444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview:

The LAMEA Modular Refineries Market holds a significant position in the energy sector, representing a vital component of the region’s oil and gas industry. Modular refineries play a crucial role in refining crude oil into valuable products such as gasoline, diesel, and other petroleum derivatives. Positioned as a flexible and scalable solution, modular refineries in the LAMEA region contribute to meeting the growing demand for refined petroleum products.

Meaning:

The term “LAMEA Modular Refineries Market” refers to the market segment dedicated to the establishment, operation, and management of modular refineries in the Latin America, Middle East, and Africa (LAMEA) region. These refineries are characterized by their modular design, allowing for flexibility in capacity, rapid deployment, and the ability to process varying types of crude oil.

Executive Summary:

The LAMEA Modular Refineries Market has witnessed substantial growth in recent years, driven by factors such as increasing demand for refined petroleum products, the need for regional energy security, and the advantages offered by modular refinery solutions. This executive summary provides a concise overview of the key dynamics shaping the modular refineries market in the LAMEA region, encompassing market drivers, challenges, and opportunities.

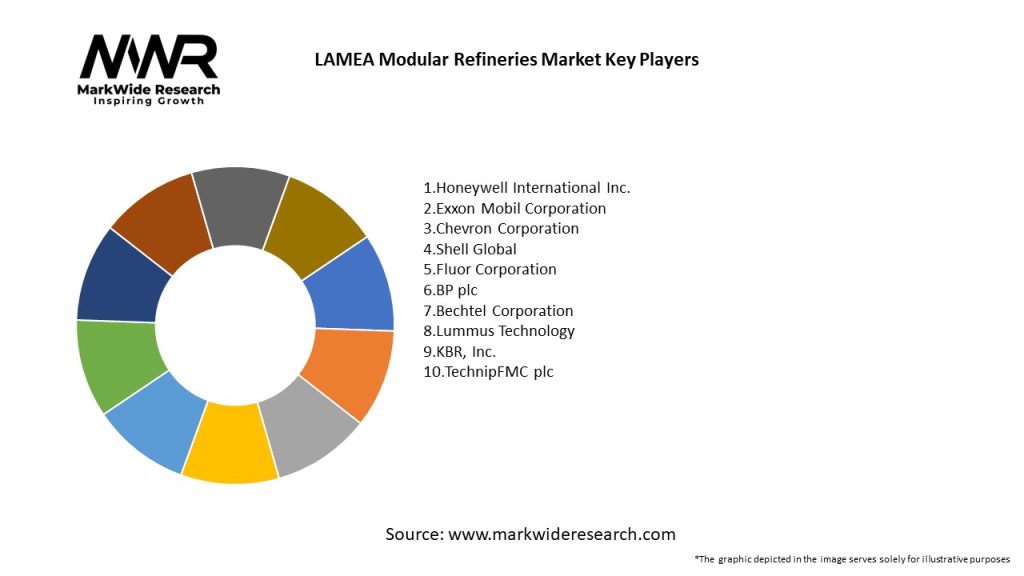

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The LAMEA Modular Refineries Market operates in a dynamic environment influenced by factors such as geopolitical developments, oil and gas market trends, technological advancements, and policy changes. Understanding these dynamics is essential for industry participants to navigate challenges and capitalize on emerging opportunities.

Regional Analysis:

The modular refineries market in the LAMEA region exhibits regional variations influenced by factors such as oil reserves, economic conditions, and government policies. Let’s delve into some key insights into specific regions:

Competitive Landscape:

Leading Companies in LAMEA Modular Refineries Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The LAMEA Modular Refineries Market can be segmented based on various factors, including:

Segmentation allows for a detailed analysis of specific market segments, enabling industry participants to tailor their strategies to the unique characteristics of each segment.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The COVID-19 pandemic has had varied impacts on the LAMEA Modular Refineries Market. While the initial phase saw disruptions in supply chains and project timelines, the adaptability of modular refineries allowed for resilience in the face of changing market conditions.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future outlook for the LAMEA Modular Refineries Market is optimistic, with sustained growth expected. As governments in the region focus on energy security, economic diversification, and sustainability, modular refineries will play a crucial role in meeting these objectives. Continued technological advancements, strategic investments, and collaborative efforts will shape the future landscape of the modular refineries market in Latin America, the Middle East, and Africa.

Conclusion:

In conclusion, the LAMEA Modular Refineries Market represents a dynamic and integral component of the region’s energy landscape. Modular refineries offer a flexible, scalable, and strategically important solution for refining crude oil and meeting the growing demand for refined petroleum products. While facing challenges related to capital intensity, regulatory complexities, and market competition, the market’s future success lies in embracing sustainable practices, investing in research and development, and forming strategic partnerships. The LAMEA Modular Refineries Market remains poised for continued growth, contributing to regional energy security, economic development, and sustainability goals.

What is Modular Refineries?

Modular refineries are small-scale, prefabricated oil refining units that can be easily transported and installed. They are designed to process crude oil into various petroleum products, making them suitable for regions with limited infrastructure or smaller production capacities.

What are the key players in the LAMEA Modular Refineries Market?

Key players in the LAMEA Modular Refineries Market include companies like Modular Refining Systems, Inc., and KBR, Inc. These companies specialize in providing modular refinery solutions and technologies, among others.

What are the growth factors driving the LAMEA Modular Refineries Market?

The growth of the LAMEA Modular Refineries Market is driven by increasing demand for petroleum products, the need for energy security, and the rising trend of decentralized energy production. Additionally, modular refineries offer flexibility and lower capital investment compared to traditional refineries.

What challenges does the LAMEA Modular Refineries Market face?

Challenges in the LAMEA Modular Refineries Market include regulatory hurdles, competition from larger refineries, and the need for skilled labor to operate these facilities. Additionally, fluctuating crude oil prices can impact the viability of modular refineries.

What opportunities exist in the LAMEA Modular Refineries Market?

Opportunities in the LAMEA Modular Refineries Market include the potential for expansion into emerging markets, advancements in refining technology, and increasing investments in renewable energy integration. These factors can enhance the operational efficiency of modular refineries.

What trends are shaping the LAMEA Modular Refineries Market?

Trends in the LAMEA Modular Refineries Market include the adoption of digital technologies for monitoring and optimization, a shift towards sustainable refining practices, and the growing interest in modular solutions for remote locations. These trends are influencing how refineries operate and adapt to market demands.

LAMEA Modular Refineries Market

| Segmentation Details | Description |

|---|---|

| Product Type | Skid-mounted, Containerized, Portable, Fixed |

| End User | Independent Refiners, Oil & Gas Companies, Government Entities, Private Investors |

| Technology | Hydrocracking, Distillation, Catalytic Reforming, Gas-to-Liquids |

| Installation | Onshore, Offshore, Remote Locations, Urban Areas |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in LAMEA Modular Refineries Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at