444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Infusion Bag Films market is a significant segment of the medical packaging industry, responsible for manufacturing films used in the production of infusion bags. These bags play a crucial role in the safe storage and transportation of intravenous fluids, such as saline solutions, medications, and nutrients, in the healthcare sector. As the demand for sterile and contamination-free packaging continues to rise, the market for infusion bag films is witnessing substantial growth.

Meaning

Infusion bag films refer to specialized films used in the manufacturing of infusion bags for medical and pharmaceutical purposes. These films are crucial components of the packaging industry, providing a safe and sterile environment for intravenous fluids, parenteral nutrition, and various other medications. Infusion bag films are designed to meet stringent quality standards and ensure the integrity and stability of the contents they hold.

Executive Summary

The global infusion bag films market has witnessed significant growth over the past few years, primarily driven by the rising demand for efficient and safe packaging solutions in the healthcare sector. As the healthcare industry continues to expand, the need for reliable and durable packaging materials for intravenous drugs and fluids has intensified. Infusion bag films play a critical role in meeting these requirements, offering advantages such as enhanced product protection, compatibility with various drug formulations, and ease of use for medical practitioners.

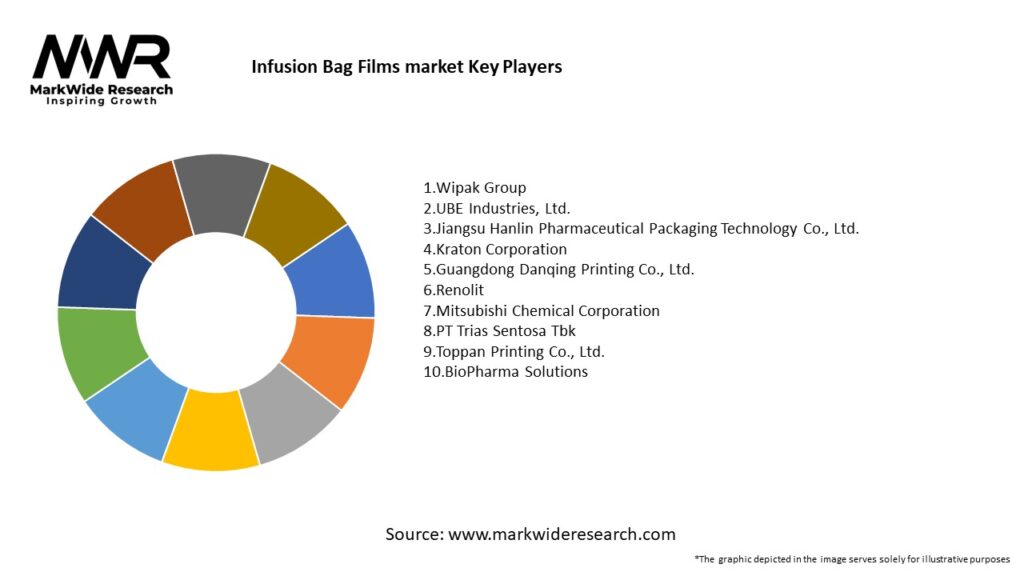

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Home Infusion Growth: The trend toward outpatient and home-based infusion therapy drives need for safe, reliable disposable infusion bags—boosting film demand.

Biologic & Specialty Therapies: Growing use of complex biologics (e.g. monoclonal antibodies, cell therapies) often require sensitive infusion systems, pushing demand for premium films with low extractables.

Barrier Enhancement Trends: Films with better barrier to oxygen, moisture, and contaminants help extend shelf life of infusion solutions and protect sensitive drugs.

Multilayer Laminate Innovation: Use of co-extruded or laminated films combining polyolefin, barrier, tie, and sealant layers balances cost and performance.

Sustainability Pressure: Medical device companies are exploring recyclable film systems or reduced PVC use, favoring alternative polymers.

Market Drivers

Rising Chronic Disease and Elderly Populations: Greater prevalence of conditions requiring IV therapies (e.g. diabetes complications, cancer, infections).

Home & Ambulatory Care Shift: Healthcare cost pressures and pandemics accelerate movement of infusion from hospital to home settings.

Biopharmaceutical Growth: Increased biologic and cell therapy volume requiring sterile fluid delivery.

Disposable Device Preference: To reduce contamination risk, single-use infusion devices are preferred over reusable systems.

Regulatory and Safety Emphasis: Regulatory norms demand high-quality, traceable, and validated materials in infusion systems.

Market Restraints

Raw Material Cost Volatility: Fluctuations in polymer feedstocks, additives, and barrier resin cost affect film pricing stability.

Technical Complexity: Achieving precise multicomponent films that balance barrier, weldability, biocompatibility, and strength is challenging.

Regulatory Barriers: film manufacturers must satisfy medical device grade qualification and certification, which slows new material adoption.

Recycling Challenges: Medical-grade films are often contaminated and difficult to recycle, limiting circular design.

High Entry Barriers: High capital costs for extrusion/lamination lines, cleanrooms, and validation limit new entrants.

Market Opportunities

Advanced Barrier Films: Use of EVOH, nanocomposites, or new barrier polymers to enhance shelf stability and drug protection.

PVC-Free Alternatives: Growth in PVC-free formulations (polyolefin-based systems) in regions where phthalates or PVC usage is restricted.

Antimicrobial or Drug-Eluting Layers: Films that inherently resist microbial growth or deliver small drug payloads.

Biodegradable or Recyclable Designs: Development of medical-grade recyclable or degradable film systems.

Customized Regional Manufacturing: Local film production near device converters in emerging markets to reduce logistical cost and lead time.

Market Dynamics

Supply-Side Factors:

Major film producers invest in medical-grade extrusion, lamination, and cleanroom capacity.

Suppliers partner with device converters to co-develop film platforms tailored to bag designs.

Material suppliers innovate additives, stabilizers, barrier resins, and compatibilizers catering to medical needs.

Demand-Side Factors:

Device manufacturers demand film stocks that simplify conversion (welding, sterilization) and reduce validation burden.

Regions with growing healthcare infrastructure (Asia-Pacific, Latin America) increase demand for local film supply.

Economic & Regulatory Factors:

Medical device regulation (FDA, MDR, ISO) exerts rigorous qualification standards on films.

Cost pressures push optimization of film thickness and multi-layer design to minimize material usage.

Regional Analysis

North America & Europe: Leading markets with high regulatory standards and premium film use; strong demand for biologics and home infusion.

Asia-Pacific: Fastest growth region, driven by healthcare expansion, domestic device manufacturing, and cost-sensitive but rising quality demand.

Latin America: Gradual growth, bolstered by local device manufacturing initiatives and import substitution.

Middle East & Africa: Nascent adoption but opportunity in healthcare infrastructure projects.

Emerging Regions: Local film production near device converters provides logistics cost advantage.

Competitive Landscape

Leading Companies in the Infusion Bag Films Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

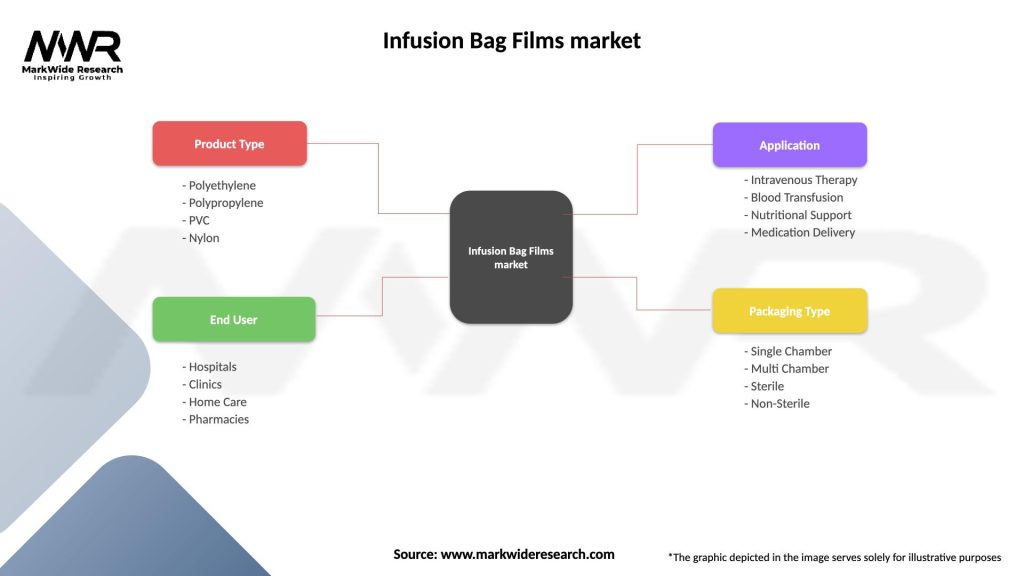

Segmentation

The infusion bag films market can be segmented based on material type, thickness, application, and end-use industry. By material type, the market includes polyethylene, polypropylene, ethylene vinyl acetate (EVA), and others. Thickness segmentation comprises standard, medium, and heavy-duty films. In terms of application, the market covers intravenous fluids, irrigation solution bags, and others. The end-use industry segment includes hospitals, clinics, ambulatory surgical centers, and pharmaceutical companies.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The infusion bag films market offers several benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT analysis of the infusion bag films market reveals:

Strengths

Weaknesses

Opportunities

Threats

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a multifaceted impact on the infusion bag films market. On one hand, the increased demand for intravenous drugs and fluids during the pandemic led to a surge in the usage of infusion bag films. On the other hand, disruptions in the supply chain and manufacturing processes due to lockdowns and restrictions affected the market’s growth. The pandemic highlighted the need for resilient and flexible packaging solutions in the healthcare sector, accelerating the adoption of advanced infusion bag films.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the infusion bag films market looks promising, driven by the continuous expansion of the healthcare industry and the demand for efficient drug packaging solutions. Innovations in material technology, smart packaging integration, and increasing environmental consciousness are expected to shape the market’s trajectory positively.

Conclusion

Infusion bag films play a vital role in ensuring the safe and efficient delivery of intravenous drugs and fluids in the healthcare sector. With the growing prevalence of chronic diseases and the need for sustainable packaging solutions, the infusion bag films market is poised for steady growth. Industry participants must focus on innovation, sustainability, and market expansion to capitalize on emerging opportunities and address the evolving needs of the healthcare industry.

What is Infusion Bag Films?

Infusion Bag Films are specialized films used in the production of infusion bags, which are essential for the storage and delivery of intravenous fluids and medications. These films are designed to be flexible, durable, and resistant to various chemicals and sterilization processes.

What are the key companies in the Infusion Bag Films market?

Key companies in the Infusion Bag Films market include Amcor, Sealed Air Corporation, and Wipak, among others. These companies are known for their innovative packaging solutions and commitment to quality in the healthcare sector.

What are the growth factors driving the Infusion Bag Films market?

The Infusion Bag Films market is driven by the increasing demand for safe and efficient drug delivery systems, the rise in chronic diseases requiring long-term treatment, and advancements in film technology that enhance product performance.

What challenges does the Infusion Bag Films market face?

Challenges in the Infusion Bag Films market include stringent regulatory requirements for medical packaging, the need for high-quality materials to ensure patient safety, and competition from alternative packaging solutions.

What opportunities exist in the Infusion Bag Films market?

Opportunities in the Infusion Bag Films market include the development of biodegradable films to meet sustainability goals, the expansion of healthcare facilities in emerging markets, and the increasing adoption of home healthcare services.

What trends are shaping the Infusion Bag Films market?

Trends in the Infusion Bag Films market include the growing focus on patient-centric packaging designs, the integration of smart technology for monitoring fluid delivery, and the shift towards eco-friendly materials in response to environmental concerns.

Infusion Bag Films market

| Segmentation Details | Description |

|---|---|

| Product Type | Polyethylene, Polypropylene, PVC, Nylon |

| End User | Hospitals, Clinics, Home Care, Pharmacies |

| Application | Intravenous Therapy, Blood Transfusion, Nutritional Support, Medication Delivery |

| Packaging Type | Single Chamber, Multi Chamber, Sterile, Non-Sterile |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Infusion Bag Films Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at