444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Industrial racking systems are essential components of warehouse storage and material handling operations. They are used to organize and store a wide variety of products, materials, and equipment. The market for industrial racking systems is driven by the increasing demand for efficient and cost-effective storage solutions across various industries.

According to a report by Allied Market Research, the global industrial racking systems market was valued at $9.4 billion in 2020 and is expected to reach $13.5 billion by 2028, growing at a CAGR of 4.5% from 2021 to 2028. The report identifies various factors driving the growth of the industrial racking systems market, including the increasing demand for organized storage solutions, the growing e-commerce industry, and the rise of the food and beverage industry.

Industrial racking systems refer to a range of storage solutions designed to meet the unique needs of industrial warehouses and other storage facilities. They are typically made of steel or other durable materials and come in a variety of configurations, including pallet racking, cantilever racking, and shelving systems.

The use of industrial racking systems can help businesses optimize their storage space and improve the efficiency of their material handling operations. By providing a safe and organized storage environment, racking systems can reduce the risk of damage to products and equipment and enhance the overall productivity of the warehouse.

Executive Summary

The global industrial racking systems market is expected to grow at a steady pace over the next few years, driven by the increasing demand for organized storage solutions across various industries. The rise of e-commerce and the food and beverage industry is expected to be a key driver of growth, as these industries require efficient and cost-effective storage solutions to manage their inventory.

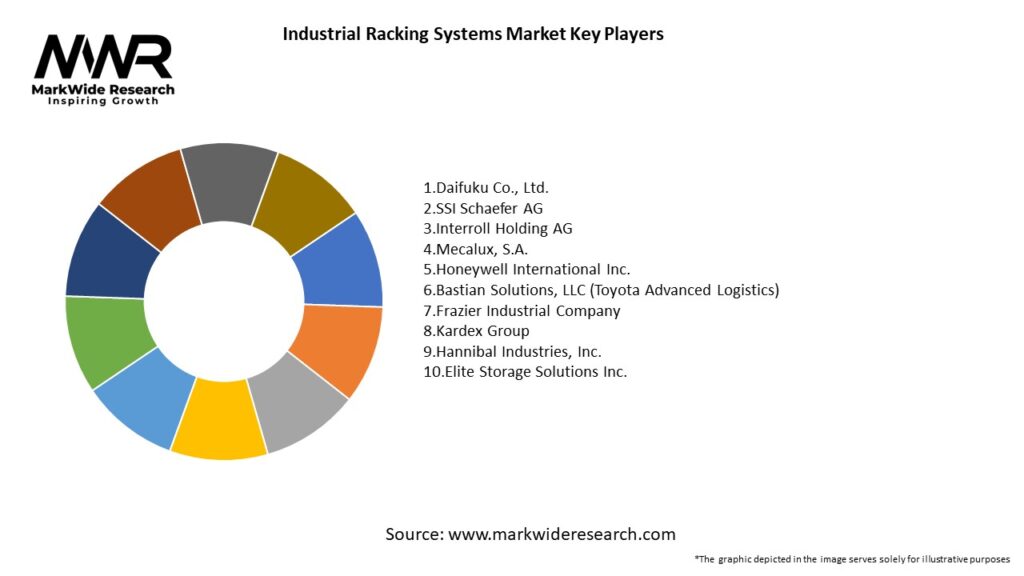

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Warehouse Automation Growth: Integration with AGVs and robotics drives demand for pallet racking and shelving.

Space Optimization: High-density systems such as mobile racking and mezzanines maximize footprint utilization.

Industry 4.0 Integration: Smart racks equipped with sensors and RFID streamline inventory tracking.

Customization Needs: Modular designs allow for tailored load capacities and configurations.

Safety Regulations: Stricter occupational standards mandate anti-collapse features and seismic compliance.

Market Drivers

E-commerce Expansion: Rising online retail fulfillment centers require advanced storage solutions.

Cold Storage Demand: Growth in frozen and refrigerated warehouses fuels insulated racking systems.

Lean Inventory Practices: Just-in-time manufacturing leads to dynamic racking adjustments.

Construction Investments: New warehouse and distribution center builds incorporate modern racking from the ground up.

Sustainability Focus: Recyclable steel and modular upgrades support circular economy goals.

Market Restraints

High Capital Outlay: Installation of automated and high-density systems requires significant investment.

Installation Downtime: Retrofitting existing facilities can disrupt operations.

Technical Expertise Needs: Designing and engineering complex systems require specialized vendors.

Maintenance Costs: Regular inspections and component replacements add to total cost of ownership.

Space Constraints: Older buildings may not support high-rise racking due to ceiling height limitations.

Market Opportunities

Retrofit Services: Upgrading legacy racks to smart, sensor-enabled systems.

Collaborative Robotics: Integrating cobots for aisle-side picking and restocking.

Lightweight Materials: Development of high-strength composites for lower-weight, high-load beams.

Digital Twin Modeling: Virtual simulations to optimize lay-outs before physical installation.

Subscription Models: As-a-service offerings for racking maintenance and upgrades.

Market Dynamics

The global industrial racking systems market is driven by various factors, including the increasing demand for organized storage solutions, the rise of the e-commerce and food and beverage industries, and the need for efficient and cost-effective storage solutions.

However, the market faces certain challenges, including the high initial cost of installation and limited customization options. These challenges are expected to be addressed by the growing demand for customized racking solutions and the emergence of Industry 4.0 and automation technologies.

Regional Analysis

The global industrial racking systems market is segmented into North America, Europe, Asia-Pacific, and the rest of the world. Asia-Pacific is expected to be the fastest-growing region in the market, owing to the growing manufacturing sector and the rise of e-commerce in the region. North America and Europe are also expected to be key regions in the market, owing to the presence of established industries and the increasing demand for efficient storage solutions.

Competitive Landscape

Leading Companies in the Industrial Racking Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

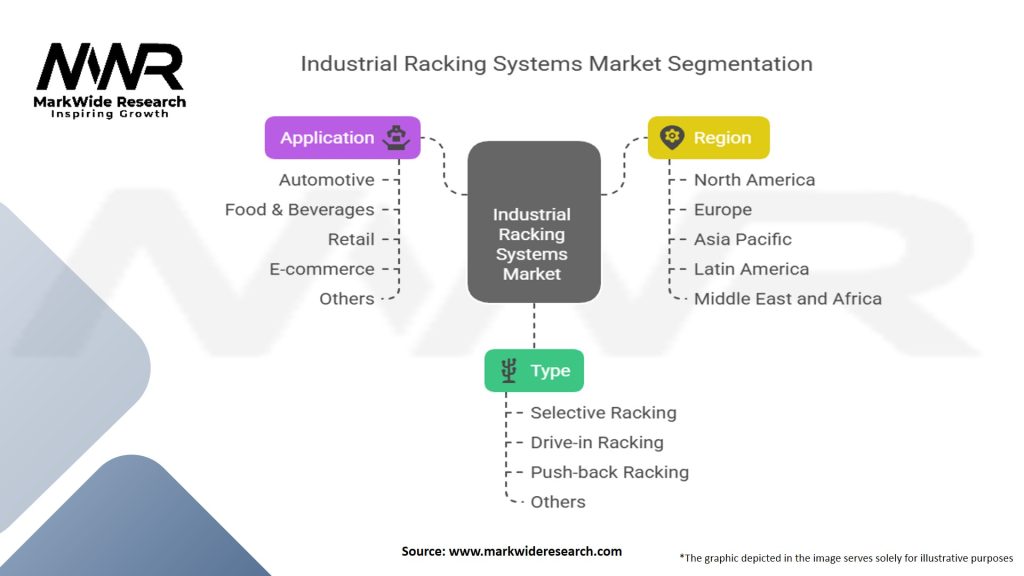

Segmentation

Category-wise Insights

Pallet racking is the most widely used type of industrial racking system, owing to its ability to provide high-density storage solutions and easy accessibility to products. The food and beverage industry is expected to be the largest end-user of industrial racking systems, owing to the need for safe and organized storage of perishable goods.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the industrial racking systems market can benefit from the following:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the industrial racking systems market, with the disruption of supply chains and the closure of warehouses and storage facilities. However, the pandemic has also led to an increase in the demand for e-commerce and online shopping, which has driven the growth of the market.

Key Industry Developments

Some of the key developments in the industrial racking systems market include:

Analyst Suggestions

Analysts suggest that the industrial racking systems market is expected to continue growing in the coming years, driven by the increasing demand for efficient storage solutions across various industries. They also suggest that players in the market should focus on product innovation and strategic partnerships to enhance their market presence and increase their revenue.

Future Outlook

The global industrial racking systems market is expected to continue growing in the coming years, driven by the increasing demand for organized storage solutions and the rise of the e-commerce and food and beverage industries. The emergence of Industry 4.0 and automation technologies is also expected to drive the growth of the market, as businesses seek to optimize their storage space and improve the efficiency of their material handling operations.

Conclusion

The industrial racking systems market is a dynamic and growing industry, driven by the increasing demand for organized storage solutions and the need for efficient and cost-effective storage solutions. The rise of the e-commerce and food and beverage industries is expected to be a key driver of growth, as these industries require safe and organized storage solutions for their products.

The market is highly competitive, with numerous players operating in the market. However, players can benefit from the growing demand for customized racking solutions and the emergence of Industry 4.0 and automation technologies.

The Covid-19 pandemic has had a significant impact on the market, with the disruption of supply chains and the closure of warehouses and storage facilities. However, the pandemic has also led to an increase in the demand for e-commerce and online shopping, which has driven the growth of the market.

What are industrial racking systems?

Industrial racking systems are storage solutions designed to hold and organize goods in warehouses and distribution centers. They come in various types, including pallet racks, shelving units, and cantilever racks, catering to different storage needs and maximizing space efficiency.

Who are the key players in the industrial racking systems market?

Key players in the industrial racking systems market include companies like Dematic, SSI Schaefer, and Interlake Mecalux, which offer a range of racking solutions for various industries. These companies focus on innovation and efficiency to meet the growing demands of logistics and warehousing, among others.

What are the main drivers of growth in the industrial racking systems market?

The growth of the industrial racking systems market is driven by the increasing demand for efficient storage solutions in e-commerce, the rise of automation in warehouses, and the need for space optimization in logistics operations. Additionally, the expansion of retail and manufacturing sectors contributes to this growth.

What challenges does the industrial racking systems market face?

The industrial racking systems market faces challenges such as fluctuating raw material prices, safety regulations that require compliance, and the need for continuous innovation to meet changing customer demands. These factors can impact production costs and operational efficiency.

What opportunities exist in the industrial racking systems market?

Opportunities in the industrial racking systems market include the adoption of smart technologies for inventory management, the growth of sustainable racking solutions, and the expansion into emerging markets. These trends can enhance operational efficiency and reduce environmental impact.

What trends are shaping the industrial racking systems market?

Current trends in the industrial racking systems market include the integration of automation and robotics, the development of modular racking systems, and a focus on sustainability. These innovations aim to improve storage efficiency and adapt to the evolving needs of various industries.

Industrial Racking Systems Market

| Segmentation | Details |

|---|---|

| Type | Selective Racking, Drive-in Racking, Push-back Racking, Others |

| Application | Automotive, Food & Beverages, Retail, E-commerce, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Industrial Racking Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at