444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The market for Resistance Temperature Detectors (RTDs) in Italy is witnessing substantial growth, driven by the increasing demand for accurate and reliable temperature measurement solutions across various industries. RTDs play a crucial role in monitoring and controlling temperature in industrial processes, laboratories, and other applications. As Italy continues to advance technologically, the RTD market is poised for further expansion, offering opportunities for both established players and new entrants.

Meaning

Resistance Temperature Detectors (RTDs) are temperature sensors that operate on the principle of electrical resistance variation with temperature changes. Typically made of platinum, RTDs provide precise and stable temperature measurements, making them valuable in applications where accuracy is paramount. The resistance of an RTD changes predictably with temperature, allowing for precise temperature readings.

Executive Summary

The Italy Resistance Temperature Detector (RTD) market is experiencing growth due to the increasing need for accurate temperature sensing solutions. RTDs offer advantages such as high accuracy, stability, and repeatability, making them suitable for critical applications. The market is characterized by the presence of established manufacturers providing a range of RTD products catering to diverse industry requirements.

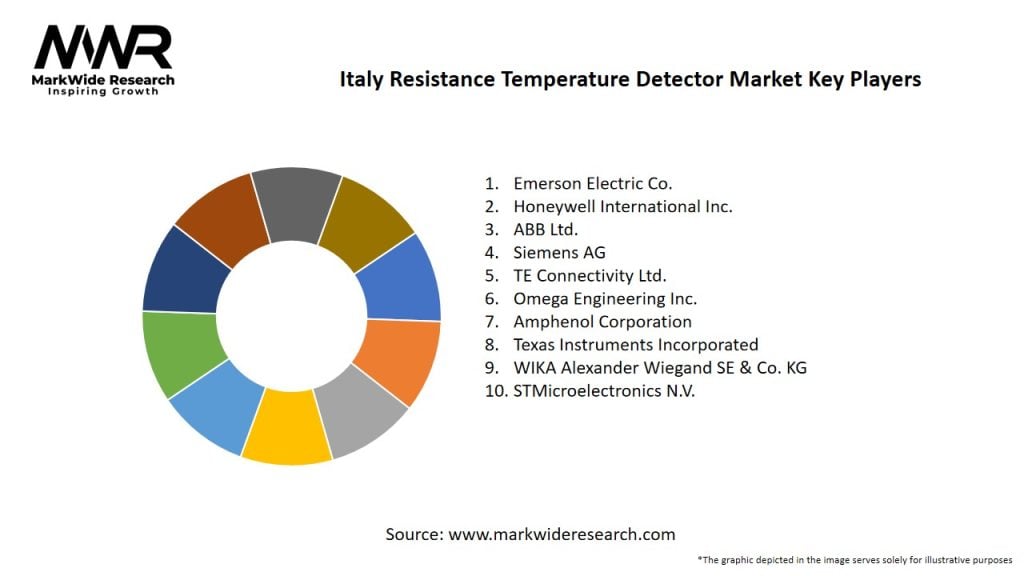

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The dynamics of the Italy RTD market are influenced by the interplay of technological advancements, industry demands, and regulatory considerations. As manufacturers strive to meet the evolving needs of end-users, the market is characterized by innovation, strategic collaborations, and a focus on quality assurance.

Regional Analysis

The regional dynamics within Italy’s RTD market may vary based on industrial clusters, technological infrastructure, and the specific needs of different regions. Industrialized areas may witness higher demand for RTDs in manufacturing processes, while research and innovation hubs may drive demand for advanced RTD technologies.

Competitive Landscape

Leading Companies in Italy Resistance Temperature Detector Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

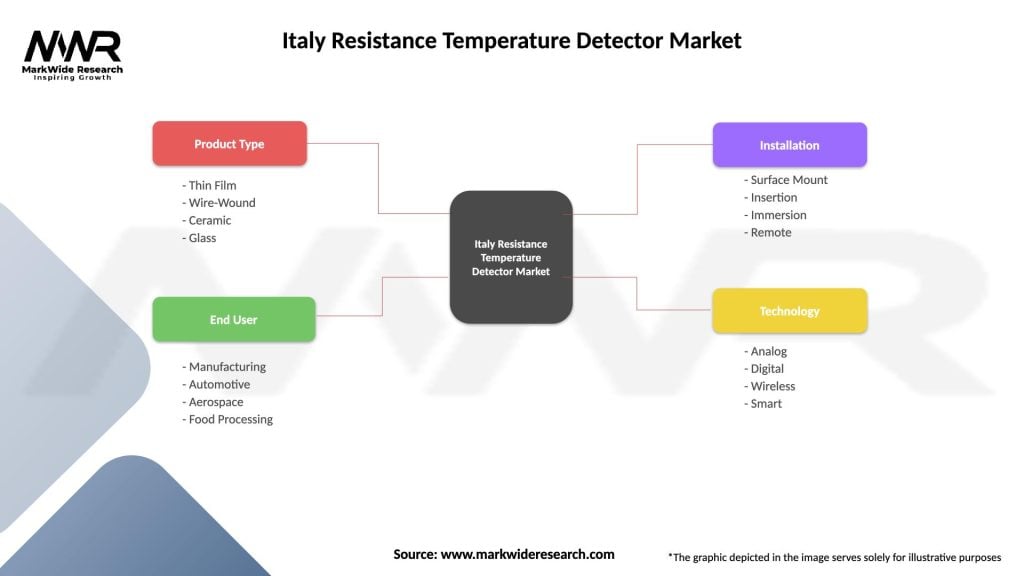

The Italy RTD market can be segmented based on various factors:

Segmentation enhances the market understanding and enables manufacturers to tailor their offerings to meet the specific demands of various customer segments.

Category-wise Insights

Market Strategies

Regulatory Landscape

The Italy RTD market is subject to regulatory standards and certifications ensuring the safety, performance, and reliability of temperature sensing devices. Compliance with international standards such as IEC 60751 and ISO 9001 is essential for manufacturers to meet regulatory requirements and gain market acceptance.

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the Italy RTD market:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has impacted the Italy RTD market in several ways:

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Italy RTD market is positive, with opportunities for growth and innovation driven by technological advancements, industry demands, and regulatory requirements. As Italy continues to prioritize industrial automation, energy efficiency, and technological innovation, the RTD market is expected to witness sustained growth, offering opportunities for manufacturers to expand their product portfolios and market presence.

Conclusion

The Italy Resistance Temperature Detector (RTD) market is characterized by steady growth, driven by the increasing demand for accurate temperature sensing solutions across diverse industries. RTDs play a critical role in industrial automation, process control, and research applications, offering advantages such as high accuracy, stability, and reliability. Ongoing technological advancements, regulatory compliance, and market diversification contribute to the dynamic landscape of the Italy RTD market. By focusing on innovation, customer satisfaction, and sustainability, manufacturers can capitalize on emerging opportunities and navigate challenges in the evolving market scenario.

What is Resistance Temperature Detector?

A Resistance Temperature Detector (RTD) is a temperature sensor that operates on the principle of electrical resistance change with temperature. RTDs are widely used in industrial applications for precise temperature measurement due to their accuracy and stability.

What are the key players in the Italy Resistance Temperature Detector Market?

Key players in the Italy Resistance Temperature Detector Market include Siemens AG, Honeywell International Inc., and Omega Engineering, among others.

What are the growth factors driving the Italy Resistance Temperature Detector Market?

The growth of the Italy Resistance Temperature Detector Market is driven by the increasing demand for accurate temperature measurement in industries such as food and beverage, pharmaceuticals, and HVAC systems. Additionally, advancements in sensor technology are enhancing the performance of RTDs.

What challenges does the Italy Resistance Temperature Detector Market face?

The Italy Resistance Temperature Detector Market faces challenges such as the high cost of RTDs compared to other temperature sensors and the need for regular calibration to maintain accuracy. These factors can limit their adoption in cost-sensitive applications.

What opportunities exist in the Italy Resistance Temperature Detector Market?

Opportunities in the Italy Resistance Temperature Detector Market include the growing trend towards automation in industrial processes and the increasing focus on energy efficiency. These trends are likely to boost the demand for reliable temperature measurement solutions.

What trends are shaping the Italy Resistance Temperature Detector Market?

Trends shaping the Italy Resistance Temperature Detector Market include the integration of IoT technology for real-time monitoring and data analysis, as well as the development of miniaturized sensors for compact applications. These innovations are enhancing the functionality and application range of RTDs.

Italy Resistance Temperature Detector Market

| Segmentation Details | Description |

|---|---|

| Product Type | Thin Film, Wire-Wound, Ceramic, Glass |

| End User | Manufacturing, Automotive, Aerospace, Food Processing |

| Installation | Surface Mount, Insertion, Immersion, Remote |

| Technology | Analog, Digital, Wireless, Smart |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Italy Resistance Temperature Detector Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at