Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Dominance of Caustic Soda: Sodium hydroxide accounts for over 40 % of market volume, underpinned by its role in alumina refining, paper bleaching, and pulp processing.

-

Emerging Green Ammonia: With the shift to renewable‐powered electrolysis, green ammonia production for fertilizer and shipping fuel is accelerating, positioning ammonia as both a base and energy carrier.

-

High‐Purity Specialty Grades: Demand for electronics‐grade potassium and sodium hydroxide in semiconductor etching and precision cleaning is rising, commanding premium pricing.

-

Water Treatment Investment: Stricter regulations on effluent pH and heavy metals drive calcium and magnesium hydroxide adoption for neutralization and softening.

-

Asia‐Pacific Growth: China, India, and Southeast Asia represent over 50 % of global consumption, driven by expanding chemical, textile, and pulp & paper industries.

Market Drivers

-

Industrialization in Emerging Economies: Rapid expansion of manufacturing hubs in Asia‐Pacific and Latin America fuels base chemical demand.

-

Stricter Environmental Regulations: Limits on effluent pH and heavy metals mandate increased use of inorganic bases in wastewater treatment.

-

Growth of Pulp & Paper Sector: Rising global paper consumption, particularly in packaging, drives caustic soda usage for pulping and bleaching.

-

Food & Beverage Safety Standards: Calcium hydroxide and ammonia play key roles in pH control, sterilization, and food additive production.

-

Technological Advancements: Improved electrolysis and membrane cell technologies lower energy intensity and production costs for NaOH and KOH.

Market Restraints

-

Energy‐Intensive Production: Chlor‐alkali electrolysis and Haber‐Bosch ammonia synthesis remain highly energy‐consuming, susceptible to electricity price fluctuations.

-

Raw Material Volatility: Fluctuating salt and natural gas prices impact caustic soda and ammonia profitability.

-

Corrosion and Handling Risks: Severe alkalinity requires specialized materials and safety protocols, adding to capital and operating costs.

-

Environmental Impact: Disposal of spent brine, chlorate by‐products, and CO₂ emissions from ammonia synthesis present compliance challenges.

-

Competition from Organic Alternatives: In some niche applications, organic amines and buffers are replacing inorganic hydroxides to reduce corrosivity.

Market Opportunities

-

Green Production Routes: Adoption of renewable‐powered electrolysis and green hydrogen for ammonia can lower carbon footprint and appeal to sustainability mandates.

-

Circular Economy Models: Recovery of sodium and potassium bases from industrial effluents and brine reuse can reduce raw material consumption and waste.

-

Specialty Grade Expansion: Tailoring high‐purity bases for pharmaceuticals, electronics, and research laboratories can yield higher margins.

-

Modular & Onsite Generation: Small‐scale, decentralized Caustic‐Soda and ammonia generation units for remote facilities reduce transportation costs and emissions.

-

Integrated Water Treatment Solutions: Bundling base chemical supply with water treatment services provides long‐term contracts and value‐added revenue streams.

Market Dynamics

-

Supply Side:

Major producers invest in capacity expansions, modernization of electrolysis plants, and energy recovery systems. Strategic alliances and joint ventures secure raw material access and share technology costs. -

Demand Side:

End‐user industries focus on cost optimization, regulatory compliance, and supply security. Bulk purchasers negotiate long‐term contracts and hedge against energy price swings. -

Economic Factors:

Global GDP growth, manufacturing PMI, and construction activity directly correlate with inorganic base consumption. Volatile energy markets and raw material prices introduce unpredictability in profit margins.

Regional Analysis

-

Asia‐Pacific:

Leading region by volume; China and India dominate. Rapid urbanization and infrastructure projects accelerate demand in water treatment and cement (slaked lime) sectors. -

North America:

Mature market with stable caustic soda demand in chemicals and pulp & paper. Innovation in green hydrogen and renewable ammonia offers growth potential. -

Europe:

Stringent environmental targets drive use of calcium and magnesium hydroxide for flue gas desulfurization and wastewater treatment. Green ammonia mandates emerge. -

Latin America:

Growing agricultural base boosts ammonia and caustic soda use in fertilizer production. Infrastructure modernization drives market entry. -

Middle East & Africa:

Oil & gas–centric economies utilize ammonia for fertilizer and urea. Desalination‐related calcium hydroxide demand grows.

Competitive Landscape

Leading Companies in the Inorganic Bases Market:

- Dow Inc.

- BASF SE

- Solvay S.A.

- Occidental Petroleum Corporation

- Formosa Plastics Corporation

- Akzo Nobel N.V.

- Tata Chemicals Limited

- Evonik Industries AG

- FMC Corporation

- Tosoh Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

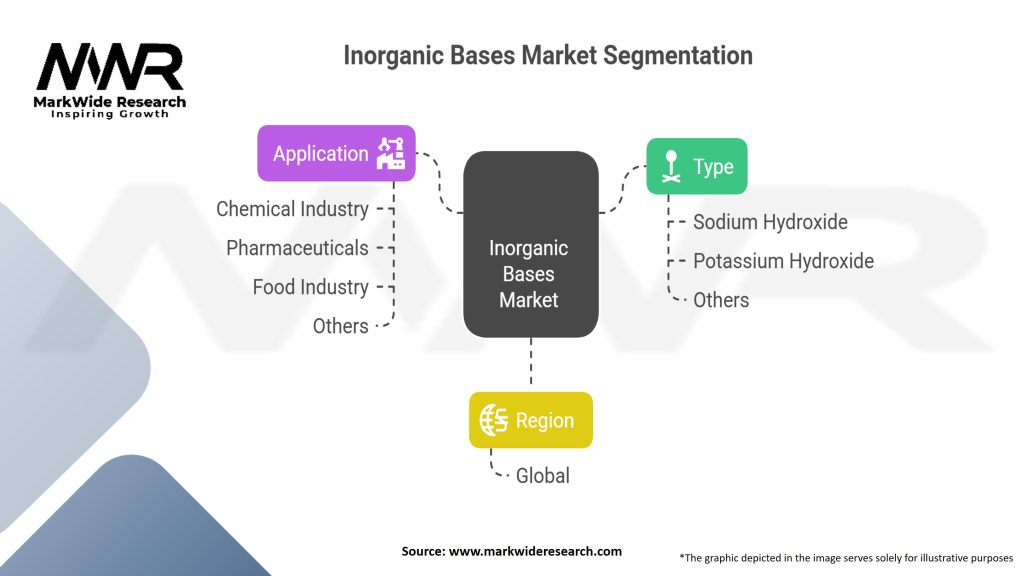

Segmentation

-

By Product:

-

Sodium Hydroxide (Caustic Soda)

-

Potassium Hydroxide

-

Calcium Hydroxide (Slaked Lime)

-

Ammonia

-

Magnesium Hydroxide

-

Other Inorganic Bases (e.g., Barium, Strontium Hydroxides)

-

-

By Purity Grade:

-

Technical/Industrial Grade

-

Food Grade

-

Pharmaceutical/High‑Purity Grade

-

-

By Application:

-

Chemical Manufacturing

-

Pulp & Paper

-

Water & Wastewater Treatment

-

Textiles & Leather Processing

-

Food & Beverages

-

Pharmaceuticals

-

Oil & Gas Refining

-

Construction & Cement

-

-

By Region:

-

North America

-

Europe

-

Asia‑Pacific

-

Latin America

-

Middle East & Africa

-

Category‑wise Insights

-

Technical Grade Caustic Soda: Drives large volume applications in alumina refining, soap manufacturing, and pulp & paper bleaching.

-

Food & Pharma Grades: Specialty potassium and sodium hydroxides see premium growth in pH control, buffer preparations, and active pharmaceutical ingredient synthesis.

-

Water Treatment Bases: Calcium and magnesium hydroxides gain traction for neutralization, softening, and heavy metal precipitation.

-

Green Ammonia: Emerging segment as fertilizer producers and energy companies pilot renewable hydrogen–based ammonia for carbon‑free applications.

Key Benefits for Industry Participants and Stakeholders

-

Versatility: Inorganic bases serve diverse functions across chemical, environmental, and manufacturing domains.

-

Scale & Cost Efficiency: Large‑scale production confers economies of scale, driving down unit costs and ensuring supply security.

-

Regulatory Alignment: Use in pollution control and pH management supports compliance with tightening environmental legislation.

-

Innovation Potential: Development of greener production methods and circular supply chains enhances corporate sustainability profiles.

-

Risk Mitigation: On‑site generation and modular plants reduce logistics costs, supply risks, and carbon footprints.

SWOT Analysis

-

Strengths:

• High volume, essential feedstocks for numerous industries

• Established global production networks and mature technologies

• Strong demand from regulated sectors (water treatment, pulp & paper) -

Weaknesses:

• High energy intensity and carbon footprint in traditional production

• Price vulnerability to energy and raw material cost fluctuations

• Corrosive nature demands specialized handling and equipment -

Opportunities:

• Expansion of green base production (renewable electrolysis, green ammonia)

• Circular economy initiatives: recovery from industrial wastewater

• Growth in emerging markets and modular, decentralized production -

Threats:

• Competition from alternative pH control/neutralization chemistries

• Regulatory pressure on emissions and effluent discharge

• Technological disruption (e.g., new battery chemistries reducing caustic demand)

Market Key Trends

-

Decarbonization of Base Production:

Electrolyzer efficiencies, renewable hydrogen for ammonia, and membrane cell chlor‑alkali processes reduce CO₂. -

On‑Demand, Modular Plants:

Small‑scale, containerized electrolytic or ammonia synthesis units sited near demand centers minimize logistics. -

Digital Process Optimization:

Advanced analytics and AI optimize energy use, maximize yield, and enable predictive maintenance. -

Integrated Wastewater Recovery:

Closed‑loop systems recover sodium and calcium hydroxides from industrial effluents, reducing raw material consumption. -

Circular Feedstock Sourcing:

Use of biomass‐derived acetic acid and carbonate from CO₂ capture aligns with sustainability goals.

Covid‑19 Impact

-

Supply Chain Disruptions: Temporary salt and gas feedstock shortages prompted strategic stockpiling and logistics diversification.

-

Demand Volatility: Slowdowns in pulp & paper and construction reduced base consumption, offset by increased water treatment needs.

-

Energy Price Fluctuations: Oil and gas price crashes impacted ammonia feedstock costs, leading to shutdowns and restarts.

-

Acceleration of Digitalization: Remote monitoring and process automation investments accelerated to reduce on‑site staffing risks.

-

Resilience Emphasis: Pandemic reinforced the value of on‑site base generation and modularized plants to ensure operational continuity.

Key Industry Developments

-

Green Ammonia Pilots: Large fertilizer companies partnering with renewable hydrogen firms to produce carbon‐neutral ammonia.

-

Electric Chlor‑Alkali Projects: Deployment of zero‑mercury and zero‑diaphragm membrane cells powered by renewables.

-

Circular Innovation Grants: Government and NGO funding for projects recovering bases from mining and industrial wastewater streams.

-

Modular Electrolysis Units: Startups commercializing skid‑mounted systems for decentralized sodium hydroxide production.

-

Sustainability Certification: Industry standards emerging for green base chemicals, enabling premium pricing and procurement preferences.

Analyst Suggestions

-

Invest in Renewable Energy Integration: Collaborate with power providers to secure green electricity at fixed rates for electrolysis operations.

-

Pursue Circular Economy Partnerships: Co‑develop recovery technologies with water treatment and mining companies to close material loops.

-

Focus on Specialty Grades: Expand high‑purity and food/pharma grade capacity to capture premium segments less sensitive to cost.

-

Scale Modular Production: Deploy small‑scale, turnkey units in emerging markets to reduce logistics and regulatory hurdles.

-

Enhance Digital Capabilities: Leverage AI and predictive analytics to optimize plant performance, reduce downtime, and cut carbon intensity.

Future Outlook

The Inorganic Bases Market is set for steady, sustainable growth driven by green transformation, circular economy adoption, and resilient supply chain strategies. While traditional high‑volume applications will remain core demand drivers, specialty and green production routes will command increasing value. As industries prioritize decarbonization and resource efficiency, base chemical producers that invest early in renewable energy, recovery technologies, and digitalization will secure competitive advantage. Expansion in emerging markets and modular, decentralized production models will offer new growth pathways, while partnerships across the value chain will accelerate innovation and standardization. Despite challenges around energy costs and regulatory compliance, the long‑term outlook remains positive, with inorganic bases continuing to underpin global industrial and environmental processes.

Conclusion

The Inorganic Bases Market represents a vital component of the global industrial ecosystem, enabling chemical synthesis, environmental protection, and materials manufacturing. Through a combination of scale economies, emerging green technologies, and circular feedstock strategies, the market is poised to evolve into a lower‑carbon, more resilient sector. Stakeholders—from legacy chlor‑alkali and ammonia producers to innovative modular technology firms—must navigate energy volatility, regulatory shifts, and changing customer expectations. By embracing sustainable production, digital optimization, and strategic partnerships, the industry can deliver essential alkali chemistry while meeting the demands of a decarbonizing, resource‑efficient future.