444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The Italy Automotive Hydraulic Actuators Market is a vital component of the automotive industry, serving as the muscle behind various functions in vehicles. Hydraulic actuators play a crucial role in enabling precise control over a range of operations, from braking and steering to clutch engagement and convertible top systems. This market is a dynamic and evolving segment within the automotive sector, deeply rooted in technology, innovation, and engineering prowess.

Meaning

Automotive hydraulic actuators are hydraulic devices used in vehicles to convert fluid pressure into mechanical force, facilitating the operation of various vehicle components. These actuators are fundamental for ensuring safety, comfort, and performance in modern automobiles.

Executive Summary

In the realm of Italian automotive engineering, hydraulic actuators have emerged as key players, propelling innovation and driving the industry forward. This executive summary provides a brief glimpse into the Italy Automotive Hydraulic Actuators Market, highlighting its significance, growth prospects, and key trends.

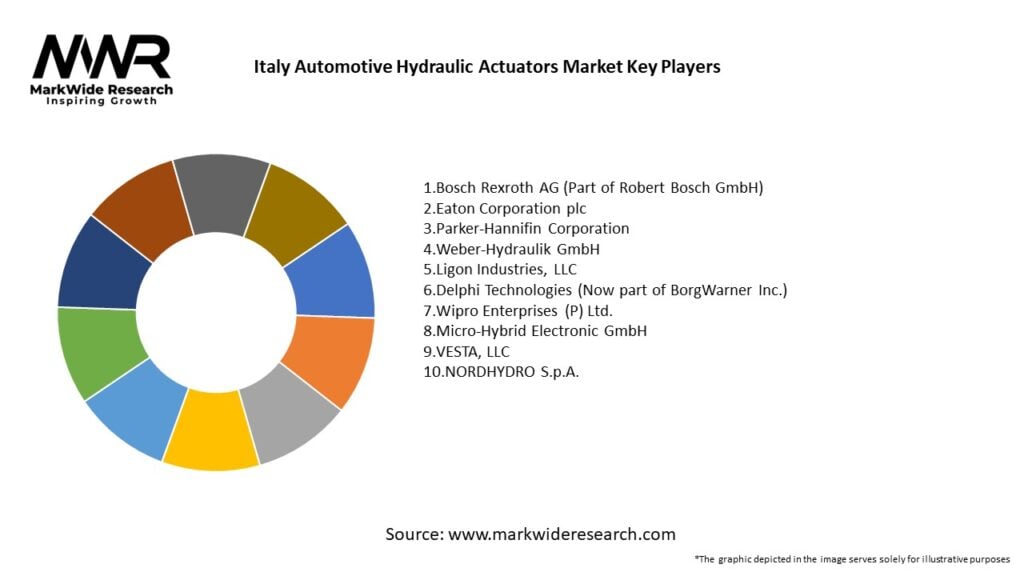

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Hydraulic actuation remains preferred in high-load, smooth control applications where electric alternatives struggle to match force or durability.

Italy’s automotive cluster supports close collaboration among actuator makers, OEMs, and test labs, enabling rapid prototyping and customization.

There is a trend toward hybrid actuation—combining hydraulic power with electronic control—for energy recovery and efficiency.

Lightweight materials (aluminum alloys, composite housings) and optimized hydraulics are increasingly important under weight and emissions constraints.

Aftermarket and retrofitting for classic Italian sports, luxury, and specialty vehicles remain an enduring demand segment.

Market Drivers

Platform Upgrades & Refreshes: OEMs modernizing existing models often add adaptive suspension or improved roof mechanisms requiring hydraulic actuators.

Performance & Comfort Demands: Premium vehicles demand smoother, responsive systems—hydraulics deliver the nuance.

Aftermarket & Specialty Vehicle Demand: Italy’s strong legacy car culture supports aftermarket parts for convertibles, race cars, and custom builds.

Hybrid and Mild-EV Architectures: Hydraulic subsystems used even in electrified powertrains for smoothing, damping, or motion where electric is less efficient.

Lightweighting & Efficiency Pressure: Designers demand compact, high-pressure, efficient actuation systems to reduce energy losses and weight.

Market Restraints

Competition from Electric Actuators: As motors and servos improve, certain use cases shift from hydraulic to electric linear actuators.

Maintenance Complexity: Hydraulic systems require fluid management, seals, and risk of leaks—raising perceived maintenance burden.

Cost Pressure: Exotic materials, high-pressure valves, and control electronics add cost in a competitive auto environment.

Emissions & Weight Regulations: The push for lightweight, electrified systems pressures hydraulic designs to reduce mass and parasitic losses.

Integration Complexity: Hydraulic systems must interface with electronic control units (ECUs), sensors, software, adding system complexity.

Market Opportunities

Smart Hydraulic Actuators: Embedding sensors, feedback loops, and control electronics to enable adaptive response and diagnostics.

Hybrid Hydraulic-Electric Systems: Designs combining hydraulic power with electric assist for energy savings, redundancy, or fallback motion.

High-Pressure Miniaturization: Compact high-performance hydraulic actuators that meet weight and space constraints of modern vehicles.

Retrofit Kits for Specialty Vehicles: Aftermarket kits for convertible roofs, suspension systems in classic or limited-run models.

Cross-Sector Applications: Supplying to off-road machinery, agricultural vehicles, and industrial mobility segments in Italy.

Market Dynamics

Supply-Side Factors:

Tier suppliers in Italy produce integrated hydraulic assemblies, valves, cylinders, and software controllers.

Small specialized firms support custom designs, prototyping, and niche vehicles.

Materials, machining precision, and sealing technologies influence actuator quality and cost.

Demand-Side Factors:

OEM design cycles dictate order volumes several years in advance.

Aftermarket demand is more responsive, especially for performance upgrades or restoration.

Niche luxury and limited-run vehicles often require flexible actuation suppliers able to handle small volumes.

Economic & Policy Factors:

European regulatory focus on emissions and weight influences actuation design choices.

Incentives or regulations favoring electrification may pressure hydraulic segment evolution.

Trade and import duties affect component sourcing decisions for design and cost structure.

Regional Analysis

Turin / Piedmont Region: Major automotive cluster with OEMs and Tier suppliers for propulsion, suspension, and actuation systems.

Modena / Emilia-Romagna: Home to luxury and supercar firms—high-end hydraulic actuation demand for exotic conversions.

Lombardy & Milan Corridor: Engineering firms, testing, and prototyping resources cluster near design consultancies.

Veneto / Veneto-Driven Manufacturing: Supporting lightweight and component suppliers for actuator parts and sealing systems.

Southern Italy & Sicily: Less dense vehicle production, but retrofit and performance markets exist, especially in specialty segments.

Competitive Landscape

Leading Companies in Italy Automotive Hydraulic Actuators Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The market can be segmented based on the type of hydraulic actuators, applications, and end-users. Common types of hydraulic actuators include hydraulic cylinders, hydraulic motors, and hydraulic pumps. Applications range from braking systems and steering systems to convertible top systems and transmission systems.

Category-wise Insights

Hydraulic Cylinders: The Backbone of Vehicle Braking Systems

Hydraulic cylinders are a vital component of vehicle braking systems. They enable the precise application of braking force, ensuring safety and control. The demand for hydraulic cylinders is expected to remain robust, driven by the emphasis on vehicle safety.

Hydraulic Motors: Powering Steering and More

Hydraulic motors play a pivotal role in power steering systems, enhancing driver comfort and maneuverability. These motors are also employed in applications such as agricultural machinery and construction equipment.

Hydraulic Pumps: Ensuring Smooth Transmission

Hydraulic pumps are integral to transmission systems in vehicles. They facilitate smooth gear changes and efficient power transmission. As vehicles become more sophisticated, the demand for high-performance hydraulic pumps is on the rise.

Key Benefits for Industry Participants and Stakeholders

Participants in the Italy Automotive Hydraulic Actuators Market can reap several benefits. These include:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Electrification and Hybridization

The shift towards electrification and hybridization is a prevailing trend in the Italy Automotive Hydraulic Actuators Market. As automakers invest in electric and hybrid vehicles, hydraulic actuators are being adapted for use in these advanced powertrains.

Lightweight Materials

To meet stringent emission standards and improve fuel efficiency, automakers are increasingly focusing on lightweight materials. This trend is influencing the design of hydraulic actuators, with a greater emphasis on materials that offer both strength and reduced weight.

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the automotive industry, including the Italy Automotive Hydraulic Actuators Market. Lockdowns and disruptions in the supply chain led to a temporary downturn in production and sales. However, as the industry recovers, there is a renewed focus on safety features, including hydraulic actuators, to address changing consumer priorities.

Key Industry Developments

In recent years, the Italy Automotive Hydraulic Actuators Market has witnessed notable developments, including:

Analyst Suggestions

To thrive in the Italy Automotive Hydraulic Actuators Market, analysts recommend:

Future Outlook

The Italy Automotive Hydraulic Actuators Market is poised for growth, driven by advancements in vehicle technology, safety regulations, and the demand for electric and hybrid vehicles. As the automotive industry evolves, hydraulic actuators will continue to play a pivotal role in enhancing vehicle performance, safety, and comfort.

Conclusion

In conclusion, the Italy Automotive Hydraulic Actuators Market represents a dynamic and essential component of the automotive sector. With a focus on innovation, adaptability, and sustainability, this market is poised for growth and will remain integral to the advancement of the automotive industry in Italy. As the industry navigates the challenges and opportunities ahead, hydraulic actuators will continue to be the driving force behind precise and reliable vehicle operations, ensuring a safer and more efficient driving experience for consumers.

What is Automotive Hydraulic Actuators?

Automotive hydraulic actuators are devices that use hydraulic pressure to control various functions in vehicles, such as braking, steering, and suspension systems. They play a crucial role in enhancing vehicle performance and safety.

What are the key players in the Italy Automotive Hydraulic Actuators Market?

Key players in the Italy Automotive Hydraulic Actuators Market include Bosch, Parker Hannifin, and Eaton, among others. These companies are known for their innovative solutions and extensive product offerings in hydraulic systems.

What are the growth factors driving the Italy Automotive Hydraulic Actuators Market?

The growth of the Italy Automotive Hydraulic Actuators Market is driven by the increasing demand for fuel-efficient vehicles, advancements in automotive technology, and the rising focus on safety features in vehicles. Additionally, the trend towards automation in vehicles is also contributing to market growth.

What challenges does the Italy Automotive Hydraulic Actuators Market face?

The Italy Automotive Hydraulic Actuators Market faces challenges such as high manufacturing costs and the complexity of hydraulic systems. Additionally, the shift towards electric vehicles may impact the demand for traditional hydraulic actuators.

What opportunities exist in the Italy Automotive Hydraulic Actuators Market?

Opportunities in the Italy Automotive Hydraulic Actuators Market include the development of advanced hydraulic technologies and the integration of smart actuators in vehicles. The growing trend of electric and hybrid vehicles also presents new avenues for innovation.

What trends are shaping the Italy Automotive Hydraulic Actuators Market?

Trends shaping the Italy Automotive Hydraulic Actuators Market include the increasing adoption of automation and smart technologies in vehicles, as well as a focus on sustainability and energy efficiency. Additionally, the rise of connected vehicles is influencing actuator design and functionality.

Italy Automotive Hydraulic Actuators Market

| Segmentation Details | Description |

|---|---|

| Product Type | Single Acting, Double Acting, Miniature, Custom |

| End User | OEMs, Aftermarket Providers, Vehicle Assemblers, Tier-1 Suppliers |

| Technology | Electro-Hydraulic, Pneumatic, Mechanical, Hybrid |

| Application | Braking Systems, Steering Systems, Suspension Systems, Transmission Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Italy Automotive Hydraulic Actuators Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at