444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The industrial conveyor belts market is expanding rapidly as automation, material handling efficiency, and safety requirements become central to manufacturing and logistics operations worldwide. Conveyor belts, essential for transporting materials in industries such as mining, food processing, automotive, and packaging, have evolved significantly with advances in materials science and automation technologies. The market is growing at a CAGR of over 5.9%, driven by rising industrial production, warehouse automation, and demand for energy-efficient conveyor systems.

Globally, nearly 70% of manufacturing facilities now employ conveyor systems to streamline operations and reduce manual labor. The surge in e-commerce and warehousing activities has also accelerated adoption of intelligent and modular conveyor belt systems. According to MarkWide Research, technological innovation in belt materials—such as lightweight polymers and temperature-resistant composites—is redefining performance and reliability, making conveyor belts a key enabler of industrial productivity.

The industrial conveyor belts market refers to the production, distribution, and usage of continuous belts designed to transport materials across manufacturing lines, warehouses, or industrial facilities. These belts are used to move goods efficiently and safely, minimizing manual intervention. Conveyor belts come in various types, including rubber, metal, fabric, and modular plastic, tailored for applications ranging from bulk material handling to precision assembly lines.

MWR emphasizes that industrial conveyor belts are integral to modern production systems. They enhance operational efficiency, ensure consistent throughput, and reduce downtime, supporting both heavy-duty industrial sectors and automated logistics hubs. The market’s evolution reflects the growing integration of automation, IoT sensors, and smart control systems into traditional material handling processes.

The global industrial conveyor belts market is projected to grow at a 5.9% CAGR through the forecast period, driven by rapid industrialization, expansion of warehousing facilities, and the global shift toward automation. Conveyor belts play a vital role in minimizing operational bottlenecks and improving safety in industries like mining, food processing, logistics, and automotive manufacturing.

Rubber conveyor belts currently dominate the market, accounting for over 45% of total usage. However, lightweight modular and plastic belts are gaining popularity due to lower maintenance and higher durability. According to MarkWide Research, the future of the market will be shaped by innovations in belt design, smart monitoring technologies, and the increasing emphasis on sustainability and energy efficiency across industrial operations.

Growing automation and industrial digitization are major drivers of the conveyor belts market. As industries strive to improve efficiency, conveyor systems have become essential for automated assembly lines and warehouse logistics. The e-commerce boom has further amplified demand for fast and reliable material handling equipment in distribution centers.

Additionally, advancements in conveyor belt materials—such as flame-resistant rubber and temperature-tolerant polymers—are enhancing operational safety and expanding use in challenging environments. Regulatory emphasis on workplace safety and energy efficiency also supports market adoption.

High initial investment costs for large-scale conveyor systems remain a barrier for small and medium enterprises. Maintenance challenges and belt wear in heavy-load operations increase operational expenses. Environmental concerns regarding rubber disposal and manufacturing emissions are also limiting factors.

Moreover, technical complexities in integrating conveyors with existing automated systems may hinder adoption in older facilities, especially in developing markets lacking modern infrastructure.

Smart conveyor systems integrated with sensors and IoT platforms offer real-time monitoring of belt performance, reducing downtime and improving safety. Lightweight modular designs and recyclable materials are emerging opportunities for eco-friendly production. Rapid industrialization in Asia-Pacific and Latin America is opening new avenues for conveyor installations in manufacturing, mining, and logistics.

The rise of automated warehouses and cold-chain logistics also creates opportunities for specialized conveyor systems designed for temperature-controlled environments.

Market dynamics are influenced by industrial modernization, sustainability goals, and labor cost optimization. With automation adoption increasing 12% annually, conveyor belts are becoming integral to next-generation production systems. Asia-Pacific leads the market in production and consumption, while North America focuses on upgrading legacy infrastructure with smart automation.

Manufacturers are investing in R&D to develop energy-efficient, low-noise, and easy-to-maintain conveyor systems suitable for multi-industry applications.

The research approach for the industrial conveyor belts market combines primary and secondary analysis. Primary research involves discussions with material handling engineers, manufacturers, and logistics professionals. Secondary research draws upon industry reports, patent filings, and government publications.

MarkWide Research integrates supply chain data, manufacturing trends, and demand-side insights into forecasting models that account for regional variations, technological adoption rates, and sustainability indicators.

Asia-Pacific leads the global market with 42% share, attributed to rapid industrialization in China, India, and Southeast Asia. North America holds 25% share, supported by automation-driven manufacturing sectors and e-commerce expansion. Europe follows with 20% share, emphasizing sustainable manufacturing and energy-efficient systems.

Latin America and Middle East & Africa are emerging regions where investments in mining, food processing, and logistics infrastructure are boosting conveyor system demand at 7–8% CAGR.

By Material Type:

By Application:

Rubber belts remain the most widely used category, providing durability and strength for bulk transport operations. Plastic modular belts are the fastest-growing segment, offering hygiene and easy maintenance benefits, particularly in food and pharmaceutical industries. Fabric belts serve lightweight applications such as packaging and sorting, while metal belts are gaining traction in high-temperature processes like metallurgy and glass production.

Strengths:

Weaknesses:

Opportunities:

Threats:

Smart conveyor systems with real-time condition monitoring are reshaping maintenance strategies. Energy-efficient belt designs using lightweight materials are gaining adoption in Europe and North America. Customized solutions for industry-specific needs, such as flame-retardant belts for mining and food-grade belts for hygiene compliance, are becoming mainstream. Recycling initiatives for worn belts are also trending as part of global sustainability drives.

The industrial conveyor belts market is set to evolve with technological advancements and sustainability imperatives. The continued expansion of automated production lines and logistics hubs will drive consistent demand. Asia-Pacific will remain the largest market, while North America and Europe lead in innovation and regulatory compliance. Adoption of smart sensors, AI-driven maintenance, and lightweight materials will transform the market’s efficiency and sustainability profile in the next decade.

The industrial conveyor belts market is entering a dynamic growth phase driven by automation, sustainability, and industrial modernization. As manufacturing and logistics operations become more digitized, conveyor systems will continue to serve as the backbone of material handling efficiency. With strong demand from industries like mining, food processing, and e-commerce, manufacturers are focusing on durability, energy efficiency, and smart monitoring. Despite challenges such as maintenance costs and raw material fluctuations, innovations in materials and digital integration ensure long-term growth. As emphasized by MarkWide Research, industrial conveyor belts will remain pivotal in driving operational excellence and sustainable productivity across the global industrial landscape.

Industrial Conveyor Belts Market

| Segmentation Details | Description |

|---|---|

| Belt Type | Flat Belt, Modular Belt, Cleated Belt, Timing Belt |

| Material | PVC, PU, Rubber, Metal |

| Application Industry | Food & Beverage, Automotive Assembly, Logistics & Warehousing, Mining & Minerals |

| Drive Mechanism | Friction Drive, Positive Drive, Servo Drive, Roller Chain |

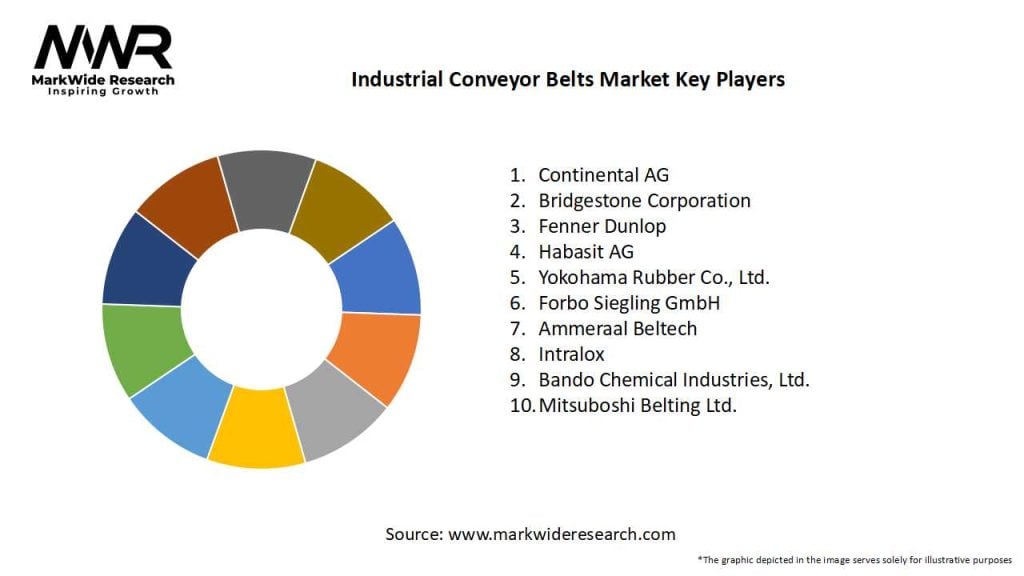

Leading Companies in the Industrial Conveyor Belts Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at