444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The industrial cable monitoring market is experiencing significant growth and is expected to continue expanding in the coming years. The increasing adoption of industrial automation and the need for continuous monitoring and maintenance of cables in various industries are the primary factors driving the market’s growth. This article will provide a comprehensive overview of the industrial cable monitoring market, including key market insights, drivers, restraints, opportunities, regional analysis, competitive landscape, segmentation, and future outlook.

Meaning

Industrial cable monitoring refers to the process of monitoring and analyzing the condition of cables used in industrial applications. It involves the use of advanced monitoring systems and technologies to detect faults, failures, or performance deviations in cables. By continuously monitoring cables, companies can ensure the reliability, safety, and efficiency of their industrial operations, minimizing downtime and avoiding costly repairs.

Executive Summary

The industrial cable monitoring market is witnessing steady growth due to the increasing demand for efficient and reliable industrial operations. The market is driven by the growing adoption of industrial automation, which requires continuous monitoring of cables to prevent failures and disruptions. Additionally, the need for proactive maintenance to optimize cable performance and the rising focus on enhancing worker safety are contributing to market growth. However, challenges such as high implementation costs and complex integration processes may hinder market expansion.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The Industrial Cable Monitoring market is projected to grow at a CAGR of ~6% through 2030, driven by the need for predictive maintenance in critical infrastructure.

Power utilities and heavy industries account for over 55% of demand, using monitoring to prevent unplanned outages and safety incidents.

Wireless and fiber-optic sensing technologies are capturing ~30% of new installations, due to ease of deployment and high sensitivity.

North America leads adoption, but Asia-Pacific is the fastest-growing region, spurred by grid modernization and industrial automation projects.

Integration with IoT platforms and SCADA systems is becoming standard, enabling real-time analytics and remote diagnostics.

Market Drivers

Predictive Maintenance Needs: Shift from time-based to condition-based maintenance reduces downtime and repair costs.

Grid Modernization: Upgrades to aging power networks include online cable health monitoring to enhance reliability.

Safety & Compliance: Stricter regulations on fire and electrical hazards compel industries to adopt continuous monitoring.

Digital Transformation: Industry 4.0 initiatives demand real-time visibility into asset health, including cabling networks.

Cost Reduction: Early detection of insulation degradation and hotspots helps avoid expensive emergency repairs.

Market Restraints

High Initial Investment: Sensors, data-acquisition hardware, and analytics platforms can be costly to install across large facilities.

Integration Complexity: Retrofitting legacy cable systems with monitoring hardware often requires extensive engineering.

Data Management Challenges: Continuous data streams necessitate robust storage, processing, and cybersecurity measures.

Skill Gaps: Interpreting sensor data and integrating predictive algorithms require specialized expertise.

Environmental Limitations: Harsh industrial environments (heat, moisture, chemicals) can affect sensor lifespan and accuracy.

Market Opportunities

Wireless Sensor Networks: Expansion of battery-powered, wireless monitoring nodes to reduce wiring and installation time.

Edge Analytics: Deploying AI models at the sensor edge for real-time anomaly detection without cloud dependency.

Service Offerings: Managed monitoring services—including installation, interpretation, and maintenance—create recurring revenue.

Cross-Sector Expansion: Applications in data centers, oil & gas pipelines, and transportation tunnels.

Standardization Efforts: Development of industry-wide protocols and interoperability standards to simplify integration.

Market Dynamics

The industrial cable monitoring market is influenced by several dynamic factors. The increasing adoption of industrial automation across industries is driving the demand for advanced cable monitoring solutions. Manufacturers are investing in robust monitoring systems to ensure the efficient and reliable performance of their industrial operations. Proactive maintenance has become a necessity to optimize cable performance and prevent costly downtime, further boosting market growth.

However, the high implementation costs associated with cable monitoring systems pose a challenge to market expansion. Additionally, integrating these systems with existing industrial infrastructure can be complex and time-consuming. Industry players are continuously working to address these challenges and develop cost-effective and easily integrable solutions.

In terms of regional analysis, the market is witnessing significant growth in North America and Europe, attributed to the presence of established industrial sectors and technological advancements. The Asia Pacific region is also experiencing rapid market growth due to the expanding industrial sector in countries like China and India.

Regional Analysis

Competitive Landscape

Leading Companies in the Industrial Cable Monitoring Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

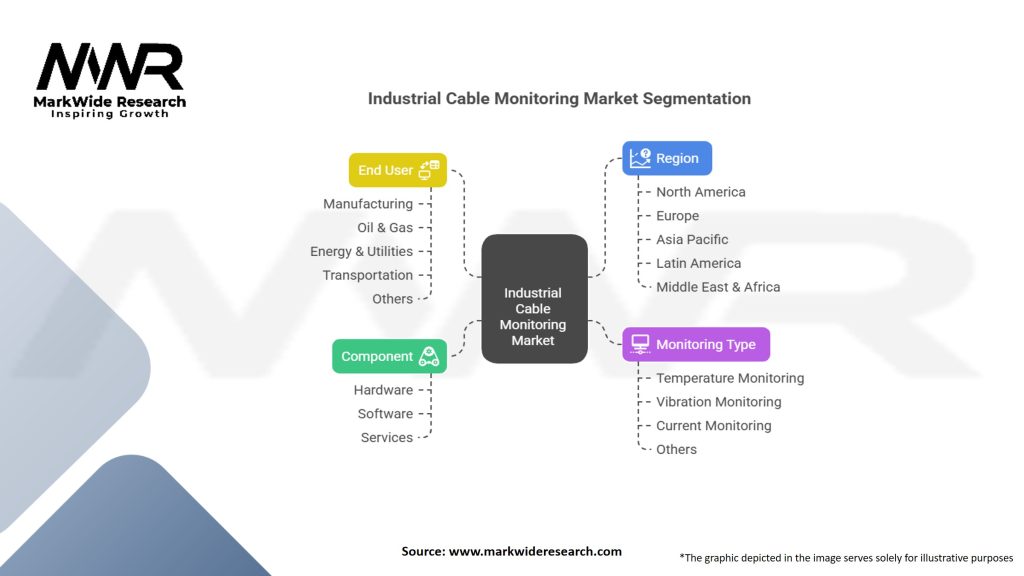

Segmentation

The industrial cable monitoring market can be segmented based on:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the industrial cable monitoring market. While the pandemic led to disruptions in various industries, it also highlighted the importance of efficient and reliable industrial operations. The need for continuous monitoring and maintenance of cables became even more critical to prevent downtime and ensure business continuity. As a result, the demand for cable monitoring solutions increased during the pandemic, driving market growth. However, supply chain disruptions and reduced investments in certain industries affected the market to some extent.

Key Industry Developments

Analyst Suggestions

Future Outlook

The industrial cable monitoring market is poised for significant growth in the coming years. The increasing adoption of industrial automation, the need for continuous monitoring and maintenance, and the rising focus on worker safety are driving market expansion. Technological advancements in cable monitoring systems, such as AI, ML, and IoT integration, will further enhance market growth. However, addressing implementation costs and complex integration processes will be crucial for market players. Overall, the future looks promising for the industrial cable monitoring market, with ample opportunities for innovation and growth.

Conclusion

The industrial cable monitoring market is witnessing substantial growth driven by the increasing adoption of industrial automation, the need for continuous monitoring and maintenance, and the rising focus on worker safety. Despite challenges such as high implementation costs and complex integration processes, the market offers significant opportunities for technological advancements and innovation. Companies that invest in developing cost-effective, advanced, and easily integrable cable monitoring solutions will be well-positioned to capture the growing market demand. The future outlook for the industrial cable monitoring market is positive, with continued expansion expected in the coming years.

What is Industrial Cable Monitoring?

Industrial Cable Monitoring refers to the technologies and systems used to oversee the performance and integrity of cables in various industrial applications. This includes monitoring for faults, temperature variations, and environmental conditions to ensure optimal operation and safety.

What are the key players in the Industrial Cable Monitoring Market?

Key players in the Industrial Cable Monitoring Market include companies such as Siemens, Schneider Electric, and ABB, which provide advanced monitoring solutions and technologies for industrial applications, among others.

What are the main drivers of growth in the Industrial Cable Monitoring Market?

The main drivers of growth in the Industrial Cable Monitoring Market include the increasing demand for automation in industries, the need for enhanced safety measures, and the rising focus on predictive maintenance to reduce downtime and operational costs.

What challenges does the Industrial Cable Monitoring Market face?

Challenges in the Industrial Cable Monitoring Market include the high initial investment costs for advanced monitoring systems and the complexity of integrating these systems with existing infrastructure, which can hinder adoption.

What opportunities exist in the Industrial Cable Monitoring Market?

Opportunities in the Industrial Cable Monitoring Market include the growing trend of smart factories and Industry Four Point Zero, which drive the need for real-time monitoring solutions, as well as advancements in IoT technology that enhance cable monitoring capabilities.

What trends are shaping the Industrial Cable Monitoring Market?

Trends shaping the Industrial Cable Monitoring Market include the increasing use of wireless monitoring technologies, the integration of AI and machine learning for predictive analytics, and a growing emphasis on sustainability and energy efficiency in industrial operations.

Industrial Cable Monitoring Market

| Segmentation | Details |

|---|---|

| Component | Hardware, Software, Services |

| Monitoring Type | Temperature Monitoring, Vibration Monitoring, Current Monitoring, Others |

| End User | Manufacturing, Oil & Gas, Energy & Utilities, Transportation, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Industrial Cable Monitoring Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at