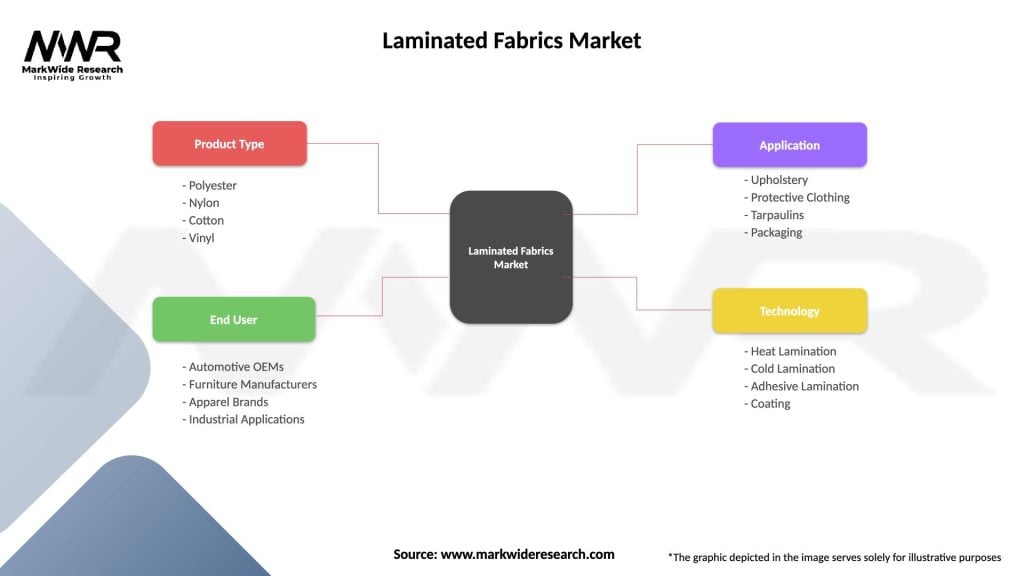

The laminated fabrics market can be segmented based on various factors, including the type of fabric, lamination technique, end-use industry, and geography. Common segmentation categories include:

Segmentation enables a deeper understanding of the market landscape, facilitating targeted strategies and identifying growth opportunities in specific segments.

Category-wise Insights

The laminated fabrics market offers category-wise insights that provide a comprehensive understanding of the market dynamics:

Category-wise insights enable stakeholders to understand the unique characteristics and applications of different types of laminated fabrics, facilitating informed decision-making and market positioning.

Key Benefits for Industry Participants and Stakeholders

The laminated fabrics market presents several key benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT analysis provides a holistic view of the laminated fabrics market by evaluating its strengths, weaknesses, opportunities, and threats:

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding the market’s strengths, weaknesses, opportunities, and threats enables industry participants to develop strategies that capitalize on market advantages while mitigating potential risks.

Market Key Trends

The laminated fabrics market is influenced by several key trends that shape its growth and evolution:

Staying abreast of market key trends enables industry participants to anticipate customer demands, capitalize on emerging opportunities, and stay competitive in the dynamic market landscape.

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the laminated fabrics market, both in terms of demand and supply. Some key observations include:

Understanding the COVID-19 impact is crucial for industry participants to adapt their strategies, mitigate risks, and capitalize on the evolving market dynamics.

Key Industry Developments

The laminated fabrics market has witnessed several key industry developments that shape its current landscape:

These key industry developments reflect the dynamic nature of the laminated fabrics market and the efforts of companies to stay at the forefront of innovation and market competition.

Analyst Suggestions

Based on the market analysis, analysts suggest the following strategies for industry participants:

Future Outlook

The future outlook for the laminated fabrics market remains positive, driven by several factors:

The laminated fabrics market is poised for steady growth, and industry participants need to embrace innovation, sustainability, and strategic partnerships to capitalize on the abundant opportunities in the evolving market landscape.

Conclusion

The laminated fabrics market is witnessing substantial growth, driven by increasing demand for durable, high-performance materials across various industries. The market offers numerous opportunities for manufacturers and stakeholders, with advancements in lamination technologies, customization, and sustainability driving market growth. However, challenges such as high production costs and supply chain complexities need to be addressed effectively. Understanding market dynamics, including key trends, regional analysis, and industry developments, is crucial for industry participants to make informed decisions and thrive in the competitive laminated fabrics market. By embracing innovation, sustainability, and strategic partnerships, manufacturers can position themselves for success in this evolving market, providing durable and performance-enhancing solutions to meet the needs of diverse industries.

What is Laminated Fabrics?

Laminated fabrics are composite materials made by bonding two or more layers of fabric together, often with a polymer film or coating. These fabrics are known for their durability, water resistance, and versatility in various applications such as outdoor gear, upholstery, and protective clothing.

What are the key players in the Laminated Fabrics Market?

Key players in the Laminated Fabrics Market include companies like DuPont, 3M, and Toray Industries, which are known for their innovative products and technologies. These companies focus on developing high-performance laminated fabrics for various applications, including automotive, healthcare, and sportswear, among others.

What are the growth factors driving the Laminated Fabrics Market?

The Laminated Fabrics Market is driven by increasing demand for lightweight and durable materials in industries such as automotive and aerospace. Additionally, the growing trend towards outdoor activities and sports is boosting the need for high-performance laminated fabrics that offer weather resistance and comfort.

What challenges does the Laminated Fabrics Market face?

Challenges in the Laminated Fabrics Market include the high cost of raw materials and the complexity of manufacturing processes. Additionally, competition from alternative materials and environmental concerns regarding the sustainability of certain laminating processes pose significant hurdles.

What opportunities exist in the Laminated Fabrics Market?

The Laminated Fabrics Market presents opportunities in the development of eco-friendly and sustainable materials, as consumer demand for environmentally responsible products increases. Innovations in technology, such as smart fabrics and enhanced performance features, also offer potential growth avenues.

What trends are shaping the Laminated Fabrics Market?

Current trends in the Laminated Fabrics Market include the rise of multifunctional fabrics that combine various properties such as breathability, waterproofing, and UV protection. Additionally, the integration of digital printing technologies is allowing for more customization and design options in laminated fabrics.

Laminated Fabrics Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polyester, Nylon, Cotton, Vinyl |

| End User | Automotive OEMs, Furniture Manufacturers, Apparel Brands, Industrial Applications |

| Application | Upholstery, Protective Clothing, Tarpaulins, Packaging |

| Technology | Heat Lamination, Cold Lamination, Adhesive Lamination, Coating |

Leading companies in the Laminated Fabrics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at