444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The Internet of Things (IoT) for manufacturing market represents a transformative technological revolution that is fundamentally reshaping industrial operations across the globe. This rapidly expanding sector encompasses the integration of connected devices, sensors, and intelligent systems throughout manufacturing facilities to create smart, data-driven production environments. Manufacturing companies are increasingly adopting IoT solutions to enhance operational efficiency, reduce downtime, and optimize resource utilization.

Market dynamics indicate that the manufacturing sector is experiencing unprecedented digital transformation, with IoT technologies serving as the backbone of Industry 4.0 initiatives. The market demonstrates robust growth potential, driven by increasing demand for predictive maintenance, real-time monitoring, and automated quality control systems. Current adoption rates show that 72% of manufacturers are implementing or planning to implement IoT solutions within the next two years.

Regional distribution reveals significant growth across North America, Europe, and Asia-Pacific, with emerging markets showing particularly strong interest in IoT-enabled manufacturing solutions. The market encompasses various technology segments including industrial sensors, connectivity platforms, data analytics software, and edge computing solutions. Manufacturing industries ranging from automotive and aerospace to food processing and pharmaceuticals are leveraging IoT technologies to achieve competitive advantages.

The Internet of Things (IoT) for manufacturing market refers to the comprehensive ecosystem of interconnected devices, sensors, software platforms, and analytical tools specifically designed to enhance manufacturing processes through real-time data collection, analysis, and automated decision-making capabilities.

IoT manufacturing solutions encompass a wide range of technologies that enable machines, equipment, and systems to communicate with each other and with centralized management platforms. These solutions facilitate predictive maintenance, quality monitoring, supply chain optimization, and energy management throughout manufacturing operations. The technology creates intelligent manufacturing environments where data flows seamlessly between production lines, inventory systems, and management dashboards.

Core components of IoT manufacturing systems include industrial sensors for monitoring temperature, pressure, vibration, and other critical parameters, wireless and wired connectivity solutions for data transmission, cloud-based platforms for data storage and analysis, and artificial intelligence algorithms for predictive analytics and automated responses.

Market expansion in the IoT for manufacturing sector is driven by compelling business needs for operational efficiency, cost reduction, and competitive differentiation. Manufacturing organizations are recognizing that IoT technologies provide essential capabilities for maintaining competitiveness in increasingly complex global markets. The sector demonstrates strong momentum with adoption rates increasing by 38% annually across various manufacturing verticals.

Technology advancement continues to accelerate, with innovations in edge computing, 5G connectivity, and artificial intelligence enhancing the capabilities and reducing the costs of IoT manufacturing solutions. These technological improvements are making IoT implementations more accessible to small and medium-sized manufacturers, expanding the total addressable market significantly.

Investment trends show substantial capital allocation toward IoT infrastructure, with manufacturing companies prioritizing digital transformation initiatives. The focus on sustainability and energy efficiency is also driving IoT adoption, as these technologies enable precise monitoring and optimization of resource consumption throughout manufacturing processes.

Strategic insights reveal several critical factors shaping the IoT manufacturing market landscape:

Operational efficiency demands serve as the primary catalyst for IoT adoption in manufacturing environments. Companies are under constant pressure to reduce costs, improve quality, and accelerate time-to-market, making IoT technologies essential for achieving these objectives. The ability to monitor equipment performance in real-time and predict maintenance needs before failures occur provides substantial competitive advantages.

Digital transformation initiatives across manufacturing organizations are creating strong demand for integrated IoT solutions. Industry 4.0 concepts are driving manufacturers to modernize their operations with smart technologies that enable data-driven decision making. This transformation is supported by decreasing costs of sensors and connectivity solutions, making IoT implementations more economically viable.

Regulatory compliance requirements in various industries are necessitating enhanced monitoring and documentation capabilities that IoT systems provide. Manufacturing companies must maintain detailed records of production processes, quality metrics, and environmental conditions, which IoT platforms facilitate through automated data collection and reporting.

Workforce optimization needs are driving adoption of IoT solutions that augment human capabilities and improve worker safety. As manufacturing faces skilled labor shortages, IoT technologies help maximize productivity of existing workforce while reducing the complexity of equipment operation and maintenance tasks.

Implementation complexity represents a significant barrier for many manufacturing organizations considering IoT adoption. The integration of IoT systems with existing manufacturing equipment and enterprise software requires substantial technical expertise and careful planning. Legacy systems often lack the connectivity and data interfaces necessary for seamless IoT integration, necessitating costly upgrades or replacements.

Cybersecurity concerns continue to challenge widespread IoT adoption in manufacturing environments. Connected devices and networks create potential vulnerabilities that could be exploited by malicious actors, potentially disrupting production operations or compromising sensitive intellectual property. Manufacturing companies must invest significantly in cybersecurity infrastructure and expertise to mitigate these risks.

Capital investment requirements can be substantial, particularly for comprehensive IoT implementations across large manufacturing facilities. While IoT technologies offer long-term cost savings, the initial investment in sensors, connectivity infrastructure, software platforms, and integration services may strain budgets, especially for smaller manufacturers.

Skills gap challenges limit the ability of many organizations to effectively implement and manage IoT systems. The shortage of professionals with expertise in IoT technologies, data analytics, and industrial automation creates bottlenecks in deployment and ongoing optimization of IoT manufacturing solutions.

Emerging market expansion presents substantial growth opportunities as developing economies invest in modern manufacturing infrastructure. Countries in Asia-Pacific, Latin America, and Africa are establishing new manufacturing facilities with built-in IoT capabilities, creating demand for comprehensive IoT solutions from the ground up.

Small and medium enterprise adoption represents a significant untapped opportunity as IoT solutions become more affordable and easier to implement. Cloud-based IoT platforms and software-as-a-service models are reducing barriers to entry, enabling smaller manufacturers to access advanced IoT capabilities without massive upfront investments.

Sustainability initiatives are creating new opportunities for IoT solutions that optimize energy consumption, reduce waste, and minimize environmental impact. Manufacturers are increasingly prioritizing green manufacturing practices, driving demand for IoT systems that provide detailed environmental monitoring and optimization capabilities.

Advanced analytics integration offers opportunities for IoT platform providers to differentiate their solutions through artificial intelligence and machine learning capabilities. The combination of IoT data collection with sophisticated analytics creates powerful insights that can transform manufacturing operations and create new value propositions.

Technology convergence is reshaping the IoT manufacturing landscape as artificial intelligence, edge computing, and 5G connectivity combine to create more powerful and responsive IoT solutions. This convergence enables real-time processing of manufacturing data at the edge, reducing latency and improving system responsiveness. Edge computing adoption in manufacturing IoT applications has increased by 52% over the past year.

Competitive dynamics are intensifying as traditional industrial automation companies compete with technology giants and specialized IoT platform providers. This competition is driving innovation and reducing costs, benefiting end-user manufacturers through improved solution capabilities and more competitive pricing structures.

Partnership ecosystems are becoming increasingly important as no single vendor can provide all components of comprehensive IoT manufacturing solutions. Strategic alliances between hardware manufacturers, software developers, system integrators, and telecommunications providers are creating integrated solution offerings that address complete manufacturing IoT requirements.

Standardization efforts are gaining momentum as industry organizations work to establish common protocols and interfaces for IoT manufacturing systems. These standardization initiatives are reducing integration complexity and improving interoperability between different IoT solution components.

Comprehensive market analysis was conducted through multiple research approaches to ensure accuracy and completeness of findings. Primary research included extensive interviews with manufacturing executives, IoT solution providers, system integrators, and technology vendors across various industry verticals and geographic regions.

Secondary research encompassed analysis of industry reports, company financial statements, patent filings, and regulatory documents to understand market trends, competitive positioning, and technology developments. MarkWide Research analysts reviewed hundreds of sources to compile comprehensive market intelligence.

Market sizing methodology utilized bottom-up and top-down approaches, analyzing adoption rates across different manufacturing segments and geographic regions. The research team validated findings through triangulation of multiple data sources and expert interviews to ensure reliability of market projections.

Technology assessment included evaluation of current IoT manufacturing solutions, emerging technologies, and future development roadmaps. This analysis provides insights into technology trends that will shape market evolution over the forecast period.

North America maintains a leading position in IoT manufacturing adoption, driven by advanced industrial infrastructure and strong technology investment. The region accounts for approximately 35% of global IoT manufacturing implementations, with the United States leading in both technology development and deployment. Manufacturing digitization initiatives supported by government programs are accelerating IoT adoption across various industrial sectors.

Europe demonstrates strong growth in IoT manufacturing applications, particularly in automotive, aerospace, and industrial machinery sectors. Germany leads European adoption with its Industry 4.0 initiatives, while other countries including France, Italy, and the United Kingdom are implementing comprehensive IoT strategies. European manufacturers are particularly focused on sustainability applications of IoT technology.

Asia-Pacific represents the fastest-growing region for IoT manufacturing solutions, with growth rates exceeding 42% annually. China, Japan, and South Korea are driving significant investments in smart manufacturing infrastructure, while emerging economies including India, Thailand, and Vietnam are adopting IoT technologies in new manufacturing facilities.

Latin America and Middle East & Africa show emerging interest in IoT manufacturing solutions, with Brazil, Mexico, and the United Arab Emirates leading regional adoption. These markets present significant long-term opportunities as manufacturing sectors modernize and expand.

Market leadership is distributed among several categories of providers, each bringing distinct capabilities and market approaches:

By Technology:

By Application:

By Industry Vertical:

Predictive Maintenance Solutions represent the most mature and widely adopted category within IoT manufacturing applications. These systems utilize vibration sensors, temperature monitors, and acoustic analysis to predict equipment failures before they occur. Implementation success rates for predictive maintenance IoT systems exceed 78%, with manufacturers typically achieving significant reductions in unplanned downtime and maintenance costs.

Quality Management Systems are experiencing rapid growth as manufacturers seek to improve product quality and reduce defect rates. IoT-enabled quality control systems provide real-time monitoring of production parameters and automated detection of quality deviations. These systems are particularly valuable in industries with strict quality requirements such as automotive, aerospace, and pharmaceuticals.

Asset Tracking and Management solutions help manufacturers optimize utilization of equipment, tools, and inventory throughout their facilities. Real-time location systems combined with utilization analytics enable better resource allocation and reduced equipment investment requirements. These solutions are especially valuable in large manufacturing facilities with extensive equipment inventories.

Energy Management Applications are gaining importance as manufacturers focus on sustainability and cost reduction. IoT-enabled energy monitoring systems provide detailed insights into energy consumption patterns and identify optimization opportunities. Energy efficiency improvements of 15-25% are commonly achieved through IoT energy management implementations.

Manufacturing Companies benefit from IoT implementations through improved operational efficiency, reduced maintenance costs, and enhanced product quality. Real-time visibility into production processes enables faster decision-making and more responsive operations. Productivity improvements of 20-30% are commonly reported following comprehensive IoT deployments.

Equipment Manufacturers can differentiate their products by integrating IoT capabilities and providing value-added services such as remote monitoring and predictive maintenance. This creates new revenue streams and stronger customer relationships through ongoing service engagements.

Technology Providers benefit from the expanding market opportunity as manufacturers increasingly invest in digital transformation initiatives. The recurring revenue model of many IoT solutions provides stable, long-term revenue streams and opportunities for continuous innovation and improvement.

System Integrators play crucial roles in IoT manufacturing implementations, providing expertise in system design, integration, and ongoing support. The complexity of IoT deployments creates substantial opportunities for specialized integration services and consulting.

End Consumers ultimately benefit from IoT manufacturing implementations through improved product quality, faster delivery times, and more competitive pricing as manufacturers achieve greater efficiency and cost reduction.

Strengths:

Weaknesses:

Opportunities:

Threats:

Edge Computing Integration is transforming IoT manufacturing architectures by enabling real-time processing and decision-making at the manufacturing floor level. This trend reduces latency, improves system responsiveness, and reduces bandwidth requirements for cloud connectivity. Edge deployment rates in manufacturing IoT applications are growing at 48% annually.

Artificial Intelligence Enhancement is becoming standard in IoT manufacturing platforms, providing predictive analytics, automated optimization, and intelligent decision support. AI-powered IoT systems can identify patterns and anomalies that human operators might miss, leading to more effective preventive maintenance and quality control.

5G Connectivity Adoption is enabling new IoT manufacturing applications that require high-speed, low-latency communication. The enhanced connectivity capabilities of 5G networks support more sophisticated real-time control applications and enable greater density of connected devices in manufacturing environments.

Sustainability Integration is driving development of IoT solutions focused on environmental monitoring, energy optimization, and waste reduction. Manufacturers are increasingly using IoT technologies to support sustainability goals and regulatory compliance requirements.

Digital Twin Development combines IoT data with simulation and modeling technologies to create virtual representations of manufacturing processes and equipment. These digital twins enable advanced scenario planning, optimization, and predictive maintenance capabilities.

Strategic partnerships between technology providers are creating more comprehensive IoT manufacturing solutions. Recent collaborations between cloud platform providers, industrial automation companies, and telecommunications firms are delivering integrated solutions that address complete manufacturing IoT requirements.

Acquisition activity continues as established industrial companies acquire IoT specialists to enhance their technology capabilities and market positioning. These acquisitions are accelerating the development of integrated IoT manufacturing solutions and expanding market reach.

Technology innovations in areas such as wireless sensor networks, edge computing processors, and AI algorithms are continuously improving the capabilities and reducing the costs of IoT manufacturing solutions. These innovations are making IoT implementations more accessible to a broader range of manufacturers.

Industry initiatives focused on standardization and interoperability are gaining momentum, with organizations such as the Industrial Internet Consortium working to establish common frameworks and protocols for IoT manufacturing applications.

Government support programs in various countries are providing incentives and funding for manufacturing digitization initiatives that include IoT implementations. These programs are accelerating adoption rates and supporting technology development.

MarkWide Research recommends that manufacturing companies approach IoT implementation strategically, starting with pilot projects that demonstrate clear value before expanding to comprehensive deployments. Organizations should focus on applications with measurable ROI such as predictive maintenance and energy management to build internal support for broader IoT initiatives.

Technology selection should prioritize solutions that integrate well with existing manufacturing systems and provide clear upgrade paths for future enhancement. Companies should evaluate vendors based on their industry expertise, integration capabilities, and long-term technology roadmaps rather than focusing solely on initial costs.

Skills development should be a priority for organizations implementing IoT manufacturing solutions. Companies should invest in training existing staff and recruiting personnel with IoT and data analytics expertise to ensure successful implementation and ongoing optimization of IoT systems.

Cybersecurity planning must be integrated into IoT implementation strategies from the beginning. Organizations should work with cybersecurity specialists to develop comprehensive security frameworks that protect IoT systems while maintaining operational efficiency and flexibility.

Partnership strategies can help manufacturers access specialized expertise and reduce implementation risks. Companies should consider working with experienced system integrators and technology partners who understand both IoT technologies and manufacturing operations.

Market evolution will be characterized by continued growth in adoption rates as IoT technologies become more mature, affordable, and easier to implement. The integration of artificial intelligence, edge computing, and 5G connectivity will create more powerful and responsive IoT manufacturing solutions that deliver greater value to end users.

Technology advancement will focus on improving interoperability, reducing implementation complexity, and enhancing security capabilities. MWR projects that standardization efforts will significantly improve over the next five years, making IoT implementations more straightforward and cost-effective.

Geographic expansion will see strong growth in emerging markets as manufacturing sectors in developing economies modernize their operations. Asia-Pacific will continue to lead growth rates, while established markets in North America and Europe will focus on advanced applications and optimization of existing IoT deployments.

Application diversification will expand beyond current focus areas to include new use cases such as worker augmentation, supply chain integration, and advanced quality prediction. The convergence of IoT with other technologies such as augmented reality and blockchain will create new opportunities for manufacturing optimization.

Industry transformation will accelerate as IoT becomes integral to manufacturing competitiveness. Companies that successfully implement comprehensive IoT strategies will gain significant advantages in efficiency, quality, and responsiveness, while those that delay adoption may face competitive disadvantages.

The Internet of Things (IoT) for manufacturing market represents a fundamental transformation in how industrial operations are managed and optimized. With demonstrated benefits in operational efficiency, cost reduction, and quality improvement, IoT technologies are becoming essential components of modern manufacturing strategies. The market shows strong growth momentum driven by technological advancement, decreasing implementation costs, and increasing competitive pressures.

Success factors for IoT manufacturing implementations include strategic planning, appropriate technology selection, skills development, and strong cybersecurity frameworks. Organizations that approach IoT adoption systematically and focus on measurable business outcomes are achieving significant returns on their investments. The expanding ecosystem of solution providers, system integrators, and support services is making IoT implementations more accessible and reliable.

Future prospects remain highly positive as emerging technologies such as 5G, edge computing, and artificial intelligence enhance IoT capabilities while reducing costs and complexity. The continued evolution of IoT manufacturing solutions will create new opportunities for operational optimization and competitive differentiation. Manufacturing companies that embrace IoT technologies strategically will be well-positioned to thrive in an increasingly digital and competitive global marketplace.

What is Internet of Things (IoT) for Manufacturing?

The Internet of Things (IoT) for Manufacturing refers to the integration of internet-connected devices and sensors in manufacturing processes. This technology enables real-time data collection, monitoring, and automation, enhancing operational efficiency and decision-making.

What are the key players in the Internet of Things (IoT) for Manufacturing Market?

Key players in the Internet of Things (IoT) for Manufacturing Market include Siemens, GE Digital, and Bosch, which provide solutions for smart manufacturing, predictive maintenance, and supply chain optimization, among others.

What are the growth factors driving the Internet of Things (IoT) for Manufacturing Market?

The growth of the Internet of Things (IoT) for Manufacturing Market is driven by the increasing demand for automation, the need for real-time data analytics, and the push for operational efficiency in manufacturing processes.

What challenges does the Internet of Things (IoT) for Manufacturing Market face?

Challenges in the Internet of Things (IoT) for Manufacturing Market include cybersecurity risks, the complexity of integrating legacy systems with new IoT technologies, and the need for skilled workforce to manage IoT solutions.

What opportunities exist in the Internet of Things (IoT) for Manufacturing Market?

Opportunities in the Internet of Things (IoT) for Manufacturing Market include advancements in AI and machine learning for predictive analytics, the expansion of smart factories, and the potential for enhanced supply chain visibility.

What trends are shaping the Internet of Things (IoT) for Manufacturing Market?

Trends in the Internet of Things (IoT) for Manufacturing Market include the rise of edge computing for faster data processing, increased adoption of digital twins for simulation and optimization, and a growing focus on sustainability through energy-efficient IoT solutions.

Internet of Things (IoT) for Manufacturing Market

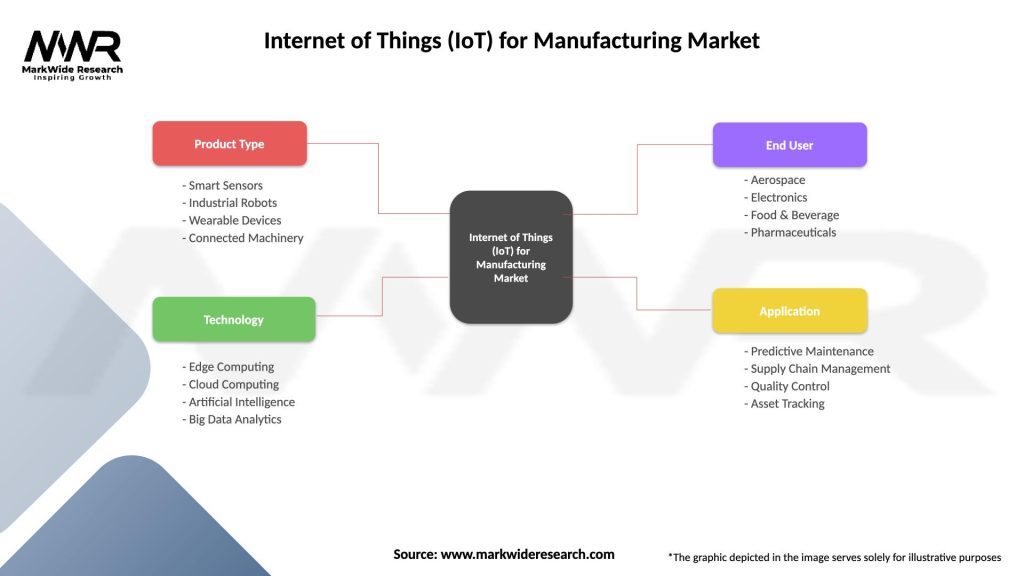

| Segmentation Details | Description |

|---|---|

| Product Type | Smart Sensors, Industrial Robots, Wearable Devices, Connected Machinery |

| Technology | Edge Computing, Cloud Computing, Artificial Intelligence, Big Data Analytics |

| End User | Aerospace, Electronics, Food & Beverage, Pharmaceuticals |

| Application | Predictive Maintenance, Supply Chain Management, Quality Control, Asset Tracking |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Internet of Things (IoT) for Manufacturing Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at